Electronics Design Project Overview

advertisement

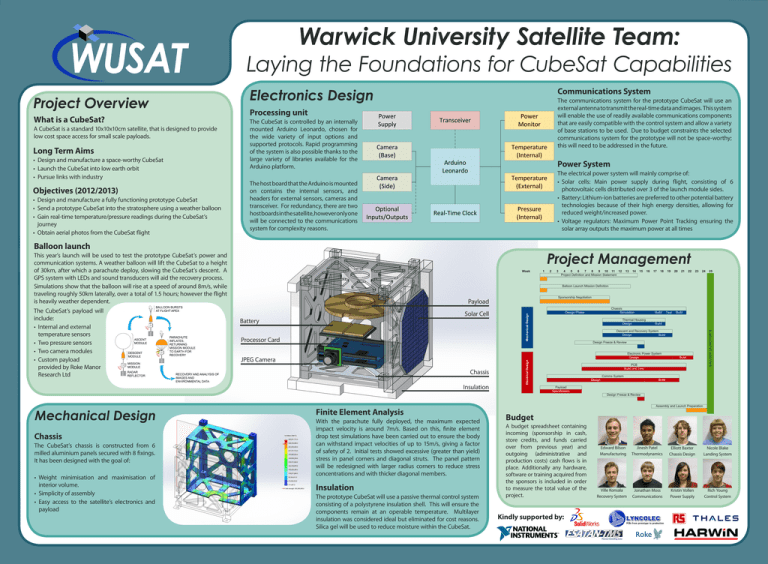

Warwick University Satellite Team: Laying the Foundations for CubeSat Capabilities What is a CubeSat? A CubeSat is a standard 10x10x10cm satellite, that is designed to provide low cost space access for small scale payloads. Long Term Aims • Design and manufacture a space-worthy CubeSat • Launch the CubeSat into low earth orbit • Pursue links with industry Objectives (2012/2013) • Design and manufacture a fully functioning prototype CubeSat • Send a prototype CubeSat into the stratosphere using a weather balloon • Gain real-time temperature/pressure readings during the CubeSat’s journey • Obtain aerial photos from the CubeSat flight The communications system for the prototype CubeSat will use an external antenna to transmit the real-time data and images. This system will enable the use of readily available communications components that are easily compatible with the control system and allow a variety of base stations to be used. Due to budget constraints the selected communications system for the prototype will not be space-worthy; this will need to be addressed in the future. Processing unit The CubeSat is controlled by an internally mounted Arduino Leonardo, chosen for the wide variety of input options and supported protocols. Rapid programming of the system is also possible thanks to the large variety of libraries available for the Arduino platform. Power System The electrical power system will mainly comprise of: • Solar cells: Main power supply during flight, consisting of 6 photovoltaic cells distributed over 3 of the launch module sides. • Battery: Lithium-ion batteries are preferred to other potential battery technologies because of their high energy densities, allowing for reduced weight/increased power. • Voltage regulators: Maximum Power Point Tracking ensuring the solar array outputs the maximum power at all times The host board that the Arduino is mounted on contains the internal sensors, and headers for external sensors, cameras and transceiver. For redundancy, there are two host boards in the satellite, however only one will be connected to the communications system for complexity reasons. Balloon launch Project Management This year’s launch will be used to test the prototype CubeSat’s power and communication systems. A weather balloon will lift the CubeSat to a height of 30km, after which a parachute deploy, slowing the CubeSat’s descent. A GPS system with LEDs and sound transducers will aid the recovery process. Simulations show that the balloon will rise at a speed of around 8m/s, while traveling roughly 50km laterally, over a total of 1.5 hours; however the flight is heavily weather dependent. Week Chassis The CubeSat’s chassis is constructed from 6 milled aluminium panels secured with 8 fixings. It has been designed with the goal of: • Weight minimisation and maximisation of interior volume. • Simplicity of assembly • Easy access to the satellite’s electronics and payload 2 3 4 5 6 7 8 9 10 11 12 Project Definition and Mission Statement 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 Balloon Launch Mission Definition Sponsorship Negotiation Solar Cell Battery Processor Card Chassis Simulation Design Phase Mechanical Design Payload Thermal Housing Design Build JPEG Camera Chassis Finite Element Analysis With the parachute fully deployed, the maximum expected impact velocity is around 7m/s. Based on this, finite element drop test simulations have been carried out to ensure the body can withstand impact velocities of up to 15m/s, giving a factor of safety of 2. Initial tests showed excessive (greater than yield) stress in panel corners and diagonal struts. The panel pattern will be redesigned with larger radius corners to reduce stress concentrations and with thicker diagonal members. Insulation The prototype CubeSat will use a passive thermal control system consisting of a polystyrene insulation shell. This will ensure the components remain at an operable temperature. Multilayer insulation was considered ideal but eliminated for cost reasons. Silica gel will be used to reduce moisture within the CubeSat. Test Build Build Descent and Recovery System Design Build Design Freeze & Review Electronic Power System Design Insulation Mechanical Design 1 Electrical Design The CubeSat’s payload will include: • Internal and external temperature sensors • Two pressure sensors • Two camera modules • Custom payload provided by Roke Manor Research Ltd Sheet1 Build PCB Build and Test Design Payload Specification Comms System BALLOON LAUNCH DATE Project Overview Electronics Design Communications System Build Design Freeze & Review Assembly and Launch Preparation Preparation of Technical Report and Budget A budget spreadsheet containing incoming (sponsorship in cash, store credits, and funds carried over from previous year) and outgoing (administrative and production costs) cash flows is in place. Additionally any hardware, software or training acquired from the sponsors is included in order to measure the total value of the project. Kindly supported by: Edward Bilson Manufacturing Jinesh Patel Thermodynamics Elliott Baxter Chassis Design Nicole Blake Landing System Page 1 Ville Konsala Recovery System Jonathan Moss Communications Kristin Vollen Power Supply Rich Young Control System