Notes Tech In-Grade Lumber Testing and Design Values for Dimension Lumber

Tech

Notes

WWPA Technical Services Division

2005-02

In-Grade Lumber Testing and Design

Values for Dimension Lumber

INTRODUCTION – WHAT WAS IN-GRADE?

The In-Grade Testing Program was one of the largest materials testing programs of a single product – dimension lumber – ever to be conducted in North

America. Some 70,000 pieces of full-size structural lumber in dimension grades were pulled from hundreds of U.S. and Canadian mills. Lumber was tested to failure to scientifically derive and classify its performance characteristics.

Because the lumber was pulled directly from mill production and tested in its actual grade, size and species, the project became known as the “In-Grade” program. This 12-year research program was conducted by the U.S. Forest Products Laboratory in cooperation with the North American softwood lumber industry.

The testing and analysis of this lumber data yielded a wealth of information on the structural performance of softwood lumber and on why lumber performs in certain ways. The data ultimately resulted in the development of ASTM Standard D 1990 for the determination of design values based on tests of fullsize pieces of lumber.

Design values resulting from the standard were published by the North American lumber industry in late

1991. For the most part, the 1991 values made only minor changes in the way lumber is used. However, architects, engineers, and building officials were required to become familiar with a new format for lumber design values (Base Values), along with some modifications to species groupings.

Since 1991, the ASTM Committee has directed a number of revisions to Standard D 1990. These revisions resulted in increases to some of the 1991

Western Lumber Base Values. The revised design values are published in WWPA's Western Lumber

Grading Rules and other publications, and in the

Design Values Supplement to the National Design

Specification ( NDS ) for Wood Construction® – an

ANSI/AF&PA standard. The NDS is a referenced standard in the major model building codes, including the International Building and the International

Residential Codes.

BACKGROUND

Current framing practices in wood-frame construction evolved from the first “light-frame” buildings of the mid-1800s. Over time, steady improvements occurred in building technology. Today, light-frame wood construction is used throughout the world as an environmentally sound, practical, economical and earthquake-resistant structural system.

The first significant tests of lumber's strength capabilities began in the late 1920s. Researchers recorded the pounds per square inch required to bend shortlength samples of clear (without knots) 2x2 wood specimens to specified limits. The results for each species were mathematically projected to create basic theoretical values for dimension lumber.

Lumber has certain natural characteristics, such as knots, that can affect its strength. Such characteristics were factored into the clear-wood design values and the impact computed. The amount of clear wood in the cross section plus other characteristics, such as the slope of the wood's grain, governed the strength of each grade.

History shows that design values based on the clearwood approach (ASTM Standards D 2555/D 245)

(continued)

Western Wood Products Association 522 SW Fifth Avenue, Suite 500 Portland, OR 97204-2122

: tel: 503-224-3930 fax: 503-224-3934 e-mail: info@wwpa.org

web site: www.wwpa.org

performed well. The long-term performance of lumber in wood-frame buildings has been what it was predicted to be. But design values are at the core of structural lumber safety and associated liabilities, thus new research using state-of-the-art technology was inevitable.

WHAT DID IN-GRADE DO?

The In-Grade Testing Program was initiated in 1978 to verify the existing softwood lumber design values and provide a more scientific basis for wood engineering procedures.

Lumber grade rules-writing agencies like WWPA, in cooperation with the U.S. Forest Products

Laboratory, tested thousands of pieces of lumber in the grade, size and species to which the design values are applied.

Lumber samples were tested in bending, shear, tension and compression forces. Detailed information was recorded for each specimen including growth characteristics, stiffness, ultimate strength and failure modes. In addition, specific-gravity values for many samples were obtained. Relationships of mechanical properties in terms of moisture content, size and grade were also developed.

WHAT WAS TESTED?

In the U.S., Douglas Fir-Larch, Hem-Fir and

Southern Pine were sampled as species groups, while some other species were sampled as individual species. For marketing and manufacturing reasons, many of the individual species were grouped together after testing. Design values for each species group are derived from the set of species in the group, which showed no statistically significant differences from the lowest species.

WHAT WERE THE RESULTS?

For the most part, design values for Western lumber existing prior to 1991 were found to be relatively accurate when compared to new data. However, some of the differences between the earlier design values and the results of the In-Grade Testing Program were significant.

Findings include:

• An increase in the bending and tension parallelto-grain stress values, in the narrow widths

(2x4) of the highest grades (Select Structural,

No. 1 & Btr., No. 1).

© 2005 WWPA 2

• An increase in compression parallel-to-grain stress values for most grades and sizes.

• A reduction in bending stress values in some grades of wider widths (2x10, 2x12, etc.)

• A slight reduction in MOE values for some species and grades.

Some of the broader findings for Western lumber were:

Fewer species groups

• In-Grade allowed an accurate analysis of the relationships among species. Instead of 10

Western Lumber species groups, the number was reduced to six for increased ease of design.

Recognition of No. 1 & Btr.

• In-Grade testing of the No. 1 & Btr. combination resulted in the recognition of design values for the No. 1 & Btr. grade in Douglas Fir-Larch and Hem-Fir.

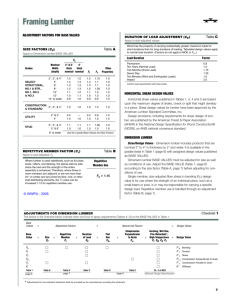

New tables and formats

• In-Grade design values for Western,

Northeastern and Canadian dimension lumber are published as Base Values, which are first adjusted for size and then for conditions of use.

The Adjusted Value becomes the design value that is applied to a piece for its particular end use.

DID THE GRADING RULES CHANGE?

The grading rules were not affected by the In-Grade

Testing Program.

In-Grade affected the design values that are applied to dimension lumber grades. And the procedure for working with those values changed because new values are published as Base Values, which must be adjusted for size as well as conditions of use.

WHAT IS THE IMPACT OF 1996 CHANGES

TO ASTM D 1990?

Design values resulting from ASTM D 1990 procedures are subject to rounding and data-grouping sensitivity procedures, which can have a minor impact on resulting Base Values. When the 1996 changes to ASTM D 1990 were applied to Western

Lumber Base Values some design values increased slightly, while others remained the same. There were no decreases.

(continued)

SHEAR DESIGN VALUES FOR LUMBER – 1999

CHANGES TO ASTM D245

Shear design values for lumber were revised to reflect changes to ASTM Standard D 245 in 1999. These revised lumber shear design values are generally higher than earlier assigned values by a factor of 1.95.

NDS editions prior to 2001 recognized increases in shear design values for splits, checks and shake.

Design provisions in the 2001 and later NDS editions reflect the utilization of the revised shear design values. Notable changes to the NDS include:

• Removal of the Shear Stress Factor, C

H splits, checks and shake.

, for

• Revision of the tension-side notching equations.

• Removal of the special design considerations for

Shear Parallel to Grain (Horizontal Shear) in

Bending Members (4.4.2 of the 1997 NDS ).

• Revision of the shear design provisions for bending members at connections.

CURRENT BASE VALUES FOR DESIGN

IN WESTERN LUMBER SPECIES

Lumber design values are developed by lumber ruleswriting agencies in accordance with ASTM standards and subject to the approval of the American Lumber

Standard Committee’s Board of Review, as directed by U.S. Department of Commerce procedures. The acceptance of lumber design values is enhanced by their incorporation in the Design Value Supplement to the National Design Specification ( NDS ) for Wood

Construction® . The NDS is referenced by all major model building codes.

Dimension Lumber Base Values must be adjusted for size prior to adjusting for conditions of use. Standard adjustment factors for conditions of use are provided in WWPA’s Western Lumber Grading Rules , the

Western Lumber Product Use Manual and the Western

Woods Use Book , as well as in the NDS .

Information in this Tech Note has been obtained by Western Wood Products Association from sources believed to be true. However, neither WWPA or its members, nor the authors guarantee the accuracy of any information published herein and these parties are not responsible for any errors, omissions or damages arising out of or relating to its use. This document is published with the understanding that WWPA, its members and the authors are supplying information, but are not attempting to render engineering or other professional services.

© 2005 WWPA 3 TN05-02/Rev.6-05