Research Journal of Applied Sciences, Engineering and Technology 6(2): 297-303,... ISSN: 2040-7459; e-ISSN: 2040-7467

advertisement

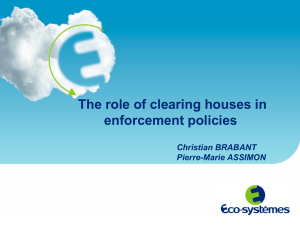

Research Journal of Applied Sciences, Engineering and Technology 6(2): 297-303, 2013 ISSN: 2040-7459; e-ISSN: 2040-7467 © Maxwell Scientific Organization, 2013 Submitted: September 22, 2012 Accepted: November 23, 2012 Published: June 10, 2013 Implementation Decision-making of WEEE Take-Back Directive Guojun Ji School of Management, Xiamen University, Xiamen, Fujian 361005, China Abstract: In this study, based on the objective of social welfare maximization, the issues of take-back network, recycling targets setting, recovery catalogs sorting, supervision and stimulation of take-back models are discussed. Conclusion demonstrates that: manufacturers, recyclers and consumers do not always share the same preference over three patterns, but the mode of manufacture-leading take-back can reach maximum social welfare; the most efficient network system should be around the manufacturer individual take-back responsibility to build; the takeback level and the recovery catalogs must synthesize the factors involve environmental impact of product, take-back cost/benefit and recycling and manufacturing industries' market structure etc., the supervision and stimulation decision matrix associated with the PROs is as an effective tool to balance the environmental benefits and social welfare. Keywords: Closed-loop supply chain, end-of-life waste, extended producer responsibility, take-back directive, twostage sequential decision-making game Organizations (PROs) perspective, Mayers (2007) based on a case of SONY Computer Entertainment in Europe, indicates that the PROs have the important role under the EU WEEE regulations; From the recycling firms, according to reverse logistics process of the waste computers, without any laws support, the firms’ benefit is less. Thus, the government should promote the circulation economic legislation as soon as possible and to promulgate; from the government's perspective, the environment subsidy policies shall have effect on the firms decision-making environment as well as motivate remanufacturers (Mitra and Webster, 2008). From the quantitive models: Savaskan et al. (2004) studies the manufacturer's decision-making to establish quantitative models of three reverse logistics operation (retailer take-back, third-party take-backand manufacturer take-back), then they found the basic properties of the three models optimization; Subramanian et al. (2009) analyzed a supply chain to know how coordination can lead to remanufactured products of better DfE under the WEEE regulations; Atasu et al. (2009b) presented the impact of product reuse design and “pick-up” patterns based on two PROs models, which found that individual take-back model has better stimulation than the collective take-back model; Toyasaki et al. (2008) based on the manufacturing and processing industries characteristics, presented the individual take-back model and the collective take-back model to the stakeholders reflect the different impacts and figured that the PROs are critical to the recovery system by using two-stage game models, but the manufacturers' disposal capacity is omitted. Atasu and Subramanian (2009a) based on the INTRODUCTION Increasing economic growth has been the principal cause of the waste increasing: economic growth reflects the increase of production, consumption and thus increases the waste. The environmental pressure based on waste generation presents: Firstly, the permanent loss of materials and energy increases day by day. Secondly, with the current landfill sites are filling up, it leads to pressure to use new sites with the loss of that land use for housing, leisure or agriculture. Thirdly, the additional waste left in these landfill sites increases air, water and land pollutions. In the early 1990s some European Union member states, notably the Netherlands, Germany and Sweden developed their own national policy to deal with their growing waste problems. This principle has been most clearly implemented in the WEEE Directive on Waste Electrical & Electronic Equipment. At present, China’s WEEE recycling disposals are undertook mainly by some informal sectors, which not only waste resources but also pollute the environment and even face the occupational safety. At the same time, without enough WEEE recycling, it will result in the official processing firms “await urgently necessary condition”, which they involve in the red state. Therefore, the government should develop and implement the feasible legislation to regulate the WEEE recycling industry. As for the consumer behavior, if the customer behaviors are willing to returns, it would help the home appliances recycling; as for the manufacturers, the home appliance firms recycling behaviors were systematically analyzed (Wang and Yin, 2008); From Producer Responsibility 297 Res. J. Appl. Sci. Eng. Technol., 6(2): 297-303, 2013 social welfare maximization objective to balance economic and environmental impacts, in order to ensure the fairness of implementation the WEEE regulations, but there is shortage of comparative analysis on the take-back and disposal models. Different with the above literatures, we will integrate various essential factors to bring into the WEEE regulations system, thus obtain the whole understanding of the PROs roles and the stakeholders. Considering the objective of social welfare maximization, the issues of take-back network, recycling targets setting, recovery catalogs sorting, supervision and stimulation of take-back models are discussed. Based on abovementioned, this study analyzes assumptions of models, then builds the takeback models and reveals the implementation decisionmaking of the WEEE regulations. concentrative take-back can be achieved. The organizations play a crucial role in successful implementation of EPR principle particularly, when small and medium-sized enterprises involving in the organizations, they can greatly reduce the difficulty and cost of WEEE recovery. And they play a good role with linkage of manufacturers, processors, retailers, governments and other interest groups (Mayers, 2007). They are also responsible for expropriation the specific take-back fund to manufacturers, build the recycling standardization system, develop the effective product DfE incentive regulation, enhance consumers' environmental education, etc. Consumers: consumers as the important stakeholders to the effective implementation of the WEEE regulations have direct effect. They not only care environmental protection, but fear manufacturers to increase product price because of adjustment WEEE take-back-related costs. Convenient for analysis, suppose that consumers reverse demand function meets P = 1-q, where, q total consumption of the product is. Then the consumer surplus reflects: ASSUMPTIONS OF MODELS Due to the above discussion, it is impossible for a qualified WEEE take-back company to operate successfully before enforcing the legislations and formulating favorable policies and regulations on WEEE. From the recycling pilot firms in China, the pilot effects reflect: • • Π C= 1 (1 − p )q 2 (1) Manufacturers: Their main responsibilities reflect: On the one hand, green production facilitates resources to synthetically utilize and design harmless processing programme, convenient for take-back materials must reach the minimum r; on the other hand, take-back WEEE by own or outsourcing must reach the minimum c. Manufacturers through two ways complete their WEEE management responsibilities (Toffel, 2003), i.e., individual take-back responsibility and collective takeback responsibility. Individual take-back responsibility refers to the manufacturers that have their own recycling network, is responsible only for take-back own manufactured products; the collective take-back responsibility is aim at all manufacturers product of one profession, manufacturers pay determinate take-back costs to PROs who take on the recycling responsibilities. Suppose that there are two identical manufacturers, both utilize the Cournot game to get their market share (Fig. 1), then 𝑃𝑃 = 1 − ∑2𝑖𝑖−1 𝑞𝑞𝑖𝑖 (i = 1, 2.), q i is the manufacturer M i sales products. Manufacturers are responsible for take-back the waste products manufactured by themselves and then decide to dispose those whether by themselves or by the qualified processing enterprises. Assume that manufacturers per unit cost of production is µ, t is the unit cost of takeback WEEE and 1-µ-tc>0. When the manufacturers dispose by themselves, they can obtain subsidies d of unit. A recycling industrial road is explored, which conforms to China's conditions, the extracted experience will help to institute China’s recycling industrial standards The management organizations similar to PROs are engendered The national WEEE take-back network systems can be established (Yang et al., 2008). Our decision sequence is as follows: firstly, the PROs determine recovery rate c, which means recovery rate after sale, reuse rate r denotes recycled products can reuse ratio (Tojo et al., 2001) and d denotes the subsidies of recovery and processing; Secondly, based on the cost of recovery and processing, manufacturers determine their products sales volume and price; Thirdly, each processing firm decides to charge a processing fee to manufacturers; and finally, the consumers purchase remanufactured products, where, 0≤c, r≤1, d≥0. The roles under the WEEE regulations reflect as follows: PROs are the nonprofit organizations, which dominated by the Government and constituted by the producers, industrial associations and the processing firms and so on, shall monitor the producers to bear the responsibilities and obligations of WEEE recovery. Usually, they are organized by product category, so the maximum efficiency of 298 Res. J. Appl. Sci. Eng. Technol., 6(2): 297-303, 2013 Fig. 1: Two-stage sequential decision-making game Outsourcing take-back model: In this model, suppose that the processing provider is as a Stackelberg leader, the manufacturers are followers. This is just as the current WEEE recovery demand in the Europe which far exceeds the existing recovery capacities, the recycling industry is still in the developing phase, at the same time the manufacturers must meet the minimum requirements of the WEEE directive. For example, in Germany there are about 20 recycling firms provide take-back service of old computers and old electrical product to more than 20,000 manufacturers and importers. Similarly, in Netherlands, non-profit organizations through four recovery firms to process the waste products of more than 1200 manufacturers and every recovery firm is only responsible for a specific product category (Future Energy Solutions, 2003). In fact, on the one hand, manufacturers face to compete in the new products market; on the other hand, processing firms set competitive recovery costs in the waste product market. • ( t + er −η ) c ( ∑ q ) i = q ( p − u − t c) = i 1, 2. Π CR (t C ) = The analysis of take-back models: At present, there are two major types of WEEE take-back models in China: one is the outsourcing take-back model, which can be divided into single take-back model and collective take-back model; another type is manufacturer internalization take-back model, i.e., recovery and processing by itself (Toffel, 2003). C i Π Ci (q= i) C i 1, 2. (2) To reverse deduce the two-stage game, considering the manufacturer Cournot game in the second stage, when given tc, manufacturer M 1 determines its output (𝑞𝑞𝑐𝑐𝐶𝐶 (𝑞𝑞2𝐶𝐶 ) from (2), then the specific response function meets: q1C (q2C ) = 1 − q2C − u − t C c 2 (3) Similarly, manufacturer M 2 response function can be deduced. Uniting two functions, Nash equilibrium solutions as follow: = qiC (t C ) 1− u − tCc = i 1, 2. 3 (4) Let (4) substitutes for (2) in the first stage, the processing provide R follows the oligopolistic games, then: tC = The collective recovery processing: From model C, based on wastes of all manufacturers in one profession, PROs usually according to the profession’s average processing cost to collect the manufacturers processing fund. The manufacturers M 1 , M 2 separately sign a contract with PROs and pay the processing cost tc, then, PROs assign the third party processing provider R to operate and pay the processing fund tc. For instance, Holland, Sweden often uses this model. 1 − u − cer + cη 2c (5) Let tc substitutes for (4), the equilibrium output and the market price of the product reflect as follows: qiC= 1 2 1 1 1 (1 − u + cer − cη ) i= 1, 2. p C = + u − cer + cη 6 3 3 3 3 (6) At the same time, we can obtain the manufacturer’s profit, processing provider’s profit, consumer’s surplus as well as the system profit, where the system profit ∏ S is defined as the sum of manufacturer’s profit, processing provider’s profit and consumer’s surplus (Table 1). Therefore, the profit function of the processing provider and the manufacturer are follows, respectively: 299 Res. J. Appl. Sci. Eng. Technol., 6(2): 297-303, 2013 Table 1: Optimal value of three take-back scheme Model C Processing fee t 1 − u − cer + cη 2 1 1 1 + u − cer + cη 3 3 3 3 Product sales q 1 (1 − u + cer − cη ) 3 1 2 (1 − u + cer − cη ) 18 1 (1 − u + cer − cη ) 2 6 1 (1 − u + cer − cη ) 2 18 5 (1 − u + cer − cη ) 2 18 Manufacturer’ profit ∏M Processing provider’s profit ∏R Consumer’ surplus Consumer’ surplus ∏C System’s profits ∏S • Model T 5 4 4 4 + u − cer + cη 9 9 9 9 4 (1 − u + cer − cη ) 9 8 (1 − u + cer − cη ) 2 81 4 (1 − u + cer − cη ) 2 27 8 (1 − u + cer − cη ) 2 81 28 (1 − u + cer − cη ) 2 81 1 2 2 2 2 + u − cer + cη − drc 3 3 3 3 3 2 (1 − u + cer − cη + drc) 3 2 (1 − u + cer − cη + drc) 2 9 1 − u − 2cer + 2cη 3c 2c Product price P Model I 2 (1 − u + cer − cη + drc) 2 9 4 (1 − u + cer − cη + drc) 2 9 Let (10) substitutes for (7) and (8), respectively, The single recovery processing: From model I, considering Cournot game, then the equilibrium each manufacturer freely signs a contract with solutions of processing expense satisfy: single processing provider, in which PROs are in the supervision role, such as Germany and Austria 1 − u − 2cer + 2cη tends to this model. Assume that manufacturer M 1 = tiI = i 1, 2. signs a recovery processing contract with 3c (11) processing provider R A and pays unit processing expense 𝑡𝑡1𝐼𝐼 to R A ; manufacturer M 2 signs a Thereby, the equilibrium output and price of the contract with processing provider R B and pays unit manufacturers are as follows: processing expense 𝑡𝑡1𝐼𝐼 to R B . Then, the profit functions of the processing providers reflect as 5 4 4 4 2 qiI= (1 − u + 2cer − cη ) i= 1, 2. p I = + u − cer + cη follows, respectively: 9 9 9 9 9 (12) ( ) Π IA (t1I ) = ( t1I + er − η ) cq1 Π IB (t2I ) = t2I + er − η cq2 (7) Therefore, in this mode, we can obtain the manufacturer’s profit, the processing provider’s profit, the consumer’s surplus as well as the system’s income (Table 1). (8) The individual take-back model: As shown, model T is a closed-loop supply chain, not only includes the forward flow of the manufacturer's product, but the reverse flow of waste product from consumers. This model is actually internalization and integration of recovery processing, which the manufacturer by oneself fulfill take-back responsibility or the WEEE regulations. For example, IBM and DELL have used the model (Toffel, 2003). The model can be performed by the third party providers as well as in virtue of retailers “trade new good for old” way etc. In this model, Government usually gives certain subsidies to manufacturers to encourage them take-back WEEE. Then, manufacturer's profit includes sales’ profit, profit from processing WEEE as well as subsidies, as follows: The manufacturers profit functions satisfy: Π iI (q= qi ( p − u − tiI c ) = i 1, 2. i) To reverse deduce a two-stage game, considering the manufacturer Cournot game in the second stage, when given the unit processing expense 𝑡𝑡1𝐼𝐼 , the manufacturer M 1 can determine its output 𝑞𝑞𝑐𝑐𝐶𝐶 (𝑞𝑞2𝐶𝐶 ), then the response function meets: q1I (q2I ) = 1 − q2I − u − t1I c 2 (9) Similarly, the manufacturer M 2 response function can be deduced. Uniting two functions, Nash equilibrium solutions follow, respectively: q1I (t1I , t2I ) = 1 − u + t2I c − 2t1I c I I I 1 − u + t1I c − 2t2I c ; q2 (t1 , t2 ) = (10) 3 3 T Π= qi ( p − u + erc − η c + drc) = i 1, 2. i 300 (13) Res. J. Appl. Sci. Eng. Technol., 6(2): 297-303, 2013 Thereby, the manufacturer through Cournot game, the Nash equilibrium of sales volume and prices satisfy: 1 (1 − u + cer − cη + drc) i= 1, 2. 3 1 2 2 2 2 pT = + u − cer + cη − drc 3 3 3 3 3 channels, encourage retailers via trade-in or deposit to recycle waste product etc. 𝜕𝜕𝑡𝑡 𝑐𝑐 𝜕𝜕𝑡𝑡 𝐼𝐼 𝜕𝜕𝑡𝑡 𝑐𝑐 𝜕𝜕𝑡𝑡 𝐼𝐼 Proposition 4: If < 0, < 0 𝑎𝑎𝑎𝑎𝑎𝑎 > , it 𝜕𝜕𝜕𝜕 𝜕𝜕𝜕𝜕 𝜕𝜕𝜕𝜕 𝜕𝜕𝜕𝜕 shows that in outsourcing take-back model, the manufacturers that improve the reuse rate can reduce the processing costs and the incentive of single recovery responsibility is more stronger than qiT = (14) At the same time, we can obtain the manufacturer's profit, consumer’s surplus and the system’s profit in the model (Table 1). By comparing optimum values of three models in Table 1, we have the following Propositions. the collective recovery responsibility; If 0 < 𝜕𝜕Π 𝐼𝐼𝑀𝑀 𝜕𝜕Π 𝑇𝑇 𝑀𝑀 2 𝜕𝜕Π 𝐶𝐶 𝑀𝑀 𝜕𝜕𝜕𝜕 < < = 𝑞𝑞𝑇𝑇 𝑐𝑐(𝑑𝑑 + 𝑒𝑒) it indicates that T model 𝜕𝜕𝜕𝜕 3 can better motivate manufacturers to improve reuse rate, In particular, when government gives subsidies. 𝜕𝜕𝜕𝜕 Proposition 1: If t C >𝑡𝑡1𝐼𝐼 , it means that the average processing costs of the collective recovery model is always greater than the single recovery model; If ∏𝐶𝐶𝑅𝑅 > ∏𝐼𝐼𝑅𝑅 = ∏𝐼𝐼𝐴𝐴 + ∏𝐼𝐼𝐵𝐵 , it indicates that processing providers prefer the collective recovery model. It is easy to see due to the lack of competition and motility of reducing cost, none but those monopoly processing providers have a better scale economy, they will collect a quite low expenses, i.e., only in the perfect recycling market, the recovery processing costs will be reduced. The EU experience of take-back packaging has demonstrated when introducing the competition mechanism to the recovery processing industry, the processing cost will be reduced obviously (Savage et al., 2006). Proposition 5: If ∏𝐶𝐶𝑆𝑆 > ∏𝐼𝐼𝑆𝑆 > ∏𝑇𝑇𝑆𝑆 , from the profit maximization of the recycling system, it shows that optimal model is T, next is model I, the worst is model C. It is easy to see from Proposition1, 2, 3, to consumers, treatment enterprises, manufacturers and other stakeholders, the preferences of take-back models are inconsistent, so coordinating the incentive of all stakeholders is almost impossible. However, whether they incent to take-back waste products (Proposition 3) or incent to product design (Proposition 4), our conclusion shows that T model is optima land according to the results of Proposition 5, PROs should first select T model, which manufacturers select individual take-back model, followed by mode I, the worst is model C. In fact, by using model T, the manufacturers can reach integration, internalization of recovery processing by themselves, reduce middle circulation channels, low transaction costs, improve the forward and reverse circulation efficiency, so increase the overall social welfare. Proposition 2: If pC>pI>pT, ∏𝑇𝑇𝐶𝐶 > ∏𝐼𝐼𝐶𝐶 > ∏𝐶𝐶𝐶𝐶, it indicates that the consumers prefer the manufacturers themselves to take-back model. In General, manufacturers’ processing funds charged can be compensated by three ways: part price transfers to the consumers, profit from the recovery processing as well as the government subsidies. In T model, Proposition 2 has shown that the processing funds have less impact on the equilibrium price and the recovery processing cost-sharing to consumers is also less. Treatment providers: under outsourcing take-back mode, there are two kinds of market structures in the recycling industry: the individual take-back model reflects Cournot competition and the collective takeback model reflects monopolistic competition. Under the latter kind of situation, the recovery processing providers, through the game to determine the processing expenses, where the recovery processing cost η (Xie and Chen, 2003) includes the disassembling costs of waste product, the remanufacturing costs, landfill and collecting costs, etc. We do not consider the economies of scale of recovery processing. Suppose that recovery processing providers may obtain the income e from reusable product. In outsourcing take-back model, the recovery processing providers can receive the unit processing profit is t from the manufactures. To guarantee the Proposition 3: If ∏𝑇𝑇𝐼𝐼 > ∏𝐼𝐼𝑖𝑖 > ∏𝐶𝐶𝐼𝐼 , it indicates that the single recovery model is optimal for manufacturers; If min( ∏𝑇𝑇𝑀𝑀 , ∏𝐼𝐼𝑀𝑀 + ∏𝐼𝐼𝑅𝑅) ≥ (∏𝐶𝐶𝑀𝑀 + ∏𝐶𝐶𝑅𝑅), it means that from the take-back incentive effect of the manufacturers, the single recovery model is better than the collective recovery model. In reality, Proposition 3 will reflect the recovery processing should pay more attention to the manufacturer participated fashion and their role, i.e., should encourage manufacturers to participate in takeback; take full advantage of the manufacturers 301 Res. J. Appl. Sci. Eng. Technol., 6(2): 297-303, 2013 Since reuse rate r is close related with the production technology, we suppose that r is exogenous variables and r = 1, i.e., full reuse. Let ρ = η-er, we have the following Proposition 6: recovery processing providers profitable, so t+er-η≥0. Let ρ = η-er denotes the net cost of recovery processing, generally, ρ≥0, the reason may reflect in the recovery processing’s costs and benefits of pilot projects. Suppose further that: • • Proposition 6: If 𝜌𝜌 ≥ The processing provider and recovery provider are regarded as one, i.e., the processing provider’s work includes take-back and processing of WEEE. Social surplus (welfare) meets linear additive condition, i.e., the social welfare (SW) equals to manufacturer’s profit recovery processing, providers’ profit + consumer’s surplus + environmental protectional benefits-Government expenditures. 1, d = 𝑐𝑐 = T • • (15) i In this way, the social welfare function reflects: • max SW (c, d ) = ΠTM + ΠTC + ΠTE − drc∑ qiT s.t. 0 ≤ c ≤ 1 and when 2 4𝜌𝜌−4𝑢𝑢𝑢𝑢 −3𝜀𝜀+3𝜀𝜀𝜀𝜀 −3𝜀𝜀𝜀𝜀 2𝜌𝜌(2𝜌𝜌−3𝜀𝜀) , when ε≥ρ, then we have c = 4 (1−𝑢𝑢)𝜌𝜌 3 (1−𝑢𝑢+𝜌𝜌) ≤ 𝜀𝜀 < 𝜌𝜌, we have , 𝑑𝑑 = 0; If 𝜌𝜌 < 1−𝑢𝑢 3 , when ε≥ρ, Proposition 6 shows that the take-back level and the take-back product catalog require comprehensive environmental consideration, such as the costs or benefits of take-back, the market competitive structure of processing industries and manufacturing industries etc. The subsidies bear fruit only if the product is serious harmful to our environment and can be effective recycled. Subsidies can compensate part of the takeback costs, but also increase the output as well as the emission of pollutants. Therefore, the PROs (government) need from two dimensions of the net processing costs and environmental pollution degree to weigh the environmental benefit and social profit. Environmental benefits (costs): Only when the firms explicitly bring environmental protection costs into their product design and production, then they are considered as environmentally friendly design. Usually, per unit product contains hazardous substances to harm our environment. The environmental impact or processing cost of the substances is defined as the environmental protection cost ε and assuming that the cost can be monetized (Atasu et al., 2009b). Where there is harmful to the environment, it will not involve the recycled part 1-c and port (1-r)c after recovery processing, so the environmental protection benefit is as follows: (∑ q ) 3 we have c = 1, d = 1-u-ρ/2 and when ε<ρ, we have c = 0, d = 0. The implementation decision-making of the WEEE regulations: Considering PROs have selected the optimal take-back model T by using the recovery rate c, reuse rate r and subsidies d, we can restrict or incent the recycling behavior of manufacturers to achieve social welfare SW maximization and balance economic and environmental impacts (Jacobs and Subramanian, 2009). The social welfare implicated by those factors should include the following items: Subsidy expenditure: to encourage manufacturers to take-back WEEE, PROs pay the manufacturers unit subsidies d, then the total subsidies are drc∑𝑞𝑞𝑖𝑖𝑇𝑇 . Π E =−ε (1 − rc ) 1−𝑢𝑢−𝜌𝜌 1−𝑢𝑢 (16) d ≥0 302 Voluntary take-back: Usually, that means products are less environmental pollution and takeback costs are relatively small, through selfdiscipline of manufacturers and the consumer's environmental drive to set recycling goals. And without no legal requirement to comply or unmeet recycling targets, firms will not be punished. For instance, carpet take-back in US Savage et al. (2006) Incomplete take-back: That means the product has the slight environmental pollution, but the takeback costs are higher. Government does not give subsidies, so use the incomplete take-back targets to protect the manufacturers or consumers benefits, such as the WEEE in home appliances. The products because of high processing costs, economies of scale has certain requirements, so manufacturers may be outsourced the take-back activities to the professional service provider, especially to small and medium manufacturers, i.e., T model will transforms to I model. Complete take-back: That means the product has heavy environmental pollution, no matter how high processing cost, it is mandatory take-back by the government regulation and government gives some subsidies to the processing firm. For example, waste oil, waste paint etc. Res. J. Appl. Sci. Eng. Technol., 6(2): 297-303, 2013 Jacobs, B. and R. Subramanian, 2009. The Impacts of Sharing Responsibility for Product Recovery Across the Supply Chain. Working Paper, Georgia Institute of Technology. Mayers, C.K., 2007. Strategic, financial and design implications of extended producer responsibility in Europe: A producer case study. J. Ind. Ecol., 11(3): 113-131. Mitra, S. and S. Webster, 2008. Competition in remanufacturing and the effects of government subsidies. Int. J. Prod. Econ., 111(2): 287-298. Savage, M., S. Ogilvie and J. Slezak, 2006. Implementation of the waste electric and electronic equipment directive in EU 25. Institute for Prospective Technological Studies (IPTS), European Commission Joint Research Centre, Technical Report Series EUR 22231 EN, ISBN: 92-79-01926-0. Savaskan, R.C., S. Bhattacharya and L.N. Van Wassenhove, 2004. Closed-loop supply chain models with product remanufacturing. Manag. Sci., 50(2): 239-252. Subramanian, R., S. Gupta and B. Talbot, 2009. Product design and supply chain coordination under extended producer responsibility. Prod. Oper. Manag., 18(3): 259-277. Toffel, M.W., 2003. The growing strategic importance of end-of-life product management. California Manag. Rev., 45(3): 102-129. Tojo, N., T. Lindhqvist and G.A. Davis, 2001. EPR programme implementation: Institutional and structural factors. Proceedings of OECD Seminar on Extended Producer Responsibility: EPR Programme Implementation and Assessment. Paris, pp: 226-275. Toyasaki, F., T. Boyaci and V. Verter, 2008. An Analysis of Monopolistic and Competitive Takeback Schemes for WEEE Recycling. Working Paper, McGill University. Wang, Z.H. and J. Yin, 2008. An analysis of the influences and characteristics of the behavior of electric waste reclaiming in China’s household appliances industry. Manag. World, 4: 175-176. Xie, J. and R. Chen, 2003. The cost-benefit analysis model of recovery processing in reverse logistics of assembly product. China Bus. Market, 1: 25-28. Yang, J.X., B. Lu and C. Xu, 2008. WEEE flow and mitigating measures in China. Waste Manag., 28: 1589-1597. CONCLUSION The elements and process of current WEEE Takeback Directive are analyzed in the current regulations. And by using a two-stage sequential decision-making game model, the economic behavior of the main stakeholders fewer than three different types of takeback models are presented in this study. Our conclusion demonstrates that: The preferences of three take-back modes for manufacturers, treatment enterprises, consumers and other stakeholders are inconsistent, but from the view of take-back incentive, product design incentives, the system profits, we find that manufacturers’ individual take-back model is optimal. Therefore, the most efficient recycling network system should focus on the manufacturers’ individual recovery responsibility, make full use of their channel advantage, encourage retailers by trade-in or deposit to recycle the waste products, etc.; To determine the take-back level and recovery product catalog, it is necessary to consider the impact on the environment, take-back costs/benefits, the market competitive structure of processing industries and manufacturing industries as well as consumers acceptance of environmental costs, etc.; The government must weigh the environmental protection benefits and social benefits. Effective subsidies only utilize in the product has great harmful to environment and fully take-back. When product has slight pollution, according to the size of the net processing cost, incomplete take-back or the voluntary take-back is considered, respectively. ACKNOWLEDGMENT This study is supported by the National Natural Science Foundation of China (NSFC) (Project nos. 70971111; 71201138) and the Young Foundation of Ministry of Education of China in 2012 project (Project nos.12YJC630264) and the Fujian Provincial Natural Science Foundation Project (2012J01304). REFERENCES Atasu, A. and R. Subramanian, 2009a. Competition under product take-back laws: Individual or collective systems? Working Paper, Georgia Institute of Technology. Atasu, A., L.N. Van Wassenhove and M. Sarvary, 2009b. Efficient take-back legislation. Prod. Oper. Manag., 18(3): 243-258. Future Energy Solutions, 2003. Study into European WEEE schemes. Study into European WEEE Schemes. Report to U.K. Department of Trade and Industry (November). Retrieved from: http:// 164.36.164.20/sustaina bility/weee/aeatreport.pdf. 303