Pharmaceutical supply chains: key issues and strategies for optimisation Nilay Shah

advertisement

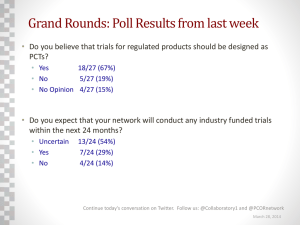

Pharmaceutical supply chains: key issues and strategies for optimisation Nilay Shah Centre for Process Systems Engineering Imperial College London 1 Outline • • • • • Some conclusions Background The pharmaceutical industry supply and value chains Supply chain issues Primary manufacturing: – Risk management – Process development • Challenges for the future 2 Some conclusions • The pharmaceutical supply chain is very complex, with many interacting facets – Difficult to generate radical improvements quickly – Piecemeal approaches (e.g. improved logistics) will generate incremental benefits • Current process technology is one of the main supply chain bottlenecks – Many “built-in” inefficiencies that constrain performance – Not a very responsive system • Current models in the research community are too “companycentric” – Future models need to consider a holistic view of an extended supply chain of specialist agents • • • • • IP generators Testing specialists Contract manufacturers Logistics providers Healthcare providers/consumers 3 Trends in the pharmaceutical and related industries • Time to market is the key metric • R&D productivity (numbers of new chemical entities registered per unit amount of investment) is declining • effective patent lives are shortening • even while active, patents provide lower barriers to entry • many cheaper product substitutes in many therapeutic areas – alternative compounds (“me-too drugs”) – off-patent generics • payers of healthcare exerting strong price pressure and influencing prescribing practices • for approval, new drugs must: – address new therapeutic areas; or – have very significant cost or health benefits over existing treatments. 4 Value growth 140 119.1 120 100 $ bn 86.3 80 60 50.6 US Japan Europe 40 20 14.7 10.1 17.5 0 1981 1999 5 Product pipeline Discovery PreClinical Clinical Trials Launch Commercial 6 Compound success rates by stages 7 Decreasing R&D efficiency Total Spending on R&D $bn New Drug Applications to FDA 8 The value chain The “supply chain” • • • • Discovery generates candidate molecules Variety of trials evaluates efficacy and safety Complex regulation process Manufacturing: – Primary manufacture of active ingredient (usually 1-2 sites) – Secondary manufacture – production of actual doses (up to 20 sites) – Often geographically separate for taxation, political etc reasons – Complex logistics • Distribution – Supply chains often global – Many third parties become involved • Distributors, health authorities etc. • Retail – Pharmacies, doctors and hospitals are main outlets for ethical drugs 9 The value chain Research & development 15% Primary manufacturing 5 - 10% Secondary mfg/packaging 15 - 20% Marketing/distribution 30 - 35% General administration 5% Profit 20% Total 100% 10 The supply chain • Difficult to get value from early stage discovery/trials processes (cf. decreasing R&D efficiency, recent mergers) – Can Process Systems Engineering techniques help generate more focussed searches/libraries? • Companies view supply chain differently: – was a means of getting product to where it was needed – now a means of delivering additional value • (At least) three interesting problems: – Process development and design – Planning of trials/testing and capacity under uncertainty – “Classical” Supply chain planning and management 11 Process development and design • Problems: – Process chemistry, solvent and catalyst choices result in • Low material efficiencies (of order 1%) – Inefficient, very traditional batch manufacturing processes result in • Low velocity ratio or value-added time (of order 1%) – Sub-optimal design of drug delivery systems results in • Low bio-availability where required (of order 1% for traditional formulations e.g. pills) • 1mg delivered to target area: – may require 10kg of materials overall! – ties up a considerable amount of capital! 12 One stage: typical overall mass balance Effluent 42% Landfill 9% Incineration 6% Material in 100% Manufacture Product 10% Recovery/recycle 29% Solvent ‘loss’ 2% By-product sold 2% 13 Typical batch process Measure React 12 hr Separate Purify 12 hr 2 days Working capital for 4 days How long does the conversion process really take? Product 12 hr Store Store 18 hr Separate 12 hr Low value-added time! 14 Longer time: higher costs and lower quality Cost Time Quality 15 Process development and design • Many research groups now working in relevant fields • More of a design than operations issue – Significant improvements in material efficiencies required • Involvement of process (systems) engineering at early stage – – – – Model-based design True catalysis rather than stoichiometric reagents Optimise overall material efficiency rather than reaction yields Large reductions in solvents » Need for better heat transfer technology – Improve manufacturing performance • • • • Run processes as close to intrinsic rates as possible Use small-scale continuous processing where possible Avoid stage-to-stage isolation where possible Cleaning and changeovers! (see later) – Improve drug delivery to be more targeted (new field) 16 The supply chain • Difficult to get value from early stage discovery/trials processes (cf. decreasing R&D efficiency, recent mergers) – Can Process Systems Engineering techniques help generate more focussed searches/libraries? • Companies view supply chain differently: – was a means of getting product to where it was needed – now a means of delivering additional value • (At least) three interesting problems: – Process development and design – Planning of trials/testing and capacity under uncertainty – “Classical” supply chain planning and management 17 Testing and capacity planning • “Traditional” sequential approach: Tests for activity fail pass Tests for toxicity fail pass Tests for efficacy Tests characterised by: Duration* Cost (in-house or outsourced)* Resource requirements* Hard precedence constraints Soft/conditional precedence constraints Probability of success *may be distributions rather than known fail Sequential approach conserves resources, but may increase time to market 18 Optimised planning of tests (Grossmann & co-workers, Pekny, Reklaitis and co-workers) • Rather than follow sequential approach, approach from a resource-constrained scheduling perspective • Some tasks have conditional dependence • Degrees of freedom on task precedence • Optimisation balances: – Risk of unnecessary expenditure – Potential rewards of coming to market earlier – Resource constraints and outsourcing costs • Resource-constrained stochastic optimisation problem – Conservative approaches (always feasible) – Hybrid simulation-optimisation approaches 19 Capacity and portfolio planning under uncertainty • What technology/capacity, where, when (plant fabrication lead times!), whether to outsource • Products to prioritise in the R&D pipeline to structure the future portfolio optimally • Most severe for pharmaceuticals: – capacity requirements very dependent on outcome of clinical trials, registration etc. • Extreme cases – pessimistic: no investment and many successful products: severe capacity limitations – optimistic: investment → plenty of capacity but no new products → patent expiry issues • Need for systematic way to balance risks 20 Product Pipeline and Capacity Plans demand materials entering CT promising CT results current products How to: • allocate capacity between products ? • plan capacity investment ? successful product life-cycle time 21 Clinical trials More than two outcomes! clinical trials Deterministic stage Success High 0.10 High Success Target 0.40 Low 0.9 0.50 0.60 0.95 Launch Failure 0.05 Minimum 0.10 Failure Failure 0.1 Phase II (~2 year) Stage 1 0.30 Not Considered yet in this work Phase III 3-5years Stage 2 & 3 Registration (1 year) 22 Scenario Tree & Clinical Trial Outcomes 1 Clinical Trial Outcomes 1 H – High Success T – Target L – Low F – Failure 1 HHT Scn 2 HH HHHT +1 Stochastic Product C2 2 HT 3 HL 4 HF HTL 7 +1 Stochastic Product C4 Periods 10 HTLF +1 Stochastic Product C3 Scn 63 HFFL 16 Stage 2 Stage 1 Scn 28 29-32 H 1 Deterministic Product C1 1 1-4 61-64 HFF Stage 3 20 Stage 4 30 40 23 Results NPV profile 24 Strategy matrix: risk analysis Worst Case ( Exposure ) NPVs (-100) Scenarios Legend Ab Aa Bc Ba Bb C D Ea Eb Fb Fa G H (-130) (INCREASING RISK) (-160) 30% 15% 0% Probability of Losses 25 Combined testing and capacity planning (Grossmann and co-workers) • Interesting way forward – Holistic analysis of value chain • Better synchronisation leads to material being ready if tests are successful – Avoid shortage of material for clinical trials • Basis for future work; extensions: – Management of risk is a key feature • Real options techniques should be relevant – Needs to take account of global trading structures – Needs to include creative possibilities in model • e.g. placing of low-commitment options with subcontractors – Needs to take more extended view of supply chain 26 The supply chain • Difficult to get value from early stage discovery/trials processes (cf. decreasing R&D efficiency, recent mergers) – Can Process Systems Engineering techniques help generate more focussed searches/libraries? • Companies view supply chain differently: – was a means of getting product to where it was needed – now a means of delivering additional value • (At least) three interesting problems: – Process development and design – Planning of trials/testing and capacity under uncertainty – “Classical” Supply chain planning and management 27 “Classical” supply chain planning and management • Some performance measures – – – – – Pipeline stocks may be 30-110% of annual demand Finished good stocks 10-50% (4-26 weeks) of annual demand Supply chain cycle times of order 1000s of hours Value added times 0.3-5% of cycle times Supply chain costs overtaking R&D costs • What can better operations deliver? – 30% stock reduction – 30% increase in value-added time – 7% reduction in supply chain costs • Benefits of improved operation for one large drug: – $30m one-off – $8-16m p.a. 28 Issues/Structure • Primary production processes usually “slow” and “unresponsive” – – – – – lowish yield labour- and time-intensive can take 30-200 days from end to end many QA steps along the way long changeovers (one to four weeks) force campaign operation • Secondary processing often geographically separate from primary – transportation lags, but sensible use of API storage can mitigate • Secondary processing sometimes serves market directly, but more commonly: – regional storage locations/wholesalers and other agents • Long supply chain cycle times (60-300 days) – Many delays in process – poor responsiveness to changes in demands – High service levels required → high stocks 29 Dynamic supply chain analysis • Dynamic analysis of existing supply chains generates considerable insight – Understand relationship between policies/parameters and performance measures • Use a generic modelling approach which captures physical and business processes • Library of supply chain objects based on generic node: Inbound material management Handling/ processing/ conversion Outbound material management 30 One SKU: forward look 3.50E+06 100 3.00E+06 2.50E+06 99.8 Average Inventory 2.00E+06 Safety Stock High Confidence 1.50E+06 Low Confidence 99.6 1.00E+06 99.4 5.00E+05 4 Nov-01 5 6 7 8 Weeks Safety Stock Dec-01 Oct-01 Sep-01 Jul-01 Aug-01 Jun-01 Apr-01 May-01 Mar-01 Jan-01 Feb-01 Nov-00 Dec-00 Oct-00 Sep-00 Jul-00 Aug-00 Jun-00 Apr-00 May-00 Mar-00 Jan-00 Feb-00 0.00E+00 Customer service level 0.7 2.50E+06 0.6 2.00E+06 0.5 1.50E+06 0.4 0.3 1.00E+06 0.2 5.00E+05 0.1 0 0.00E+00 4 5 6 7 Weeks Safety Stock Expected number of stock out (per period) 8 4 5 6 7 8 Weeks Safety Stock Average inventory kept 31 A particular market • • • • End-user demand fairly steady, but Internal processes create additional dynamics Need for high safety stocks to buffer Aim for high service levels – high perceived opportunity cost • What if demand was more in line with end-use ? 32 Demand profiles 700000 600000 500000 400000 P a xil2 01 00(Ac tu a l) (Fitting) 300000 Prediction 200000 100000 Sep-00 Jul-00 May-00 Mar-00 Jan-00 Nov-99 Sep-99 Jul-99 May-99 Mar-99 Jan-99 Nov-98 Sep-98 Jul-98 May-98 Mar-98 Jan-98 Nov-97 Sep-97 Jul-97 May-97 Mar-97 Jan-97 0 includes our forecasting algorithms for future forecasts – these pick up key dynamics 33 Current policy: performance Service Level Average stock 100 800000 98 700000 600000 % packs 96 94 92 500000 400000 300000 90 200000 2 3 4 5 weeks cover 6 7 8 2 3 4 5 6 7 weeks cover 34 8 Smoothed performance Average stock 102 800000 100 700000 98 600000 packs % Service Level 96 94 500000 400000 92 300000 90 200000 2 3 4 5 weeks cover 6 7 8 2 3 4 5 6 7 8 weeks cover 35 Comparison of two supply chain responses • Pharmaceutical process – primary production has five synthesis stages – two secondary manufacturing sites • Two different process principles – Case A: QC at the end of each synthesis stage and the final products – Case B: QC for the product of the primary process (AI), and the final product 36 Inventory variation for one SKU Base Case for Pack C Results for Pack C with QC (Monte Carlo 400 simulations) 300000 300000 mean quantity mean quantity safety stock safety stock 250000 95% upper confidence 250000 95% upper confidence 95% lower confidence Pack C stock level / packs Pack C stock level / packs 95% lower confidence 200000 150000 100000 200000 150000 100000 50000 50000 0 0 0 0 20 40 60 80 100 20 40 60 80 100 Time / weeks Time / weeks Case A Case B 37 SCM more generally… • Re-emphasise need for better process technology for 10 manufacture • Currently push-based at back-end of supply chain: – hard to be responsive – complicated dynamics – can’t exploit short-term opportunities (e.g. tenders) • aim for much faster processes • avoid too many quality control interventions and isolations • aim for easy to clean/reconfigure (disposable?) plants – Move towards short-term scheduling • Interim: – optimise campaign planning (cf. literature of 1980s!) – optimise changeovers using SMED concepts 38 SCM more generally (cont’d) … • Current SCM methodologies involve a degree of decentralisation – – – – Regional demand management Primary or secondary planning Subcontractors Robust, but built-in inefficiencies • Need for more integrated, seamless planning – Very large-scale multi-site problems with large geographical span – Looser alliances may arise (e.g. semiconductors, computers) • Increased co-ordination problems – Tailored optimisation algorithms will be required – Need to build in robustness (cf. work of Maranas and co-workers, Sahinidis and co-workers) 39 Some conclusions • The pharmaceutical supply chain is very complex, with many interacting facets – Difficult to generate radical improvements quickly – Piecemeal approaches (e.g. improved logistics) will generate incremental benefits • Current process technology is one of the main supply chain bottlenecks – Many “built-in” inefficiencies that constrain performance – Not a very responsive system • Current models in the research community are too “companycentric” – Future models need to consider a holistic view of an extended supply chain of specialist agents • • • • • IP generators Testing specialists Contract manufacturers Logistics providers Healthcare providers/consumers 40 Future perspectives • Industry – at crossroads? • “Big is beautiful” v. alliances of specialists • Latter will need next generation of supply chain tools • Products – More complex, more synthesis stages, more chiral, more active, smaller lot-sizes – Better drug delivery mechanisms • Smaller dosages – Likely to become more specialised • Local solutions to local problems • Genetic research leading to target sub-populations • Current manufacturing and supply chain poorly suited to this – Economies of scale 1-2 orders of magnitude out – Rapid response vaccines (civilian and military) – More crop-derived products – new supply chains 41 Acknowledgements • Members of Britest project (www.britest.co.uk) • UK Engineering and Physical Sciences Research Council • Fellow researchers: Gabriel Gatica, Jonatan Gjerdrum, Wing Yan Hung, Rodney Johnson, Lazaros Papageorgiou, Nouri Samsatli, Mona Sharif, Trevor Tsang 42