SEARC 2014 Agricultural Research Report of Progress 1105

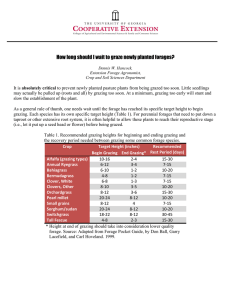

advertisement