―Experimental and Finite Element Analysis of Rectangular

advertisement

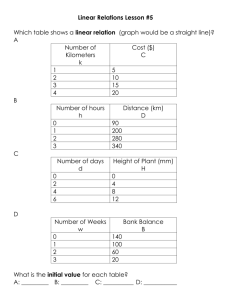

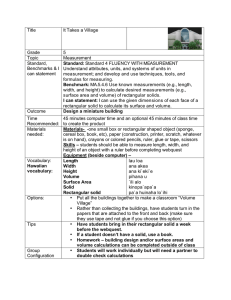

International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) ―Experimental and Finite Element Analysis of Rectangular Straight Fin and Rectangular Straight Fin with Variable Fin Density” Govind Sahebrao Badgujar#1, Dr. Atul A. Patil*2, Prof. V.H.Patil#3 # M.E. Student, Department of Mechanical Engineering, GF’s Godavari College of Engineering, Jalgaon , Maharashtra, India. * Associate Professor, Dept. of Mechanical Engineering, GF’s Godavari College of Engineering, Jalgaon ,Maharashtra, India. # Associate Professor, Dept. of Mechanical Engineering, GF’s Godavari College of Engineering, Jalgaon ,Maharashtra, India. Abstract— In the past decades, Due to the rapid growth of electronic technology these microelectronic systems have shown extraordinary growth. The most common method for cooling electronic devices is by finned heat sinks made of aluminium. The Test Model having the Thermal Conductivity is Kf= 185 W/m°C. Pressure drop across heat sink is one of the key variables that govern the thermal performance of the heat sink in forced convection environment. In order to design an effective heat sink it having large heat transfer rate, low pressure drop, simple construction, and reasonable cost. The purpose of a heat sink is to maintain the device temperature below the maximum allowable temperature specified by the device manufacturer. Thermoelectric coolers used in applications where temperature stabilization or cooling below ambient required. The present model study to conduct for application of heat sink in thermoelectric can cooler, where in the device shall be used to cool beverage cans. The size of the device is constraint due to this device is used as a portable device hence to be compact. Thus the study is focused on development and testing of heat sink with straight fins and straight fins with variable fin density. Keywords—Heat Sink, Straight fin, Thermal Condutivity, Thermoelectric Coolers. 1. INTRODUCTIONA heat sink is a component or assembly that efficiently transfers heat generated within a solid material to a fluid medium, such as air or a liquid. Heat sinks are primarily used to remove unwanted heat from a device to keep it from overheating. Examples of heat sinks is thermoelectric can cooler, where in the device shall be used to cool beverage cans. Rapid development in packaging technology allows portable electronics to gain faster processing speed and enhanced Capabilities. However, thermal management in the portable electronics environment is becoming increasingly difficult. Due to high heat load and dimensional constraints. Proper selection of fans and fin pitch in the heat sink is crucial to ensure the thermal design of the system is optimized. In this ISSN: 2231-5381 paper, the experimental conducted in Air duct is a fabricated structure with the entry and exit section 160 x 160 mm cross-section with the central section 120 x 120 mm that include heater arrangement .ventureaction in provided for enhanced performance by a gradual decreasing and gradually increasing section. In that Test Model of fin heat sinks made of aluminium having the Thermal Conductivity is Kf=185 W/m°C. Study of the heat transfer to enhancement obtained by Comparitatively study of Rectangular Straight and Rectangular Straight with variable Fin Density is the main objective of the present work. In that Mass Flow of hot Air passing through in Air Duct which content the Fins Test Model. Due to Changing Density of Test model Structure of Rectangular Straight and Rectangular Straight with variable Fin Density .Finally we can find out Comparatively study of Parameters of Pressure Drop, Heat Flow ,Temperature gradient ,Overall Heat transfer Coefficient by plotting on the Graph. And just only changing the mass flow rate of Air passing through in the Duct. The Main Application it is used in portable device like heat sink in thermoelectric can cooler. Here we are testing on two Test Models of fin Structure 1) Rectangular Straight fin & 2) and Rectangular Straight with variable Fin Density. The parameters of sink can be derived for theoretical validation a)Heat sink profile and geometry drawing using 2-D AutoCAD .b) Solid modelling of the heat sink models using NX Unigraphix. c) Thermal analysis for temperature distribution using ANSYS R14.5. 1.1 Basic Heat Sink Heat Transfer Principle:Heat sink is an object that transfers thermal energy from a higher temperature to a lower temperature in fluid medium. To understand the principle of a heat sink, consider Fourier's law of heat conduction. Fourier’s law of heat conduction, simplified to a one-dimensional form in the x-direction, shows that when there is a temperature gradient in a body, heat will be transferred from the higher temperature region to the lower temperature region. The rate at which heat is transferred by conduction, Q http://www.ijettjournal.org Page 339 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) is proportional to the product of the temperature gradient and the cross-sectional area through which heat is Q=-k×A× (∂T/∂x). Fig.1: Sketch of a heat sink in a duct used to calculate the governing equations from conservation of energy and Newton’s law of cooling. Consider a heat sink in a duct, where air flows through the duct, It is assumed that the heat sink base is higher in temperature than the air. Applying the conservation of energy, for steady-state conditions, and Newton’s law of cooling to the temperature nodes shown in Fig.1 gives the following set of equations. Where, Is the air mass flow rate in kg/s. = 2.2 Rectangular Straight with variable Fin Density- Fig.3 2D Geometry of Rectangular Straight Fin with variable fin density Heat Sink. Measurement Mass Properties is Volume = 55656.00 mm3 Area = 24306.00 mm2 Mass = 0.435822100 kg Weight = 4.273958651 N Density = 0.000007831 kg/ mm3 2.3 Analytical Calculations for finding the different parameters for Test Model1) Discharge (Q) – Q= Cd × (π/4) × d2 × Cp, in (Tair, out- Tair, in) , m3/sec. 2) Mass flow of air = Density x discharge, Kg/min. 3) Heat flow = m x Cp x ΔT, Watt 4) Overall H.T Coefficient (U)= (heat flow / A x ΔT), W/m2K. 2. HEAT TRANSFER RATE OF RECTANGULAR FINS:here we are testing on two Test Models of fin Structure 1) Rectangular Straight fin & 2)Rectangular Straight with variable Fin Density having the Mass Properties from NX Unigraphix & geometry drawing using 2-D AutoCAD given below 2.1 Rectangular Straight fin- 3. EXPERIMENTATION USING AIR DUCTStart the heater by switching on the power. Maintain the Power same as100 watts, Voltage - 230 Volt AC. for all readings. Start the blower and adjust and maintain speed at level-1.Take manometer reading (h1) mm of water using this reading to find pressure drop across the test model. Take manometer reading (h2) mm of water using this reading to find velocity of air and discharge of speed of blower. Note down thermocouple temperature reading (T f) .Gradient of temperature (ΔT) = (Tf- Ta). Repeat the same set of reading for different levels of manometer readings level-2. Level-3. Level-4, level-5& level-6. 3.1 Experiment Set-up- Fig.2 2D Geometry of Rectangular Straight Fin Heat Sink. Measurement Mass Properties Volume = 56088.00 mm3 Area = 24738.00 mm2 Mass = 0.156709872 kg Weight = 1.536800253 N Radius of Gyration = 30.731330231 mm Centroid =36.098844673, 33.401155327, 2.418485237 mm Density = 0.000002794 kg/ mm3 ISSN: 2231-5381 http://www.ijettjournal.org Page 340 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) 20 18 Pressure Drop 16 14 12 Temp gradient 10 8 6 Heat flux 4 Fig.4 Experiment Set-up 2 3.2 Test Model of Rectangular Straight Fins – 0 Overall heat transfer coeff. Mass Flow Rate (Kg/min) Graph no.1 Different Parameters Vs Mass Flow rate of Rectangular Straight fin. Fig .5 Test Model of Rectangular Straight Fins in NX Unigraphix. 3.3 Test Model of Rectangular Straight Fins with variable fin density – Fig.6 Test Model of Rectangular Straight Fins with variable density in NX Unigraphix. 3.3 Combine Parameters of Rectangular Straight fin on Graph from Result Table- From graph no.1 Pressure drop across fins increases with increase in Mass flow rate. Temperatures gradient increases with increase in Mass flow rate. Heat flux increases with increase in flow rate with maximum of 3.28 W/mm2. Overall heat transfer coefficient of fins is best at elevated flow rates. 3.4 Combine Parameters of Rectangular Straight with variable fin density on Graph from Result Table18 16 14 12 10 8 6 4 2 0 Pressure Drop Temp gradient Heat flow mass flow rate (kg/min) Overall heat transfer coefficient . Graph no.2 Different Parameters Vs Mass Flow rate of Rectangular Straight with variable fin density. From graph no.2 Pressure drop across fins increases with increase in flow rate. Temperature gradient increases with increase in flow rate of air. Heat flux increases with increase in flow rate with maximum of ISSN: 2231-5381 http://www.ijettjournal.org Page 341 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) 3.177 W/mm2. Overall heat transfer coefficient of fins is best at elevated flow rates. 4. FINITE ELEMENT ANALYSIS OF RECTANGULAR FINS4.1Finite Element Analysis of Rectangular Straight FinsIn Finite Element Analysis of Rectangular Straight Fin & Rectangular Straight Fin with variable fin density is draw in ANSYS of R14.5 Version. Geometry- Fig. 10 Directional heat flux in X –direction of Test Model of Rectangular Straight Fins. 4.2Finite Element Analysis of Rectangular Straight Fin with variable fin densityGeometry- Fig.11 Geometry of Test Model of Rectangular Straight Fins with variable density in ANSYS R14.5 Meshing - Fig.7 Geometry of Test Model of Rectangular Straight Fins in ANSYS R14.5 Meshing - Fig.12 Meshing of Test Model of Rectangular Straight Fins with variable density. Total Heat Flux - Fig. 8Meshing of Test Model of Rectangular Straight Fins. Total Heat Flux - Fig.13 Total heat flux Test Model of Rectangular Straight Fins with variable density Directional Heat flux- Fig. 9Total heat flux of Test Model of Rectangular Straight Fins. Directional Heat flux- Fig.14 Directional heat flux in X direction of Test Model of Rectangular Straight Fins with variable density. ISSN: 2231-5381 http://www.ijettjournal.org Page 342 International Conference on Global Trends in Engineering, Technology and Management (ICGTETM-2016) 5.COMPARISON BETWEEN RECTANGULAR STRAIGHT & RECTANGULAR STRAIGHT FINS WITH VARIABLE DENSITYAnalysis resultsSr. No Parameter Rectangular straight fins Rectangular straight fins with Variable density 30.547 1.9703 0.83676 1 2 3 Max. Tip temp 31.89 Total heat flux 1.9816 Directional heat 0.96929 flux Table no.1 Analysis results Rectangular Straight & Rectangular Straight Fins with variable density. The Rectangular Straight fins show marginally better performance than the Rectangular Straight fins with variable fin density Experimental resultsSr. No Parameter Rectangular straight fins 1 Pressure drop across fin Temperature gradient (max) Heat flow ( max) Overall Heat Transfer Coefficient 0.35 Rectangular straight fins with Variable density 0.36 19 17 3.287 6.9215 3.177 6.85 2 3 4 Table no .2 Analytical results Rectangular Straight & Rectangular Straight Fins with variable density. The rectangular straight fins show less pressure drop across fins hence they will be preferred over variable density fins as they will lead to less cross heating of components. Overall heat transfer coefficient and heat flow of the straight fins is marginally better than the variable density fins hence they perform slightly better than the variable density fins. variable fin density.& from Experimental results the Conclusion is The rectangular straight fins show less pressure drop across fins hence they will be preferred over variable density fins as they will lead to less cross heating of components. Overall heat transfer coefficient and heat flow of the straight fins is marginally better than the variable density fins hence they perform slightly better than the variable density fins. RERENNCES[1] D. B. Tuckerman and R. F. W. Pease, ―High-performance heat sinking for VLSI,‖ IEEE Trans. Electron Dev., vol. 2, no. 5, pp. 126–129, May 1981. [2] P. Lall, M. G. Pecht, and E. B. Hakin, Influence of Temperature on Microelectronic and Reliability. Boca Raton, FL: CRC Press, 1997. [3] S. G. Kandlikar and W. J. Grande, ―Evaluation of single phase flow in microchannels for high flux chip cooling: Thermohydraulic performance enhancement and fabrication technology,‖ in Proc. ASME 2nd Int. Conf. Microchann. Minichann., Jun. 2004, pp. 5–16. [4] J. P. McHale and S. V. Garimella, ―Heat transfer in trapezoidal microchannels of various aspect ratios,‖ Int. J. Heat Mass Trans., vol. 53, nos. 1–3, pp. 365–375, 2010. [5] R. W. Knight, D. J. Hall, J. S. Goodling, and R. C. Jaeger, ―Heat sink optimization with application to microchannels,‖ IEEE Trans. Compon. Hybrids Manuf. Technol., vol. 15, no. 5, pp. 832–842, Oct. 1992. [6] D. V. Pence, ―Reduced pumping power and wall temperature in microchannel heat sinks with fractal-like branching channel networks,‖Microscale Thermophys. Eng., vol. 6, no. 4, pp. 319–330, 2002. [7] Y. Peles, A. Ko¸sar, C. Mishra, C. J. Kuo, and B. Schneider, ―Forced convective heat transfer across a pin fin micro heat sink,‖ Int. J. Heat Mass Trans., vol. 48, no. 17, pp. 3615–3627, 2005. [8] M. E. Steinke and S. G. Kandlikar, ―Single phase liquid heat transfer with plain and enhanced microchannels,‖ in Proc. 4th ASME Int. Conf. Nanochann. Microchann. Minichann., Limerick, Ireland, 2006, pp. 943–951. 6. CONCLUSIONFrom Analysis results the Conclusion is the Rectangular Straight fins show marginally better performance than the Rectangular Straight fins with ISSN: 2231-5381 http://www.ijettjournal.org Page 343