Advance Journal of Food Science and Technology 9(3): 197-201, 2015

advertisement

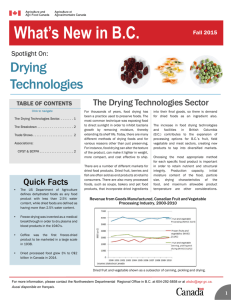

Advance Journal of Food Science and Technology 9(3): 197-201, 2015 DOI: 10.19026/ajfst.9.1992 ISSN: 2042-4868; e-ISSN: 2042-4876 © 2015 Maxwell Scientific Publication Corp. Submitted: February 13, 2015 Accepted: March 12, 2015 Published: August 10, 2015 Research Article Technology Advances and Mechanistic Modelling in Freeze-drying and Dehydration of Food Wanren Chen, Xiang Gui and Hua Li School of Chemical and Energy Engineering, Zhengzhou University, Zhengzhou 450001, China Abstract: Aim of study is to introduce some advanced freeze-drying technology and mechanistic modelling in freeze-drying and dehydration of food, freeze-drying is based on the dehydration by sublimation of a frozen product, due to very low temperature, all the deterioration activity and microbiological activity are stopped and provide better quality to the final product. Meanwhile the main problems of the freeze-dried food were proposed and its prospect and outlook was also analyzed, expecting to obtain technical and theoretical support for the production of freezedrying food. Keywords: Food, mechanistic modelling, problem, technology advances, vacuum freeze-drying expect to obtain technical and theoretical support for the production of freeze-drying food. INTRODUCTION With the improvement of the living standard, people’s requirements on food qualitatively changed as well. The modern consumers also pursue “nature, nutrition, safety, health and convenience” besides color, smell and taste. Vacuum freeze-dried food well matches with the three development trends of “green food”, “convenient food” and “health food”. The development of freeze-dried food is not only the need of the sack industry, but also the new development direction of food in 21st century. It is well know that conventional drying (hot air) may affect the quality of products. The phenomena underlying this process is a complex problem involving simultaneous mass and energy transport in a hygroscopic, shrinking system. Freeze-drying is based on the dehydration by sublimation of a frozen product. Due to the absence of liquid water and the low temperatures required for the process, most of deterioration and microbiological reactions are stopped which gives a final product of excellent quality. The solid state of water during freeze-drying protects the primary structure and the shape of the products with minimal reduction of volume. Despite of many advantages, freeze-drying has always been recognized as the most expensive process for manufacturing a dehydrated product. In this study, technology advances and mechanistic modelling of the phenomena involved in freeze-drying and dehydration of food were introduced, some important characteristics such as glass transition temperature, cost and new improvement were taken into account and objective of the study was to RESULTS AND DISCUSSION Technology advances in drying and dehydration of food: The main method of drying includes freeze, vacuum, hot air drying, cabinet or tray, ultrasound, microwave and combination thereof (George et al., 2004). Except for freeze drying, applying heat energy during drying process through conduction, convection and radiation are the basic techniques used to force water to vaporize, while forced air is applied to encourage the removal of vapor. A large number of foods are dehydrated in a variety of units with diverse processing conditions. The choice of drying method depends on various factors such as the type of product, availability of dryer, cost of dehydration and final quality of desiccated product. Energy consumption and quality of dried products are other critical parameters in the selection of a drying process. The main methods of drying are the follows. Hot air drying: Drying of food has been principally accomplished by convective drying (Nijhuis et al., 1998). There are a number of studies that have addressed the problems associated with conventional convective drying. Some important physical properties of the products have changed such as loss of change of texture, chemical changes affecting flavor and nutrients and shrinkage (Mayor and Sereno, 2004). Besides, convective drying gives little scope for prior rehydration to further processing after drying for a minimal quality (Khraisheh et al., 2004). The high Corresponding Author: Hua Li, School of Chemical and Energy Engineering, Zhengzhou University, No. 100 Science Road, Zhengzhou, Henan 450001, China, Fax: 0086-371-63886154 This work is licensed under a Creative Commons Attribution 4.0 International License (URL: http://creativecommons.org/licenses/by/4.0/). 197 Adv. J. Food Sci. Technol., 9(3): 197-201, 2015 temperature of the drying process is an important cause for loss of quality. Lowering the process temperature has great potential for improving the quality of dried products (Nindo et al., 2003; Beaudry et al., 2004). However in such conditions, the operating time and the associated cost become unacceptable. To reduce the operational cost, different pre-treatments and new methods of low temperature and low energy drying methods are evolved. surface of the material hence combining processes to form what is called “microwave convective drying”. The air temperature passing through the product can be varied to shorten the drying time. Use of microwave energy in drying can reduce drying time and complements conventional drying in later stages by specifically targeting the internal residual moisture (Osepchuk, 2002). The drying of fruit with microwave demonstrated that good quality dried products can be achieved by varying power density and duty cycle time. In dried carrots, quality improvement was found in color, shrinkage and rehydration property (Wang and Xi, 2005). The quality of raisins dried by microwave was superior to hot air dried samples in color, damage, darkness, crystallized sugar, stickiness and uniformity (Tulasidas et al., 1995). Compared to the conventional freeze-drying, microwave assisted freeze-drying lead to products of similar or even higher quality (Barrett et al., 1997; Rosenberg and Bogl, 1987), but microwave freeze-drying is still not widely used in industry since many technical problems can be encountered (i.e., corona discharges, melting and over-heating of the frozen kernel, non-uniform heating, etc.). Freeze drying: Freeze drying of biological materials is one of the best methods of water removal which results in final product of the highest quality. Freeze drying is sublimation of ice fraction where water passes from solid to gaseous state. Due to very low temperature all the deterioration activity and microbiological activity are stopped and provide better quality to the final product. Recently the market for organic products is increasing. Therefore, the use of freeze drying of food, fruit and vegetables is not only increasing in volume but also diversifying (Brown, 1999). Freeze drying seems to be better preservation method over other dehydration methods such as air or drum drying. Nonetheless, freeze drying of small fruits (strawberry) received particular attention by several researchers (Paakkonen and Mattila, 1991; Hammami and Rene, 1997; Shishegarha et al., 2002). Strawberry dried at 20°C retained better quality than at 60°C. The product mostly collapses i.e., loss in structure, reduction in pore size and shrinkage at higher temperature (Hammami and Rene, 1997). Paakkonen and Mattila (1991) have found that low processing temperature improved the sensory quality of dried fruits. Adsorption freeze-drying: Adsorption freeze-drying uses a desiccant (e.g., silica gel) to create a high vapor drive at low temperatures (Bell and Mellor, 1990a). The adsorbent replaces the condenser and let a reduction of 50% in total costs as compared to traditional freezedrying. Despite the many advantages as compared to regular freeze-drying (Bell and Mellor, 1990b), the quality of adsorption freeze-dried foods is slightly reduced and some poor as compared to that obtained by traditional freeze-drying. Vacuum drying: Vacuum drying is an important process for heat sensitive materials. The process of vacuum drying can be considered according to physical condition used to add heat and remove water vapor. Low temperature can be used under vacuum for certain methods that might discolor or decompose at high temperature. A comparison of drying technologies in review by Khin et al. (2005) showed that freeze drying, vacuum drying and osmotic dehydration are considered too costly for large scale production of commodity. Fluidized atmospheric freeze-drying: Fluidized atmospheric freeze-drying has recently been developed; its freeze-drying process can be defined with three words: adsorption, fluidization and atmospheric pressure. The cut off is approximately 34% as compared to vacuum freeze-drying (Wolff and Gibert, 1990). However, drying times are increased 1-3 times since the use of atmospheric pressure turns the control of the process from heat to mass transfer, which makes the kinetic extremely slow. Recent studies showed that in addition, quality of products is not excellent when atmospheric pressure is used instead of vacuum, since the risk of product collapse is increase (León-Martínez et al., 1997). Microwave drying: Microwave technology uses electromagnetic waves that pass through material and cause its molecules to oscillate generating heat. Microwave heating generates heat within the material and heats the entire volume at about the same rate. When the material couples with microwave energy, heat is generated within the product through molecular excitation. Since the frozen region has a high thermal conductivity, microwave energy helps sublimation to decrease freeze-drying times up to 60-75% (Rosenberg and Bogl, 1987). The critical next step is to immediately remove the water vapor. A simple technique for removing water is to pass air over the Ultrasound: Acoustic streaming can affect the thickness of boundary layer which exists between stirred fluid and solid. Cavitation, a phenomenon produced by the sonication, consists of the formation of bubbles in the liquid which can collapse and generate localized pressure fluctuation. This ultimately increases the mass transfer of osmotic treatment. The rate of transfer depends on pressure and frequency of the wave produced by sonication (Raghavan et al., 2005). 198 Adv. J. Food Sci. Technol., 9(3): 197-201, 2015 The higher the process temperature above the glass transition temperature (Tg), the higher the structural collapse. The methods of freeze and hot air drying can be compared based on this theory. In freeze-drying, since the temperature is below Tg’ (maximally freeze concentrated Tg), the material is in the glassy state. Hence shrinkage is negligible. As a result the final product is very porous. In hot air drying, on the other hand, since the temperature of drying is above Tg’ or Tg, the material is in the rubbery state and substantial shrinkage occurs. Hence the food produced from hot air drying is dense and shrivelled (Peleg, 1996, Sablani and Rahman, 2002). Mechanistic modelling of the phenomena involved: Freeze-drying is a dehydration process in which water is removed from frozen materials by ice sublimation. Three stages of a typical freeze-drying cycle are freeze, primary drying and secondary drying. A number of freeze-drying models to predict freeze-drying cycles for product quality control have been published; such as the sublimation front of pure ice in freeze-drying has been studied to investigate basic heat and mass transfer mechanisms in the primary drying stage of vial lyophilization, they concluded that the sublimation front was curved and strongly depended on heat transfer in the vial walls (Wang and Chen, 2009) and have also experimentally and numerically studied freeze-drying in porous materials. They have concluded that temperature and ice saturation profiles show sublimation in the pre-interface moving region, which takes place after the interface movement is completed. Therefore, the sublimation interface can be naturally formed rather than constrainedly inserted (Wang and Chen, 2009). On the other hand, pore size influences water vapor flow through dried mass in the freezedrying process; as a consequence, water vapor diffusion coefficients are influenced by this feature of porous materials. To study the process at pore-scale to gain a better understanding of freeze-drying and know how pore size influences sublimation front morphology, micro models were built (Segura and Oyarzún, 2012), they are particularly important in freeze-dried porous materials such as foods, drugs, or rocks. Transparent micro models are an interesting tool to study freezedrying in a porous structure. These micro models can be defined as transparent pore networks (pore bodies) and constrictions (pore throats) that simulate some of the complexities of natural porous media (Buckley, 1991). Hot air drying usually destroys the cell structure and thereby takes more time for dehydration while due to solid state of water during freeze drying protects primary structure and shape of products keeping the cells almost intact, with a high porosity product with three-dimensional net texture (Saguy et al., 2004). Pretreatments given to foods before drying or optimal drying conditions are used to create a more porous structure so as to facilitate better mass transfer rates. Maintaining moisture gradient levels in the solid, which is a function of drying rate, can reduce the extent of crust formation; the faster the drying rate, the thinner the crust (Achanta and Okos, 1996). Depending on the end use, hard crust and pore formation may be desirable or undesirable. Rahman (2001) has outlined the current knowledge on the mechanism of pore formation in foods during drying and related processes. The glass transition theory is one of the concepts proposed to explain the process of shrinkage and collapse during drying and other related processes. According to this concept, there is negligible collapse (more pores) in a material when it is processed below the glass transition. The problems and countermeasures of freeze-dried food: • • • • • Freeze-drying is needs to operate under the high vacuum and at low temperature; therefore the cost of the freeze-dried food is high. The price of freeze-dried food is 4-6 times than hot-air dried food in international market. The freeze-dried food easily absorbs moisture and rancidity once exposed to the air. Freeze-dried food is porous and loose, thus is easily broken or powdered during transportation and sales process. The investment cost of the freeze-drying is relatively high, the main reason for high cost is the need to operate under a vacuum and at low temperature. Different freeze-dried foods have different technologies, therefore the lyophilization curve must be tested by the measurement of the melting point, thermal conductivity and the optimal technological condition can be find out only by the experiment of lyophilization curve (Hua, 2005; Sansiribhan et al., 2012; León-Martínez et al., 2011). Based on the above-mentioned, some methods can be considered as follows: • • • 199 Select reasonable material, to increase its additional value and reduce the ratio of energy consumption. If the material has high quality, special nutrition and high additional value, then the superiority of the freeze-dried food in quality, level and price will be outstanding. Improve the equipment of freeze-drying by shortening the drying time to reduce the energy consumption. Improve process of freeze-drying, by shortening time to reduce the energy consumption. As to different materials and pretreatments, the reasonable temperature of heating plate, pressure of Adv. J. Food Sci. Technol., 9(3): 197-201, 2015 • Brown, M., 1999. Focusing on freeze drying. Food Manuf., 76(9): 34-36. Buckley, J.S., 1991. Multiphase Displacement in Micromodels. In: Morrow, N.R. (Ed.), Interfacial Phenomena in Petroleum Recovery. Marcel Dekker Inc., New York, pp: 157-189. George, S.D., S. Cenkowski and W.E. Muir, 2004. A review of drying technologies for the preservation of nutritional compounds in waxy skinned fruit. Proceeding of North Central ASAE/CSAE Conference. Winnipeg, Manitoba, Canada, pp: 04-104. Hammami, C. and F. Rene, 1997. Determination of freeze drying process variables for strawberries. J. Food Eng., 32: 133-154. Hua, Z.Z., 2005. Vacuum Freeze-drying Technology. Science Press, Beijing. Khin, M.M., W. Zhou and C. Perera, 2005. Development in combined treatment of coating and osmotic dehydration of food-A review. Int. J. Food Eng., 1: 1-19. Khraisheh, M.A.M., W.A.M. McMinn and T.R.A. Magee, 2004. Quality and structural changes in starchy foods during microwave and convective drying. Food Res. Int., 37: 497-503. León-Martínez, F.M., J. Rodríguez-Ramírez, L.L. Medina-Torres, L.L. Méndez Lagunas, J.I. Lombrana and M. Villaran,1997. The influence of pressure and temperature on freeze-drying in an adsorbent medium and establishment of drying strategies. Food Res. Int., 30(3/4): 213-222. Mayor, L. and A.M. Sereno, 2004. Modelling shrinkage during convective drying of food materials. J. Food Eng., 61: 373-386. Nijhuis, H.H., H.M. Torringa, S. Muresan, D. Yukel, C. Leguijt and W. Kloek, 1998. Approaches to improving the quality of dried fruits and vegetables. Trends Food Sci. Tech., 9: 13-20. Nindo, C.I., T. Sun, S.W. Wang, J. Tang and J.R. Powers, 2003. Evaluation of drying technologies for retention of physical quality and antioxidants in asparagus. Lebensm. Wiss. Technol., 36: 507-516. Osepchuk, J.M., 2002. Microwave power applications. IEEE T. Microw. Theory, 50: 975-985. Paakkonen, K. and M. Mattila, 1991. Processing, packaging and storage effects on quality of freeze dried strawberries. J. Food Sci., 56: 1388-1392. Peleg, M., 1996. On modelling changes in food and biosolids at and around their Tg temperature range. Crit. Rev. Food Sci., 36: 49-67. Raghavan, G.S.V., T.J. Rennie, P.S. Sunjka, V. Orsat, W. Phaphuangwittayakul and P. Terdtoon, 2005. Overview of new techniques for drying biological materials with emphasis on energy aspects. Braz. J. Chem. Eng. Cem., 22: 195-201. Rahman, M.S., 2001. Toward prediction of porosity in foods during drying: A brief review. Dry. Technol., 19: 1-13. freeze-drying chamber and food thickness can be selected correctly. Improve the technology of freeze-drying. Introducing new technology such as the adsorption freeze-drying etc. and shortening the time of sublimation to reduce the energy consumption of freeze-drying and improve the product quality. The prospect and outlook: With global environment deterioration, clean and green food becomes more and more welcome, green food becomes the main tendency in food industry. With the rapid tempo of modern life, people require more and more fast food, thus the convenient food become the another trend in the development of food industry. With the increasing incidence of hyperlipidemia, hypertension, diabete and cardiovascular or cerebrovascular disease, health food with low calorie or low-fat became another development trend. Freeze-drying technology suits the three development tendencies: "green food", "convenient food" and "health food" well. Although freeze-drying process is not widely used in the food industry due to its high operation cost. However, with the increasing concern about food quality, food vacuum freeze-drying technology could be considered as a valuable alterative to preserve foods in 21st century. CONCLUSION In this study, advanced freeze-drying technology and mechanistic modelling in freeze-drying and dehydration of food were introduced, in which, freezedrying technology is well matched with the development trends of “green”, “convenient” and “health”, is the new development direction of food in the future. REFERENCES Achanta, S. and M.R. Okos, 1996. Predicting the quality of dehydrated foods and biopolymersresearch needs and opportunities. Dry. Technol., 14: 1329-1368. Barrett, A.H., A.V. Cardello, A. Prakash, L. Mair, I.A. Taub and L.L. Lesher, 1997. Optimization of dehydrated egg quality by microwave assisted freeze-drying and hydrocolloid incorporation. J. Food Process. Pres., 21(3): 225-244. Beaudry, C., G.S.V. Raghavan, C. Ratti and T.J. Rennie, 2004. Effect of four drying methods on the quality of osmotically dehydrated cranberries. Dry. Technol., 22: 521-539. Bell, G.A. and J.D. Mellor, 1990a. Adsorption freezedrying. Food Aust., 42(5): 226-227. Bell, G. A. and J.D. Mellor, 1990b. Further developments in adsorption freeze-drying. Food Res. Quaterly, 50(2): 48-53. 200 Adv. J. Food Sci. Technol., 9(3): 197-201, 2015 Rosenberg, U. and W. Bogl, 1987. Microwave thawing, drying and baking in the food industry. Food Technol., 41(6): 85-91. Sablani, S.S. and M.S. Rahman, 2002. Pore formation in selected foods as a function of shelf temperature during freeze drying. Dry. Technol., 20: 1379-1391. Saguy, I.S., A. Marabi and R. Wallach, 2004. Water imbibition in dry porous foods. Proceeding of 9th International Conference on Engineering and Food Montpellier. France, pp: 147-152. Sansiribhan, S., S. Devahastin and S. Soponronnarit, 2012. Generalized microstructural change and structure-quality indicators of a food product undergoing different drying methods and conditions. J. Food Eng., 109(1): 148-154. Segura, L.A. and C.A. Oyarzún, 2012. Experimental evidence of mass transfer mechanisms during freeze-drying in a capillary porous medium. Int. J. Refrig., 35: 2102-2109. Shishegarha, F., J. Mackhlouf and C. Ratti, 2002. Freeze drying charcterestics of strawberries. Dry. Technol., 20: 131-145. Tulasidas, T.N., G.S.V. Raghavan and A.S. Mujumdar, 1995. Microwave drying of grapes in a single mode cavity at 2450 MHz-i. Drying kinetics. Dry. Technol. Int. J., 13: 1949-1971. Wang, J. and Y.S. Xi, 2005. Drying characteristics and drying quality of carrot using a two-stage microwave process. J. Food Eng., 68: 505-511. Wang, W. and G. Chen, 2009. Freeze-drying of initially frozen materials from aqueous solution. Proceeding of 4th Inter-American Drying Conference. Montreal, Canada, pp: 395-403. Wolff, E. and H. Gibert, 1990. Atmospheric freezedrying Part 2: Modelling drying kinetics using adsorption isotherms. Dry. Technol. Int. J., 8(2): 405-428. 201