SEI Webinar: Critical Lessons Learned in the Content and Delivery

advertisement

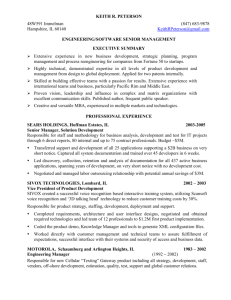

SEI Webinar: Critical Lessons Learned in the Content and Delivery off Six Si Si Sigma T Training i i Robert Stoddard Dave Zubrow June 30, 2010 SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University ` NO WARRANTY THIS CARNEGIE MELLON UNIVERSITY AND SOFTWARE ENGINEERING INSTITUTE MATERIAL IS FURNISHED ON AN “AS-IS" BASIS. CARNEGIE MELLON UNIVERSITY MAKES NO WARRANTIES OF ANY KIND, EITHER EXPRESSED OR IMPLIED,, AS TO ANY MATTER INCLUDING,, BUT NOT LIMITED TO, WARRANTY OF FITNESS FOR PURPOSE OR MERCHANTABILITY, EXCLUSIVITY, OR RESULTS OBTAINED FROM USE OF THE MATERIAL. CARNEGIE MELLON UNIVERSITY DOES NOT MAKE ANY WARRANTY OF ANY KIND WITH RESPECT TO FREEDOM FROM PATENT TRADEMARK, PATENT, TRADEMARK OR COPYRIGHT INFRINGEMENT. INFRINGEMENT Use of any trademarks in this presentation is not intended in any way to infringe on the rights of the trademark holder. This Presentation may be reproduced in its entirety, entirety without modification, modification and freely distributed in written or electronic form without requesting formal permission. Permission is required for any other use. Requests for permission should be directed to the Software Engineering Institute at p permission@sei.cmu.edu. @ This work was created in the performance of Federal Government Contract Number FA8721-05-C-0003 with Carnegie Mellon University for the operation of the Software Engineering Institute, a federally funded research and development center. center The Government of the United States has a royalty royalty-free free government-purpose license to use, duplicate, or disclose the work, in whole or in part and in any manner, and to have or permit others to do so, for government purposes pursuant to the copyright license under the clause at 252.227-7013. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University The Co-Authors Robert Stoddard Dave Zubrow Senior Member of Tech Staff Senior Member of Tech Staff SEI SEMA* SEI SEMA* *SEI SEMA = Software Engineering Institute, Software Engineering Measurement and Analysis Polling Question 1 H How did you h hear about b this hi webinar? bi ? 1. 1 2. 3. 4. 5. Email invitation from the SEI SEI Website Website with webinar calendar (ie www.webinar-directory.com) Social Media site ( LinkedIn, Twitter) Other Today’s Talk Introduction Six Sigma Training Challenge History of Six Sigma Training Lessons Learned from SEI Research and Experience •Training Design •Training Implementation SEI Six Sigma Training Solutions Contact Info and Questions SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 5 Introduction A wide variety of sources of Six Sigma training abound making it difficult for organizational leaders to identify which training and Six Sigma implementations are best for their work situations. Additional confusion arises due to different philosophies on how to best train practitioners and domain experts in applied Six Sigma methods. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 6 Six Sigma Training Challenge Critical lessons learned, in both the content and delivery of Six Sigma training, have been identified by SEI researchers from their experiences with several large corporations. The Challenge: Successful adoption and usage of Six Sigma for tactical process improvement versus a failed investment in Six Sigma training that i lless useful is f l and d lless practical ti l iin ttoday’s d ’ fast-paced business environment. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 7 History of Six Sigma Training 1980’s – Traditional statistical training to manufacturing personnel; focus on manufacturing operational scorecards 1990’s – Traditional statistical training g with COTS statistical tools;; focus moves beyond scorecards to improvement project methodology Early 2000’s 2000 s – Traditional statistical training to non-manufacturing non manufacturing domains; focus on new product design, development and transaction Late L t 2000’s 2000’ – Applied A li d statistical t ti ti l ttraining i i with ith modern d ttools l tto a wide id variety of domains; focus on training domain experts use of statistics rather than training statisticians in domain knowledge SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 8 Lessons Learned from SEI Research and Experience Critical lessons learned have been identified in both the content and delivery of Six Sigma training Identified up p to 8 yyears ago, g , most organizational g deployment p y champions p and Six Sigma training providers seem to be unaware of the lessons learned As such, inferior training and improper use of Six Sigma methods and tools persists in the community, resulting in false starts and disappointing b i business results lt SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 9 Polling Question 2 How would you characterize your organization’s Six Sigma methods and tools training? 1. Very good 2. Above Average 3. Below Average 4. Minimal 5. Don’t know SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 10 30 June 2010 © 2010 Carnegie Mellon University ` Training Design SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 1) Theory & Formula vs What, When & Why Traditional Approach: Traditional Six Sigma training forces students to learn the formulas and theory behind each technique. technique Often, this can include details of the original derivation of the technique. Lesson Learned: Taking advantage of both modern statistical packages and hands-on coaching, Six Sigma training should properly focus class time on connecting the business problem space with the appropriate technique or method. method Experience has shown that busy practitioners will not use the methods if their training focuses mostly on the theory and formulas formulas. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 12 30 June 2010 © 2010 Carnegie Mellon University 2) Statistical Purism vs Practical Use Traditional Approach: Often, Six Sigma training still gets “wrapped around the axle” regarding statistical purism. Thus, the training appears to ignore the fact that we are training practitioners, not college statistical students! Lesson Learned: Six Sigma courses should teach only what is needed for busy practitioners to use the methods, with occasional help from a coach. p is the on-going g g discussion within the Six Sigma g community y An example about how religious one treats the prerequisite of normality before using a number of methods, including SPC. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 13 30 June 2010 © 2010 Carnegie Mellon University 3) Theoretical Examples vs Real World Problems Traditional Approach: Many Six Sigma courses primarily offer thought experiments and theoretical examples related to the methods and tools tools. This behavior actually blurs the lines of distinction between skill training vs education vs general awareness. Lesson Learned: Six Sigma training should focus on skill building through a combination of real-world and realistic case studies. Thus, the students can learn the skills in context of specific business situations and problems. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 14 30 June 2010 © 2010 Carnegie Mellon University 4) Manufacturing vs Software and Systems Traditional Approach: Because Six Sigma training originated in the manufacturing domain, many training providers still teach the methods strictlyy in context of manufacturing. Consequently, many organizations have seen their software ft engineers i question ti the th applicability li bilit off Six Sigma to their work. Lesson Learned: Six Sigma courses should stress the application of Six Sigma methods and tools among a wide ide variety ariet of areas areas, ssuch ch as b butt not limited to to: ne new product development, research, transaction processing and service, as well as, strategic planning and technical product marketing. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 15 30 June 2010 © 2010 Carnegie Mellon University 5) Continuous Data vs Continuous & Discrete Data Traditional Approach: Most Six Sigma training providers only teach methods conducive for continuous data types while excluding treatment of discrete or categorical data data. This arises because the original manufacturing application had primarily continuous data (Interval or Ratio). Lesson Learned: We recognize that software-intensive systems systems, complex systems and systems-of-systems development need to deal with all types of data. In fact, experience has shown that a majority of the data to be analyzed ma be categorical (Nominal or Ordinal) in nat may nature. re Examples: Defect type = Nominal; Severity score = Ordinal SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 16 30 June 2010 © 2010 Carnegie Mellon University 6) Domain Agnostic vs CMMI & Domain Specific Traditional Approach: Some Six Sigma training providers create training materials to be reused across industries and domains domains. As a result, the concepts and skills are not taught in the domain language of the student! Lesson Learned: Six Sigma students should learn skills applicable within their specific domain and, beneficially, against a backdrop of the CMMI constellations (Development, Acquisition, and Services). Case studies from a number of domains should be included to ensure coverage of all students’ backgrounds. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 17 30 June 2010 © 2010 Carnegie Mellon University Polling Question 3 To what degree would these training content lessons-learned benefit your organization? 1. Very much 2. Often 3. Somewhat 4. Minimal 5. Don’t know SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 18 30 June 2010 © 2010 Carnegie Mellon University ` Training Implementation SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 June 2010 © 2010 Carnegie Mellon University 1) One Instructor vs Two Instructor Paradigm Traditional Approach: A majority of Six Sigma training conducted today is via a single instructor and often via online or elearning. As a result result, the learning experience is significantly constrained by the single instructor’s experience and limited interaction with students, if any interaction at all! Lesson Learned: We believe a two two-instructor instructor approach is superior for several reasons: 1) While one instructor is lecturing and leading the class, the other th instructor i t t can walk lk around d tto help h l with ith ttooll use, and d 2) The two-instructor approach dramatically enriches the learning p via complementary p y instructor backgrounds. g experience SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 20 30 June 2010 © 2010 Carnegie Mellon University 2) Statistical Prerequisites vs No Prerequisites Traditional Approach: Many Six Sigma training courses have a deeply-rooted structure of prerequisite courses, often requiring college classes in statistics statistics. As such, many domain experts find themselves excluded resulting in classes filled mostly with students from the quality function. Lesson Learned: Because domain knowledge has been shown to be more important than statistics in driving process improvement , we have seen organizations prioriti e the class seats for the domain st prioritize students dents who ho ma may ha have e no prior knowledge of statistics. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 21 30 June 2010 © 2010 Carnegie Mellon University 3) Manual Calculation vs Modern Tools Traditional Approach: Most Six Sigma training offerings are still locked in the past, e.g. 1980’s. They still teach students to perform heavy calculations on calculators or program formulas in spreadsheets. Lesson Learned: A healthy set of modern tools are now available to conduct applied statistical analysis and report the results. A such, we believe that the teaching focus on manual calculations is a serio s distraction from the real foc serious focus: s connecting the problem space with methods and tools! SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 22 30 June 2010 © 2010 Carnegie Mellon University 4) Lecture vs Hands-on Practice Traditional Approach: Much of today’s Six Sigma training is still rooted in traditional classroom lecture, or unassisted elearning. elearning Both approaches have been shown to be inferior to hands-on, hands on, coached skill training. Lesson Learned: We believe a combined use of lecture, individual and group exercises, and interactive use of modern tools is superior for skill building. A seemingly superior class design guide is to limit lecture to no more than 30-40% of the class time. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 23 30 June 2010 © 2010 Carnegie Mellon University 5) “Use it or Lose it” vs “Self-Refresher” Screen Shots Traditional Approach: Traditional Six Sigma training often includes training materials that do not stand alone. As such, students often find the need to retake the training later on when the opportunity to apply a given method or tool arises! Lesson Learned: Six Sigma training should include rich information, decision flowcharts and actual screen shots of the step-by-step process for each method using a modern tool. In this fashion, students may interactively follow along during class, as well as, self-refresh on topics later on when needed. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 24 30 June 2010 © 2010 Carnegie Mellon University 6) Memorization vs Laminated Color Job Aids Traditional Approach: To this day, most Six Sigma training involves memorizing formulas, as well as, which techniques to use in different situations based on the type of available data data. This memorization requirement continues to stall Six Sigma deployments. Lesson Learned: A number of Six Sigma courses use quick reference job aids aids, which embody most of the decisions related to techniques based on the situational factors. At the SEI, we have created several laminated, color job aids that are in great demand by our students. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 25 30 June 2010 © 2010 Carnegie Mellon University 7) Standard Data Sets vs Additional Student Data Sets Traditional Approach: It is common for Six Sigma training to provide data sets to be analyzed as part of the skill building. However, these data sets are often narrowly constrained and unrealistic to the situations that the student will encounter! Lesson Learned: Students should not only utilize prepared data sets to practice the different techniques, but should be encouraged to bring their own organizational and/or project data to analyze. analyze In this manner, students can build compelling predictive models for their p needs during g the class! workplace SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 26 30 June 2010 © 2010 Carnegie Mellon University 8) Book Knowledge vs Self-Sufficiency Traditional Approach: Regretfully, many training providers, coaches and practitioners seem to be only book knowledgeable of Six Sigma techniques techniques. As such, they are disadvantaged wrt the operation and strength of the different techniques. Lesson Learned: Six Sigma training should be designed to build self-sufficiency within students through the repeated practice of individual analytical techniques and tools. We believe skill building of this nature creates more self-sufficient students who need less coaching and are more confident in applying the techniques within the workplace. workplace SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 27 30 June 2010 © 2010 Carnegie Mellon University 9) One time event vs On-going coaching Traditional Approach: Most Six Sigma training is designed as a one-time training event, in which the students must go back to the workplace and apply the concepts on their own own. Even the best training suffers without the appropriate hand holding during first real use. “hand-holding” Lesson Learned: Six Sigma students should be encouraged to solicit coaching for on-going advice and help, as this psychologically promotes their use of the methods without fear. Superior Six Sigma deployments achieve coaching structures within each of the major domains in their organization, such that practitioners are coached by someone in their domain domain. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 28 30 June 2010 © 2010 Carnegie Mellon University Polling Question 4 To what degree would these training implementation lessons-learned benefit your organization? 1. Very much 2. Often 3. Somewhat 4. Minimal 5. Don’t know SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 29 30 June 2010 © 2010 Carnegie Mellon University SEI Six Sigma Training Solutions The SEI offers two courses that embody the lessons learned described in this talk. • Improving Process Performance using Six Sigma (IPPSS) • Designing Products and Processes using Six Sigma (DPPSS) SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 30 30 June 2010 © 2010 Carnegie Mellon University IPPSS Course Details Title: Improving Process Performance using Six Sigma (IPPSS) (5 days) SEI url: http://www.sei.cmu.edu/training/p49b.cfm Aka: Green Belt training for Software and Systems Engineers Topics included: 1. Full treatment of the Six Sigma DMAIC process 2. Analysis using ANOVA and Hypothesis Testing 3. Sample size determination 4. Predictive modeling using Regression modeling 5. Role of these methods specifically related to the following CMMI-Dev 1.2 Process Areas: MA, QPM, OPP, CAR and OID SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 31 30 June 2010 © 2010 Carnegie Mellon University DPPSS Course Details Title: Designing Products and Processes using Six Sigma (DPPSS) (5 days) SEI url: http://www.sei.cmu.edu/training/p56b.cfm Aka: Black Belt training for Software and Systems Engineers Topics included: 1 1. Treatment of the Six Sigma DMADV process 2. Voice of Customer techniques including KJ and Kano analysis 3 3. Monte Carlo simulation and Optimization modeling 4. Predictive modeling using Dummy Variable and Logistic Regression modeling 5 5. Process Modeling using Discrete Event Simulation 6. Design of Experiments for practical, short experiments, and 7. Software Reliability y Growth Modeling g and p prediction of latent defects. SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 32 30 June 2010 © 2010 Carnegie Mellon University Polling Question 5 Which of these SEI courses seem attractive and timely to meet your organization’s needs? 1. Improving Process Performance Using Six Sigma (IPPSS) 2. Designing Products and Processes Using Six Sigma (DPPSS) 3. Both of the above 4. Neither of the above 5. Don’t know SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 33 30 June 2010 © 2010 Carnegie Mellon University Open Question Any additional questions or comments on the critical lessons learned in the content and delivery of Six Sigma training? SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 34 30 June 2010 © 2010 Carnegie Mellon University Thank You for Your Attention! Robert Stoddard Email: rws@sei.cmu.edu rws@sei cmu edu Dave Zubrow E il dz@sei.cmu.edu Email: d @ i d World Wide Web: www.sei.cmu.edu i d U.S. mail: Software Engineering Institute Customer Relations 4500 Fifth Avenue Pittsburgh, PA 15213-2612 USA Customer Relations E il customerEmail: t relations@sei.cmu.edu Telephone: +1 412-268-5800 SEI Phone: +1 412-268-5800 SEI Fax: +1 412-268-6257 SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 35 30 June 2010 © 2010 Carnegie Mellon University g the data yyou need? Are y you measuring SEI Measurement and Analysis training equips i you with ith the th skills kill needed. d d SEI Training www.sei.cmu.edu/training SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 36 30 June 2010 © 2010 Carnegie Mellon University Analyzing Project Management Indicators Three-day course teaching managers and practitioners how to use measurement as the foundation for making informed decisions about projects. July 13 – 15, 2010 (SEI Arlington, VA) Register Now: www.sei.cmu.edu/training/p07d.cfm SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 37 30 June 2010 © 2010 Carnegie Mellon University D i i P d t and dP Designing Products Processes g Six Sigma g Using Five-day course taking a hands-on, measurement-oriented approach to product development, providing participants with a toolkit of analysis methods and leveraging industry best practices practices. December 13 – 17, 2010 (SEI Arlington, VA) Register Now: www.sei.cmu.edu/training/p56b.cfm SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 38 30 June 2010 © 2010 Carnegie Mellon University Implementing CMMI for High Performance, and Executive Seminar One-day introductory course for executives and middle managers covers the key concepts and strategy behind the SEI’s new fast track to process improvement from a management perspective perspective. October 18, 2010 (SEI Arlington, VA) Register Now: www.sei.cmu.edu/training/p22b.cfm SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 39 30 June 2010 © 2010 Carnegie Mellon University Implementing Goal-Driven Measurement Three-day course teaching managers and practitioners how to identify and define indicators and measures that directly support an organization’s business, process improvement, and project goals. September 21 – 23, 2010 (SEI Arlington, VA) Register Now: www.sei.cmu.edu/training/p06.cfm SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 40 30 June 2010 © 2010 Carnegie Mellon University Improving Process Performance Using Six Sigma Five-day course taking a hands-on, problem-solving approach to data analysis, providing participants with a toolkit of analysis methods and leveraging industry best practices such as Six Sigma and Goal-Driven Software Measurement. 20 2010 (SEI Pittsburgh PA) August 16 – 20, Register Now: www.sei.cmu.edu/training/p49b.cfm SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 41 30 June 2010 © 2010 Carnegie Mellon University Start here Webinar start SEI Webinar: Critical Lessons Learned in the Content and Delivery of Six Sigma Training 42 30 June 2010 © 2010 Carnegie Mellon University