Sustainability Method of Solid Waste Management: Anaerobic Digestion for FWL Ms. K.V.Navale

advertisement

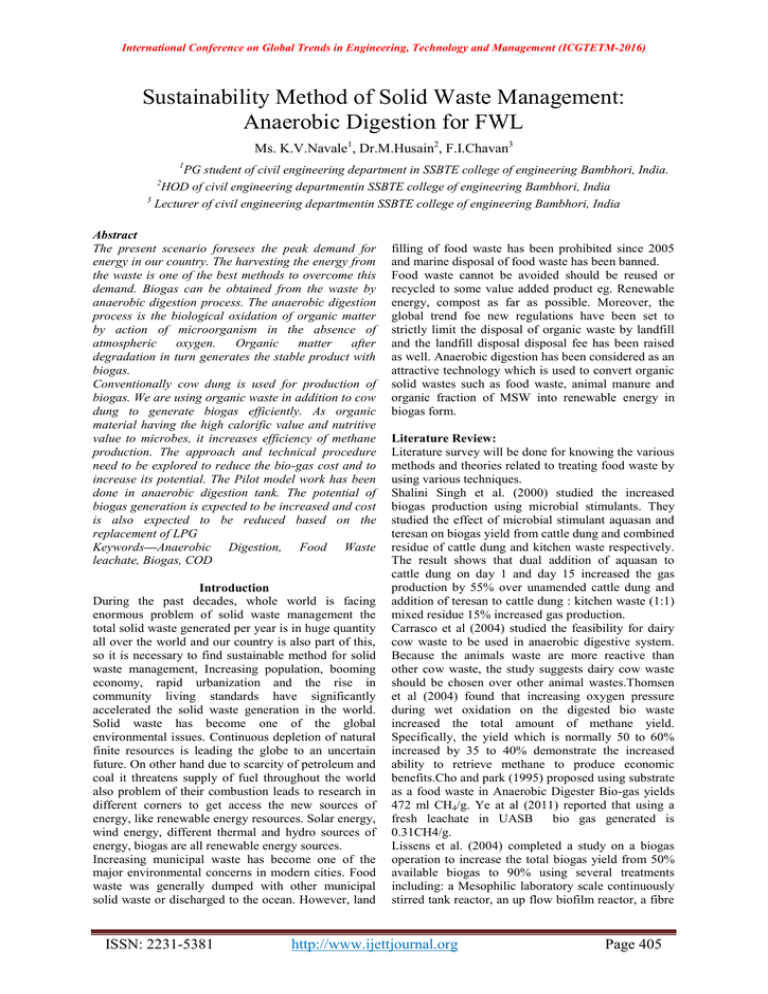

International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) Sustainability Method of Solid Waste Management: Anaerobic Digestion for FWL Ms. K.V.Navale1, Dr.M.Husain2, F.I.Chavan3 1 PG student of civil engineering department in SSBTE college of engineering Bambhori, India. HOD of civil engineering departmentin SSBTE college of engineering Bambhori, India 3 Lecturer of civil engineering departmentin SSBTE college of engineering Bambhori, India 2 Abstract The present scenario foresees the peak demand for energy in our country. The harvesting the energy from the waste is one of the best methods to overcome this demand. Biogas can be obtained from the waste by anaerobic digestion process. The anaerobic digestion process is the biological oxidation of organic matter by action of microorganism in the absence of atmospheric oxygen. Organic matter after degradation in turn generates the stable product with biogas. Conventionally cow dung is used for production of biogas. We are using organic waste in addition to cow dung to generate biogas efficiently. As organic material having the high calorific value and nutritive value to microbes, it increases efficiency of methane production. The approach and technical procedure need to be explored to reduce the bio-gas cost and to increase its potential. The Pilot model work has been done in anaerobic digestion tank. The potential of biogas generation is expected to be increased and cost is also expected to be reduced based on the replacement of LPG Keywords—Anaerobic Digestion, Food Waste leachate, Biogas, COD Introduction During the past decades, whole world is facing enormous problem of solid waste management the total solid waste generated per year is in huge quantity all over the world and our country is also part of this, so it is necessary to find sustainable method for solid waste management, Increasing population, booming economy, rapid urbanization and the rise in community living standards have significantly accelerated the solid waste generation in the world. Solid waste has become one of the global environmental issues. Continuous depletion of natural finite resources is leading the globe to an uncertain future. On other hand due to scarcity of petroleum and coal it threatens supply of fuel throughout the world also problem of their combustion leads to research in different corners to get access the new sources of energy, like renewable energy resources. Solar energy, wind energy, different thermal and hydro sources of energy, biogas are all renewable energy sources. Increasing municipal waste has become one of the major environmental concerns in modern cities. Food waste was generally dumped with other municipal solid waste or discharged to the ocean. However, land ISSN: 2231-5381 filling of food waste has been prohibited since 2005 and marine disposal of food waste has been banned. Food waste cannot be avoided should be reused or recycled to some value added product eg. Renewable energy, compost as far as possible. Moreover, the global trend foe new regulations have been set to strictly limit the disposal of organic waste by landfill and the landfill disposal disposal fee has been raised as well. Anaerobic digestion has been considered as an attractive technology which is used to convert organic solid wastes such as food waste, animal manure and organic fraction of MSW into renewable energy in biogas form. Literature Review: Literature survey will be done for knowing the various methods and theories related to treating food waste by using various techniques. Shalini Singh et al. (2000) studied the increased biogas production using microbial stimulants. They studied the effect of microbial stimulant aquasan and teresan on biogas yield from cattle dung and combined residue of cattle dung and kitchen waste respectively. The result shows that dual addition of aquasan to cattle dung on day 1 and day 15 increased the gas production by 55% over unamended cattle dung and addition of teresan to cattle dung : kitchen waste (1:1) mixed residue 15% increased gas production. Carrasco et al (2004) studied the feasibility for dairy cow waste to be used in anaerobic digestive system. Because the animals waste are more reactive than other cow waste, the study suggests dairy cow waste should be chosen over other animal wastes.Thomsen et al (2004) found that increasing oxygen pressure during wet oxidation on the digested bio waste increased the total amount of methane yield. Specifically, the yield which is normally 50 to 60% increased by 35 to 40% demonstrate the increased ability to retrieve methane to produce economic benefits.Cho and park (1995) proposed using substrate as a food waste in Anaerobic Digester Bio-gas yields 472 ml CH4/g. Ye at al (2011) reported that using a fresh leachate in UASB bio gas generated is 0.31CH4/g. Lissens et al. (2004) completed a study on a biogas operation to increase the total biogas yield from 50% available biogas to 90% using several treatments including: a Mesophilic laboratory scale continuously stirred tank reactor, an up flow biofilm reactor, a fibre http://www.ijettjournal.org Page 405 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) liquefaction reactor releasing the bacteria Fibrobactersuccinogenes and a system that adds water during the process. These methods were sufficient in bringing about large increases to the total yield; however, the study was under a very controlled method, which leaves room for error when used under varying conditions. However, Bouallagui et al. (2004) did determine that minor influxes in temperature do not severely impact the anaerobic digestion for biogas production. Jantsch and Mattiasson (2004) discuss how anaerobic digestion is a suitable method for the treatment of wastewater and organic wastes, yielding biogas as a useful by-product. However, due to instabilities in start-up and operation it is often not considered. A common way of preventing instability problems and avoiding acidification in anaerobic digesters is to keep the organic load of the digester far below its maximum capacity. There are a large number of factors which affect biogas production efficiency including: environmental conditions such as pH, temperature, type and quality of substrate; mixing; high organic loading; formation of high volatile fatty acids; and inadequate alkalinity. As Taleghani and Kia (2005) observed, the resource limitation of fossil fuels and the problems arising from their combustion has led to widespread research on the accessibility of new and renewable energy resources. Solar, wind, thermal and hydro sources, and biogas are all renewable energy resources. But what makes biogas distinct from other renewable energies is its importance in controlling and collecting organic waste material and at the same time producing fertilizer and water for use in agricultural irrigation. Biogas does not have any geographical limitations or requires advanced technology for producing energy, nor is it complex or monopolistic. SuyogVij (2010-11) present this Project was to create an organic processing facility to create biogas which will be more cost effective, eco-friendly, cut down on landfill waste, generate a high-quality renewable fuel, and reduce carbon dioxide & methane emissions. Overall by creating biogas reactors on campus in the backyard of our hostels will be beneficial. Kitchen (food waste) was collected from different hostels of National Institute of Technology, Rourkela‘s Mess as feedstock for our reactor which works as anaerobic digester system to produce biogas energy. The 4 anaerobic digestion of kitchen waste produces biogas, a valuable energy resource anaerobic digestion is a microbial process for production of biogas, which consist of primarily methane (CH4) & ISSN: 2231-5381 carbon dioxide (CO2). Biogas can be used as energy source and also for numerous purposes. But, any possible applications require knowledge &information about the composition and quantity of constituents in the biogas produced. The continuously-fed digester requires addition of sodium hydroxide (NaOH) to maintain the alkalinity and pH to 7. For this reactor we have prepared our Inoculum than we installed batch reactors, to which inoculum of previous cow dung slurry along with the kitchen waste was added to develop our own Inoculum. A combination of these mixed inoculum was used for biogas production at 37°C in laboratory(small scale) reactor (20L capacity) In our study, the production of biogas and methane is done from the starch-rich and sugary material and is determined at laboratory scale using the simple digesters. Materials and Methods Food waste was collected from MSW at Nashik, which was composed of food residues, fruits grains, Vegetables, starch and grease etc. The food was shredded into 5-10 mm size pieces by food grinder. Sewage sludge obtained from building waste water treatment plant, was composed of secondary activated sludge. Here characteristics of FW and WS used in this study, in terms of total solids(TS), SS, COD, VFA, PH Alkalinity, Phosphorous and Nitrogen are presented in table 1. Pilot Scale model consists of following component: 1. Pre digester: - Firstly we have modified our model by adding a predigester. It helps to increase retention time of feedstock, resulting in overall reduction of retention time of the plant. It has capacity of 20 lit. The pre digester is kept at 1/3rd above the height of main digester i.e. 0.35m above G.L. The pH of the pre digester range is 4 – 6 at temperature from 30 to 400 c. 2. Digester: - In Digester, slurry undergoes anaerobic digestion by Archae Bacteria belonging to Methanococcus which produce biogas consisting of methane. Digester is made of syntax tank of capacity 50 lit. Total 50 lit. of slurry can be retained in the digester . The retention period of digester is maintained 14-16 days. This increases gas producing capacity of slurry also the biogas is produced in this tank and, it holds the slurry for sufficiently long time to complete the digestion. The digester holds the biogas produced in it. And collected in to the tyre by providing arrangement of gas valve at the top http://www.ijettjournal.org Page 406 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) of the tank. 3. Inlet Pipe: - The provision of inlet pipe is made for the feeding of feedstock. It is connected from the outlet of predigester to the inlet of main digester. Outlet pipe: - The provision of an outlet is made to take out the digested portion of slurry. Also it helps to regulate outlet slurry depending upon amount of feeding done. Analytical methods The anaerobic digestion process was evaluated by measuring the following parameters: total suspended solids, volatile solids, COD, VFA, pH, Alkalinity, Phosphorous, nitrogen and daily bio gas production were determined in accordance with standard methods. Result and Discussion Performance of anaerobic digester 2. Acidification 3. Methane Formation These stages are shown in fig. is as follows: From the pre digester tank, the slurry enters into the main digester. At this stage the digestion process is started. ‘Digestion’ is a biological process that occurs in the absence of oxygen and in the presence of anaerobic organisms at ambient pressure and temperatures of 35-40ºc. We are maintaining the temperature into the digester range 30-37 ºc. The gas is produced in main digester and collected in tube. The gas is collected in the tube the tube is swell. And the day to day biogas is measured.At the side of tube the gas outlet valve is provided to easily removal of the gas by user’s requirement. ISSN: 2231-5381 The plant is started with digested slurry and food wastes then we are getting result of biogas yield from this organic waste upto .The rate of loading increases slowly to stabilize the digester. The biogas is measured after 15 days intervals. Biogas is produced through the conversion of organic matters by anaerobic microorganism. With conversion of organic matters into biogas the amount of organic matters would be reduce. In this paper concluded that AD is excellent method of treating the food waste with controlled environmental issues. The rate of loading increases slowly to stabilize the digester. The model is in working condition and the partially the results of the biogas is 0.325CH4/g. biogas production rate in batch condition is directly equal to specific growth of Methonogenic bacteria. The value of BOD 50-55% and COD 35-40% is reducing. The COD removal efficiency is 50%. A decrease in the processes pH was observed in the first few days of the digestion and this is due to high volatile fatty acid (VFA) formation. The pH increased to its normal operating value after VFAs metabolism. The pH was observed to increase substantially with little variation on the commencement of the batch operation and also the gas production increases.PH was measured after 15 days interval from starting of project and shown in graph: 8 7.8 7.6 PH Working of pilot model: Firstly we fed the digested slurry of 50 lit. which is taken from the another biogas the purpose is to make a culture of the microorganisms so that when fresh food waste is added then biogas production is enhanced after that the food waste is collected and grinded into the grinder this waste is converted into the slurry by mixing of equal of quantity of water into it the loading increases gradually. Continuous Feeding of slurry is done for several days to fill the pre digester fully. At the pre digester the slurry is partially digested and then it is transferred to the main digester by liquid flow through outlet of pre digester and inlet of main digester respectively. The hot water is also mixed with the waste to maintain the temperature in the range of 30 – 40o c. Anaerobic Digestion System consists of the following three stages: 1. Hydrolysis 7.4 7.2 7 6.8 http://www.ijettjournal.org 1 15 30 45 Number of Days Page 407 60 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) I. I Characteristics of food waste and sewage sludge in this study 15. Biogas Plant Construction Manual Fixed-dome Digester: 4 to 20 Cubic Meters United States Forces – Afghanistan, Joint Engineer Directorate Kabul, Afghanistan April 2011. 16. S.Ashok Kumar, C.Marimuthu, E.P.Balaji, S.ShakeelRiswan Parameters TS mg/l SS mg/l COD mg/l VFA Alkalinity mg/l Phosphorous Nitrogen mg/l PH Food Waste 70,520 35,441 201,008 693.4 185.9 825 6274 4.4 Sewage Sludge 45,100 37,968 17,116 593.4 114.8 278 1200 6.6 Biogas Production from Kitchen Waste Water using USAB Reactor International Journal of ChemTech Research CODEN (USA): IJCRGG [September 2014], ISSN: 0974-4290 Vol.6, No.9, pp 4135-4142. 17. S.Mohan, K.Jagadeesan Production of Biogas by Using Food Waste International Journal of Engineering Research and Applications (IJERA) , Vol. 3, Issue 4, Jul-Agu 2013, pp. 390-394, ISSN: 2248-9622. Acknowledgement:The author is gratefully acknowledge the HOD of Civil DeptDR.M.Husain and Prof. F.I.Chavan of SSBTE college of engineering and technology Bambori, Jalgaon for the guidance of preparation of the paper. Reference: 1.Er. R.K. Rjput Non- Conventional Energy Sources and Utilization ( Energy Engineering) S.Chand 2. Howard S. Peavy, Donald R. Rowe, George Technoglous Environmental Engineering- McGRAW HILL INTERNATIOAL Editions Civil Engineering Series. 3. Chen, Shulin Food Waste Engineering- Vol.IV 4. Amrit B. Karkicbiogas as renewable energy from organic waste Biotechnology vol. X 5. Manual on Muncipal Solid Waste Disposing and Handling Rules Edition 2000 by central Public pollution control board of Govt. of India. 6.Tchobanoglous G. Burten F. Stensel H. Wastewater engineering: treatment and reuse. 4 th ed. Columbs, OH: MCGraw-hill 2002 7. M.H. Zandvoot, E.D. van Hullebush, F.G. Fermoso, P.N.L. Lens, trace metal in anaerobic granular sludge reactors: biovailability and dosing strategies. Eng. Life Sci.6(2006) 293-301 8.A. HilkiahIgoni, M.J.Ayotamunao, C.L.Eze, S.O.T.Ogaji, S.D. Probert, Design of anaerobic digester for producing biogas from municipal solid waste. (2008) doi:10.1016/j.apenergy.2007.07.013 9. Jiexu Ye, Yongji Mu, Xiang Cheng, Dezhi Sun, Treatment of fresh leachate with high strength organics and calcium from municipal solid waste incineration plant using UASB reactor (2011) doi.10.1016./j.biortech.2011.01.0 10. Seil Kim, JaesangBae, Okkyoung Choi, Donghun JU, Jungmin Lee, Hyunje sung, Seongbum Park, Byoung In Sang, Youngsoon Um, Pre-treatment and anaerobic digestion of food waste for high rate methane production (2014),http://dx.doi.org/10.1016/j.jece.2014.07.024 11.Wanli Zhang, Lei Zhang, Aimin Li, Anaerobic co- digestion of food waste with MSW incineration plant fresh leachate: process performance and synergistic effects(2015) http://dx.doi.org/10.1016/j.cej.2014.08.039 12.C. Ratanatamskul, O. Wattanayommanaporn, K. Yamamoto, An on- site proto type two stage anaerobic digester for co- digestion of food waste and sewage sludge for biogas production from high- rise building (2015) http://dx.doi.org/10.1016/j.jece.2015.03.019 13. Werner Kossmann, UtaPönitz, Stefan Habermehl, Thomas Hoerz, Pedro Krämer, B. Klingler, C. Kellner, Thomas Wittur, F. v. Klopotek, A. Krieg, H. Euler Biogas digest volume II Biogas application and product development Information and advisory service on Appropriate Technology 14. DhanalakshmiSridevi V.1 and Ramanujam R.A. Biogas Generation in a Vegetable Waste Anaerobic Digester: An Analytical Approach Research Journal of Recent Sciences Vol. 1(3), 41-47, March (2012) ISSN 2277-2502. ISSN: 2231-5381 http://www.ijettjournal.org Page 408