Monitoring for Fine Particulate Matter Elisa Eiseman

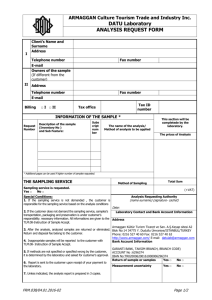

advertisement