Advance Journal of Food Science and Technology 5(3): 289-294, 2013

advertisement

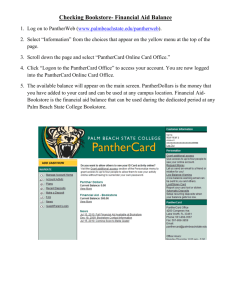

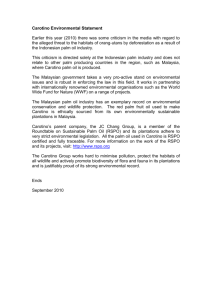

Advance Journal of Food Science and Technology 5(3): 289-294, 2013 ISSN: 2042-4868; e-ISSN: 2042-4876 © Maxwell Scientific Organization, 2013 Submitted: October 03, 2012 Accepted: December 02, 2012 Published: March 15, 2013 Material-mass Balance of Smallholder Oil Palm Processing in the Niger Delta, Nigeria Elijah I. Ohimain, Sylvester C. Izah and Francis A.U. Obieze Department of Biological Sciences, Faculty of Science, Niger Delta University, Wilberforce Island, Bayelsa State, Nigeria Abstract: This study evaluates the material-mass balance of smallholder oil palm processing in Niger Delta Nigeria. Ten smallholder oil palm processing mills were randomly sampled. Measuring scale was used to measure the weight of the Fresh Fruit Bunch (FFB) and all the processing intermediates/products including Threshed Fresh Fruit (TFF), Palm Pressed Fibre (PPF), Palm Kernel Shell (PKS), Empty Fruit Bunch (EFB), Crude Palm Oil (CPO), chaff and nut. During the study period (13-22 April 2012), 8 of the mills processed 90-400 bunches of Dura variety, while the remaining 2 mills processed 65-200 bunches of Tenera variety. During the batch processing of Dura variety, the proportion of the intermediate products computed in relation to the weight of the FFB (100%) are as follows; TFF (66.0-75.0%), mesocarp (44.8-51.1%), nuts (19.0-27.5%), kernel (5.7-7.2%), water in mesocarp (9.0-12.1%) and water in nut (2.4-3.4%), EFB (23.7-32.4%), chaff (0.8-2.4%), Palm Kernel Shell (PKS) (10.0-18.8%), Palm Press Fibre (PPF) (23.2-28.1%) and Crude Palm Oil (CPO) (9.4-12.8%). For the Tenera varieties, the compositions are as follows; TFF (70.9-72.9%), mesocarp (56.4-58.0%), nuts (14.5-14.9%), kernel (5.5-5.6%), water in mesocarp (10.110.4%) and water in the nut (1.9-2.1%), EFB (25.7-28.2%), chaff (0.9-1.4%), PKS (6.8-7.5%), (19.1-20.3%) and CPO (26.0-28.2%). This result shows that Tenera produces more oil and less wastes compared to the Dura variety. The solid wastes fractions are used as energy sources during the processing of oil palm and as filling materials for upgrading access roads to palm plantations. Except the huge volume of wastes (71.8-90.6%) generated by smallholder oil palm processors is effectively utilized, the process will be unsustainable. Keywords: Material-mass balance, oil palm, solid wastes stagnant water (Hartley, 1988). It requires a relative humidity of not less than 75% and a temperature range of 17-28°C (Poku, 2002). In West African, two distinct varieties known as the Dura and Pisifera were dominant until a third variety was discovered from the hybrid of the Dura and Pisifera called Tenera, which produces the highest oil content of the three species. In Nigeria, about 80% of oil palm plantation is covered with Dura and Pisifera and are cultivated by smallholders, while Tenera covers approximately 20%. The Tenera has a thin-shelled fruit and improved partition of dry matter within it. It gives 30% increase in oil yield at the expense of shell, without changing the total dry matter production (Corley and Lee, 1992). Over 40% of an individual palm fruit and over 20% of a fruit bunch from a typical Tenera variety of oil palm can be extracted as palm oil (Sridhar and AdeOluwa, 2009). During the processing of oil palm several byproducts and residues with high economical potentials are formed. The oil palm processing waste streams include solid, liquid and gaseous emissions. The oil palm industry generates a large quantity of solid residues and wastes in the form of Empty Fruit Bunch (EFB), Palm Kernel Shell (PKS), Palm Pressed Fibre INTRODUCTION Oil palm is a perennial crop cultivated extensively in the humid tropical region (Yusoff, 2004) of West Africa where it was first cultivated (Poku, 2002). It is the most important species of the genus Elaeis belonging to the family Palmae (Rupani et al., 2010). In Nigeria, oil palm trees were originally inter-planted in traditional agricultural production systems along with annual crops. It was said to have been domesticated some 5,000 years ago in Nigeria (Sridhar and AdeOluwa, 2009). But production during this time was for subsistence. Elaeis guineensis has been variously reported as the most productive oil crop in the world (Tagoe et al., 2012; Akangbe et al., 2011; Okechalu et al., 2011; Ngando et al., 2011; Dimelu and Anyaiwe, 2011; Rupani et al., 2010; Sumathi et al., 2008), with one hectare of oil palm producing 10-35 tonnes of Fresh Fruit Bunch (FFB) per year (Sridhar and AdeOluwa, 2009; Singh et al., 2010; Singh et al., 2011). According to Embrandiri et al. (2012), oil palm normally grows in the lowlands of the humid tropics within 15°N and 15°S where there is evenly distributed rainfall (1,800-5,000 mm/year). Oil palm adapts to soil with a low pH, but sensitive to high pH (>7.5) and to Corresponding Author: Elijah I. Ohimain, Department of Biological Sciences, Faculty of Science, Niger Delta University, Wilberforce Island, Bayelsa State, Nigeria 289 Adv. J. Food Sci. Technol., 5(3): 289-294, 2013 (PPF) and chaff. When palm oil is extracted and processed, it also produces effluents with high organic matter, suspended matter, oil and grease (Sridhar and AdeOluwa, 2009; Rupani et al., 2010; Ma, 1999; Ma, 2000). Gaseous emissions are often unreported. These processing wastes if not adequately managed causes adverse environmental impacts including land and aquatic ecosystem contamination, loss of land and resources, negative impacts on soil micro flora and fauna and loss of biodiversity (Sridhar and AdeOluwa, 2009). Palm oil is a multipurpose raw material used by both food and non-food industries (Armstrong, 1998) for the manufacturing of margarine, soap, candle, base for lipstick, waxes and polish bases, confectionaries (Embrandiri et al., 2012; Aghalino, 2000; Armstrong, 1998), pharmaceutical (Helleiner, 1966), tin plating, lubricant, fuel (biodiesel) (Pleanjai et al., 2007; Armstrong, 1998). Oil palm processing by-products can be further converted to useful products, for instance EFB and PKC have been successfully converted into compost by enriching with goat manure or poultry manure and were useful in developing oil palm nurseries and other food crops as fertilizers (Sridhar and AdeOluwa, 2009; Er et al., 2011). Also, composting of EFB has been carried out to improve soil quality (Prasertsan and Prasertsan, 1996). Palm oil mills in general, are self-sufficient in energy generation due to the large amount of solid fuel feedstock available. Currently, processors use solid wastes as boilers fuel and plantation-based mills return the solid by-products except PKS which is used as hardening material for the construction of roads to mills and plantations. The use of oil processing wastes as compost and mulch is a cost-saving measure as it aids in the reduction of fertilizer dependency by the plantation owners. PPF can be processed into various products to suit specific applications other than the once mentioned earlier such as mattress cushions, soil stabilization/compaction, landscaping and horticulture, ceramic and brick manufacturing (Ramli et al., 2002). Other scarcely notable wastes are the chaff. It is Fig. 1: A flow chart of small holder oil palm processing showing all the intermediatries in Niger Delta, Nigeria 290 Adv. J. Food Sci. Technol., 5(3): 289-294, 2013 Fresh Fruit Bunch (FFB) Empty Fruit Bunch (EFB) Chaff Palm Press Fiber (PPF) Nut Palm Kernel Shell (PKS) Fig. 2: Processing intermediates from FFB of oil palm produced during splitting of the FFB and sieving of threshed fruits. They are of lighter weight compared to all other solid wastes. The chaff can also be used as fuel and manure, though when used as fuel it burns quickly due to its light weight. In view of the abundance of oil palm by-products in Niger Delta, Nigeria and other parts of the world, sustainable management of these byproducts is necessary for sustainable development. As wastes of biological origin, composting as well as vermi-composting can be a good option for sustainable management of these wastes (Rupani et al., 2010; Singh et al., 2011; Singh et al., 2010; Embrandiri et al., 2012). Material mass balance analysis is very important in oil palm processing because it provides a means of quantifying the expected wastes from the process and making provisions for their utilization to avoid environmental impacts. During oil palm processing, about 20-24% of FFB are converted to oil (Poku, 2002), while the remaining 76-80% are essentially wasteproducts. Studies on material-mass balance have not been carried out on smallholders’ oil palm processor in 291 Adv. J. Food Sci. Technol., 5(3): 289-294, 2013 Nigeria. Hence, this study investigates the materialmass balance of smallholder oil palm processing in Niger Delta Region of Nigeria. respectively. Nut accounted for 19.0-27.5 and 14.514.9% of the FFB for Dura and Tenera varieties respectively, while the mesocarp accounted 44.8-51.1 and 56.4-58.0%, respectively. This shows that the Dura variety generates high quantity of nut and less mesocarp, while Tenera produces smaller nuts with larger mesocarp. This may be the reason why the Dura varieties produce less CPO when compared to Tenera varieties. The kernel from the nut consists of 5.7-7.2 and 5.5-5.6% of the FFB for Dura and Tenera varieties respectively. The PKS produced from the nut consists of 10.0-18.8 and 6.8-7.5% of the FFB for Dura and Tenera varieties respectively, while water in the nut consists of 2.4-3.4 and 1.9-2.1%, respectively. The result showed that there is a significant variation in PKS and water content of the nut. The CPO from the mesocarp of Dura and Tenera varieties ranged from 9.4-12.1 and 26.0-28.2%, respectively of the FFB. The significant variation is a true reflection of the different varieties. The Tenera varieties produce more CPO than Dura varieties. This may be attributed to the thickness and oil content of their mesocarp. The water from the mesocarpranged from 9.0-12.1 and 10.1-10.4% of the FFB for Dura and Tenera varieties respectively, while the PPF from the mesocarp ranged from 23.2-28.1 and 19.1-20.3%, respectively. The high PPF from the Dura varieties may be associated to the low CPO content, because the fibre occupies a significant proportion of the mesocarp along side with the nut. The material-mass balance of different fractions of FFB produced during the processing of oil palm by smallholder is summarized in the Fig. 3. The total FFB were taken to be 100% for both Dura and Tenera. Hence, the composition of the products/intermediates produced during the processing of Dura variety are as follows; TFF (66.0-75.0%), mesocarp (44.8-51.1%), nuts (19.0-27.5%), kernel (5.7-7.2%), water in mesocarp (9.0-12.1%) and water in nut (2.4-3.4%), EFB (23.7-32.4%), chaff (0.8-2.4%), PKS (10.0- MATERIALS AND METHODS Field visit/data collection: Ten smallholder’s oil palm processing sites were visited at Elele, River State, Niger Delta region of Nigeria from 13-22 April 2012. Oil palm is processed in batches at all the milling sites depending on the availability of FFB. The process of oil palm extraction at these sites is basically the same and is presented in Fig. 1. Measuring scale was used to measure the weight of the FFB and all the processing intermediates (PPF, PKS, EFB, CPO chaff and nut) which are presented in Fig. 2. From where the proportions (in %) of the intermediates to the FFB was computed. RESULTS AND DISCUSSION Table 1 presents the different fractions of the products derived during oil palm processing at the ten different mills. The mills processed FFB ranging from 90-400 and 65-200 bunches for Dura and Tenera respectively. In all the mills, oil palms are mostly processed in batches due to the small-scale nature of their operations and the limited availability of palm bunches. The average weight of Dura and Tenera bunches ranged from 12.8-14.0 and 14.7-15.1%, respectively. This indicates that the Tenera variety have a bigger bunch size. The total weight of FFB processed is varied depending on the number of FFB available and the bunch size. TFF of Dura and Tenera varieties accounted for 66.1-75.0 and 70.9-72.9% of the FFB respectively. Chaff accounted for 0.8-2.4 and 0.9-1.4% of the FFB for Dura and Tenera varieties respectively, while EFB accounted for 25.7-28.2 and 25.7-32.4%, Table 1: Different fractions of the product derived during oil palm processing Site # No. of FFB Average weight of FFB (Kg) Total weight of FFB (Kg) TFF (%) EFB (%) Chaff (%) Nut (%) A* 90 14.0 1,260 68.0 30.6 1.4 19.0 B* 260 12.8 3,328 66.4 32.0 1.6 21.2 C* 260 13.5 3,510 70.4 28.3 1.3 25.2 D* 200 13.0 2,600 67.7 31.5 0.8 22.9 E* 400 12.4 4,960 72.6 25.0 2.4 21.5 F** 65 15.1 981.5 70.9 28.2 0.9 14.5 G* 300 12.9 3,870 68.1 30.3 1.6 19.0 H** 200 14.7 2,940 72.9 25.7 1.4 14.9 I* 200 12.8 2,560 75.0 23.7 1.3 27.5 J* 200 12.7 2,540 66.1 32.4 1.4 21.0 Site # Kernel (%) PKS (%) Water in nut (%) Mesocarp (%) PPF (%) CPO (%) Water in mesocarp (%) A* 6.3 10.0 2.7 49.0 28.1 10.9 10.0 B* 6.5 11.6 3.1 45.2 25.6 10.1 9.5 C* 7.2 14.6 3.4 45.2 23.7 9.7 11.8 D* 6.0 14.5 2.4 44.8 23.2 10.5 11.1 E* 5.7 13.3 2.5 51.1 26.2 12.8 12.1 F** 5.6 6.8 2.1 56.4 20.3 26.0 10.1 G* 5.8 10.0 3.2 46.1 26.4 10.2 9.5 H** 5.5 7.5 1.9 58.0 19.4 28.7 10.4 I* 5.8 18.8 2.9 47.5 25.0 11.0 11.5 J* 6.5 11.5 3.0 45.1 25.4 10.7 9.0 FFB: Fresh fruit bunch; TFF: Threshed fresh fruit; EFB: Empty fruit bunch; PKS: Palm kernel shell; PPF: Palm press fibre; CPO: Crude palm oil; *: Dura variety; **: Tenera variety 292 Adv. J. Food Sci. Technol., 5(3): 289-294, 2013 Fig. 3: Material-mass balance of FFB processed by small holders in Nigeria Figures in bracket are the percentage of the different fraction of FFB: ( ) = Dura variety, [ ] = Tenera variety 18.8%), PPF (23.2-28.1%) and CPO (9.4-12.8%). While that of Teneraare as follows; TFF (70.9-72.9%), mesocarp (56.4-58.0%), nuts (14.5-14.9%), kernel (5.55.6%), water in mesocarp (10.1-10.4%) and water in nut (1.9-2.1%), EFB (25.7-28.2%), chaff (0.9-1.4%), PKS (6.8-7.5%), PPF (19.1-20.3%) and CPO (26.028.2%). Prasertsan and Prasertsan (1996), recorded the composition of palm bunch as follows: FFB (100%), EFB (20-30%), fruits (70-74%), dry EFB (14-16%), pericarp (51-55%), nut (18.9-19.2%), kernel (8.48.5%), PKS (6.8-7.4%), moisture (3.3-3.4%), PPF (1213%), CPO (25-28%) and moisture (13-14%). Also, Hambali et al. (2010) presented mass balance of palm oil processing as follows: FFB (100%), EFB (21.0%), fruits (64.5%), nuts (11.9%), mesocarp (53.4%), kernel (4.9%), shell (6.4%), CPO (23.5%) and fibre (14.4%). The result of this study is similar to what was reported by Prasertsan and Prasertsan (1996) and Hambali et al. (2010) for EFB, FF, mesocarp and PKS. However, the proportion of nut, water in mesocarp and CPO to the FFB for Tenera variety is close to the findings of Prasertsan and Prasertsan (1996), whereas there is disparity in the percentage of kernel and PPF produced. Also, Mahalia et al. (2001) reported the CPO, PKS, kernel FF (fruitlet), nut and PPF as 23.52, 5.2, 5.2, 67.43, 11.8 and 10.62%, respectively. Chavalparit et al. (2006) reported EFB, shell and PPF to be 24, 6 and 14%, respectively. None of these studies mention chaff as a component of the FFB, whereas in this study chaff is a major constituent of the FFB. CONCLUSION This study investigated the material-mass balance of smallholder’s oil palm processing in Elele, Rivers State, Nigeria. It was found that CPO and kernel which are the major products of FFB accounting for 9.4-12.8 and 26.0-28.2% for Dura and Tenera varieties respectively. The differences in the quantity of CPO produced may be associated to the superiority of the Tenera variety over the Dura. Thus, since Dura varieties of oil palm covers about 80% of the oil palm plantation in Niger Delta region, it has contributed significantly to the low yield of CPO in the mills. Kernel accounted for 5.7-7.2 and 5.5-5.6% of the FFB for Dura and Tenera varieties respectively. Because of the low yield of oil, large volume of processing wastes are generated in the form of PPF, PKS, EFB, chaff and water. The wastes are used in the mills mostly as energy source for boilers; PKS is used to upgrade access roads to mills and plantation, while chaff and EFB are commonly used as mulch and compost. ACKNOWLEDGMENT The authors wish to thank and acknowledge the following undergraduates students of the Niger Delta 293 Adv. J. Food Sci. Technol., 5(3): 289-294, 2013 Ma, A.N., 2000. Environmental management for the oil palm industry. Palm Oil Dev., 30: 1-10. Mahalia, T.M.I., M.Z. Abdulmium, T.M.I. Alamsyah and D. Mukhlishien, 2001. An alternative energy source from palm wastes industry for Malaysia and Indonesia. Energy Conver. Manag., 42: 2109-2118. Ngando, E.G.F., M.E.A. Mpondo, E.E.L. Dikotto and P. Koona, 2011. Assessment of the quality of crude palm oil from smallholders in Cameroon. J. Stor. Prod. Posthar. Res., 2(3): 52-58. Okechalu, J.N., M.M. Dashen, P.M. Lar, B. Okechalu and T. Gushop, 2011. Microbiological quality and chemical characteristics of palm oil sold within Jos Metropolis, Plateau State, Nigeria. J. Microbiol. Biotechnol. Res., 1(2): 107-112. Pleanjai, S., S.H. Gheewala and S. Garivait, 2007. Environmental evaluation of biodiesel production from palm oil in a life cycle perspective. Asian J. Energy Environ., 8(1-2): 15-32. Poku, K., 2002. Small-Scale Palm Oil Processing in Africa.FAO Agriculture Services Bulletin 148, Food and Agricultural Organization of the United Nations, Rome, Italy. Prasertsan, S. and P. Prasertsan 1996. Biomass residues from palm oil mill in Thailand: An overview on quantity and potential usage. Biomass Bioenerg., 11(5): 387-395. Ramli, R., S. Shaler and A. Jamaludin, 2002. Properties of medium density fibreboard from oil palm empty fruit bunch fibre. J. Oil Palm Res., 14: 34-40. Rupani, P.F., R.P. Singh, H. Ibrahim and N. Esa, 2010. Review of current Palm Oil Mill Effluent (POME) treatment methods: Vermicomposting as a sustainable practice. World Appl. Sci. J., 11(1): 70-81. Singh, R.P., A. Embrandiri, M.H. Ibrahim and N. Esa, 2011. Management of biomass residues generated from oil mill: Vermicomposting a sustainable option. Resour. Conserv. Recy., 55: 423-434. Singh, R.P., M.H. Ibrahim, E. Norizan and M.S. Iliyana, 2010. Composting of waste from palm oil mill: A sustainable waste management practice. Rev. Environ. Sci. Biotechnol., 9: 331-344. Sridhar, M.K.C. and O.O. AdeOluwa, 2009. Palm Oil Industry Residue, In: Nigam, P.S. and A. Pandey (Eds.), Biotechnology for Agro-industrial Residues Utilisation. Springer, USA, pp: 341-355. Sumathi, S., S.P. Chai and A.R. Mohamed, 2008. Utilization of oil palm as a source of renewable energy in Malaysia.Renewab.Sustainab. Energy Rev., 12: 2404-2421. Tagoe, S.M.A., M.J. Dickinson and M.M. Apetorgbor, 2012. Factors influencing quality of palm oil produced at the cottage industry level in Ghana. Int. Food Res. J., 19(1): 271-278. Yusoff, S., 2004. Renewable energy from palm oil innovation on effective utilization of waste. J. Clean. Prod., 14: 87-95. University that participated in the measurement exercise during field work; Eke Rita, Inatimi Sampson, Alaka Evelyn, Jeremiah Ikakita, Okonkwo Amaka, Oghenegueke Ejiroghene, Ereke Samuel, Kakiri Gift, Perewarebo Glory, Biriduba Woyengitonyokopa, Clarke Ebisine and Eretinghe Dorcas. REFERENCES Aghalino, S.O., 2000. British colonial policies and the oil palm industry in the Niger delta region of Nigeria, 1900-1960. Afr. Stud. Monogr., 21(1): 19-33. Akangbe, J.A., G.B. Adesiji, S.B. Fakayode and Y.O. Aderibigbe, 2011. Towards palm oil selfsufficiency in Nigeria: Constraints and training needs nexus of palm oil extractors. J. Hum. Ecol., 33(2): 139-145. Armstrong, R. 1998. Palm Oil. The Australian National University, Retrieved from: http://www. anu.edu.au/ Forestry/wood/nwfp/palmoil.html. Chavalparit, O., W.H. Rulkens, A.P.J. Mol and S. Khaodhair, 2006. Option for environmental sustainability of the crude palm oil industry in Thailand through enhancement of industrial ecosystem. Env., Dev. Sustainab., 8:271-287. Corley, R.H.V. and C.H. Lee, 1992. The physiological basis for genetic improvement of oil palm in Malaysia. Euphyt. J., 60: 179-184. Dimelu, M.U. and V. Anyaiwe, 2011.Priorities of smallholder oil palm producers in ika local government area of delta state: Implication for agricultural extension service in Nigeria. World J. Agric. Sci., 7(2): 117-123. Embrandiri, A., R.P. Singh, H.M. Ibrahim and A.A. Ramli, 2012. Land application of biomass residue generated from palm oil processing: Its potential benefits and threats. Environmentalist, 32: 111-117. Er, A.C., Abd. R.M. Nor and K. Rostam, 2011. Palm oil milling wastes and sustainable development. Am. J. Appl. Sci., 8(5): 436-440. Hambali, E., A. Thahar and A. Komarudin, 2010.The potential oil palm and rice biomass as bioenergy feedstock.7th Biomass Asia Workshop. Jakarta, Indonesia. November 29-December 01, 2010. Hartley, C.W., 1988. The Oil Palm. 3rd Edn., Longmans Scientific and Technical, London, pp: 1-761. Helleiner, G.K., 1966. Peasant Agriculture, Government and Economic Growth in Nigeria. R.D. Irwin, Homewood, pp: 600. Ma, A.N., 1999. Treatment of Palm Oil Mill Effluent. In: Singh, G., K.H. Lim, T. Leng and L.K. David (Eds.), Oil Palm and the Environment: A Malaysian Perspective. Malaysian Oil Palm Growers’ Council, Kuala Lampur, pp: 277. 294