Research Journal of Applied Sciences, Engineering and Technology 1(3): 149-153,... ISSN: 2040-7467 © M axwell Scientific Organization, 2009

advertisement

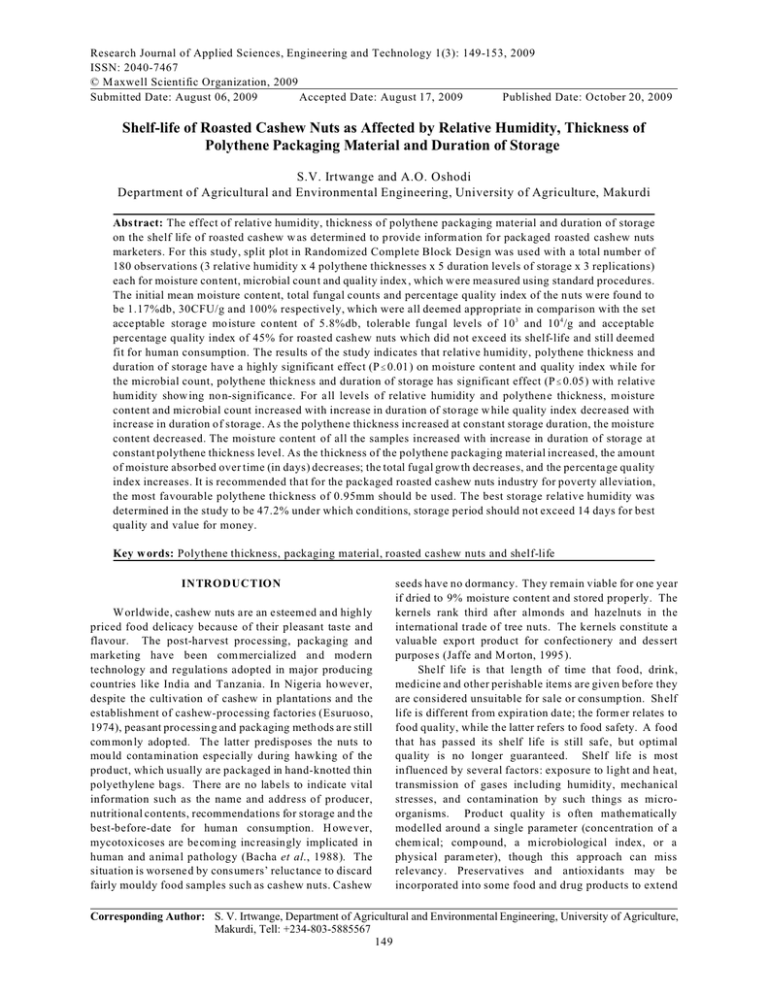

Research Journal of Applied Sciences, Engineering and Technology 1(3): 149-153, 2009 ISSN: 2040-7467 © M axwell Scientific Organization, 2009 Submitted Date: August 06, 2009 Accepted Date: August 17, 2009 Published Date: October 20, 2009 Shelf-life of Roasted Cashew Nuts as Affected by Relative Humidity, Thickness of Polythene Packaging Material and Duration of Storage S.V. Irtwange and A.O. Oshodi Department of Agricultural and Environmental Engineering, University of Agriculture, Makurdi Abstract: The effect of relative humidity, thickness of polythene packaging material and duration of storage on the shelf life of roasted cashew w as determined to provide inform ation for pack aged roasted cashew nuts marketers. For this study, split plot in Randomized Complete Block Design was used with a total number of 180 observations (3 relative humidity x 4 polythene thicknesses x 5 duration levels of storage x 3 replications) each for moisture con tent, microbial coun t and quality index , which w ere measured using standard procedures. The initial mean m oisture content, total fungal counts and percentage quality index of the nuts w ere fou nd to be 1.17%db, 30CFU/g and 100% respectively, which were all deemed appropriate in comparison with the set acceptable storage mo isture co ntent of 5.8%db, tolerable fungal levels of 10 3 and 10 4 /g and acceptable percentage quality index of 45% for roasted cashew nuts which did not exceed its shelf-life and still deemed fit for human consumption. The results of the study indicates that relative humidity, polythene thickness and duration of storage have a highly significant effect (P#0.01) on m oisture content and quality index while for the microbial count, polythene thickness and duration of storage has significant effect (P#0.05) with relative hum idity show ing no n-sign ificance. For all levels of relative humidity an d polythen e thickness, m oisture content and microbial count increased with increase in duration of sto rage w hile quality index decreased with increase in duration of storage. As the polythene thickness increased at con stant storage duration, the moisture content decreased. The moisture content of all the samples increased with increase in duration of storage at constant polythene thickness level. As the thickness of the polythene packaging material increased, the amount of moisture absorbed over time (in days) decreases; the total fugal grow th decreases, and the percentage qu ality index increases. It is recommended that for the packaged roasted cashew nuts industry for poverty alleviation, the most favourable polythene thickness of 0.95mm should be used. The best storage relative humidity was determined in the study to be 47.2% under which conditions, storage period should not exceed 14 days for best quality and value for money. Key w ords: Polythene thickness, packaging material, roasted cashew nuts and shelf-life INTRODUCTION W orldwide, cashew nuts are an esteem ed an d high ly priced food delicacy because of their pleasant taste and flavour. The post-harvest processing, packaging and marketing have been com mercialized an d mod ern technology and regulations adopted in major producing countries like India and Tanzania. In Nigeria ho wev er, despite the cultivation of cashew in plantations and the establishment of cashew-processing factories (Esuruoso, 1974), peasant pro cessin g and pack aging methods are still com mon ly adop ted. Th e latter predisposes the nuts to mou ld contamination especially during hawking of the product, which usually are packaged in hand-knotted thin polyethylene bags. There are no labels to indicate vital information such as the name and address of producer, nutritional contents, recommendations for storage and the best-before-date for human consumption. H owe ver, mycotoxicoses are becom ing increasingly implicated in human and anima l pathology (Bacha et al., 1988). The situation is worsened by consume rs’ reluctance to discard fairly mouldy food samples such as cashew nuts. Cashew seeds have no dormancy. They remain viable for one year if dried to 9% moisture content and stored properly. The kernels rank third after almonds and hazelnuts in the international trade of tree nuts. The kernels constitute a valua ble expo rt produ ct for confectionery and dessert purpose s (Jaffe and M orton, 1995 ). Shelf life is that length of time that food, drink, medicine and other perishable items are given before they are considered unsuitable for sale or consump tion. Shelf life is different from expiration date; the form er relates to food quality, while the latter refers to food safety. A food that has passed its shelf life is still safe, but optimal quality is no longer guaranteed. Shelf life is most influenced by several factors: exposure to light and h eat, transmission of gases including humidity, mechanical stresses, and contamination by such things as microorganisms. Product quality is often mathematically modelled around a single parameter (concentration of a chem ical; comp ound, a m icrobiological index, or a physical param eter), though this approach can miss relevancy. Preservatives and antioxidants may be incorporated into some food and drug products to extend Corresponding Author: S. V. Irtwange, Department of Agricultural and Environmental Engineering, University of Agriculture, Makurdi, Tell: +234-803-5885567 149 Res. J. Appl. Sci. Eng. Technol., 1(3): 149-153, 2009 their shelf life. Some companies use induction sealing and vacuum pouches to assist in the extension of the shelf life of their products. The principal factors that affect shelf life are the nature of the food and the mechanisms by which it undergoes deterioration; the size of package in relation to volume; the atmosph eric condition which the package is required to withstand during transit and before use and the overa ll resistance of the package of moisture, atmosphe ric gases and odours, including the closures and folded areas (Dwe m, 1997). The shelf life of processed food is determ ined by the type of food, the degree of microbial destruction or inactivation achieved by the process, control of hygiene during processing and packaging, the barrier properties of the packaging materials and the temperature during distribution and packag e (Ade bajo and Diyaolu, 2003). Roasted cashew nut can be consumed either directly, or used as a raw material. In whichever form, the excess has to be preserved for future us e. The greater value of this product is lost to spoilage after a period of time due to improper handling an d storage conditions and this result in great loss of product and investment. Roasted cashew nut is vulnerable to deterioration over time and this result from improper packaging to adverse storage conditions. The rate of this spoilag e is dependent on moisture content of stored nuts; relative humidity of storage enviro nme nt; perm eability of packaging m aterial; ambient temperature and insect infestation. Based on these effects, roasted cashew nuts deteriorate by m ould growth, rancidity and insec t attack (Ayiko ye, 2004 ). Since the society and most importantly investors suffer great losses as a result of the deterioration of polythene-packaged cashew nuts, it becomes imperative to study and analyze the effect of the thickness of the polythene used as the packaging material on the spoilage rate under enviro nme ntal condition with a view to making recom men dations base d on the resu lt of the ex perim ent. material. Each of the samples were suspended in the airspace containers co ntaining solution of dilute tetraoxosulphate VI acid (sulphuric acid) of different levels of dilution thus creating three relative hu midity environm ents of 47.2% , 70.4% and 8 8.8% in accordance with W east and Astle (1989). After insertion of the samples and the solutions, the containers were closed and exposed to ambient temperature. The set up was monitored daily for four weeks (28 days). On the first day, i.e. day zero (0), the moisture content, microbial count and o rganoleptic tests were carried out. These tests were repeated on day 7, day 14, day 21, and day 28. Three replications were performed for each set up for the samples. Moisture content: The Gallen K amp vacu um o ven-air method was used for moisture content test. About 10g of sample was crushed in a mortar and about 5g bits was measured into a crucible whose weight had been zeroed. The crucible with the samples was then put into the oven and dried at 103ºC for 4.5 hours. The weight of the sample was taken again after they were cooled in the desiccators. The percentage moisture content on dry ba sis was calculated using % moisture content (dry basis) = (chan ge in w eight/w eight of dry m atter) x 100. Microbial count: The pour plate techniqu e was use d to obtain the microbial count. Nine (9) ml of distilled water was measured using a pipette into each of the sterile testtubes and w ere sterilized in an autoclave at 121ºC for 15 minutes after which they were brought out and coo led to about body temperature. The roasted cashew nuts were cut into small pieces with a sterile scalpel and 1g was mixed with 9 ml of distilled water and then properly shaken. The serial dilution was carried out to 10 G4 dilution i.e. 1ml of the solution was drawn out using a pipette and was introduced into a second test-tube containing 9ml of distilled water and this was done serially until the last tube was reached. A fresh pipette was used at each stage. The potato dextrose agar was melted and cooled . Sterile petri dishes were set out for each dilution and they w ere labelled with the dilution number. 1ml of each dilution was pipetted into the centre of the appropriate dishes, using a fresh pipette for each dilution. Potato dextrose agar was pou red into each of the plates, enough to cover the 1ml solution in them. The medium was allowed to solidify, then inverted and incubated at 37ºC for 24 hours. The numbers of colonies were counted with the use of a colon y cou nter. MATERIALS AND METHODS M aterials: The roasted cashew nuts used for this study were procured in Obollo-Afor in Enugu State, Nigeria. Packaging films (polythene) of three different thicknesses: 0.91mm, 0.93mm and 0.95mm and m osqu ito net. Plastic air-tight containers were used as storage containers. Equipment and machines used include GallenKamp vacuum oven, desiccators, autoclave, incubator, weighing scale, sealing machine, test tubes, petri dishes, pipettes, mortar and pestle, crucibles (moisture test cans). Chemicals and reagen ts include diluted tetraoxosulphate VI acid (sulphuric acid), distilled water, potato dextrose agar. The cashew nuts were roasted in open pans (FAO, 2000). Twenty five gramm es (25g) of roa sted sample seeds were tied in polythene bags of three different thicknesses (0.91mm, 0.93mm, and 0.95mm) and a control set using mosquito net, all purchased from Modern Market, M akurdi, Benue State as its packaging Quality index: Three students of the University o Agriculture, Makurdi were trained to chew and report on the overall acceptability in terms of taste, crispiness and visible mould incidence of the samples in percentages. Each person’s decision was independent of the other. The cashew nuts were tasted on days 0, 7, 14, 21, and 28. The nuts were reported as being very goo d (80% and abo ve), good (60-79% ), fairly good (45-59%), fairly bad (40- 150 Res. J. Appl. Sci. Eng. Technol., 1(3): 149-153, 2009 44% ), bad (30-39% ) and v ery ba d (belo w 30% ) to indicate the degree of quality. 80.5%RH while comparisons between 47.2 and 80.5%RH were all statistically different. In the case of the microbial count, 81.25, 37.5 and 50% non significance was observed between 47.2 and 70.4, 47.2 and 80.5, and 70.4 and 80.5%RH respectively whereas for quality index, 50, 0 and 6.25% non-significance was sim ilarly observed. In general, the greater the non significance percentage difference, the closer the similarities between the levels of measured parameters being compared. Experimental Design: The experimental design for the study is split plot in Randomized Complete Block Design (RCBD) made up of three levels of packaging films (polythene) of three different thicknesses: 0.91mm, 0.93mm and 0.95mm and mosquito net; three levels of relative hum idity environmen ts: 47.2% , 70.4% and 88.8% and five levels of days of storage (0, 7, 14, 21 and 28 days). The an alysis of variance (ANO VA ) and Fishers Least Significant D ifference (F-LSD ) were carried out using Genstat statistical package. Effect of Polythene Thickness: The results show that as the polythene thickness increased at constant storage day, the moisture content decreased (Table 1). For example, at storage day 14, the moisture content decreased from 4.54 to 2.11%db for 47.2%RH, 5.63 to 2.78%db for 70.4% RH and from 6 .84 to 3.39% db for 80.5% RH . Similarly microbial coun t decreased from 1 100 to 120, 2700 to 200 and 12400 to 500 CFU/g for 47.2, 70.4 and 80.5% RH respectively whereas quality index increased from 63 to 80.5, 60 to 76.25 and 50 to 71% at same % RH values. The analysis of variance (Table 2) show s highly significant (P#0.01) polythene thickness effect on moisture content and quality index while microbial count is considered significant (P#0.05). A 2-tailed F-LSD test at 5% level of significance shows that in the case of 47.2% RH, the 10 mean moisture content comparisons were found to be statistically different for control but 10, 20 and 30% non-significance for 0.91, 0.93 and 0.95mm respectively. Again 10% non-significance was observed for 0.91, 0.93 and 0.95mm at 70.4%RH and 0.91 and 0.95mm at 80.5% RH while all other com parisons w ere statistically different. In the case of microbial count, all 10 comparisons at 47.2%RH were non-significant while 40, 60, 60 an d 100% non-significance was observed at 70.4%RH for control, 0.91, 0.93 and 0.95mm respectively. Similarly, 10% non-significance for control and 40% for 0.91, 0.93 and 0.95mm at 80.5%RH w as observed. For quality index, 10 and 30% non-significance was observed for control and 0.91mm while 20% was observed for 0.93 and 0.95mm at 47.2% RH . The quality index was also 10% non-significant for control and 20% for 0.91, 0.93 and 0.95mm at 70.4%RH while 10, 20, 30 and 20% non-significance was recorded at 80.5%RH for control, 0.91, 0.93 and 0.95mm respectively. RESULTS AND DISCUSSION Table 1 show s the results of the mean m oisture content, total fungal counts and the percentage qu ality index as affected by relative humidity, polythene thickness and day s of storage. The various F-LSD s are indicated for the purpose of mean comparisons while the Analysis of Variance (ANOVA) is show n in Table 2. The ANOVA table shows highly significant relative humidity, polythene thickness an d days o f storage effect (P#0.01) for moisture content and quality index while for the microbial count, there was significant effect (P#0.05) for polythene thickness an d days of stora ge w ith relative hum idity showing non-significance. For all the shelf-life param eters m easured, interaction was non -significa nt. Effect of Relative Hum idity: For all the relative hum idity and at all polythene thickness levels, moisture content and m icrobial coun t increased w ith increase in days of storage w hile quality inde x dec reased with increase in days of stora ge (Table 1). For example, for relative humidity of 47.2% and polythene thickness of 0.91mm, moisture content increased from 1.17 %db on day 0 to 9.61 %db on day 28, microbial count increased from 30 to 2100 CFU/g while quality index decreased from 100 to 61.67%. Also for all the relative humidity and at all days of storage levels, moisture content and microbial count decreased with increase in polythene thickness wh ile qua lity index increased w ith increa se in polythene thickness. C onsidering 47.2% relative hum idity and storage day 14, moisture content decreased from 4.54 for the control to 2.1 1% db at polythene thickness of 0.95mm, microbial count decreased from 1100 to 120 CFU/g while quality index increased from 63 to 80.25%. The analysis off variance (Table 2) shows highly significant (P#0.01) relative hum idity (RH) effect on moisture content and q uality index while microbial count is non-significant. In terms of moisture content, a 2-tailed F-LSD test at 5% level of significance between 7-28 days of storage and four levels of polythene thicknesses representing 16 mean comparisons shows that between 47.2 and 7 0.4 %RH, 31.25% of the mean comparisons were non-significant. Similarly, 43.75% non-significance was observed in the mean comparisons between 70.4 and Effect of Duration of Storage: The results show that the moisture content of all the samples increa sed w ith increase in duration of sto rage at constant polythene thickness level (Table 1). For storage days range of 0 to 28 at constant polythene thickness of 0.95mm, moisture content at 47.2% RH increased from 1.17 to 8.65, 70.4% RH from 1 .17 to 9.70 an d for 80 .5%RH from 1.17 to 10.75%db. Similarly, microbial count increased from 30 to 1060, 30 to 3130 and 30 to 14600 CFU/g for 47.2, 70.4 and 80.5%RH respectively whereas quality index decreased from 1 00 to 6 9.34, 100 to 67.17 and 1 00 to 63.16% at same % RH values. 151 Res. J. Appl. Sci. Eng. Technol., 1(3): 149-153, 2009 Tab le 1: Mean values for moisture content, microbial count and quality index as affected by relative humidity, polythene thickness and duration of storage* Re lativ e H um idity , % Polythene Thickness, mm Duration of S torage (Days) ------------------------------------------------------------------------------------0 7 14 21 28 Moisture Content (%db) 47 .2 Control 1.17 2.77 4.54 9.25 14.76 0.91 1.17 2.56 3.01 6.00 9.61 0.93 1.17 2.24 2.87 5.60 9.42 0.95 1.17 1.97 2.11 5.50 8.65 70 .4 Control 1.17 3.41 5.63 9.63 15.97 0.91 1.17 3.00 3.08 7.18 10.95 0.93 1.17 2.67 3.07 6.30 10.86 0.95 1.17 2.65 2.78 6.18 9.70 80 .5 Control 1.17 4.15 6.84 9.89 17.02 0.91 1.17 3.41 3.81 7.19 11.75 0.93 1.17 3.16 3.78 6.80 11.00 0.95 1.17 3.13 3.39 6.74 10.75 Microbial count (CFU/g) 47 .2 Control 30 700 1100 2800 3660 0.91 30 400 520 1800 2100 0.93 30 300 487 1100 1580 0.95 30 120 120 1000 1060 70 .4 Control 30 850 2700 8500 21950 0.91 30 500 800 1900 15790 0.93 30 425 500 1530 12350 0.95 30 180 200 1200 3130 80 .5 Control 30 950 12400 22600 31860 0.91 30 580 9700 15400 16400 0.93 30 500 2500 14800 15100 0.95 30 310 500 10700 14600 Q ua lity In de x (% ) 47 .2 Co ntro l100 67.67 63.00 56.00 48.00 0.91 100 75.50 71.00 65.34 61.67 0.93 100 79.00 74.25 68.00 65.33 0.95 100 82.00 80.25 70.33 69.34 70 .4 Control 100 63.00 60.00 52.00 40.00 0.91 100 73.00 67.34 65.00 56.67 0.93 100 76.50 70.50 66.67 61.66 0.95 100 80.00 76.25 68.00 67.17 80 .5 Control 100 57.00 50.00 35.00 32.00 0.91 100 68.00 63.45 59.50 52.17 0.93 100 70.00 66.25 62.50 60.00 0.95 100 74.00 71.00 64.67 63.16 *Values are means of three replications Fishers Least Significant Difference (F-LS D) Moisture Content (% db) F-LSD (P=0.05) of the d ifference between tw o relative humidity means = 0.547; F-LSD (P=0.05) of the difference between two polythene thickness means = 0.843; F-LSD (P=0.05) of the difference between two duration of s to r ag e m eans = 1.346 To tal fung al cou nt (C FU /g) F-LSD (P=0.05) of the difference between two relative humidity means = 6355.3; F - L SD (P=0.05) of the difference between two polythene thickness means = 2192.9; F-LSD (P=0.05) of the difference between two duration of storage means = 6853.0 Qu ality Ind ex (% ) F-L SD (P= 0.05 ) of th e diff eren ce b etw een two relativ e humidity means = 3.179; F-LSD (P=0.05) of the difference between two polythene thickness means = 3.451; F-LSD (P=0.05) of the difference between two duration of storage means = 5.848 Table 2: Summary of AN OV A for moisture content, microbial count and quality index Source of Variation Degree of Freedom Moisture Content (%db) Microbial Count (CFU/g) Duration of Storage 4 371.36** 3.80* Relative Humidity 2 10.74** 3.81 N S Error (a) 8 Polythene T hickness 3 17.42** 8.21* Interaction 6 0.03 N S 1.46 N S Error (b) 36 **Highly significant difference (1%), * Significant difference (5%), NS Non significant The analysis of varian ce (Table 2) show s highly significant (P#0.01) duration of storage effect on moisture content and quality index while microbial count is considered significant (P#0.05). A 2-tailed F-LSD test at 5% level of significance from 0-28 days of storage shows that for the 6 mean moisture content comparisons, all comparisons were different on day 7 while 33.33, 50 and 33.33% non-significant differences were observed on days 14, 21 and 2 8 respectively at 47.2%RH. How ever, at 70.4%RH, 100, 50, 16.67, 16.67 and for 80.5%RH , 66.67, 50, 50, 33.33% mean comp arisons w ere found to be non- Q ua lity In de x (% ) 5% 183.41** 2.78 14.79** 5.14 1% 4.22 10.19 34.06** 0.62 N S 9.78 3.36 4.76 2.36 significant on days 7, 14, 21 and 28 respectively. In the case of the microbial count, all the comparisons at 47.2%RH were statistically different excep t on day 28 between control and 0.95mm where non-significance was observed. In the case of 70.4%RH , 100, 66.67, 50, 100 and for 80.5%RH , 100, 16.67, 16.67, 50% nonsignificance was recorded for control, 0.91, 0.93 and 0.95mm respectively. For quality index, 16.67% nonsignificance was observed on days 7, 14 and 28 at 47.2%RH with 33.33% on day 21. At 70.4%RH, the index was 16.67% and 50% non-significant on days 14 152 Res. J. Appl. Sci. Eng. Technol., 1(3): 149-153, 2009 and 21 respectively while on days 7 and 28, all the differences were statistically different. In the case of 80.5%RH, quality index indicated 16.67% nonsignificance difference on days 7, 14 and 28 while on day 21, 66.67% non-significant difference was observed. C Practical Industry Applications: From the resu lts obtained from the moisture content on each test day and at all %RH values, taking 5.8%db as the moisture content threshold value which is considered as the maximum permissible percentage amount of moisture for safe storage of roasted cashew nuts ( Henderson, 1985; Pixton, 1986), the shelf life of the nuts was deduced to be less than 21 days irrespective of the storage %RH and thickness of the polythene packaging material excluding that packaged in mosquito net (contro l) which had a shelf life of less than 21 day s at storage % RH of 47.2 and less than14 days at storage %RH s of 70.4 and 80.5. W ith reference to quality, irrespective of the polythene thickness excluding the control, the stored roasted cashew nuts still remained edible after 28 days as the percentage quality index did not drop below 45% which was set as the lowest acceptable percentage quality index. In accordance to ICMSF(1986), the maximum set fungal tolerance acceptable for packaged nuts fit for human consumption is 104 /g. Based o n the results, the shelf-life of the nuts stored in polythene thicknesses of 0.91, 0.93 and 0.95mm was 14 days as the results beyond day 14 exceeded the tolerable fungal count. Conversely the nuts stored under the control had a shelf-life of 7 days. The nuts stored in 0.95mm , which is the thickest polythene, absorbed the least amount of moisture; had the smallest total fugal count, and the highest percentage quality index at all %RH and day of storage levels in comparison with the values obtained from the other less thicker polythene. This is followed by nuts stored in 0.93mm, 0.91mm and control in that order. The results further show that the rate of deterioration of the nuts increased with higher storage RH. Considering the three storage RH used in the study, the most favourable storage RH irrespective of the thickness of the packa ging m aterial is 47 .2% . Adebajo (1992) found out that the highest tolerable RH for polythene packaged foods (including nuts) is 70%, if the moisture content is to be maintained below 5.8% db for a reasonable length of time. REFERENCES Adebajo, L.O., 1992. Spoilage Moulds and Deterioration of the Nigerian Groundnut Cake Under Three Storage Methods. Nahrung, 36: 221-227. Adebajo, L.O. and S.A. Diyaolu, 2003, Mycology and spoilage of retail cashew nuts. Afr. J. Biotech ., 2(10): 369-373. Ayikoye, A.A., 2004. Effect of Polythene Bag Thickness on the Shelf-life of Roasted Groundnut (Arachis hypogae). Unpublished B. Eng Project. Department of Agricultural and Environmental Engineering. University of Agriculture, Makurdi, pp: 40. Bacha, H., R. Hadidane, E. Creppy, C. Regnault, F. Ellouze, and G . Dirhe imer, 1988. Monitoring and Identification of Fungal Toxins in Food Products, Animal Feeds and Cereals in Tunisia. J. Stored Produce Res., 24: 199-206. Dwem, N.N ., 1997 . Storag e Stab ility of Roasted Groundnuts and Bambara Nuts at Various Relative Hum idities. Unpublished B. Eng Project. Department of Agricultural and Environmental Engineering. University of Agriculture. Makurdi, pp: 40. Esuruoso, O.F., 1974. Fungi Associated with Kernel Rot Disease of Cashew (Ana card ium occidentale L.) in Nigeria. International Biodetn. Bulletin No. 10: 57-59. FAO, 2000. Food and Agriculture Organisation of the United Nations (FAO) production database. http://apps.fao.org/page/collections. Henderson, S., 198 5. The Re lationsh ip Betw een M oisture Content and Equilibrium R elative H umid ity of Pig Feed. J. Stored Produce Res., 21: 131-134. ICMSF, 1986. Microorg anism s in Foods 2. Sampling for Microbiological Analysis: Principles and Specific Applications 2 n d Edn., The International Commission on Microbiological Specifications for Foods. University of Toronto Press, Toronto. Jaffe, S. and J. Morton, 19 95 . M arketing Africa’s High Value Foods: Comparative Experiences of an Emergent Private Sector. The World Bank, Washington, USA. Pixton, S.W., 1986. The Importance of Moisture and Equilibrium Relative Hum idity in Stored Products: Tropical Stored Products Inf., 43: 16-29. W east, R.C. and M. J. Astle, 1979. CRC Handbook of Chemistry, 62 n d Edition. CRC Press Inc. Bana, Raton Florida. CONCLUSIONS Based on the results obtained in this study the following conclusions are drawn: C C quality index decreased with increase in duration of storage. As the polythene thickness increased at constant storage duration, the moisture content decreased. The moisture content of all the samples increased with increase in duration of storage at constant po lythene thickness level. For packaged roasted cashew nuts industry for poverty alleviation, the most favourable storage relative humidity is 47.2% with polythene thickness of 0.95mm. Storage period should not exceed 14 days for best quality and value for money. There is highly significant effect of relative humidity, polythene thickness and duration of storage (P#0.01) on moisture content and quality index while for the microbial count, polythene thickness and duration of storage has significant effect (P#0.05) with relative humidity showing non-significance. For all levels of relative humidity and polythene thickness, moisture content and microbial count increased with increase in duration of storage while 153