Where Broiler Production is Heading in Brazil Antônio Mário Penz Junior

advertisement

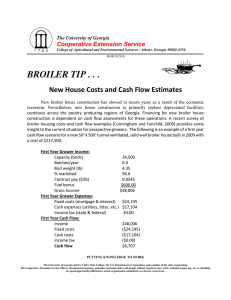

Where Broiler Production is Heading in Brazil Antônio Mário Penz Junior Daniel Gonçalves Bruno Cargill Animal Nutrition Introduction The advances of the Brazilian poultry industry during the last four decades launched the country to a lead world position. Currently, Brazil is the third and seventh larger broiler meat and egg producer, respectively. Also, the country had been the larger world broiler meat exporter since 2004. This strong development came in line with the animal nutrition industry. The objective of the current text is reviewing the main factors that led Brazilian poultry industry to a such position, to evaluate some tendencies for the upcoming years and also to discuss the main challenges for the future. History of Brazilian Poultry Industry The begging of industrial poultry production in Brazil can be traced back to the 1950 decade. During that period, an agreement was signed with the US (Project ETA 42), when a commission brought pure breeds of poultry with the objective to promote genetic improvement (Patrício, 2011). It was observed in the states of São Paulo, Rio de Janeiro and Minas Gerais the first attempts to improve the activity by means of technological development (Dambrós Junior, 2010). Integration, a model largely used in the country, was first observed in the southern state of Santa Catarina, during early 1960’s, stimulated by a large availability of credit for long term investments, associated with technical assistance provided by the integration system (Dambrós Junior, 2010; Patrício, 2011). The consolidation of Brazilian poultry industry started during the 1980’s, when a huge increase in exported broiler meat volume coupled with the beginning of cuts exports to Japan (Patrício, 2011), despite the negative influence of internal economic stagnation on domestic consumption and, consequently, to the performance of the industry. During the 1990’s, more changes came to the industry (mainly the broiler meat) to higher technical and productive levels. Consequently, the competitiveness of the industry increased, with an increase of the efficiency and the use of new technologies and the reduction of the cost of production. Those transformations observed during the 90’s were driven mainly by the economic opening, stabilization of inflation and increase in the income of the population. Also, it was observed a process of internationalization and acquisition of companies mainly in south of Brazil (Dambrós Junior, 2010; Patrício, 2011). During late 1990’s, Brazil started to export processed chicken products to Europe, giving special attention to characteristics related to performance and meat yield (Mior, 2005). Current situation of Brazilian poultry production Brazilian poultry industry currently provides jobs for more than 4.5 million people and is associated to 1.5% of the gross domestic product (GDP). Currently, the country is the third largest world broiler producer, very close to the second one (China). In 2010 Brazil produced 12.23 million tons of broiler meat, whereas China and USA (lead world producer) were responsible for 12.55 and 16.563 million tons, respectively (UBABEF, 2012). Furthermore, an expressive egg production was observed at the same time. According to Mendes (2010), Brazil is the seventh largest world egg producer. In 2011, 2.7 billion dozens were produced in the country, with 4.3% increase in relation to the previous year (IBGE, 2012). As the the largest broiler meat exporter (Figure 1), in 2010 Brazil exported more than 3.8 million tons, to 150 countries. Despite this expressive number, only 31% of the production was exported, whereas domestic consumption accounted for 69% of the total production. Figure 1. World broiler meat exports in 2010 (Source: UBABEF (2012) In line with the massive quantitative increase observed in the production of Brazilian poultry industry, its efficiency had improved significantly, too. From 1990 to 2009, Patrício (2011) analyzed production data of broiler companies from all over the country (in total 4.6 billion birds were evaluated). The author concluded that daily weight gain improved 30.0%, feed conversion rate improvement decreased the cost of each kg of live weight in R$ 0.205 (U$ 0.101), live weight increased in 28.4% and livability reduced 2.0%. Also, the gains in terms of performance approached the full genetic potential of poultry during this period, in comparison to previous years. According to this study, birds achieved 85% of the genetic potential of body weight gain and 93.4% of the feed conversion rate. Drivers of Brazilian poultry production and poultry feed industries for the upcoming years Productivity growth of grains and broiler meat Besides social, economic and politic factors quoted previously, other factors are associated to the Brazilian poultry industry productivity and competitiveness. They are related to the climate of the country (allowing lower costs on thermal control of poultry houses), proportional to other countries low labor cost, fast assimilation of new technologies, facilitated by the integration system, presence of a modern and structured industrial park, associated with a relatively low production cost of equipment and inputs for the whole production chain. All together help to decrease the production cost, encouraging competitive exports (Mendes, 2010). Another major driver of the growth of poultry industry is the availability of grains, mainly corn and soybean, the main vegetal constituents of Brazilian poultry diets. Figures 2 and 3 highlight the evolution of Brazilian productivity of these crops both in terms of total amount produced and yield of the grains from 1986 to 2010. 6 3 Figure 2 – Corn production in Brazil: Production (tons x 10 ), yield (Hectogram x 10 /hectare) 6 and area harvested (Hectare x 10 ).Source: FAO, 2012 6 Figure 3 – Soybean production in Brazil: Production (tons x 10 ), yield (Hectogram x 3 6 10 /hectare) and area harvested (Hectare x 10 ). Source: FAO, 2012 According to estimates from Brazilian Ministry of Agriculture, Livestock and Food Supply (MAPA), the forecasts for the country´s increase in corn and soybean production are 2.0 and 2.5%, per year, respectively, from 2011 to 2020/2021. The same source suggests for broiler meat production, domestic consumption and exports increases of 2.6, 2.5 e 2.9%, per year, respectively, during the same period (Table 1) (MAPA, 2011). Factors such as the wide extension of land and huge availability of water (Figure 4) favor the grain production of Brazil in the coming years. Grains Broiler Meat Table 1. Production, domestic consumption and exports of broiler meat and production of corn and soybean in Brazil during 2010/2011 and projections for growth until 2021. 2010/2011 2020/2021 Increase (%/year) Production 12.23 15.74 2.60% Domestic consumption 8.41 10.57 2.50% Exports 3.82 5.17 2.90% Corn 52.85 65.54 2.00% 68.72 86.53 2.30% Soybean 6 * Unity = tons x 10 * Source = MAPA, 2011 Figure 4 – Availability of renewable 3 m /inhabitant/year). Source = FAO, 2012 water resources (surface and groundwater, Focus on food safety and feed The concept that feed and food safety are direct linked is increasing every year (Hartog, 2003). Hence, the search towards a better management of feed quality is a tendency which is expected to rise in the next years. This can be evidenced by the increasing the use of Good Manufacturing Practice (GMP) and Hazard Analysis and Critical Control Point (HACCP) systems by the industry, supported by govern requirements. GMP is a system to ensure that products, processes, services and buildings meet food safety (Anaruma, 2009), quality and legal requirements. Restrictions on the use of antimicrobial agents as growth promoters The restrictions on the use of antimicrobials as growth promoters (AGP), due to consumer demands and to recent understanding of the interaction between nutrients and intestinal health, intestinal microbiota, and immune system, are a challenge for the Brazilian animal feed industry and it will require that nutritionists change their paradigms. Brazilian regulatory agencies are evaluating all the antimicrobial agents which can pose potential hazards for human health from the scientific point of view, through the creation of Work Groups (GT) by Brazilian Ministry of Agriculture, Livestock and Food Supply (MAPA). Already, some agents had been banned as growth enhancers. In 2004 it was olaquindox, in 2005 it was carbadox and in 2012 it was spiramycin and erythromycin. Focus on sustainability The term sustainability encompasses the actions and activities which aim to supply human economic, environmental and social needs, compromised with the long-term maintenance of natural resources for the future generations (Azevedo, 2012). When it comes to poultry nutrition, sustainability is related not only with the formulation of least cost diets but diets that also optimize the economic performance of the flocks. Thus, there will be an increase tendency to use some new technologies. The analysis of each feedstuff batch to allow more accurate feed formulation is limited to wet chemistry techniques, which are usually expensive and timeconsuming. This limitation may be overcame by the use of NIRS (Near Infrared Reflectance Spectroscopy), that allows immediate analysis of the energy value as well as amino acid composition and digestibility of each feedstuff batch. In addition, this technology can be used to analyze additives, and therapeutic compounds (Penz-Jr et al., 2009). The design of new feed mills will have to consider the use of NIRS, providing more storage, dosing, and milling flexibility, which will allow savings that are unfeasible today due to the lack of physical infrastructure. The progress in information technology will allow the application of growth models and several related mathematical equations, which will estimate animal growth according to rearing conditions. The ultimate objective will be optimizing the rearing process, as a function of the company’s or farmer’s needs. Feed intake and broiler growth prediction models under different scenarios, as those developed by Emmans, Fisher and Gous, will allow better definition of strategies that will favor production efficiency. Also, Gous (2005) mentioned that the idea of abandoning the convention formulation proposal and adopting a dynamic proposal, based on several factors, in addition to those considered in least-cost formulations, is not new. In order to decrease the impact of poultry industry on the environment, a growing trend of Brazilian feed industry within the next few years will be the formulation with higher quality raw materials, avoiding larger safety margins by means of a better understanding of the nutritional content of ingredients. Furthermore advances in the knowledge of the effects of particle size and feed processing technologies, such as pelleting and expander on the digestibility of nutrients for birds, will enable to improve the retention of feed nutrients by poultry, decreasing their excretion to the environment. In this context, enzymes will be increasingly used, as they improve ingredient digestibility and nutrient absorption, as well as reduce the detrimental effects of anti-nutritional factors, thereby allowing higher flexibility in the use of feedstuffs, reducing feed costs and pollutant excretion in animal waste (Penz-Jr and Bruno, 2010). New mineral sources, with higher bioavailability are under evaluation and it will be more frequently used in feeds. Focus on biosafety One of the keys to the current status of Brazilian poultry industry is the advances observed in terms of biosafety within the last years, giving credibility to Brazilian poultry products in high-demand markets, such as Europe, assuring Brazilian leadership in exports. One of the milestones of the evolution of biosafety in Brazil is the launching of the National Plan of Poultry Health (PNSA), by the Brazilian government, back in 1994. The PNSA has many objective such as the control of the entrance of products from animal origin inside the country, standardized sanitation and disinfection procedures at farm level, prophylactic control and biosafety standards (monitoring flocks and certificating those free from specific diseases), establishing actions to ensure flock health, according to the risk of occurrence of diseases and a plan of contingency in case of outbreaks (Gonçalves et al, 2012; Santos and Falconi, 2007). According to Mendes (2010), the tendency within the next years will be the increase in investments in biosafety and quality programs, important concerns to maintain the leadership position of Brazil within the world market of broiler meat. Bottlenecks of Brazilian poultry industry Despite the competitiveness of poultry industry, the country must tackle some issues that still hinder its growth. One major problem is the logistics infrastructure of the country, which leads to increases in costs due to losses in production, lack of adequate logistic conditions, affecting both the access of grains (corn and soybean meal) to the poultry production areas and the transport of broiler meat to the ports, where they are sent for export. Also, the sharp increase in raw material costs observed recently is a major concern for the poultry industry. During the last months, feed cost increased, in average, 30%. Once in Brazil 85% of feed cost is due to corn and soybean prices, increase the prices of these grains are associate with a flattening of profit margins of producers (Mendes et al, 2012). Other issues affecting Brazilian poultry industry are associated with non-uniform quality of the educational system, lack of access to capital by the producer, the high cost of credit, high social and labor charges, high tax burden, bureaucracy and high costs of regulation (Mendes, 2010). Conclusions Technical, social and economic advances observed in Brazil throughout the last four decades led the country to be the third and seventh largest producer of broiler meat and eggs, respectively, and the largest world broiler meat exporter. Poultry nutrition and genetic advances are supporting such strong growth. Still, there is enough room for increases in corn and soybean production, and to the production, domestic consumption and exports of broiler meat, too. A tendency of consolidation for the poultry industry is expected within the next years, with a focus on feed quality and food safety. Regarding feed production, technologies associated with decreasing safety margins, with emphasis on economic and environmental sustainability will be used more frequently. However, some bottlenecks still hinder its growth such as problems in logistics infrastructure, low quality of the educational system, lack of access to capital by the producer, the high cost of credit, high social and labor charges, high tax burden, bureaucracy and high costs of regulation. References Anaruma, R.J. Site da Associação Brasileira de Zootecnistas. 2009. http://www.abz.org.br/publicacoes-tecnicas/anais-zootec/palestras/22277-Boasprticas-fabricao-APPCC-estabelecimento-produtos-destinados-alimentaoanimal.html Azevedo, D. As chaves da sustentabilidade. Rev. Aveworld, N° 57, abr/mai p. 2832, 2012. Dambrós Junior, D. A avicultura no Brasil. 2010. http://www.cnpsa.embrapa.br/cias/index.php?option=com_content&view=article&id =13&Itemid=15 FAO, 2012. http://www.fao.org/corp/statistics/en/ Gonçalves, F.M.; Domingues, L.S.P.; Oliveira, C.O.; Souza, D.M.; Rutz, F. PNSA: O que mudou 17 anos depois? Rev. Aveworld, 56:40-44, fev/mar 2012. Gous, R.M. Determining the Feed Composition and Feeding Program that will Optimize the Performance of a Broiler Flock. Proceedings of 15th Symposium on Poultry Nutrition. Balatonfured, Hungary. p. 412-420, 2005. Hartog, J. den. Aplicação de HACCP na produção de dietas para animais. Seminário realizado em 27/10/2003 In: Relatório PAT 2003. Embrapa Suínos e Aves. Concórdia SC. 2003. IBGE – Instituto Brasileiro de Geografia e Estatística. Abates de frangos e suínos e produção de leite e ovos crescem em 2011. 2012. http://www.ibge.gov.br/home/presidencia/noticias/noticia_visualiza.php?id_noticia= 2107&id_pagina=1 MAPA - MINISTÉRIO DA AGRICULTURA, PECUÁRIA E ABASTECIMENTO. BRASIL PROJEÇÕES DO AGRONEGÓCIO 2010/2011 a 2020/2021. Brasilia, June, 2011 Mendes, A.A. Avicultura Brasileira: Avanços, gargalos e desafios. In: Anais da Conferência FACTA 2010 de Ciência e Tecnologia Avícolas. Santos, SP, Brasil. p.123-138. 2010 Mendes, L.H.; Kiss, J.; Veloso, T. Custos espremem margens em aves e suínos no Brasil. 2012. http://sindiracoes.org.br/custos-espremem-margens-em-aves-esuinos-no-brasil Mior, L.C. Agricultores Familiares, Agroindústrias e Redes de Desenvolvimento Rural. Chapecó:Argos. 338 p. 2005. Patrício, I.S. Vinte anos do desempenho de frangos nas condições brasileiras. In: Anais da Conferência FACTA 2011 de Ciência e Tecnologia Avícolas. Santos, SP, Brasil, p. 91-112, 2011. Penz-Jr A.M., Figueiredo, A.N., Bruno, D.G. Nutrição de frangos - Mudanças de paradigmas para o futuro. In: Anais da Conferência FACTA 2009 de Ciência e Tecnologia Avícolas. Anais... Porto Alegre, RS, 2009. Penz-Jr AM, Bruno, DG. Nutrição e meio ambiente. O que deve mudar na nutrição para atender estas novas exigências? In: Anais da Conferência FACTA 2010 de Ciência e Tecnologia Avícolas, p.17-34, 2010. Santos, C.A.; Falconi, F.A. Relationship between Ecological Concepts and Biosafety in Broiler Breeder Farms. Brazilian Journal of Poultry Science. 9:3, p.151-155. 2007. UBABEF. Relatório anual 2010/2011 da União Brasileira de Avicultura. São Paulo, 72p. 2012.