DOCUMENTATION OF CHEMICAL HYGIENE TRAINING Kansas State University

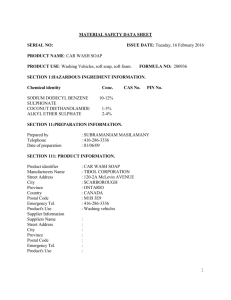

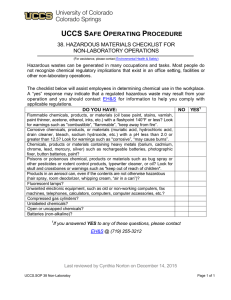

advertisement