Prediction of Ultra-High Aspect Ratio Nanowires from Self-Assembly

advertisement

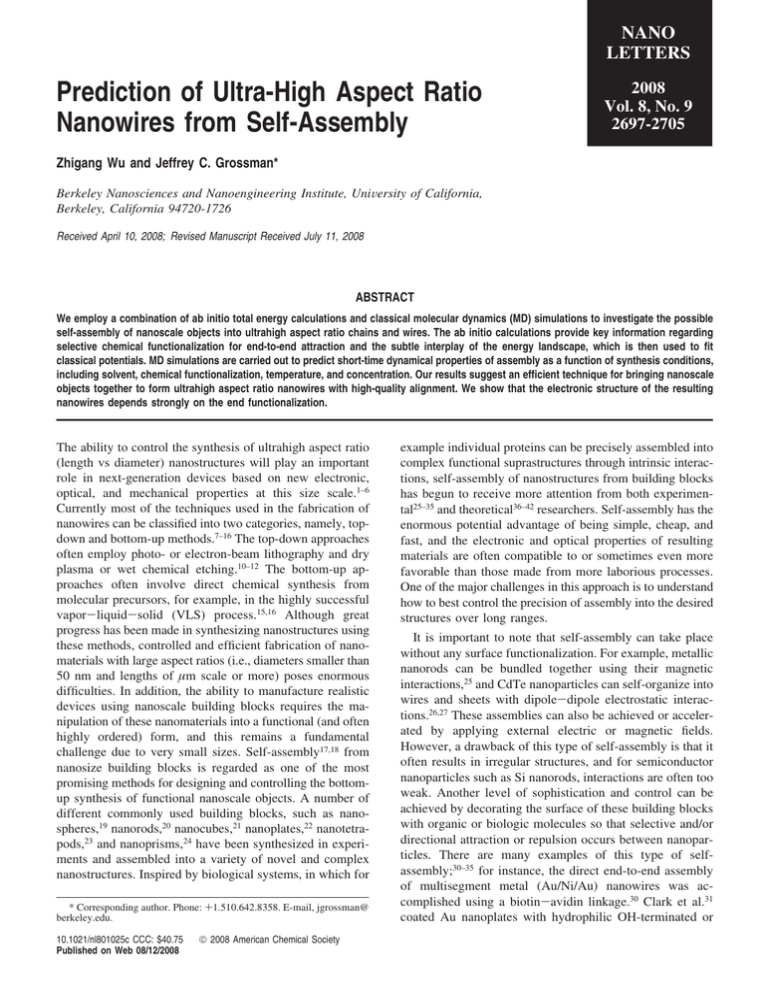

NANO LETTERS Prediction of Ultra-High Aspect Ratio Nanowires from Self-Assembly 2008 Vol. 8, No. 9 2697-2705 Zhigang Wu and Jeffrey C. Grossman* Berkeley Nanosciences and Nanoengineering Institute, UniVersity of California, Berkeley, California 94720-1726 Received April 10, 2008; Revised Manuscript Received July 11, 2008 ABSTRACT We employ a combination of ab initio total energy calculations and classical molecular dynamics (MD) simulations to investigate the possible self-assembly of nanoscale objects into ultrahigh aspect ratio chains and wires. The ab initio calculations provide key information regarding selective chemical functionalization for end-to-end attraction and the subtle interplay of the energy landscape, which is then used to fit classical potentials. MD simulations are carried out to predict short-time dynamical properties of assembly as a function of synthesis conditions, including solvent, chemical functionalization, temperature, and concentration. Our results suggest an efficient technique for bringing nanoscale objects together to form ultrahigh aspect ratio nanowires with high-quality alignment. We show that the electronic structure of the resulting nanowires depends strongly on the end functionalization. The ability to control the synthesis of ultrahigh aspect ratio (length vs diameter) nanostructures will play an important role in next-generation devices based on new electronic, optical, and mechanical properties at this size scale.1–6 Currently most of the techniques used in the fabrication of nanowires can be classified into two categories, namely, topdown and bottom-up methods.7–16 The top-down approaches often employ photo- or electron-beam lithography and dry plasma or wet chemical etching.10–12 The bottom-up approaches often involve direct chemical synthesis from molecular precursors, for example, in the highly successful vapor-liquid-solid (VLS) process.15,16 Although great progress has been made in synthesizing nanostructures using these methods, controlled and efficient fabrication of nanomaterials with large aspect ratios (i.e., diameters smaller than 50 nm and lengths of µm scale or more) poses enormous difficulties. In addition, the ability to manufacture realistic devices using nanoscale building blocks requires the manipulation of these nanomaterials into a functional (and often highly ordered) form, and this remains a fundamental challenge due to very small sizes. Self-assembly17,18 from nanosize building blocks is regarded as one of the most promising methods for designing and controlling the bottomup synthesis of functional nanoscale objects. A number of different commonly used building blocks, such as nanospheres,19 nanorods,20 nanocubes,21 nanoplates,22 nanotetrapods,23 and nanoprisms,24 have been synthesized in experiments and assembled into a variety of novel and complex nanostructures. Inspired by biological systems, in which for * Corresponding author. Phone: +1.510.642.8358. E-mail, jgrossman@ berkeley.edu. 10.1021/nl801025c CCC: $40.75 Published on Web 08/12/2008 2008 American Chemical Society example individual proteins can be precisely assembled into complex functional suprastructures through intrinsic interactions, self-assembly of nanostructures from building blocks has begun to receive more attention from both experimental25–35 and theoretical36–42 researchers. Self-assembly has the enormous potential advantage of being simple, cheap, and fast, and the electronic and optical properties of resulting materials are often compatible to or sometimes even more favorable than those made from more laborious processes. One of the major challenges in this approach is to understand how to best control the precision of assembly into the desired structures over long ranges. It is important to note that self-assembly can take place without any surface functionalization. For example, metallic nanorods can be bundled together using their magnetic interactions,25 and CdTe nanoparticles can self-organize into wires and sheets with dipole-dipole electrostatic interactions.26,27 These assemblies can also be achieved or accelerated by applying external electric or magnetic fields. However, a drawback of this type of self-assembly is that it often results in irregular structures, and for semiconductor nanoparticles such as Si nanorods, interactions are often too weak. Another level of sophistication and control can be achieved by decorating the surface of these building blocks with organic or biologic molecules so that selective and/or directional attraction or repulsion occurs between nanoparticles. There are many examples of this type of selfassembly;30–35 for instance, the direct end-to-end assembly of multisegment metal (Au/Ni/Au) nanowires was accomplished using a biotin-avidin linkage.30 Clark et al.31 coated Au nanoplates with hydrophilic OH-terminated or hydrophobic CH3-terminated monolayers; when these nanoplates are added into water, highly ordered one-, two-, or three-dimensional structures assemble spontaneously. Another class of buiding blocks is the polyhedral oligomeric silsesquioxane (POSS) nanocubes, synthesized with various organic tethers, which can bring these POSS nanocubes together to form highly ordered complex structures.32,33 Recently, great progress in precisely patterning and functionalizing the surface of nanoparticles has been achieved,43 making it possible to accurately control the interactions between ever-smaller building blocks. The experiments mentioned above clearly and broadly demonstrate the feasibility of nanomaterials design through self-assembly of building blocks. However, the parameter space is enormous, and by varying, for example, nanoparticle shapes and sizes, functional groups, solvents, temperatures, concentrations, and many other attributes, the number of possible outcomes of this approach is nearly limitless. For this reason, and given the vast potential impact of selfassembly on nanomaterials design, computation can play a key role, by rapidly exploring regions of this complex phase space and by providing important understanding of the static and dynamical mechanisms that drive the interactions. Many efforts have been made to study self-assembly using simulations.36–42 Zhang et al.36 performed classical molecular dynamics (MD) simulations to study the self-assembly of nanoparticles with oligomeric tethers attached to specific locations on surfaces of nanoparticles with various shapes. Horsch et al.37 used classical MD simulations of laterally tethered nanorods to predict the formation of stepped-ribbonlike micelles. Zhang and Glotzer38 performed a general simulation of “patchy” particles with discrete attractive interaction sites, and various ordered structures, such as chains, sheets, rings, pyramids, tetrahedra, and staircase structures, were obtained through suitable design of surface patterns. Recently Zhang et al.39 reported classical Monte Carlo (MC) simulations of the self-assembly of CdTe nanoparticles into wires and sheets with thioglycolic acid and dimethylamino-ethanethiol stabilizer used, respectively, demonstrating that the delicate balance of charge-dipole interactions is responsible for the one- or two-dimensional assembly. Despite these and other important works, there have been very few fully atomistic simulations of self-assembly, as most of these previous theoretical studies are based on mesoscopic coarse-grained models. Although these models give direct insight into competing forces, it is a challenge to apply such methods to small building blocks that form complex nanostructures, which may have a high degree of nonhomogeneity at the atomic level. In addition, most previous theoretical studies of self-assembly are carried without including solvent molecules explicitly, while in experiment the building blocks are often exposed in some solvents, and the interaction between solvent molecules and building blocks can be an important factor. In this work, we report a theoretical study of the functionalization of Si nanorods with small organic molecules on their end surfaces and the corresponding self-assembly under various conditions. We demonstrate the feasibility of 2698 using self-assembly to form ultrahigh-aspect-ratio chains and wires out of these building blocks, which are attracted to one another via hydrogen bonds. A combination of ab initio quantum mechanical approaches and classical MD simulations is employed, with the parameters in the classical potential model fitted to ab initio results. The end-to-end attraction is adjusted by controlling the pattern of the rodend chemical functionalization, which we find to have a major impact on chain alignment. By exploring different solvents (water, CCl4, Ar), functionalization groups, temperatures, and building-block concentrations, we show that under appropriate conditions well-aligned, ultrahigh aspect ratio wires could be assembled from small building blocks. Ab initio calculations were carried out within density functional theory (DFT) with both a planewave basis approach (ABINIT package,44 version 5.3) and an atomic orbital basis approach (SIESTA package,45 version 2.0), in which the double-ζ plus polarization (DZP) basis sets are used for all atoms. The same norm-conserved pseudopotentials and the generalized gradient approximation46 (GGA) are used in both approaches. In order to check the accuracy of our choice of localized basis, we carried out both the planewave and the local basis DFT calculations for small systems (<100 atoms). Excellent agreement between them is found. Then, we carried out the local basis DFT calculations for larger systems, for the purpose of fitting classical potentials and the investigation of electronic properties of the assembled nanowires. We employed the GROMACS package47 (version 3.2) to perform the classical MD simulations. The Lennard-Jones (LJ) potential and Coulomb interaction are used for the nonbonded interaction, with cut-offs of 1.0 and 2.0 nm, respectively. For bonded interactions, the fourth power potential Vbond ) 1/4Cr(r2 - r20)2, the cosine potential Vangle(θ) ) 1/2Cθ[cos(θ) - cos(θ0)]2, and the Ryckaert-Bellemans function VRB ) ∑n5 ) 0 Cn[cos(φ - π)]5 are chosen for the bond stretching, angle distortion, and dihedral interaction, respectively. Here, θ is the bond angle and φ is the dihedral angle between two planes. The parameters for these potentials are based on the GROMOS96 (ffG43a1) parametrization.48 The parameters for LJ potentials (Table 1) are further optimized to better fit our ab initio results of representative interactions and systems involved in the current self-assembly scheme. The charge on each type of atoms is determined from a Mulliken population analysis of the ab initio results. The SPC3 model49 is chosen for water. The simulation time step is 0.5 fs, and a Berendsen thermostat with a coupling time of 0.5 ps is employed. In all MD simulations, functionalized rods are evenly distributed and randomly oriented in a periodically repeating boundary box filled with solvent molecules. The hydrogen bond is well-suited for self-assembly since it is both selective and directional, with a typical strength greater than van der Waals forces but weaker than most valence, ionic, or metallic bonds. In this work, the simple chemistry of carboxyl group -COOH (designated as functional group A) and methylamine group -CH2-NH2 (functional group B) is used to provide the hydrogen bonding that Nano Lett., Vol. 8, No. 9, 2008 Table 1. Parameters for the L-J Potential, VLJ(r) ) 4ε(σ12/r12 - σ6/r6), Used in the Molecular Dynamics Simulations σ (nm) ε (KJ/mol) 0.281 0.361 0.325 0.317 0.339 0.125 0.406 0.711 0.650 0.426 H C N O Si directs the self-assembly. Thus, the Si nanorod end surfaces are functionalized with either -COOH (A) or -CH2-NH2 (B). In order to test the interacting strengths between these groups when attached to Si, we performed test calculations of SiH3-A and SiH3-B structures (Table 2). Figure 1a shows that two hydrogen bonds are formed between a pair of SiH3-COOH, resulting in a stronger bonding between a single AA pair than a single AB pair. Both the AA and AB pairs form much stronger bonding than the BB pair, as expected, because of the well-known fact that OH-N and OH-O bonds are much stronger than the HN-H bonding. In addition, we note that for the AB pair, the hydrogen bond could form between either OH-N or NH-O, though the OH-N bond has much larger bonding energy. The AB pair shown in Figure 1a has the OH-N hydrogen bond. Table 2 also shows excellent agreement between our two DFT approaches, validating our choice of local orbital basis for accurately describing these systems. For all cases, Si nanorods in our simulations are axially oriented along the [111] direction, since, for this growth direction, the chemical bonds between Si and the functional groups are nearly perpendicular to the surface, allowing for the possibility of good alignment in the assembled chains. Beginning with short Si rods (diameter d ) 0.9 nm and length l ) 0.5 nm), the H-termination at the rod ends are replaced with functional groups A or B. Pairs of these functionalized rods are then brought into contact with each other in a variety of configurations, some of which are shown in Figure 1b, and DFT structural optimization was performed. In addition, low energy variations of these ground-state configurations are obtained by annealing from 300 K using the classical MD simulations, and then reoptimizing snapshots with DFT. Table 3 summarizes the bonding energies of the configurations shown in Figure 1b. As expected, the end-to-end attractions are much stronger than those of endto-side. As diameter d increases, the end-to-end attraction increases quadratically, while the end-to-side interaction increases roughly linearly. The A-A and A-B interactions between these rods are similar in magnitude, much larger than that of B-B, following the same trends as for our test cases of single pairs. Further, we note that the total interaction between functionalized rods which have 6 AA pairs is less than 6 times that of a single AA pair (Figure 1a); this is due to bond bending caused by the need to conform to the Si surface. In contrast, the A-B and B-B interactions between rods are equal or larger than 6 times of those of single AB and BB pairs, respectively; this can be understood by the fact that additional attractions other than 6 single OH-N or NH-N hydrogen bonds occur among these functional group pairs. The ab initio data in Tables 2 and 3 (as well as data Nano Lett., Vol. 8, No. 9, 2008 Table 2. Binding Energy Eb (eV) and Length l0 (Å) between Molecules in Figure 1a SiH3-A-A-SiH3 SiH3-A-B-SiH3 SiH3-B-B-SiH3 ABINIT SIESTA GROMACS Eb l0 Eb l0 Eb l0 0.68 0.70 0.69 1.59 1.63 1.60 0.54 0.60 0.59 1.60 1.60 1.61 0.14 0.15 0.14 2.21 2.20 1.98 Table 3. Binding Energy Eb (eV) For the Functionalized Nanorod Systems in Figure 1b SIESTA GROMACS A-A A⊥rod B⊥rod A-B B-B 3.54 3.53 0.42 0.42 0.43 0.54 3.57 3.52 1.02 1.04 from additional rod-rod interacting configurations other than those shown in Figure 1b) are used to fit the parameters of the classical potentials described earlier. As can be seen in Table 2, good agreement between the classical force fields and our ab initio data is obtained. Our MD calculations show that the patterning of functional groups on rod ends impacts both the assembly rate and the alignment of assembled chains. In order to quantify and compare the assembly efficiency and alignment quality, we introduce an individual reaction rate parameter η for a linkage i (which consists of two connected rods), defined as ηi ) mcp i /mi, where mi is the number of functional groups on the connecting surface of one rod that has an equal or fewer number of functional groups than the other (these two rods form the linkage i), and mcp i is the number of coupling pairs in this linkage. For any linkage, 0 e η e 1.0; the value of η indicates the degree to which the rods are aligned: perfect alignment is achieved only if η ) 1.0. A quality factor q for a specific system can thus be defined as q(R) ) ∑i ηi (if ηi > R); and a total reaction rate parameter p of a simulation system is the sum of η: p ) ∑iηi. If p ) 0, no assembly has occurred, while if p ) N0 - 1 (N0 is the number of building blocks in the unit cell of a simulation), then all rods are connected perfectly and a single chain is formed. A normalized reaction rate parameter can then be defined as pj ) p/N0. It may appear that optimal assembly occurs when every H atom on the rod ends is replaced with a functional group (A or B). In some forms of self-assembly, the goal is simply to bring nanoparticles together, and then this would be indeed the case. However, for our present goal of assembling highaspect-ratio nanowires with good alignment, if all H atoms on rod ends are functionalized, the outermost (radially) functional groups would attract other rods in ways that can work against parallel alignment. In addition, when an endto-end assembly occurs, functional groups may be only partially coupled, resulting in poor alignment. To avoid these disadvantages, we choose to decorate the center regions of the end surfaces while leaving the outer edge. Examples of these different types of functionalization pattern are shown in Figure 2b,c. There are a number of ways in which this coaxial functionalization at the end surfaces might be realized in experiments, for example, by precise surface patterning,50 by using core-shell nanowires with the choice of shell material based on its lower affinity to the functional group, or by doping a pure nanowire such that the dopant, being 2699 Figure 1. Optimized structures from a combination of classical molecular dynamics simulations and ab initio total energy calculations for various rod-rod interactions, used to fit the classical potentials. Here the chemical functional groups (-COOH and -CH2-NH3) are attached to (a) SiH3 and (b) Si nanoparticles. In panel a, the dotted lines indicate the hydrogen bonds. Figure 2d; however, the quality factor q(R) differs greatly (right side). The system with partially functionalized rod ends has a much higher q factor than that with fully functionalized rods, confirming the prior assumption that a coaxial patterning scheme for the functionalization chemistry may be much better suited to form highly aligned chains. In fact, most of the time in our calculations over a broad range of systems, the reaction rate parameter η for the partially functionalized rod system is 1.0 or very close to 1.0. Because of the great gain in efficiency and quality, in the following simulations and discussion, all end surfaces of the Si nanorods are functionalized in this partial manner, leaving the outermost ring of H atoms intact (Figure 2c). Figure 2. Effects of surface patterning on self-assembly. The upper three square panels show configurations of rod ends with (a) terminating H atoms, (b) replacing all H atoms with functional group A, and (c) partially replacing H atoms with functional group A. In d, the computed reaction rate parameter p is shown (left) for the first 4 ns of an MD simulation for two of these cases [scheme (a) does not lead to assembly]. The calculated quality factor q (right) is also shown for partial and full alignment (see text for details). diffused around the surface,51 binds differently to the functional group than the pure wire. To compare the assembly efficiency and alignment quality using the two schemes illustrated in Figure 2b,c, we carried out simulations of 32 uniform AA-type functionalized rods (d ) 2.1 nm, l ) 4.7 nm) with both patterning schemes. The simulation box is filled with Ar gas at ambient pressure, and the temperature T ) 300 K. Both cases show similar p parameters versus time t, as summarized on the left side of 2700 Figure 3a-d displays a series of snapshots from one of our simulated self-assembly processes. In this particular case, the system contained 64 identical AA-type rods (d ) 2.2 nm, l ) 1.1 nm) in a unit cell filled with roughly 104 000 Ar atoms at T ) 300 K under ambient pressure. The simulation shows that the assembly process occurs rapidly, beginning at t ≈ 0.3 ns and forming chains as long as 7 connected rods within several nanoseconds. Figure 3e shows the distributions of chain length L (in unit of the length of the building block) at t ) 1, 2, and 4 ns. The average chain length Lav can be determined from the length distributions, and it increases with time as expected (Figure 3f). Because parameters η are close to 1.0 for most chain linkages in the simulation, Lav ≈ N0/(N0 - p) ) 1/(1 - pj). In order to model the growth behaviors, we turn to the work by Flory from over seventy years ago, who showed that, for the steppolymerization of two monomers AA and BB with two reaction sides each, the average polymer length increases linearly with time until reaching equilibrium.52 The end-toend self-assembly of nanowires is very similar to the steppolymerization process, and so we employ here the same av linear fit, Lav(t) ) Lav 0 + n0k(t - t1), where L0 is the initial average chain length, n0 is the concentration of building blocks (n0 ) N0/V0), t1 is the relaxation time beyond which Nano Lett., Vol. 8, No. 9, 2008 Figure 3. (a-d) Snapshots of a simulated self-assembly process. (e) Histograms of nanowire chain length (in units of the length of the building block) at time t ) 1, 2, and 4 ns. (f) Average chain length Lav as a function of time. The solid line is a linear leastsquares fit to the data (open circles). Lav increases linearly, and k is the chemical functional group collision rate constant. Figure 3f shows a plot of our simulation data and the fitted model. Note that the end-toend nanowire self-assembly can be well-described by the Flory model. In this particular simulation, the slope of the line gives n0 ) 1.78 × 10-3 nm-3, n0k ) 0.32/ns, resulting in the constant k ) 180 nm3/ns, and an average collision time, τ ) 1/N0n0k, is 49 ps, which indicates rather rapid rodto-rod collisions under these conditions. As assembly continues beyond what is shown in Figures 2 and 3 in the examples above, the chain length increases and will eventually become comparable to the dimensions of the periodic box. Yet, our analysis of assembly at this point in the simulation would be nonphysical, as artifacts would be introduced into our calculations from finite-size effects. Thus, the essential properties and mechanisms of the experimental assembly processes are better described by the beginning stage of our simulations than by later stages, and we confine our presentation of results to the onset and initial period of assembly. In addition, the concentration of building blocks decreases as the assembly occurs. We carried out calculations of systems with different concentrations of building blocks under the same conditions, and the results (details in later paragraphs) show no change in assembly behavior. In order to provide guidance for the impact of key experimental conditions on the assembly procedure, we examine the dependence on choice of solvent, functional group, temperature, and concentration. The dimensions of nanorod building blocks are held fixed at 1.5 nm in diameter Nano Lett., Vol. 8, No. 9, 2008 Figure 4. Panels (a-c) summarize the average chain length Lav as a function of time t for different choices of (c) solvents, (d) functional groups, and (e) temperatures. The inset in panel (b) displays a typical snapshot of assembled chains. and 3.7 nm in length for all of the following simulations. Variations in the building block size do impact the results but do not change the qualitative trends, as already demonstrated in the above simulations. In each case, 6 independent simulations are carried out, and 16 functionalized rods are distributed randomly in the unit cell, which is filled with Ar gas (except for simulations of the solvent variation), whose volume V0 ) 4.0 × 104 nm3 (except for simulations of the concentration variation) and T ) 300 K (except for simulations of the temperature variation). A typical snapshot of one of these simulations is shown in Figure 4b. Figure 4a-c summarizes the assembly rate dependence on solvent, functionalization, and temperature. For solvent 2701 comparisons (Figure 4a), the AA-type functionalization is used, although we find that other types of functionalization generate similar results. We obtain a collision rate constant k ) 4.6 and 54 nm3/ns for the simulation system filled with CCl4 and Ar, respectively, and k < 0.2 nm3/ns for water. In our current scheme of self-assembly, polar solvents such as water and ethanol, can also bond to the functional groups on the rod ends. Our ab initio calculations of binding energies for SiH3-A-H2O, SiH3-B-H2O, and H2O-H2O are 0.445, 0.322, and 0.229 (0.235 in experiment) eV, respectively; compared with SiH3-A-A-SiH3 and SiH3-A-B-SiH3 binding energies of 0.681 and 0.539 eV, respectively. Thus, the competition between solvent molecules and functional groups to bond rods together makes polar solvents inefficient for self-assembly; on the other hand, in nonpolar solvents, such as toluene and CCl4, solvent molecules do not block the functional groups from bonding together. The selfassembly process in Ar gas is similar to that in CCl4, but in the former assembly speed is more than 10 times faster due to much higher (∼40 times) viscosity in CCl4 than in Ar gas. We note that CCl4 has slightly higher viscosity than water at room temperature. Figure 4b compares self-assembly rates from our calculations with different functional groups. We obtain k ) 54 and 35 nm3/ns for AA-only and a 50/50 mixture of AA and BB, respectively. Because the strength of the B-B bond is much weaker than that of A-A or A-B bonds, two B-functionalized rod-ends coliding may not result in a linkage, that is, in the mixed cases building blocks will “attempt” to link rods that cannot link. This explains why kAA is bigger than kAB. Although we only employed AAfunctionalized rods in the simulations shown in Figures 4f and 5a,b, the results for AA + BB mixtures are similar. Figure 4c shows the results of temperature variation. For T ) 300, 400, and 500 K, we obtain k ) 54, 105, and 236 nm3/ns, respectively. When temperature increases, the building blocks gain greater mobility, resulting in shorter average collision time; higher temperatures also help building blocks to overcome the energy barriers associated with assembly. Thus, a larger rate constant k at higher temperature is expected. The well-known Arrhenius equation describes the dependence of the rate constant k of chemical reactions on temperature: k(T) ) A exp(-γ/T), where the constant γ is proportional to the activation energy. We plot ln(k) versus 1000/T in Figure 5a, which shows that the Arrhenius equation matches reasonably well with the temperature dependence of the nanowire assembly rate in our current study. We obtain A ) 1.6 × 103 nm3/ns and γ ) 1.1 × 103 K. Figure 5b shows the results of concentration variation, where in this case n0k (the fitted slope of the Lav-t curve) versus n0 is plotted. Our results show that the rate constant k is independent of the building-block concentration n0, provided that the mean separation of building blocks is much larger than their length. This simulated result agrees very well with experimental findings for functionalized metal nanowire self-assembly,30 and it can be understood by considering that, when the mean separation of building blocks is much larger than their length, the mean free length jl is 2702 Figure 5. (a) Temperature-dependence of the collision rate constant k as determined from Figure 4e. Note that the k axis is logarithmic. (b) Building-block concentration-dependence of k. Here, n0k versus n0 is drawn so that the slope of the solid line corresponds to the value of k. proportional to 1/n0. We note that τ ) 1/N0 jl/νj and k ) 1/N0n0τ ) νj/n0jl (where νj is the most appropriate speed); therefore, k is a constant with respect to concentration, and for fixed N0, τ ∝ 1/n0. We obtain an average collision rate constant k ) 51 ( 4 nm3/ns for AA-type end-to-end bonding, while τ increases from 0.31 ns for n0 ) 40 × 10-4 nm-3 to 6.2 ns for n0 ) 2 × 10-4 nm-3. Finally we discuss the change in the electronic structure of a wire that is constructed in this segmented manner, by comparing it to an ideal, continuous silicon nanowire. The influence of these functional groups on electronic properties of the assembled Si nanowires is probed by ab initio calculations of both the individual building blocks (l ) 5.0 nm and d ) 1.7 nm) shown in Figure 6b,c and the assembled chains (Figure 7b,c) consisting of two of these building blocks. The upper part of Figure 6a shows the projected (electron) density of states (PDOS) for Si atoms in the (infinite) nanowire with d ) 1.7 nm, and the calculated electronic band gap Ewire is 1.50 eV. The middle and lower g parts of Figure 6a show the PDOS of the AA- and BB-functionalized rods, in which it can be seen that the PDOS of Si atoms are very similar to that in the hydrogenonly terminated wire, with calculated energy gaps Eg between the highest occupied (HOMO) and the lowest unoccupied molecular orbitals (LUMO) 1.61 and 1.58 eV for AA and BB, respectively, slightly larger than Ewire because of g additional axial confinement. The PDOS curves for functional groups indicate that the HOMO and LUMO energy levels Nano Lett., Vol. 8, No. 9, 2008 Figure 6. (a) Projected (electron) density of states (PDOS) for the isolated Si nanorods (d ) 1.7 nm, l ) 5.0 nm) with AA or BB types of functionalization. The dashed curve shows the PDOS for Si atoms in the (infinite) 1.7 nm nanowire. Here, all PDOS have been normalized to the number of valence electrons of the Si atoms or the functional groups. The two vertical dashed lines indicate the nanowire’s band gap. The energy zero is set to the vacuum level. (b,c) Isosurfaces (green) of the charge density of the LUMO, HOMO, and HOMO-1 orbitals for the isolated AA- (b) or BB- (c) functionalized nanorods, plotted at 10% of their respective maximum. Figure 7. (a) Projected (electron) density of states (PDOS) for 2-molecule chains assembled from the functionalized Si nanorods shown in Figure 6b. The upper part shows the PDOS for the AA-AA chain; the lower part shows PDOS for the AA-BB chain, where the solid black, maroon, and green curves correspond to the Si PDOS for the whole chain, the left side (AA functionalization), and the right side (BB functionalization), respectively. Panels b and c show the isosurfaces (green) of the charge density of the HOMO and LUMO orbitals for the AA-AA chain (b) and the AA-BB chain (c), plotted at 10% of their respective maximum. of -COOH fall well below and above the Si energy gap, respectively; the LUMO energy level of -CH2-NH2 is also well above the Si energy gap, whereas its HOMO lies just below the top of the Si valence states. The isosurfaces of the near-gap orbitals (Figure 6b,c) of these functionalized rods indicate that all of the LUMO, HOMO, and HOMO-1 orbitals in both of the functionalized rods are mainly located inside the rod, with the exception of the HOMO-1 orbital of the BB-type rod which is mainly located on the functional groups. The current results of B-group end-functionalization Nano Lett., Vol. 8, No. 9, 2008 are in good agreement with the recent DFT results of sidefunctionalization of amino acids on Si nanowries.53 Reference 51 showed that if HOMO and LUMO energy levels of functional groups fall well below and above the Si nanowire band gap, the conductivity of the functionalized nanowire will be hardly affected; on the other hand, if the HOMO or LUMO are close to the band gap, the conductance will drop to zero at certain energies because of the resonant backscattering. In this sense, our calculations show that B-type functionalization is less favorable than A-type for 2703 transport, since the HOMO of -CH2-NH2 lies immediately below the nanorod energy gap. Figure 7b shows the PDOS of the assembled chain with AA-AA or AA-BB connections. For the AA-AA chain, the PDOS of Si and A-groups and the energy gap Eg are almost the same as those of a single AA-type functionalized rod. However Eg of the AA-BB chain is reduced to 1.07 eV, much smaller than that in either type of isolated functionalized rod. This rather dramatic decrease of Eg in the AA-BB chain can be understood by considering the PDOS of Si atoms for the AA-side and BB-side separately, as shown in the lower part of Figure 7a. We find that the Si PDOS of the AA-side (BB-side) shift to higher (lower) energy by ∼0.25 eV, and PDOS for -COOH (-CH2-NH2) also shift to higher (lower) energy by ∼0.25 eV. This energy level shift is due to electron transfer from BB-side to AAside, assisted by the hydrogen bond,54 and it leads to the HOMO being located on the AA-side while the LUMO is on the BB-side, as shown in Figure 7c, unlike in the AA-AA chain, where both HOMO and LUMO are distributed inside every rod (Figure 7b). Thus, in the AA-BB chain, a type II junction is formed between AA- and BB-functionalized rods. We note that this junction is between Si nanorods, instead of between functionalization groups and Si nanorods. Further exploration of the electronic and optical properties of these assembled wires and their potential impact in various applications will be discussed in a separate work. In summary, the MD simulations presented here show selfassembly of functionalized Si nanorods into high-aspect-ratio nanowires. We use two different types of small organic molecules to replace termination H atoms on rod-end surfaces, and the weak hydrogen bond is responsible for the end-to-end attraction. We propose a coaxial pattern of (partial) functionalization in order to improve the chain alignment, although we demonstrate that long chains can also form with fully functionalized ends. Within the present functionalization scheme, the polar solvents such as water and ethanol are inefficient for nanowire assembly because of the formation of hydrogen bonds between solvent molecules and the chemical groups. Nonpolar solvents such as CCl4 and Ar gas are shown to yield rapid assembly in our MD simulations (nanosecond time scale). Our calculations demonstrate that the end-to-end nanorod assembly process can be described by Flory’s step-polymerization model, in which the average chain length increases linearly with time. We also find that higher temperatures speed up assembly as expected, and the collision rate constant k among building blocks is independent of their concentration if the average separation of rods or chains is much longer than their length. Our ab initio study of the resulting wires shows that both HOMO and LUMO of the -COOH functional group fall well below and above the nanorod energy gap. For -CH2-NH2, the LUMO is also well above the energy gap while the HOMO is very close to the top of the valence states. Thus, the AA-type functionalization may be more favorable than the BB-type for certain electronic applications. In the AA-AA chains, the HOMO and LUMO states are 2704 located in every building block; interestingly, in the AA-BB chains, the HOMO and LUMO are separated to the AAside and the BB-side, respectively; thus, a type II junction is formed between functionalized rods because of hydrogenassisted electron transfer. Taken together, our calculations point toward a possible novel and efficient route for synthesizing ultrahigh-aspectratio nanowires. The present functionalization scheme could also prove useful in self-assembly of other nanostructures, for example, carbon nanotubes and nanosheets, as long as it is possible to functionalize and pattern the end-rings of nanotubes or the edges of nanosheets. Finally, it may ultimately be possible to remove the small functional groups that drive the assembly once the wires are formed, at which point the building blocks could be close enough to bind together covalently. Acknowledgment. This work was supported by the National Science Foundation (NSF) by University of California at Berkeley under Grant 0425914. Part of the program to generate topology files for GROMACS input was written by Niv Levy. We thank useful discussions with A. Greaney and Shan-Haw Chiou. Z.W. acknowledges the support from the Molecular Foundry at Lawrence Berkeley National Laboratory. References (1) Alivisatos, A. P. Science 1996, 271, 933–937. (2) Cui, Y.; Wei, Q.; Park, H. K.; Lieber, C. M. Science 2001, 293, 1289– 1292. (3) Huynh, W. U.; Dittmer, J. J.; Alivisatos, P. A. Science 2002, 295, 2425–2427. (4) Artemyev, M.; Moller, B.; Woggon, U. Nano Lett. 2003, 3, 509–512. (5) Harnack, O.; Pacholski, C.; Weller, H.; Yasuda, A.; Wessels, J. M. Nano Lett. 2003, 3, 1097–1101. (6) Duan, X.; Huang, Y.; Agarwal, R.; Lieber, C. M. Nature 2003, 421, 241–245. (7) Koo, S. M.; Li, Q.; Edelstein, M. D.; Richter, C. A.; Vogel, E. M. Nano Lett. 2005, 5, 2519–2523. (8) Wang, D. L.; Qian, F.; Yang, C.; Zhong, Z. H.; Lieber, C. M. Nano Lett. 2004, 4, 871–874. (9) Tang, Y. H.; Sham, T. K.; Jurgensen, A.; Hu, Y. F.; Lee, C. S.; Lee, S. T. Appl. Phys. Lett. 2002, 80, 3709–3711. (10) Westwater, J.; Gosain, D. P.; Tomiya, S.; Usua, S.; Ruda, H. J. Vac. Sci. Technol. B 1997, 15, 554–557. (11) Juhasz, R.; Elfstrom, N.; Linnrod, J. Nano Lett. 2005, 5, 275–280. (12) Menke, E. J.; Thompson, M. A.; Xiang, C.; Yang, L. C.; Penner, R. M. Nat. Mater. 2006, 5, 914–919. (13) Morales, A. M.; Lieber, C. M. Science 1998, 279, 208–211. (14) Zhang, Y. F.; Xing, Y. H.; Hang; Wang, N.; Yu, D. P.; Lee, C. S.; Bello, I.; Lee, S. T. Appl. Phys. Lett. 1998, 72, 1835–1837. (15) Wagner, R. S.; Ellis, W. C. Appl. Phys. Lett. 1964, 4, 89–90. (16) Givargizov, E. I. J. Cryst. Growth 1975, 31, 20–30. (17) Whitesides, G. M.; Grzybowski, B. Science 2002, 295, 2418–2421. (18) Kramien, R. D. Science 2003, 299, 1671–1673. (19) Murray, C. B.; Kagan, C. R.; Bawendi, M. G. Annu. ReV. Mater. Sci. 2000, 30, 545–610. (20) Busbee, B. D.; Obare, S. O.; Murphy, C. J. J. AdV. Mater. 2003, 15, 414–416. (21) Sun, Y. G.; Xia, Y. N. Science 2002, 298, 2176–2179. (22) van der Kooij, F. M.; Kassapidou, K.; Lekkerkerker, H. N. Nature 2000, 406, 868–871. (23) Manna, L.; Milliron, D. J.; Meisel, A.; Scher, E. C.; Alisatos, A. P. Nat. Mater. 2003, 2, 382–385. (24) Jin, R. C.; Cao, Y. W.; Mirkin, C. A.; Kelly, K. L.; Schatz, G. C.; Zheng, J. G. Science 2001, 294, 1901–1903. (25) Love, J. C.; Urbach, A. R.; Prentiss, M. G.; Whitesides, G. M. J. Am. Chem. Soc. 2003, 125, 12696–12697. (26) Tang, Z. Y.; Kotov, N. A.; Giersig, M. Science 2002, 297, 237–240. (27) Tang, Z. Y.; Zhang, Z. L.; Wang, Y.; Glotzer, S. C.; Kotov, N. A. Science 2006, 314, 274–278. Nano Lett., Vol. 8, No. 9, 2008 (28) Tian, Z. R.; Liu, J.; Xu, H.; Voigt, J. A.; McKenzie, B; Matzke, C. M. Nano Lett. 2003, 3, 179–182. (29) Zhang, H. F.; Dohnalkova, A. C.; Wang, C. M.; Young, J. S.; Buck, E. C.; Wang, L. S. Nano Lett. 2002, 2, 105–108. (30) Chen, M.; Season, P. C. AdV. Mater. 2005, 17, 2765–2768. (31) Clark, T. D.; Tien, J.; Duffy, D. C.; Paul, K. E.; Whitesides, G. M. J. Am. Chem. Soc. 2001, 123, 7677–7682. (32) Knischka, R.; Dietsche, F.; Hanselmann, R.; Frey, H.; Mulhaupt, R.; Lutz, P. J. Langmuir 1999, 15, 4752–4755. (33) Leu, C. M.; Reddy, G. M.; Wei, K. H.; Shu, C. F. Chem. Mater. 2003, 15, 2261–2265. (34) Gray, J. L.; Atha, S.; Hull, R.; Floro, J. A. Nano Lett. 2004, 4, 2447– 2450. (35) Pierrat, S.; Zins, I.; Breivogel, A.; Sonmichsen, C. Nano Lett. 2007, 7, 259–263. (36) Zhang, Z.; Horsch, M. A.; Lamm, M. H.; Glotzer, S. C. Nano Lett. 2003, 3, 1341–1346. (37) Horsch, M. A.; Zhang, Z.; Glotzer, S. C. Nano Lett. 2006, 6, 2406– 2413. (38) Zhang, Z.; Glotzer, S. C. Nano Lett. 2004, 8, 1407–1413. (39) Zhang, Z; Tang, Z.; Kotov, N. A.; Glotzer, S. C. Nano Lett. 2007, 7, 1670–1675. (40) Lamm, M. H.; Chen, T.; Glotzer, S. C. Nano Lett. 2003, 3, 989–994. (41) Zhang, X.; Chan, E. R.; Glotzer, S. C. J. Chem. Phys. 2005, 123, 184718. (42) Horsch, M. A.; Zhang, Z.; Glotzer, S. C. Phys. ReV. Lett. 2005, 95, 056105. (43) Jackson, A. M.; Myerson, J. W.; Stellacci, F. Nat. Mater. 2003, 13, 259–263. Nano Lett., Vol. 8, No. 9, 2008 (44) Gonze, X.; Beuken, J. M.; Caracas, R.; Detraux, F.; Fuchs, M.; Rignanese, G. M.; Sindic, L.; Verstraete, M.; Zerah, G.; Jollet, F.; Torrent, M.; Roy, A.; Mikami, M.; Ghosez, P.; Raty, J. Y.; Allan, D. C. Comput. Mater. Sci. 2002, 25, 478–492. (45) Soler, J. M.; Artacho, E; Gale, J. D.; Garcı́a, A.; Junquera, J.; Ordejón, P.; Sánchez-Portal, D. J. Phys.: Condens. Matter 2002, 14, 2745– 2779. (46) Perdew, J. P.; Burke, K.; Ernzerhof, M. Phys. ReV. Lett. 1996, 77, 3865–3868. (47) Lindhal, E.; Hess, B.; van der Spoel, D. J. Mol. Model. 2001, 7, 306– 317. (48) van Gunsteren, W. F.; Billeter, S. R. ; Eising, A. A.; Hunenberger, P. H.; Kruger, P.; Mark, A. E.; W. R. P.; Scott, W. R.; Tironi. I. G. Biomolecular Simulation: The GROMOS96 Manual and User Guide; VdF Hochschulverlag and der ETH Zurich: Zurich, Germany, 1996. (49) Robinson, G. W.; Zhu, S.; Singh, S.; Evans, M. W. Water in Biology, Chemistry and Physics: Experimental OVerViews and Computational Methodologies; World Scientific: Singapore, 1996. (50) Nie, Z.; Kumacheva, E. Nat. Mater. 2008, 7, 277–290. (51) Ma, D. D.; Lee, C. S.; Lee, S. T. Appl. Phys. Lett. 2001, 79, 2468– 2470. (52) Flory, P. J. J. Am. Chem. Soc. 1936, 58, 1877–1885; ibid., 1939, 61, 3334; ibid., 1942, 64, 2205. (53) Blase, X.; Fernandez-Serra, M.-V. Phys. ReV. Lett. 2008, 100, 046802. (54) Del Re, G.; Brahimi, M.; Peluso, A. Chem. Phys. Lett. 1999, 299, 511–517. NL801025C 2705