Wireless Sensor Network 2 class – Department of Network

advertisement

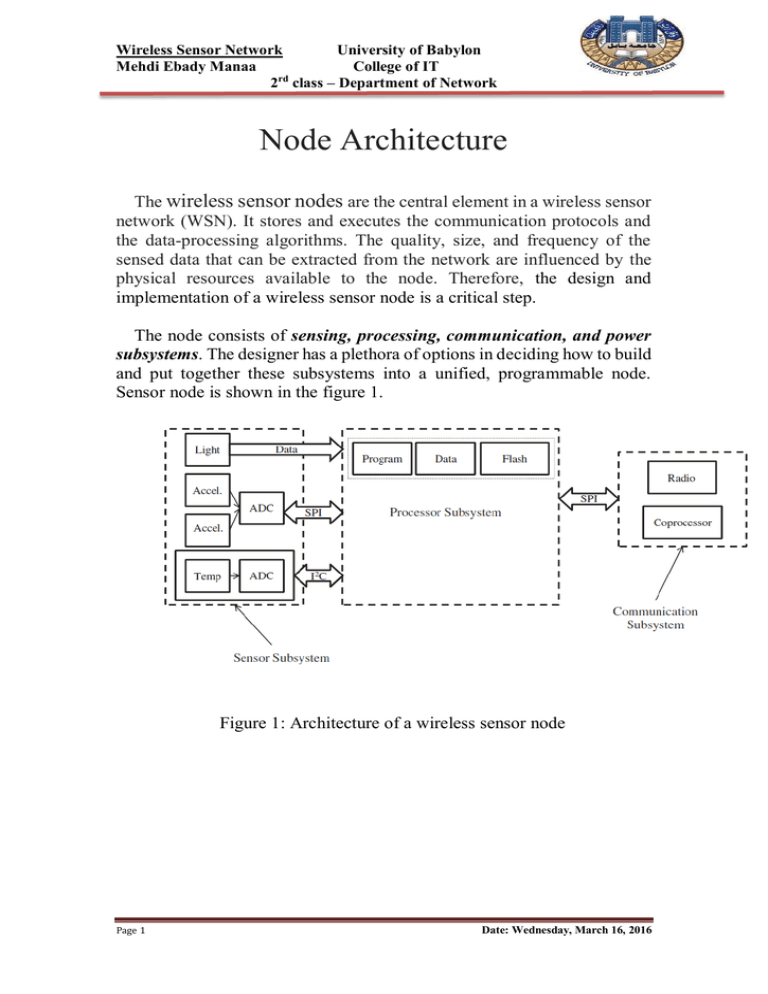

Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network Node Architecture The wireless sensor nodes are the central element in a wireless sensor network (WSN). It stores and executes the communication protocols and the data-processing algorithms. The quality, size, and frequency of the sensed data that can be extracted from the network are influenced by the physical resources available to the node. Therefore, the design and implementation of a wireless sensor node is a critical step. The node consists of sensing, processing, communication, and power subsystems. The designer has a plethora of options in deciding how to build and put together these subsystems into a unified, programmable node. Sensor node is shown in the figure 1. Figure 1: Architecture of a wireless sensor node Page 1 Date: Wednesday, March 16, 2016 Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network I. The Sensing Subsystem The sensing subsystem integrates one or more physical sensors and provides one or more analog-to-digital converters as well as the multiplexing mechanism to share them. Nowadays, there are a plethora of sensors that measure and quantify physical attributes at a cheap price. A physical sensor contains a transducer, a device that converts one form of energy into another form of energy, typically into an electrical energy (voltage). The output of this transducer is an analog signal having a continuous magnitude as a function of time. Therefore, an analog-to-digital converter is required to interface a sensing subsystem with a digital processor. Analog-to-Digital Converter The analog-to-digital converter (ADC) converts the output of a sensor – which is a continuous, analog signal into a digital signal. This process requires two steps: (a) the frequency and magnitude of the signal; and (b) the available processing and storage resources. 1. The analog signal has to be quantized (i.e., converted from a continuous valued signal into a discrete valued signal; discrete both in time and magnitude). The most important decision at this stage is to determine the number of allowable discrete values. This decision in turn is influenced by two factors: 2. The sampling frequency. In communication engineering and digital signal processing, this frequency is decided by the Nyquist rate (the minimum sampling rate should be twice the bandwidth of the signal) in wireless sensor networks, however, the Nyquist rate does not suffice. Oversampling is required because of noise. The prevailing consequence of the first step is the quantization error while the second is aliasing. An ADC is specified, among other things, in terms of its resolution, which is an expression of the number of bits that can be used to encode the digital output. For example, an ADC with a resolution of 24 bits can represent 16,777,216 distinct discrete values. The resolution of an ADC can also be expressed in volts – since the output of most MicroelEctroMechanical Systems MEMS sensors is analog voltage. The Page 2 Date: Wednesday, March 16, 2016 Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network voltage resolution of an ADC is equal to its overall voltage measurement range divided by the number of discrete intervals. In other words: Where Q: - is the resolution in volts per step (volts per output code). Epp: - is the peak-to-peak analog voltage; M: - is the ADC’s resolution in bits. Example Consider an industrial process whose thermal property ranges from −20 to +80◦ C. The choice of the physical sensor as well as the ADC depends on the type of thermal change that is of interest. If, for example, a change of 0.5 ◦C is required, an ADC with a resolution of 8 bits is sufficient. If, on the other hand, a change of 0.0625 ◦C is required, then the ADC should have a resolution of 11 bits. II. The Processor Subsystem The processor subsystem brings together all the other subsystems and some additional peripherals. Its main purpose is to process (execute) instructions pertaining to sensing, communication, and self-organization. It consists of a processor chip, a nonvolatile memory (usually an internal flash memory) for storing program instructions, an active memory for temporarily storing the sensed data, and an internal clock, among other things. Whereas a wide range of off-the-shelf processors are available for building a wireless sensor node, one has to make a careful choice, as it affects the cost, flexibility, performance, and energy consumption of the node. If the sensing task is well defined from the outset and does not change over time, a designer may choose either a field programmable gate array or a digital signal processor. These processors are: 1- Very efficient in terms of their energy consumption; Page 3 Date: Wednesday, March 16, 2016 Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network 2- For most simple sensing tasks, they are quite adequate However As these are not general-purpose processors, the design and implementation process can be complex and costly. Most existing sensor nodes at present use microcontrollers. There are some justifications besides those just mentioned. WSNs are emerging technologies; and the research community is still active with research for developing energy-efficient communication protocols and signal-processing algorithms. As this requires dynamic code installation and update, the microcontroller is the best option. Microcontroller A microcontroller is a computer on a single integrated circuit, consisting of a comparatively simple central processing unit and additional components such as high-speed buses a memory unit, and an external clock. Microcontrollers are integrated in many products and embedded devices. Today such simple systems as elevators, ventilators, office machines, household appliances, power tools, and toys ubiquitously employ microcontrollers Microcontroller Board Advantages and Disadvantages Page 4 Date: Wednesday, March 16, 2016 Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network A microcontroller can be chosen over other types of small-scale processors because of: 1- Programming flexibility it offers. 2- Its compact construction and small size. 3- Low power consumption. 4- Low cost make it suitable for building computationally less intensive, standalone applications. 5- There are development environments that offer an abstraction of all the functionalities of a microcontroller. This enables application developers to program microcontrollers without the need to have a lowlevel knowledge of the hardware. Microcontrollers are not as powerful and as efficient as some custom made processors such as digital signal processors (DSPs) and field programmable gate arrays (FPGAs). Moreover, for applications which demand simple sensing tasks but large-scale deployments (such as in precision agriculture and active volcano monitoring), one may prefer to use architecturally simple but energy- and cost-efficient processors such as application specific integrated circuits. III. Communication subsystem The communication subsystem consists of a wireless transceiver and an antenna that are used to transmit and receive messages one bit or symbol at a time.as shown in figure bellow. XBEE Communication Modules Wireless Sensor Network Gateway The functions available in most transceivers are the selection of a frequency channel and a transmit power, the modulation transmitted and demodulation of received data, symbol synchronization and clock generation for received data. A transceiver may also include additional functions, which reduce the processing requirements of Micro-Controller Unit (MCU). Page 5 Date: Wednesday, March 16, 2016 Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network For example, an IEEE 802.15.4 synchronization of an incoming frame, clear channel assessment for detecting ongoing traffic in a frequency channel, Received Signal Strength Indicator (RSSI) and Link Quality Indication ) LQI) for measuring signal strength and estimating link quality to neighboring nodes, Cyclic Redundancy Check (CRC) calculation for checking bit errors on received frames, data encryption/decryption for improving network security and automatic acknowledge transmissions after received frames. Since these features are implemented most efficiently in physical layer, they can improve overall network energyefficiently. Yet, the increased complexity raises hardware cost. In practice, the lowest power COTS (commercial off-the-shelf) transceivers available today include only some of these features. A wireless transceiver can be based on acoustic, optical or RF waves. 1- Acoustic communication: is typically used for under water communications or measuring distances based on time-of-flight measurements. The disadvantages are long and variable propagation delay, high path loss, noise, and very low data rate. Also, a large external antenna is needed. 2- Optical communication: has low energy consumption especially in reception mode, and it can utilize very small antenna. A transmitter can be implemented by a Light Emitting Diode (LED) or a laser, and a receiver by a photo diode. However, radiation is directional and a Line-of-Sight (LOS) is required. Hence, the alignment of a transmitter to a receiver is difficult or even impossible in large-scale WSN applications. 3- RF communication combines the benefits of high data rate, long range and nearly omnidirectional radiation, making it the most suitable communication technology for WSNs. Disadvantages are large antenna size and higher energy consumption compared to the optical technology. In general, an RF transceiver (radio) has four operation modes: transmit, receive, idle, and sleep. Radio is active in transmit and receive modes, when power consumption is also the highest. In idle mode, most of circuitry is shut down, but the transition to the active mode is fast. The lowest power consumption is achieved in sleep mode when all circuitry is switched off. Most short-range radios utilized with WSNs operate in the 433 MHz, 868 MHz ,915 MHz, and 2.4 GHz license-free Industrial Scientific Medical (ISM) frequency bands. The 2.4 GHz band is the widest providing more channels, while obstacles have least effect on lower frequency bands. Page 6 Date: Wednesday, March 16, 2016 Wireless Sensor Network University of Babylon Mehdi Ebady Manaa College of IT 2rd class – Department of Network Depending on the frequency band and antenna type, operating range with 1mW transmission power is from few meters to hundreds meters. IV. Power subsystem The power subsystem stores supply energy and converts it to an appropriate supply voltage level. The subsystem consists of an energy storage, a voltage regulator, and optionally an energy scavenging unit. 1- Energy Storage The energy storage can be a non-rechargeable (primary) battery, a rechargeable (secondary) battery, or a super capacitor. Primary batteries are cheap and have the highest energy density. They are the most common power source for WSNs. Secondary batteries have lower energy density and are more expensive, but they can be recharged only 500 - 1000 times. Compared to secondary batteries, super capacitors have lower energy density and they are more expensive. However, their lifetime is in the order of a million charging/discharging cycles. Super capacitors are suitable to be used with an energy generator, since energy is typically generated in peaks during short periods of time, and the amount of stored energy can be relatively low 2- Energy scavenging As energy storages have finite capacity, there is a requirement for self-powered devices. In energy scavenging, a node collects energy from its surrounding environment. this enables more active and longer term operation by reducing the dependency on batteries or eliminates the need for them completely. Installation costs are reduced as self-powered wireless sensors do not require wires or conduits, and are therefore very easy to install. Page 7 Date: Wednesday, March 16, 2016