Accounting Managerial Accounting [ADVANCED HIGHER]

advertisement

![Accounting Managerial Accounting [ADVANCED HIGHER]](http://s2.studylib.net/store/data/013060819_1-3ef3eca615378e888d9ae8550b4b43fe-768x994.png)

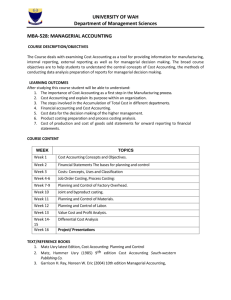

NATIONAL QUALIFICATIONS CURRICULUM SUPPORT Accounting Managerial Accounting [ADVANCED HIGHER] Lindsay Mitchell The Scottish Qualifications Authority regularly reviews the arrangements for National Qualifications. Users of all NQ support materials, whether published by LT Scotland or others, are reminded that it is their responsibility to check that the support materials correspond to the requirements of the current arrangements. Acknowledgement Learning and Teaching Scotland gratefully acknowledge this contribution to the National Qualifications support programme for Accounting. First published 2005 © Learning and Teaching Scotland 2005 This resource may be reproduced in whole or in part for educational purposes by educational establishments in Scotland provided that no profit accrues at any stage. 2 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Contents Introduction 4 Section 1: Activity-Based Costing (ABC) 5 Section 2: Multi-Product Break-Even Analysis 30 Section 3: Contract Costing Statements 46 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 3 INTRODUCTION Introduction This pack contains notes and exercises for three topics – activity-based costing, multi-product break-even analysis and contract costing. Activity-based costing and multi-product break-even analysis are both new topics for Advanced Higher and it is intended that the enclosed material will provide guidance to tutors as to what students are expected to know when covering the topics. Contract costing appeared in the old Higher Accounting and Finance arrangements but is now included in the Advanced Higher content. As no previous material on this topic has been produced it is hoped that this package will fill the gap. Each topic contains notes, exercises and full solutions. 4 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) Section 1 Activity-Based Costing (ABC) In your studies in Higher Accounting one of the major topics in the Cost/Management Accounting part of the syllabus was the treatment of overhead costs within a business. This involved the allocation and apportionment of overheads among cost centres and the subsequent absorption of these cost-centre overheads into the cost units produced in the cost centres. The whole process described above can best be illustrated by the following diagram. Overhead Costs Allocation Apportionment using selected basis Single Cost Centre Multiple Cost Centres Production Cost Centres Service Cost Centres Re-apportionment using selected basis Cost Units using appropriate absorption rate The above approach is sometimes referred to as the ‘trad itional’ approach to overhead absorption. Activity-based costing has been developed within the last 20–30 years in an effort to avoid defects in the traditional system. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 5 ACTIVITY-BASED COSTING (ABC) The main characteristics of the traditional system are as follows: • it was developed in manufacturing industry • there were typically a narrow range of products • production processes were much simpler than now • direct material and labour costs were the main production costs • overhead costs were relatively small • inaccuracies due to arbitrary nature of process were therefore relatively unimportant. Activity-Based Costing (ABC) has therefore emerged due to the following: • product ranges have increased • overhead costs have become more significant • manufacturing concerns no longer dominate • service organisations account for a much larger share of economic activity • production is more complex and capital intensive. The main ideas behind ABC are: • costs are caused by activities – for example ordering, material handling, scheduling, machining, assembling, etc. • production of products or supply of services creates the demand for these activities • costs are therefore assigned to products or services on the basis of consumption of these activities. 6 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) Therefore ABC involves a number of stages. 1. Identify the major activities of the organisation. 2. Identify the factors which affect the cost of an activity. These factors are known as COST DRIVERS e.g. the number of purchase orders might be considered as the cost driver for the costs of a purchasing department. 3. Collect the associated costs of each activity. This is known as the COST POOL. 4. Allocate costs to products/services based on the demand created for the cost drivers. As with the traditional approach, ABC can be illustrated by a diagram: Identify major activities Create cost pool for each activity Identify cost driver for each activity Produce absorption rate for each pool based on cost driver Overhead cost per unit Let us now look at an example which will show both the traditional approach to the treatment of overheads and then how ABC would treat the same situation. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 7 ACTIVITY-BASED COSTING (ABC) Example Deeside plc manufactures three products, A, B and C in their factory and uses a factory-wide absorption rate for absorbing overheads based on direct labour hours. The following information relates to Period 5 of Year 3. Product Production (units) Direct Material Cost p.u. Direct Labour Hours p.u. A 12,000 £40 4 B 8,000 £30 6 C 4,000 £20 2 Direct labour is paid at £8 per hour. The overhead costs for Period 5 are as follows: Machining Set-up Assembling Goods Receiving Dispatch £ 312,000 56,000 80,000 128,000 100,000 676,000 (a) Calculate the factory-wide absorption rate for Period 5. (b) Calculate the cost p.u. of each product under the traditional approach to treatment of overheads. The company is considering using ABC as a method of arriving at the cost per unit of their products and the following information is available for this purpose: The overheads have been investigated and while machining costs will be absorbed on the basis of machine hours, cost drivers have been identified for the other overheads. Overhead Set-up Assembling Goods Receiving Dispatch 8 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Cost Driver No. of production runs No. of production orders No. of receipts No. of production orders ACTIVITY-BASED COSTING (ABC) The following additional information is also available: Product Machine hours per unit No. of Production runs No. of Material receipts No. of Production orders A 2 1 3 3 B 3 2 5 2 C 1 5 24 5 (c) Calculate a cost driver absorption rate for each of the above overheads. (d) Calculate the cost per unit for each product under the ABC system. This question contains a lot of information and lots of figures and therefore it is important to read it carefully with a view to deciding which information relates to each part of the question. The purpose of this question is to show how the traditional method of overhead absorption works and then to demonstrate the Activity -Based Costing approach. At the end of the question we will compare the two methods and see if we can explain the differing results they produce. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 9 ACTIVITY-BASED COSTING (ABC) Solution (a) This opening part of the question asks us to calculate a factory -wide overhead absorption rate (sometimes called a ‘blanket rate’), b ased on labour hours. You should recall that the calculation of an overhead absorption rate divides the relevant overhead (which may be for a cost centre or, as in this case, for the whole factory) by the relevant units of the base selected. (There were actually six possibilities, i.e. per unit, % on material, % on wages, % on prime cost, per labour hour or per machine hour). In this question we are using labour hours and therefore the calculation is as follows: Overhead Absorption Rate = Factory Overheads Labour Hours Although we know the total factory overheads we need to calculate the total labour hours, i.e. A– B– C– = 48,000 = 48,000 = 8,000 104,000 We can now calculate the factory-wide rate = £676,000 104,000 = £6.50 per labour hour 10 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) (b) In this next part we are asked to calculate the total cost per unit for each product using the traditional approach. This total cost will be the sum of the two direct costs – material and labour, plus overheads. The question gives us the material cost p.u. for each product, but we will have to calculate the figures for labour and overheads. For labour this will be the number of labour hours per unit multiplied by the labour rate per hour. For overheads it will be the number of labour hours per unit multiplied by the overhead absorption rate calculated in part (a), i.e. Cost per unit Material Labour Overheads A £40 £32 (4 £26 B £30 £48 £39 C £20 £16 £13 £117 £49 £98 The remaining parts of the question now introduce the Activity -Based Costing technique. (c) This part asks us to calculate cost driver absorption rates for the separate overheads. The total overhead of the factory has been broken down into five activities. For the first of these, machining, a traditional -style absorption rate is to be used, i.e. machine hour rate. Machine Hour Rate = Machine Overhead Machine Hours Once again we know the overhead but need to calculate the machine hours, i.e. A – 12,000 B– C– = 24,000 = 24,000 = 4,000 52,000 Therefore the calculation is MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 11 ACTIVITY-BASED COSTING (ABC) £312,000 52,000 = £6 per m/c hour Machine Hour Rate = 12 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) For the other activities, which comprise the factory overheads, appropriate cost drivers have been identified and we can use these to calculate the relevant absorption rate. The cost drivers identified are the number of production runs, the number of production orders and the number of receipts. Therefore before we go any further we must calculate the relevant figure for each driver. Production Runs – A B C 1 2 5 8 Production Orders – A B C 3 2 5 10 Receipts – A B C 3 5 24 32 Now we can calculate the absorption rate for each activity, based on the relevant cost driver. Set-up = £56,000 8 = £7,000 per run Assembling = £80,000 10 = £8,000 per order Goods Receiving = £128,000 32 = £4,000 per receipt Dispatch = £100,000 10 = £10,000 per order MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 13 ACTIVITY-BASED COSTING (ABC) (d) The final part requires us to use these figures to produce a cost per unit for each product. Therefore we need to calculate the overhead cost per unit to add to the material and labour costs which we calculated in part (b). Machinery overhead is the simplest, i.e. machine hours per unit multiplied by machine hour rate. £6 = £18 A– B– C– For the other overhead activities we need to relate the cost driver absorption rate to the units produced. Set-up A £7,000 12,000 = £0.58 B £14,000 (7,000 C £35,000 8,000 = £1.75 4,000 = £8.75 Assembling £24,000 (8,000 12,000 =£2 Goods £12,000 12,000 =£1 £30,000 12,000 = £2.50 3)£20,000 Receiving Dispatch £16,000 £40,000 8,000 = £2 £20,000 4,000 =£10 £96,000 8,000 = £2.50 8,000 = £2.50 4,000 = £24 £50,000 4,000 = £12.50 Therefore using ABC total cost per unit for the products would be as follows: Direct Materials Direct Labour Machinery Set-up Assembling 14 A £40 £32 £12 £0.58 £2 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 B £30 £48 £18 £1.75 £2 C £20 £16 £6 £8.75 £10 ACTIVITY-BASED COSTING (ABC) Goods Receiving Dispatch £1 £2.50 £24 £2.50 £2.50 £12.50 £90.08 £104.75 £97.25 Contrast these figures with the ones produced in the ans wer to part (b) of the question. The most striking change is in the increase in the cost per unit of Product C, although there is also a less substantial decrease in the cost per unit of the other two products. The increase in the cost of C has arisen because most of the charges relating to C were not identified under the traditional absorption system. The cost drivers identified in the ABC system are responsible for generating these charges and thus we can suggest that the ABC system produces a more accurate cost for each product. The following examples will provide practice in applying the ABC system. Solutions are provided at the end of this section. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 15 ACTIVITY-BASED COSTING (ABC) Question 1 Your company currently produces and sells 4 products, Alpha, Beta, Gamma and Delta. The following information relates to Period 3. Production (units) Costs per unit: Direct material Direct labour Machine hours per unit Number of production runs Number of requisitions raised Number of orders completed Alpha 180 Beta 150 Gamma 120 Delta 180 £46 £21 4 6 30 18 £58 £14 3 5 30 15 £35 £7 2 4 30 12 £70 £14 3 6 30 18 Currently the production overhead is absorbed by the machine -hour rate method and the following are the total production overhead costs for Period 3. £ 24,540 6,300 7,200 3,150 7,560 48,750 Machine Department Set-up costs Receiving costs Inspection costs Despatch costs Cost drivers have been identified as follows: Set-up costs Stores receiving Inspection Despatch Number Number Number Number of of of of production runs requisitions raised production runs orders completed You are required to calculate: (a) (i) The machine-hour rate currently used to absorb the production overhead. (ii) The total cost per unit for each product if overheads are absorbed by the method in (a)(i). (b) The cost per unit for each product using an ABC approach. 16 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) Question 2 Jomit plc has budgeted for the following overhead costs for Period 6. Material receipt costs Power costs Material handling costs £ 31,200 39,000 27,300 The company produces 3 products, P, Q and R for which the following budgeted information is available for Period 6. Product Output (units) Material batches P 4,000 20 Q 3,000 10 R 1,600 32 Per Unit Direct material (kg) Direct material (£) Direct labour (hours) Number of power operations Direct labour rate per hour 4 6 0.2 6 £8 6 5 0.5 3 £8 3 9 1.0 2 £8 Currently the overhead costs are each absorbed using a rate per direct labour hour. However, the company is considering applying overheads using an ABC approach and has identified drivers for the activities as follows: Material receipt costs Power costs Material handling costs number of batches of material number of power operations kg of material handled You are required to calculate: (a) The total cost per unit for each product using the current overhead absorption method. (b) The total cost per unit for each product using the ABC method. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 17 ACTIVITY-BASED COSTING (ABC) Question 3 Your company currently produces a range of three products, D, E and F to which the following details relate for Period 2. D 1,500 £18 1 3 Production (units) Material cost per unit Labour hours per unit Machine hours per unit E 2,500 £10 3 2 F 14,000 £20 2 6 Labour costs are £8 per hour and production overheads are currently absorbed in the conventional system by reference to machine hours. Total production overheads for Period 2 have been analysed as follows: Set-up costs Handling costs Machining costs Inspection costs (a) £ 327,250 187,000 140,250 280,500 935,000 Calculate the cost per unit for each product usi ng conventional methods. The introduction of an ABC is being considered and to that end the following volume of activities have been identified with the current output levels. Number of set-ups Number of material issues Number of inspections D 90 16 180 E 138 28 216 F 576 116 804 (b) Calculate the cost per unit for each product using the ABC approach. 18 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) Question 4 The following table summarises the details of the production levels, costs and cost drivers for Abtronics Ltd who have traditionally absorbe d overheads into production on the basis of a labour hour absorption rate. They wish to move to an ABC system. Product Material cost per unit Labour hours per unit Machine hours per unit Number of production runs Number of production orders Number of orders delivered Number of receipts Production (units) P £20 4 4 6 45 30 12 15,000 Q £15 6 3 14 30 20 28 10,000 R £10 3 6 40 75 50 80 4,000 Labour hours are paid for at £10 per hour. Overheads Machining Set-up costs Receiving costs Packing costs Engineering costs £ 684,000 60,000 240,000 300,000 450,000 1,834,000 Cost Driver machine hours production runs number of receipts number of orders delivered number of production orders (a) Calculate the cost per unit for each product using the traditional overhead absorption approach. (b) Calculate the cost per unit using the ABC approach. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 19 ACTIVITY-BASED COSTING (ABC) Question 5 Param plc has incurred the following overheads in its factory during Period 6. Quality control Process set-ups Purchasing Order processing Occupancy costs £ 90,000 135,000 105,000 120,000 150,000 Param plc produces a range of products, two of which are Product X and Product Y. The following information relate to these two products. Material costs per unit Labour cost per unit Number of process set-ups Number of purchase orders issued Number of customer orders Machine hours per unit Production (units) X £5 £8 150 500 1,000 3 10,000 Y £8 £12 210 300 800 2 6,000 Inspection takes place after each process set -up. The cost drivers which have been identified for the factory are: Quality control Process set-ups Purchasing Order processing Occupancy costs 450 inspections 450 set-ups 1,000 purchase orders 2,000 customer orders 75,000 machine hours Calculate the cost per unit for Products X and Y using: (i) existing overhead absorption rate per machine hour (ii) an activity-based costing approach. 20 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 ACTIVITY-BASED COSTING (ABC) Solutions Question 1 (a) (i) Total machine hours: Alpha Beta Gamma Delta 720 450 240 540 = 1950 Total overheads = £48,750 £48,750 1,950 = £25 Machine hour absorption rate = (ii) Cost per unit Direct material Direct labour Production overhead (b) Cost Machine Dept Set-up Receiving Inspection Despatch £ 24,540 6,300 7,200 3,150 7,560 Alpha £ 46 21 100 167 Beta £ 58 14 75 147 Driver m/c hours Runs Requisitions Runs Orders Gamma £ 35 7 50 92 Driver transactions 1950 21 120 21 63 Delta £ 70 14 75 159 Cost per driver £12.58 £300 £60 £150 £120 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 21 ACTIVITY-BASED COSTING (ABC) Overheads cost per unit Alpha Beta Gamma Delta Set-up £1800 = £10 180 £1500 = £10 150 £1200 = £10 120 £1800 = £10 180 Receiving £1800 = £10 180 £1800 = £12 150 £1800 = £15 120 £1800 = £10 180 Inspection £900 = £5 180 £750 = £5 150 £600 = £5 120 £900 = £5 180 Despatch £2160 = £12 180 £1800 = £12 150 £1440 = £12 120 £2160 = £12 180 Machine Dept = £50.32 = £37.74 = £25.16 = £37.74 Total cost per unit Materials Labour Set-up Receiving Inspection Despatch Machine Dept 22 Alpha £ 46.00 21.00 10.00 10.00 5.00 12.00 50.32 154.32 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Beta £ 58.00 14.00 10.00 12.00 5.00 12.00 37.74 148.74 Gamma £ 35.00 7.00 10.00 15.00 5.00 12.00 25.16 109.16 Delta £ 70.00 14.00 10.00 10.00 5.00 12.00 37.74 158.74 ACTIVITY-BASED COSTING (ABC) Question 2 (a) Direct labour hours: R 1,600 = = = 3,900 800 1,500 1,600 Overhead absorption rates: Material receipt £31,200 = £8 per labour hour 3,900 Power £39,000 = £10 per labour hour 3,900 Material handling £27,300 = £7 per labour hour 3,900 Overhead cost per unit Material receipt P £ = £1.60 Q 0.5 = £4 R = £8 = £2 = £5 £10 = £10 Material handling £ = £1.40 = £3.50 = £7 Total cost per unit P £ 6.00 1.60 1.60 2.00 1.40 12.60 Power Direct material Direct labour Material receipt costs Power costs Material handling Q £ 5.00 4.00 4.00 5.00 3.50 21.50 R £ 9.00 8.00 8.00 10.00 7.00 42.00 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 23 ACTIVITY-BASED COSTING (ABC) (b) ABC absorption rates Material receipt £31,200 = £503.23 per batch 62 Power £39,000 = £1.08 per operation 36,200 (W1) Material handling £27,300 = £0.70 per kg 38,800 (W2) Overhead costs per unit P Q R £503.23 20 4,000 £503.23 10 3,000 £503.23 10 1,600 = £2.52 = £1.68 = £10.06 Power = £6.48 £1.08 = £3.24 £1.08 = £2.16 Material handling = £2.80 = £4.20 = £2.10 Material receipts Total cost per unit Direct material Direct labour Material receipt costs Power costs Material handling costs 24 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 P £ 6.00 1.60 2.52 6.48 2.80 19.40 Q £ 5.00 4.00 1.68 3.24 4.20 18.12 R £ 9.00 8.00 10.06 2.16 2.10 31.32 ACTIVITY-BASED COSTING (ABC) Question 3 (a) Number of machine hours = D = E = F Overhead absorption rate = 2,500 = = = = 4,500 5,000 84,000 93,500 £935,000 93,500 = £10 per machine hour Cost per unit Material Labour Overhead (b) D £18 £8 £30 £56 Total number of set-ups Absorption rate per set-up Total number of issues Absorption rate per issue E £10 £24 £20 £54 F £20 £16 £60 £96 = 90 + 138 + 576 = 804 £327,250 804 = £407.03 per set-up = = 16 + 28 + 116 = 160 £187,000 160 = £1,168.75 = £140,250 93,500 = £1.50 = Absorption rate per machine hour Total number of inspections Absorption rate per inspection = 180 + 216 + 804 = 1,200 £280,500 1,200 = £233.75 = MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 25 ACTIVITY-BASED COSTING (ABC) Overheads per unit Set-up Issue Machining Inspection D 90 £407.03 1,500 = £24.42 £1.50 = £4.50 = £3 = £9 180 £233.75 1,500 = £28.05 216 £233.75 2,500 = £20.20 804 £233.75 1,400 = £13.42 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 F 576 £407.03 14,000 = £16.75 16 £1,168.75 28 £1,168.75 116 £1,168.75 1,500 2,500 14,000 = £12.47 = £13.09 = £9.68 Total cost per unit Material Labour Set-up costs Handling costs Machine costs Inspection costs 26 E 138 £407.03 2,500 = £22.47 D £18.00 £8.00 £24.42 £12.47 £4.50 £28.05 £95.44 E £10.00 £24.00 £22.47 £13.09 £3.00 £20.20 £92.76 F £20.00 £16.00 £16.75 £9.68 £9.00 £13.42 £84.85 ACTIVITY-BASED COSTING (ABC) Question 4 (a) Total labour hours = P Q R = 60,000 = 60,000 = 12,000 132,000 Total overheads = £1,834,000 £1,834,000 132,000 = £13.89 Total absorption rate Cost per unit Direct material Direct labour Production overheads (b) P £20.00 £40.00 £55.56 £115.56 Q £15.00 £60.00 £83.34 £158.34 R £10.00 £30.00 £41.67 £81.67 Cost driver absorption rates Machining Set-up costs £684,000 114,000 = £6.00 per machine hour £60,000 (6 + 14 + 40) = £1,000 per production run Receiving costs £240,000 (12 + 28 + 80) = £2,000 per receipt Packing costs £300,000 (30 + 20 + 50) = £3,000 per order delivered Engineering costs £450,000 (45 + 30 + 75) = £3,000 per production order MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 27 ACTIVITY-BASED COSTING (ABC) Overhead cost per unit Machining Set-up costs Receiving costs Packing costs Engineering costs Total cost per unit Direct material Direct labour Machining Set-up Receiving Packing Engineering 28 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 P Q R £6.00 = £24.00 = £18.00 = £36.00 6 £1,000 15,000 = £0.40 14 £1,000 10,000 = £1.40 40 £1,000 4,000 = £10 12 £2,000 15,000 = £1.60 28 £2,000 10,000 = £5.60 80 £2,000 4,000 = £40 30 £3,000 15,000 = £6 20 £3,000 10,000 = £6 50 £3,000 4,000 = £37.50 45 £3,000 15,000 = £9 30 £3,000 10,000 = £9 75 £3,000 4,000 = £56.25 P £ 20.00 40.00 24.00 0.40 1.60 6.00 9.00 101.00 Q £ 15.00 60.00 18.00 1.40 5.60 6.00 9.00 115.00 R £ 10.00 30.00 36.00 10.00 40.00 37.50 56.25 219.75 ACTIVITY-BASED COSTING (ABC) Question 5 (i) Total Factory Overheads = Total machine hours Absorption rate Cost per unit Material Labour Overheads (ii) £90,000 £135,000 £105,000 £120,000 £150,000 £600,000 = 75,000 £600,000 75,000 = £8 per machine hour X £ 5.00 8.00 24.00 37.00 Y £ 8.00 12.00 16.00 36.00 Cost Driver Absorption Rates Quality control £90,000 450 = £200 per inspection Process set-up £135,000 450 = £300 per set-up Purchasing £105,000 1,000 = £105 per order Order processing £120,000 2,000 = £60 per order Occupancy costs £150,000 75,000 = £2 per machine hour MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 29 ACTIVITY-BASED COSTING (ABC) Overhead cost per unit Quality control Process set-up Purchasing Order processing Occupancy Cost per unit Material Labour Quality control Set-up Purchasing Order processing Occupancy 30 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 X Y 150 £200 10,000 = £3 210 £200 6,000 =£7 150 £300 10,000 = £4.50 210 £300 6,000 = £10.50 500 £105 10,000 = £5.25 300 £105 6,000 = £5.25 1,000 £60 10,000 = £6 800 £60 6,000 = £8 £6 £4 X £ 5.00 8.00 3.00 4.50 5.25 6.00 6.00 37.75 Y £ 8.00 12.00 7.00 10.50 5.25 8.00 4.00 54.75 MULTI-PRODUCT BREAK-EVEN ANALYSIS Section 2 Multi-Product Break-Even Analysis You will recall from your studies of Break-Even Analysis in Higher Accounting that the basis of this technique was the ability to classify all costs in an enterprise as either fixed or variable. That is not to say that all costs are either totally fixed or totally variable. Indeed there will be very few costs in the long run which could be said to fall into either of these categories. However, the assumpt ion that is made is that all costs will be made up of a variable component and a fixed component, and that these can be separated. Thus we could add all the variable components together to arrive at a total variable cost per unit, and all the fixed components to arrive at total fixed costs, e.g. if we consider a cost like machine maintenance it can be argued that there would be a minimum amount of maintenance required even if production was zero. That then would constitute the fixed component of machine maintenance. Then, of course, as output builds up the machines will be subject to more wear and tear and breakdowns, and thus require more and more maintenance. This would constitute the variable component of machine maintenance. However, in your past studies the behaviour of costs (i.e. how costs change as output changes) was kept relatively simple (e.g. direct costs like material and wages were often assumed to be perfectly variable and costs like rent assumed to be perfectly fixed). In fact there were a number of assumptions made in break-even analysis which had the effect of keeping things relatively simple e.g. the relationship between sales revenue and volume was based on the assumption that the selling price was constant at all levels of output and variable costs per unit were also assumed to stay constant. As far as this section of notes is concerned there was one further assumption which simplified matters and which we are now going to relax, i.e. we assumed that we were dealing with a single pro duct model or perhaps, if there were more than one product, we assumed a constant sales mix. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 31 MULTI-PRODUCT BREAK-EVEN ANALYSIS Therefore what we are now going to consider is the effect of several products on the calculations of break-even and profit and loss and the effect of changes in product or sales mix. Basic Concepts of Break-Even Analysis It is perhaps worth revising the basic relationships which Break -Even Analysis depends on. As already stated the starting point is Total Costs = Fixed Costs + Variable Costs Since, by definition, fixed costs have no relationship with output/sales no attempt is made to arrive at a total cost per unit. The next step is to find what is left over out of sales revenue once the variable costs have been met. This is called the contribution. Contribution = Sales – Variable Costs It is so called because it is the contribution towards paying the fixed costs. If there is sufficient contribution to pay the fixed costs and have something left over then that will be profit (since all costs have now be en met). If there is insufficient contribution to cover the fixed costs then a loss will be made (since the total costs have exceeded sales revenue). In between these two situations there must be a point where there is just sufficient contribution to pay the fixed costs and thus neither a profit nor a loss is made. This is known as Break-Even Point and is where Contribution = Fixed Costs Remember as we said above Contribution – Fixed Costs = Profit (if positive) = Loss (if negative) The key to calculating the profit or loss in any situation is therefore contribution, and profit/loss can only be found by two steps, i.e. • find contribution by comparing sales and variable costs • deduct fixed costs from contribution to determine profit or loss. 32 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 MULTI-PRODUCT BREAK-EVEN ANALYSIS Break-Even Point is important, because it marks the output level where a business moves from loss into profit; therefore there is an important formula which allows us to calculate it, i.e. Break-Even Point (units) = Fixed Costs Contribution per unit To convert this into Break-Even Sales we only need to multiply the break even units by the selling price per unit. Break-Even Point (£) = B/E unitsSelling Price per unit There is one other relationship which is important in break -even analysis and that is the relationship between contribution and sales value. This is calculated as contribution/sales and is sometimes referred to as the Profit/Volume Ratio, although it can be referred to simply as the contribution/sales ratio. The important thing about this ratio is that it will remain constant at all levels of output. This is because all the constituent parts of the ratio are by definition variable, i.e. sales, variable costs and consequently contribution. It must be remembered, however, that this ratio will only remain constant as long as the basic assumptions mentioned earlier hold true, i.e. a constant selling price per unit and a constant variable cost per unit. The advantage of this ratio is that once calculated you can apply it at any level of output and thus determine the contribution earned from a particular level of sales or the sales necessary for a particular level of contribution and hence profit. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 33 MULTI-PRODUCT BREAK-EVEN ANALYSIS Multi-Product Break-Even The problem with calculating the break-even point for a business with more than one product is that another variable has been added, i.e. the product mix. Product mix means the relative percentage or share of tot al sales which each product represents. If each product earns a different contribution per unit then any change in the relative volume of sales of each product will cause difficulties. The way round this is to calculate a weighted average contribution pe r unit to apply when calculating the break-even point. Example CMA plc produce a range of three products to which the following details relate: Product Selling Price p.u. Variable Costs p.u. Basic £205 £130 Special £250 £145 Deluxe £350 £200 Fixed costs for CMA plc total £600,000 Let us take each product in turn and calculate what the break -even point would be if only that product were produced and sold. Basic Contribution per unit = £205 – £130 = £75 Break-Even Point (units) = 34 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 £600,000 £75 = 8,000 MULTI-PRODUCT BREAK-EVEN ANALYSIS Special Contribution per unit = £250 – £145 = £105 Break-Even Point (units) = £600,000 £105 = 5,715 (approx.) Deluxe Contribution per unit = £350 – £200 = £150 Break-Even Point (units) = £600,000 £150 = 4,000 The two extreme outcomes for break-even are 8,000 units if all sales were the basic model and 4,000 units if all sales were deluxe. Therefore any sales mix will be bound to produce a break -even point which lies somewhere between these two levels. Given a sales mix the break-even point can be found using the familiar formula but using a weighted average contribution per unit. Using the figures from the above example let us calculate the break -even point if sales were split evenly between the thr ee products. Weighted Average Contribution per unit = (1/3£75) + (1/3£105) + (1/3£150) = £25 + £35 + £50 = £110 Break-Even Point (units) = £600,000 £110 = 5454.5 = 5455 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 35 MULTI-PRODUCT BREAK-EVEN ANALYSIS We can prove that this is correct by working out the r elevant figures. Basic 1,818 Special 1,818 Deluxe 1,818 Sales (£) Variable Costs 372,690 236,340 454,500 263,610 636,300 363,600 Contribution 136,350 190,890 272,700 Sales (units) Total Contribution Fixed Costs £599,940 £600,000 –60 (caused by rounding units) Now let us see what happens when the sales mix changes. Suppose the product mix is 3:2:1 for Basic/Special/Deluxe. Total sales are then represented by Basic 3/6 = 1/2 Special 2/6 = 1/3 Deluxe 1/6 Weighted Average Contribution per unit = (1/2£75) + (1/3£105) + (1/6£150) = £37.50 + £35 + £25 = £97.50 Break-Even Point (units) £600,000 £97.50 = 6154 (nearest unit) = The answer is greater than the previous answer and that makes sense because we have moved to a situation where we are selling most of the product which has the lowest contribution per unit and we are selling fewest of the one with the highest contribution per unit. 36 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 MULTI-PRODUCT BREAK-EVEN ANALYSIS Once again we can prove that this is the correct answer by multiplying out the figures. Total Units = 6,154 Split as follows: Sales (£) Variable Costs Basic Special Deluxe Basic 630,785 400,010 Contribution 230,775 Total Contribution Fixed Costs 3077 (1/2) 2051 (1/3) 1026 (1/6) Special Deluxe 512,750 359,100 297,395 205,200 215,355 153,900 £600,030 £600,000 30 (due to rounding) This approach can then be used to answer the typical range of questions which you associate with basic break-even problems, i.e. calculating the level of sales required to earn a specified profit. For example, using the sales mix of 3:2:1 above calculate the sales in units of each product which would produce a profit of £100,000. Remember in marginal or break-even problems there is no direct connection between units and profit, and therefore we must convert profit into contribution. Contribution = Fixed Costs + Profit = £600,000 + £100,000 = £700,000 Total No. of Units Required = Units of Basic = 1/2 7,180 = 3,590 Units of Special = 1/3 7,180 = 2,393 Units of Deluxe = 1/6 7,180 = 1,197 £700,000 £97.50 = 7,180 (approx) MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 37 MULTI-PRODUCT BREAK-EVEN ANALYSIS Let us just prove that this is the correct solution. Sales (£) Variable Costs Basic 735,950 466,700 Special 598,250 346,985 Deluxe 418,950 239,400 Contribution 269,250 251,265 179,550 Total Contribution Less: Fixed Costs Profit £700,065 £600,000 100,065 (due to rounding) If we now consider the opposite type of problem: How much profit will be made from sales of 9,000 units, also assuming a ratio of 3:2:1 between sales of the three pro ducts? Once again we must convert the units into contribution before we can calculate profit. Contribution from 9,000 units Less: Fixed Costs Profit = 9,000 £97.50 = £877,500 £600,000 £277,500 Once again we can prove the result: Sales Mix Basic – 1/2 9,000 = 4,500 Special – 1/3 9,000 = 3,000 Deluxe – 1/6 9,000 = 1,500 Sales (£) Variable Costs Basic 922,500 585,000 Special 750,000 435,000 Deluxe 525,000 300,000 Contribution 337,500 315,000 225,000 Total Contribution Fixed Costs £877,500 £600,000 £277,500 Here are some questions to try. 38 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 MULTI-PRODUCT BREAK-EVEN ANALYSIS Question 1 Clear Picture Ltd produce two models of television sets, Brilliant and Super Bright to which the following details relate for the current year. Selling price per set Variable cost per set Current sales (units) Brilliant £250 £125 5,000 Fixed costs £600,000 Super Bright £350 £190 2,500 (a) Calculate the profit which Clear Picture would earn from the above situation. (b) Calculate the total number of sets which require to be sold to break even if the above sales mix applies. (c) Prepare a detailed Profit Statement to show the full figures for each product at break-even point. (d) What would the break-even point be if the sales mix changed to three Brilliant sets for every Super Bright set? (e) Explain why the increase/decrease in break-even point was predictable. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 39 MULTI-PRODUCT BREAK-EVEN ANALYSIS Question 2 MPV plc manufactures and sells three products with the following selling prices and variable costs: Unit selling price Unit variable cost Current sales (units) Basic £3.00 £2.10 500,000 Superior £3.75 £1.50 230,000 Supreme £5.00 £3.25 190,000 Existing fixed costs amount to £1,000,000. (a) Calculate the total number of units MPV plc will require to sell in order to break even if the current sales mix persists. (b) Prepare a Profit Statement showing the relevant figures for the three products to prove your answer to (a). 40 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 MULTI-PRODUCT BREAK-EVEN ANALYSIS Question 3 Easylearn Ltd provide expert tutoring on a range of subjects. Next year’s budget shows the following expected figures: Accounting 2,500 £40 £10 Expected hours of work Charge per hour Variable cost per hour Maths 3,000 £50 £15 English 3,500 £45 £9 French 1,000 £35 £10 Fixed costs for the year are expected to be £198,600. (a) Calculate the total number of hours Easylearn Ltd will have to work to break even, assuming the above mix of tutoring hours. (b) Calculate the contribution from each subject and in total at break-even point. (c) Using the same mix as above prepare a Profit Statement for Easylearn plc to earn a profit of £100,000. (d) The actual hours provided during the year turned out to be: Accounting Maths English French 1,500 1,000 4,500 3,000 Calculate the break-even number of hours. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 41 MULTI-PRODUCT BREAK-EVEN ANALYSIS Solutions Question 1 (a) Contribution p.u. Total Contribution Brilliant £125 5,000 £125 = £625,000 Total Contribution for company less: Fixed Costs Profit (b) Sales (units) – Brilliant – Super Bright Super Bright £160 2,500 £160 = £400,000 £1,025,000 600,000 425,000 5,000 2,500 7,500 67% 33% 100% Weighted Average Contribution p.u.= (£125 67%)+(£16033%) = £83.75 + £52.80 = £136.55 B/E Point (units) = £600,000 £136.55 = 4,394 (nearest unit) (c) Sales (units) Profit Statement for Year Sales 736,000 Variable Costs Contribution Total Contribution less: Fixed Costs 42 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Brilliant 4394 67% 2944 Super Bright 4394 33% 1450 Brilliant £ 507,500 368,000 368,000 Super Bright £ £600,000 £600,000 275,500 232,000 MULTI-PRODUCT BREAK-EVEN ANALYSIS (d) Weighted Average Contribution p.u. = (£125 75%)+(£160 25%) = £93.75 + £40 = £133.75 B/E point (units) = £600,000 £133.75 = 4,486 (e) Since they were selling more of the product with the lower contribution per unit, it was inevitable that the break-even point would increase. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 43 MULTI-PRODUCT BREAK-EVEN ANALYSIS Question 2 (a) Sales (units) Basic Superior Supreme Contribution per unit 500,000 230,000 190,000 920,000 – Basic – Superior – Supreme 0.5435 0.25 0.2065 1.0 or or or 54.35% 25% 20.65% 100% = £0.90 = £2.25 = £1.75 Weighted Average Contribution p.u. = (£0.90x0.5435)+(£2.25 x 0.25) + (£1.75 0.2065) = 48.915p + 56.25p + 36.138p = 141.303p B/E point (units) = £1,000,000 £1.413 = 707,714 (b) Total Sales (units) = 707,714 Basic Superior Supreme = 707,714 0.5435 = 707,714 0.25 = 707,714 0.2065 = 384,643 = 176,928 = 146,143 MPV – Profit Statement Sales Variable Costs Contribution Fixed Costs 44 Basic £ 1,153,929 807,750 346,179 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Superior £ 663,480 265,392 398,088 Supreme £ 730,715 474,965 255,750 Total £ 2,548,124 1,548,107 1,000,017 1,000,000 17 MULTI-PRODUCT BREAK-EVEN ANALYSIS Question 3 (a) Tutoring hours: Accounting Maths English French Contribution per hour – – – – 2,500 3,000 3,500 1,000 10,000 Accounting Maths English French 25% 30% 35% 10% 100% £30 £35 £36 £25 Weighted Average Contribution per hour = (£3025%) + (£3530%) + (£3635%) + (£2510%) = £7.50 + £10.50 + £12.60 + £2.50 = £33.10 B/E Point (hours) = £198,600 £33.10 = 6,000 (b) Hours of Tutoring Contribution Accounting 1,500 Maths 1,800 English 2,100 French 600 1,500 £30 1,800 £35 2,100 £36 600 £25 £45,000 £63,000 £75,600 £15,000 Total 6,000 198,600 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 45 MULTI-PRODUCT BREAK-EVEN ANALYSIS (c) Contribution required = £198,600 + £100,000 = £298,600 Number of hours required = £298,600 £33.10 = 9,021 (nearest hour) Hours per subject: Accounting Maths English French 25% 30% 35% 10% – 2,255 – 2,706 – 3,158 – 902 Profit Statement for Easylearn Ltd Sales Variable Costs Contribution less: Fixed Costs Profit (d) Accounting Maths English French Accounting £ 90,200 22,550 67,650 1,500 1,000 4,500 3,000 10,000 Maths £ 135,300 40,590 94,710 English £ 142,110 28,422 113,688 French £ 31,570 9,020 22,550 15% 10% 45% 30% 100% Weighted Average Contribution per unit = (15%£30) + (10%£35) + (45%£36) + (30%£25) = £4.50 + £3.50 + £16.20 + £7.50 = £31.70 B/E Point (hours) = £198,600 £31.70 = 6,265 46 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Total £ 399,180 100,582 298,598 198,600 99,998 CONTRACT COSTING STATEMENTS Section 3 Contract Costing Statements A long-term contract is defined as: ‘A contract entered into for the design, manufacture or construction of a single substantial asset or the provision of a service where the time taken to complete the contract is such that the contract activity falls into different ac counting periods.’ So a contract is really an example of job costing with the following important features: • it usually takes a long time to complete • it is usually completed at a particular site which is not the contractor’s workplace. Therefore contracts are common in most types of building and construction work, civil engineering, shipbuilding, etc. These contracts pose a particular problem for the accountant, i.e. when should any profit on the contract be recognised in the accounts? The problem arises because there is a conflict between two fundamental accounting concepts or principles, i.e. matching and prudence. The matching or accruals concept states that income and expenditure should be matched against one another and placed in the accounting period to which they relate. Clearly in the case of long-term contracts the costs and indeed the revenues will overlap more than one accounting period. Because a contractor cannot wait until the end of a contract before he receives any income from it, t he work is valued at regular intervals by architects who certify the value of the work at selling price. When this is compared with the costs incurred to date it may well indicate a profit on the contract. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 47 CONTRACT COSTING STATEMENTS However, the prudence concept states that profi ts should not be anticipated and therefore recording profit on an incomplete contract could be construed as breaching that concept. As with many problems where basic principles conflict, the resolution of the problem is something of a compromise. It woul d clearly be unacceptable only to recognise contract profit at the end of the contract. This would mean that in any accounting period the profits would simply relate to those contracts which had finished during the period, irrespective of the length of pe riod of the contracts. It seems that recognition of profit on a contract would be acceptable as long as the concept of prudence is not ignored. Statement of Standard Accounting Practice Number 9 (SSAP 9) gives guidance on this matter. It states that profits should only be recognised on a contract when its outcome can be assessed with reasonable certainty. The profit to be included should be calculated prudently and should reflect the amount of work completed at the accounting date. On the other hand if losses are anticipated they must be recognised in full. The standard does not give unequivocal guidance on a formula to be applied in recognising profit on a contract, and several methods have been developed which meet the underlying principles outlined above. One approach is to determine the expected profit at the conclusion of the contract and recognise a proportion of this figure based on the percentage completion of the contract at the appropriate date. 48 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 CONTRACT COSTING STATEMENTS Consider the following example: At 31 December Year 4 the figures relating to an incomplete contract are as follows: Costs to date Estimated costs to complete Value of certified work Contract price £ 3m 1m 4m 5m We can calculate the expected outcome of the contract as follows: Cost of work completed Add: estimated costs to complete estimated total costs contract price estimated profit Profit Recognised = = £3m £1m £4m £5m £1m Estimated Profit Value of Certified Wor k Contract Price £1m 4m 5m = £800,000 However, if a contract is not close to compl etion the forecast of expected profits may be deemed to be too unreliable to adopt as a basis for profit recognition. In these circumstances the fraction may be based on the notional profit at that point in the life of the contract rather than on the esti mated profit at the end of the contract, i.e. Profit recognised = Work Certified Notional Profit Contract Price What is important is that whichever formula is used takes into account the degree of completion of the contract, which both of the formulae above do. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 49 CONTRACT COSTING STATEMENTS Preparing Contract Accounts Example A builder is currently working on two major contracts, both of which are incomplete at the end of his financial year on 31st March Year 7. The details of the contracts are as follows: Contract A £000s Contract B £000s – – – – 1,620 80 300 20 Costs Incurred During Year to 31st March Year 7 Materials Delivered to Site Wages Paid Salaries Value of Plant Delivered Head Office/Establishment Charges Apportioned 340 180 60 800 40 880 400 160 140 80 Closing Balances at 31st March Year 7 Materials on Site Value of Plant on Site Wages Accrued 80 600 20 – 80 40 800 1,200 3,200 5,800 Opening Balances at 1st April Year 6 Completed Work Materials on Site Plant & Machinery (written down value) Wages Accrued Other Details Value of Work Certified at year end Contract Price Profit is recognised using the following formula: Work Certified Notional Profit Contract Price Prepare accounts for each of the contracts showing clearly the calculations of any profit to be taken for the period. 50 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 CONTRACT COSTING STATEMENTS Solution Contract A a/c 340 Materials Wages Paid add: accrued Salaries Plant & Machinery Head Office costs 180 20 Cost of Contract Profit & Loss a/c (Profit Taken) Profit not Taken Balances b/d: material plant 200 60 800 38 1,438 Balances c/d material plant Cost of contract to date 80 600 758 1,438 758 28 12 800 Work Certified 80 600 Balances b/d wages 800 800 20 Working Notional Profit = Value of Work Certified less cost of contract to date = 800 – 758 = 42 Profit Recognised = 800 42 1,200 = 28 The first step is to charge or debit the Contract a/c with all the costs incurred during the year to date, including any accruals, e.g. in this case wages accrued. However, not all of these costs have been used up in the course of the year so any remaining unused, i.e. material and plant and machinery are carried down as balances to start the next period. This allows the cost of the contract to date to be calculated as the sum of the debit entries less the credit balances being carried forward. The working for the notional profit and the part of it which is going to be recognised can now be done, using whichever formula the question suggests. The profit taken is then debited to the account as it will go to the credit of the Profit & Loss a/c. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 51 CONTRACT COSTING STATEMENTS Contract B a/c Balances b/d Completed Work Material Plant & Machinery Materials Delivered Wages Paid add accrued Salaries Plant & Machinery Head Office Costs 1,620 80 300 880 400 40 Cost of Contract 440 160 140 80 3,700 3,600 Balance b/d: Wages Balances c/d: Plant Cost of Contract to date Work Certified Profit & Loss (Loss written off) 3,600 Balances b/d: plant 80 Balances b/d wages 20 80 3,600 3,700 3,200 400 3,600 40 There are a number of differences to be accounted for with Contract B. Firstly, this is a contract which was already under way at the start of the year and therefore has opening balances which must be entered in the account to start with. Thereafter the procedure is the same, but when we attempt to calculate the notional profit we discover that in fact the contract is showing a loss at this point in time. When that happens we have to write off the whole of the loss (there is no division into part recognised and part not recognised) to comply with the prudence concept. The above question illustrated a number of basic principles of accounting for longterm contracts: • • • • how how how how to to to to deal with opening balances calculate notional profit apply formulae for recognising profit treat anticipated losses. The following questions give you the opportunity to test your understanding of these principles. Some of the questions are based on previous Higher Accounting or Higher Accounting and Finance paper questions. 52 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 CONTRACT COSTING STATEMENTS Question 1 (based on Higher Paper II 1997 Q7) JBC plc, a construction company, undertook a 2 -year contract with Factory Outlets Ltd for a fixed price of £1m. Work began in September of Year 5 and on 1 January Year 6 the following information was available. Direct materials on site Plant at cost on site £10,000 £90,000 At 31 December Year 6 the following information was available. Direct materials sent to site Materials requisitioned from stores Materials returned to stores Direct wages paid Direct expenses Sub-contracting costs £ 350,000 5,000 2,000 337,000 20,000 28,000 Architect’s fees Insurance Hire of special equipment Plant maintenance Value of plant on site at 31 Dec Year 6 Value of work certified by architect Cost of work not yet certified at 31 Dec Year 6 Direct wages due at 31 Dec Year 6 Direct materials on site at 31 Dec Year 6 2,000 1,000 6,000 2,000 78,000 850,000 15,000 3,000 3,000 Overheads are charged at 10% of Direct Wages cost. JBC plc recognises profit using the formula Notional Profit Work Certified Contract Price Prepare the Contract Account at 31 December Year 6 showing clearly the profit recognised. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 53 CONTRACT COSTING STATEMENTS Question 2 (based on Higher 1993 Paper II Q2) Appin Builders plc started work on a 3 -year contract on 1 April Year 2 at a contract price of £5m. On 31 March Year 3 the following information was available. Plant sent to site Materials sent to site Materials delivered from store Sub-contracting costs Direct wages Direct expenses Hire of scaffolding Work certified by architect Cost of work not yet certified Value of plant at 31 March Year 3 Material unused on site at 31 March Year 3 Accrued wages £000s 75 375 50 48 250 85 20 1,000 150 50 23 10 Overheads are recognised at 10% of Direct Material costs (including sub -contract costs). Appin Builders plc recognise profit using the formula Notional Profit Work Certified Contract Price Prepare the Contract Account for year ended 31 Ma rch Year 3. 54 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 CONTRACT COSTING STATEMENTS Question 3 (based on Higher 1992 Paper II Q4(a)) Contract Builders plc undertook a 3-year contract in January Year 4 for a fixed price of £4,800,000. On 31 December Year 4 the following information was available relating to the first year of the contract. Materials sent to site Direct wages paid Direct expenses Overhead charged Plant hire £000s 535 380 180 200 110 At 31 Dec Year 4 Material on site Wages accrued Value of work certified Cost of work completed but not certified 10 20 1,000 165 Prepare the Contract Account for the year ended 31 December Year 4. MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 55 CONTRACT COSTING STATEMENTS Question 4 The following information relates to Contract 654 of Builders plc at 31 December Year 5. Materials sent to site Materials delivered from store Materials transferred to other contracts Direct wages Plant purchased Plant transferred from other contracts Sub-contract costs Site expenses £ 108,400 1,320 3,100 84,310 25,500 10,000 40,137 10,172 At 31 December Year 5 Materials on site Value of plant on site Accrued wages Site expenses prepaid Value of work certified Contract price 36,680 29,500 1,840 1,014 420,000 560,000 Overheads are charged at 10% of wages cost. Profits are recognised using the formula Notional Profit Work Certified Contract Price Prepare the Contract 654 Account for year ended 31 December Year 5. 56 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 CONTRACT COSTING STATEMENTS Solutions Question 1 £ 10,000 Material b/f Plant b/f Material sent to site Materials taken from stores Direct wages paid add: accrued Direct expenses Sub-contract costs Architect’s fees Insurance Hire of equipment Plant maintenance Overheads 90,000 350,000 5,000 337,000 3,000 20,000 28,000 2,000 1,000 6,000 2,000 34,000 888,000 Cost of contract Profit taken 805,000 51,000 Profit not taken 9,000 865,000 3,000 78,000 805,000 ………. 888,000 Value of work certified Cost of work not certified 850,000 15,000 ………. 865,000 £850,000 – (£805,000 – £15,000) £850,000 – £790,000 £60,000 Notional profit = = = Profit taken = £60,000 = Material returned to stores Material c/d Plant c/d Cost of contract £ 2,000 850,000 1,000,000 £51,000 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 57 CONTRACT COSTING STATEMENTS Question 2 Material sent to site Material from store Sub-contract costs Plant sent to site Direct wages Add: accrued Direct expenses Hire of scaffolding Overheads (10% 450) Contract a/c £000s 375 50 48 75 250 10 260 85 20 45 958 Cost of contract Profit taken Profit not taken 885 Value of work certified 53 Cost of work not certified 212 £1,150 Notional Profit = 1,000 – (885 – 150) = 1,000 – 735 = 265 Profit Taken = 1,000 265 5,000 = 53 58 Material c/d Plant c/d Cost of contract MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 £000s 23 50 885 … 958 1,000 150 …… £1,150 CONTRACT COSTING STATEMENTS Question 3 Contract a/c £000s 535 380 20 400 180 110 200 1,425 Material Wages add: accrued Direct expenses Plant hire Overheads Cost of contract 1,415 …… 1,415 Profit/loss on contract Loss Material c/d Cost of contract £000s 10 1,415 …… 1,425 Value of work certified 1,000 Value of work not certified 165 Loss on contract 250 1,415 = 1,000 – (1,415 – 165) = 1,000 – 1,250 = 250 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 59 CONTRACT COSTING STATEMENTS Question 4 Contract 654 a/c Material sent to site Material from store Direct wages add: accrued Plant purchased Plant transferred Sub-contract costs Site expenses less: prepaid Overheads £ 108,400 1,320 84,310 1,840 10,172 1,014 Cost of contract Profit taken Profit not taken 86,150 25,500 10,000 40,137 9,158 8,615 289,280 220,000 150,000 50,000 420,000 Notional profit = £420,000 – £220,000 = £200,000 Profit taken = £200,000 = £150,000 60 MANAGERIAL ACCOUNTING (AH) © Learning and Teaching Scotland 2005 Material transferred Material c/d Plant c/d Cost of contract 420,000 560,000 £ 3,100 36,680 29,500 220,000 …… 289,280 Work certified 420,000 …… 420,000