Document 13405371

advertisement

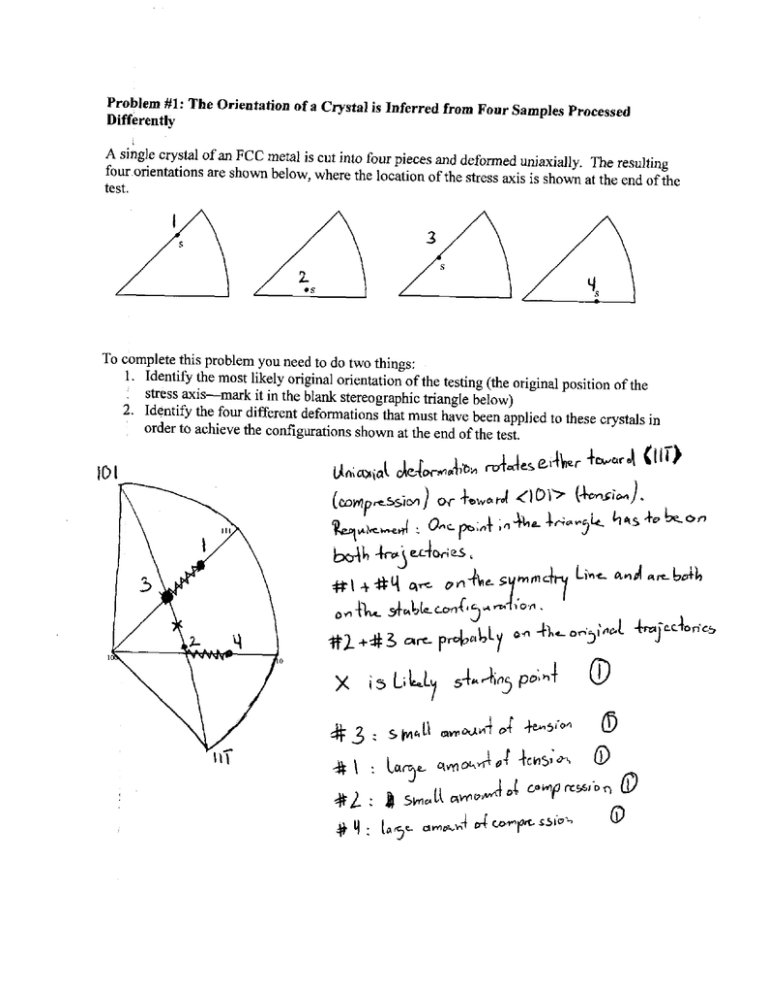

Problem #I: The Orientation of a Crystal is Inferred from Pour Samples Processed

Differently

A single crystal of an FCC metal is cut into four pieces and deformed uniaxially The resulting

four orientations are shown below, where the location of the stress axis is shown at the end of the

test.

To complete this problem you need to do two things:

Identify the most likely original orientation of the testing (the original position ofthe

1 stress axis-mark

it in the blank stereographic triangle below)

Identify the four different deformations that must have been applied to these crystals in

order to achieve the configurations shown at the end of the test,

2.

10I

un;n>ia(

&e&wa4ibb

( m w p - s i 1~ w +em ,.J 410.i~

(~sim).

l.q*k-rl O . i l a : ~;.r,me.

5L b * s + ~ h o ~

I

43

#\

sMkU

:

0

3en5iM

0

-tosI'* 0

csw rrsslbT, B

~~~.~irnrna+'o'

P

Ia3r orn~~l-4

dwwpsSioiO

J,4

: L u c y qwoh

* i

+Y

t .C

rn"3lw.n

Problem #2: Lock, Stock, and a Barrel Full of Partials

Consider two dislocations moving on different { I l l ) planes in an FCC crystal, which are

coming together at the same position as shown.

The two initial dislocations have Burgers vectors of a/2<110> type as shown; however, as the

picture implies, these dislocations are actually separated into partials of a/6<211> type.

Part A:

Write out the correct Burgers vectors for the four partials in this problem (not just familiesmake sure all the signs and order of the digits hkl are correct, and make sure that they lie in the

slip plane).

Part B:

Draw a picture showing the dislocation reaction that will occur when these dislocations meet.

Will the reaction lead to a sessile or a glissile configuration?

Problem 3: Twinning

In class we analyzed twinning in HCP metals quite thoroughly. We mentioned that twinning can

happen in FCC metals, although it is not as common. In fact, we discussed the fact that in FCC

crystals, the twinning plane is (1 1I), and the twinning direction is (1 12) .

Part A:

Twinning involves two undistorted planes. The second undistorted plane is

first undistorted plane?

'1.

What is the

Part B:

Knowing the twinning planes and twinning direction, do a simple calculation to determine the

amount of shear strain that would be produced by a twin. (Hint: you may want to draw some

pictures of the unit cell in order to get a feeling for the orientation of these planes and directions

with respect to one another)

,=\m-wO

y=-* (e-96*j*Z1

Part C:

0

-

.L c

4o0

Do you think that twinning would have a sign dependence to it in an FCC crystal? In other

words, will a positive stress cause twinning, but a negative stress not cause it (or vice versa)?

Explain your thinking.

Problem #4: Post-UROP Forensics

Working in an MIT lab, you are studying deformation and annealing of single crystals. You

have three identical specimens of the same metal, but which are cut with different crystal

orientations. You carefully perform tensile tests to a fixed level of strain, and then unload them.

You find:

stress

stress

Specimen A

strain

Specimen B

strain

Specimen C

strain

Now

take the three specimens and give them to your UROP, with the request that they all be

annealed at the same temperature for the same amount of time. Your UROP dutifully follows

your orders, but manages to forget which sample is which! Looking for clues to sort out this

mess, you perform metallography to look at the microstructure. Here is what you see:

Structure I

Structure I1

Structure 111

Sort out which post-annealing microstructure belongs to which sample, and write a short

explanation for your choices.

Problem 5: Annealing in Stereo

Below are five stereographic projections presented in the external reference frame. These

projections show the distribution of crystal orientations in different samples of an HCP metal.

The points represent the orientations of thec-axis (0001) of the crystals.

Which of these projections corresponds to each of the following situations? Provide one

sentence of explanation for each answer, please.

a. A single crystal is bent and then annealed lightly

> m e m y o T a r n C sign +poLy3m*.

5*nsl\m,,Dncm3q?icn

r

i* 0

~ U ~ Dk

5C,$+

b w A ; - ~ dl

P 7

-2 9

a n

b. A single crystal is deformed slightly in compression and annealed lightly

t

bLit

I0 4w a n ?

D&wl.t*\;a-

55h5

rnc*

J

odm-hi,bn,

7

sx

n u ? m,31h1

kxrs 5

Y

c. A single crystal is deformed slightly in compression and annealed thoroughly

,.h ;~4-?-

->

5%->

I

d. A single crystal is deformed heavily in compression and annealed

0

e. The sample from 'd' above is again deformed heavily and annealed

+ kL.

s ~ , , US~m . n ~ w o e 5x**i

m r t4om o*c-kj,oni

I

-b

3

Problem 6: In Which We Consider the Interaction Among Non-Parallel Dislocations,

Including Those That are Crossed and Those That Form Intriguing Loop Configurations

In class we dealt with the stress-field interactions between parallel dislocations only; we did not

talk about whether dislocations feel each other in other configurations. Based on your

understanding of dislocation stress fields, indicate whether the interaction in the following cases

would be attractive, repulsive, or non-existent. In each picture below, the Burgers vectors are

shown as arrows

Case A: Two screw dislocations separated by a distance Ax, at 90' from one another. (The

picture is drawn in perspective; the dislocations are parallel to the y and z axes)

""X

Case B: Two edge dislocatlo s separated by a distance Ax, at 90' from one another. (The picture

is drawn in perspective; the dislocations are parallel to the y and z axes)

7

-7,

y73

GX*

Case C: An edge and a screw dislocation separated

(The

is drawn in perspective; the dislocations are parallel to the y and z axes)

lsyy

~pulri~

sL-

in the plane of the loop, and

one with it normal to the loop.

i",LL4i-

Helpful (?) Bonus Information

Stress field around an edge dislocation:

all other 0 components are = 0.

Stress field around a screw dislocation:

all other 0 components are = 0, and note that rZ= xZ+$

Forces between dislocations:

Parallel edge:

Parallel screw:

JMAK Equation:

f = 1-exp(-kvdtd+l )

001

014

013

014

012

023

012

023

113

011

013

104

103

114

113

123

114

113 123

011

102

213 112

032

133

213 203

122

132

101

021

313

212

021

132

212

111

111

313 302

121

031

031

121

312

312

131

131

201

221

211

041

041

211

231

221

141

141

231

311 301

401 311

331 321

321 331

110 120 140

140 120 110

210 410 100 410 210

010

010

310

320

230 130

130 230

320 310

321

311

331

331

301

231

231

311

141

211

321

141

221

041

201

221

041

211 312

131

131

312

302

031

121

031

121

111 313 101 212

111

132

132

021

212

313

021

122

122

213 203

133

032

032

213 112

112

133

102

113

113 123

103

123

011

011

114 104 114

023

023

012

012

013

013 014

014

001

133

122

032

112

Figure by MIT OpenCourseWare.

112

123

213

011

101

113

114

023

132

012

013

331

221

121

104

014

123

203

102

313

103

001 114 113

213

312

212

211

112

311

113 114 104

014

112

411

103 114 013

141

111

123 111

213

231

321

012

212

102

113

221

023

221

122

313 203

112

331

133

331

312

123

213

011 132

101

321

313

121

211

133

231

212

032

302

122

201 312

110

111 132 021

110

131

311

320

031

301

121

411 401

211 221

131

041 141

230

310

311

141

410

120

140

411 321 331 231

210

130

310 320 110 120 140

100

010

410

141

411

231

321

230 130

210

131

411

141 041

411

321 331

401

231

311

311

131

031

301

121

211

221

211

121

021

201

131

312

302

101

312

212

313

213

111

114

132

221

113

112

032

132

331

011

123

Figure by MIT OpenCourseWare.

MIT OpenCourseWare

http://ocw.mit.edu

3.40J / 22.71J / 3.14 Physical Metallurgy

Fall 2009

For information about citing these materials or our Terms of Use, visit: http://ocw.mit.edu/terms .