Lincoln University Digital Dissertation

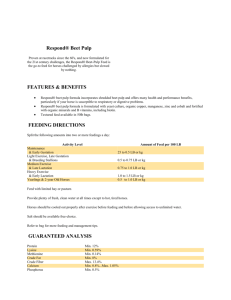

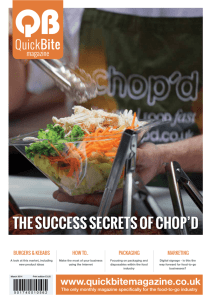

advertisement