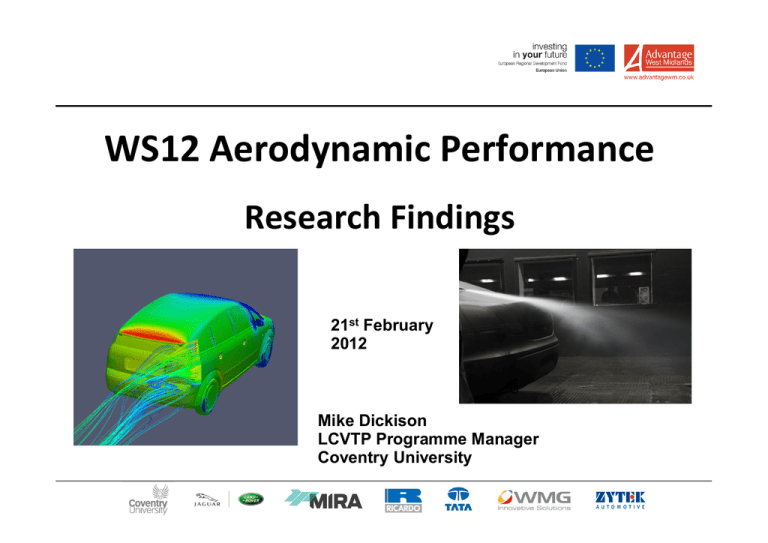

WS12 Aerodynamic Performance Research Findings 21 February

advertisement

WS12 Aerodynamic Performance Research Findings 21st February 2012 Mike Dickison LCVTP Programme Manager Coventry University Workstream Task Summary LCVTP WS12 Aerodynamics: Overview Project Plan WS Summary Report Task 1 Technology benchmark Concept selection Task 2 Concept evaluation study Task 3 Conceptual packging study Task 4 Concept vehicle Aero performance integration Task 5 Aero simulaton & testing Task 6 Implementation & evaluation Individual test reports exist Project Resource Five partners • • • • • Jaguar / LandRover (JLR) Tata Motors European Technology Centre (TMETC) MIRA Ltd Ricardo Coventry University (Workstream Leader) Specialist input from 3 Universities • • • Cranfield Durham Loughborough Task 12.1 – Technology Benchmark Study/ Concept Selection (MIRA Lead) • Identified technologies that are likely to produce significant drag reduction • The research groups from Coventry University and MIRA searched available literature for suitable solutions • Library of relevant references was created • Summary of all relevant data compiled into report – see example to right Task 12.2 – Concept Evaluation Study (CU Lead) Weight Front End Rear End Misc. Cooling Underbody Wheels / Wheel Arches Turning vanes Vortex Generators Lower bumper contraction Air curtains Base pressure recovery Tapering Cavities Vortex generators Wake splitting Diffusing spoiler Base bleed Suction Active spoilers Spoilers Synthetic jets Rear view cameras Surface treatment (rough/smooth) Wind average drag Interaction of systems Number of radiators and placement/duct design Direct air cooling in engine compartment Drive cycle and thermal analysis Radiator sizing & new materials - novel heat exchangers Active intake blanking (radiator) EV cooling requirements (changes depending on time) Active intake blanking (EV specific systems) Active intake blanking (brakes) Synthetic jets Vortex generators Surface treatment of flat underbodies (rough/smooth) Underbody Diffusers (Front and Rear) Shaped wheel deflectors Wheel arch flow control Wheel covers (hub caps - convex) Active wheel fairings Secondary wheel covers / arches Air curtains 1-5 4 5 3 5 5 5 3 4 3 3 4 4 3 5 4 5 3 5 3 3 4 5 5 5 3 4 4 1 Box Maturity of the Potential aero Vehicle safety Predicted cost Manufacturing Total technology advantages regulations Comments mark 1-5 1-5 1-5 1-5 1-5 5 5 5 4 4 27 2 5 1 3 4 20 2 3 2 3 4 17 3 box 5 5 3 5 5 28 2 3 4 4 3 21 5 5 1 5 5 26 2 3 4 2 1 15 1 4 3 3 5 20 3 3 4 3 4 20 3 2 5 3 4 20 4 3 3 3 4 21 3 box 5 4 3 4 5 25 2 2 4 2 3 16 2 3 3 4 1 18 1 4 4 3 5 21 3 box 5 4 2 4 5 25 5 3 3 4 5 23 2 box 4 4 4 4 5 26 2 box 2 2 5 2 3 17 2 box 4 3 5 4 5 24 2,3 box 5 4 2 4 5 24 2,3 box 4 5 4 4 5 27 2,3 box 5 4 5 4 5 28 5 4 2 5 5 26 3 3 5 4 5 23 3 box 4 4 4 4 5 25 2,3 box 4 4 5 4 5 26 Task 12.3 – Conceptual Packaging Study to Exploit Low Carbon Architectures (CU Lead) test Idea Visualise Task 12.3 – Steps in Implementation Idea test Task 12.3 – Steps in Implementation Concept visualise Task 12.3 – Steps in Implementation Idea Visualise test Concept Task 12.4 – Conceptual Vehicle Styling/ Aerodynamic Performance Integration (CU Lead) Using the different components as an aerodynamic toolbox for developing concept vehicles Task 12.4 – Implementation Task 12.5 – Aerodynamic Simulation/Testing Process (MIRA Lead) Background Initial survey gave areas of research: Base pressure recovery Wheels and wheel arches Performance simulations on EV’s (Ricardo) benefits of drag reduction over several drive cycles Task 12.5 – Aerodynamic Simulation/Testing Process Programme CFD (CU & MIRA) Full scale testing at MIRA (All) + Benchmarking Model scale testing (Outsourced to the 3 Universities) Aero process development (MIRA) Performance simulation & prediction (Ricardo) Drive cycle analysis Effects of drag reduction Validation of findings (All) Concept and feasibility of solutions (CU) Task 12.5 – Programme: CFD, Scale Models, and Vehicles Method CFD & scale models CFD FSWT MG FSWT Location MIRA France GIE S2a Model Scale [%] Status Mair body - Complete MIRA Ref Car - Ongoing MIRA/JLR X351(XJ) - Ongoing MIRA Small MPV - Ongoing Tata LCVTP 30 Complete Rotating wheel rig 80 Complete Durham Uni Bluff body (Ahmed) 25 Complete Loughborough Uni Windsor /Audi A2 25 Nr Complete Coventry Uni Model WT (External Research) Method Location Cranfield Uni Model Status Small MPV (Audi A2) Nr Complete Freelander Complete MIRA Reference Car Nr Complete X351 (XJ) Aerobuck Ongoing Audi A2 November 11 X351(XJ) Aerobuck November 11 Full scale models & Vehicles Task 12.5 – Base Pressure Recovery On Basic Models – Ventilated Cavities Durham Uni •Ahmed body with ventilated base cavity. •Baseline square-back configuration •Effect of cavity depth for: • • • • Solid walled cavity Ventilated cavity with slots Modified slot geometry Model tested in ground effect and freestream •Particle Image Velocimetry (PIV) base flow measurements •Pressure measurements in cavity Task 12.5 – Base Pressure Recovery On Basic Models – Rear Taper Loughborough University • Windsor body with boat-tailed upper rear body (rear body taper) • PIV base flow measurements • Pressure measurements on boat-tail and base PIV results (Particle Image Velocimetry) Task 12.5 – Scale Model WT Testing Cranfield University LCVTP model 0.280 0.270 0.260 0.250 Cd 0.240 0.230 0.220 0.210 Baseline 1° Floor 4° Diffuser Wider Top Body Wiper recess Rear Wheel Front Wheel blanked Arch Blanked Spoilers fitted (20x40) Task 12.5 – CFD (CU) - Mair Model Coventry University Mair body study (aspect ratio L/H, W/H, backlight angle, boat tailing) - Complete. MIRA Reference Car (backlight angle, boat tailing, base plate) Scanned surfaces from W/T model Task 12.5 – CFD (CU) - Mair Model No of afterbodies 0 0 2 4 6 8 10 -0.02 12 70 deg backlight experiment -0.04 experiment round edges -0.06 quater model k-ε quater model k-ω -0.08 half model quater model k-ε ΔCd -0.1 C70 k-ε -0.12 Mair body: Change in Cd with afterbodies Task 12.5 – CFD (CU) - MIRA RC •MIRA Reference Car • Validating CFD with wind tunnel tests • MIRA reference car model morphing and testing through CFD •Scanned from MIRA FS model •Correlation with FS wind tunnel tests • Within 5% of FSWT result Task 12.5 – CFD (MIRA) Jaguar XJ Full vehicle analysis of Jaguar XJ and small MPV Wheels, wheel arches and base pressure recovery techniques Task 12.5 – Full Scale Testing Small MPV •Full Scale Wind Tunnel Testing at MIRA •Development programme carried out •Cd reduced from 0.29 to 0.21 Progression of CD During WT Session 0.290 0.280 0.270 0.260 CD 0.250 0.240 0.230 0.220 0.209 0.210 0.200 Standard Production Car Wheel Covers on Flat Floor Fitted Front Intakes All Front End Door Mirrors Underfloor Closed Vents and removed Wheel Arch Gaps Sealed Blanking Modification 7° Diffuser 30mm Front 65mm Wheel Extrusion Spoilers Tailgate Box Cavity Wheel /Sill Panel Task 12.5 – Full Scale Testing MIRA Reference Car The drag from the rear surfaces of a vehicle can account for more Drag Coefficient Percentage Reduction MIRA Reference Car, Squareback Reduction > Drag Coefficent change, % 8.0% 6.0% 4.0% 2.0% 0.0% 0.00 0.10 0.20 0.30 0.40 0.50 -2.0% < Increase than one third of total vehicle drag Conventional methods and new concepts to increase base pressure are being explored -4.0% -6.0% -8.0% -10.0% -12.0% Base Plate Offset, x/H 6.4% Drag Reduction 83% Base 66% Base 51% Base 38% Base 38% Base - Cut Out Task 12.5 – Full Scale Testing Jaguar XJ Reducing wheel and wheel-arch drag (approximately a quarter of the overall drag) Annular rings can be more effective than using discs For the X351 blanking the outer 35% of face area (shown) reduced drag by 2% Task 12.5 – FSMGWT S2A results • Validation tests with a moving ground plane • S2A wind tunnel at Paris used for this evaluation • Provided the opportunity to evaluate modifications designed in fixed ground plane wind tunnel • Moving ground plane tests gave similar drag reduction results to the earlier work, thus providing further confidence in the design concepts • Detailed results are available in the project reports Process development (MIRA) CFD - OpenFOAM process fully developed for external aero application Correlated with wind tunnel data to examine complex scenarios Large Volume Airflow Visualization (LVAV) - Several wind tunnel tests used to show bubble flow visualization (achieved at wind speed in excess of 20m/s) Transient, with surface mounted microphones pressure measurements : progressed with work ongoing Task 12.6 – Implementation and Evaluation with Generic technology validation Vehicles (JLR/Tata Lead) Effect of aerodynamic improvements over legislative and real world drive cycles • Ricardo’s V-SIM software used to perform drive cycle analysis of EV’s > Range of Cd and frontal areas > Three different vehicle segments (A, C, E) • Effect on Electrical energy consumption and EV range • Effect of aerodynamics on potential regenerative braking energy • 8 different drive cycles analysed including: > European legislative cycle (NEDC) > US legislative cycles > Real world Artemis cycles Task 12.6 – Effect of aerodynamic improvements over legislative and real world drive cycles • Improvements gained vary with drive cycle and vehicle type • Larger gains are on high speed cycles where aerodynamic loads • • are dominant > Low speed urban cycles are largely unaffected The potential for regenerative braking is increased by improving the vehicles aerodynamic drag > City cycles have the largest potential for regenerative braking but the increase by improving Cd is small Smaller, lighter vehicles see a greater percentage gain by improving vehicle drag Aero ‘Design’ Manual • Assumptions > Passenger cars, light commercials, sports, SUV, etc > SME’s, Niche vehicle manfufacturers > Level: entry, assuming some engineering knowledge, • student > Content from WS including illustrations Topics/sections > Intro, basics of drag > Design for low drag > How to do it > Effects on fuel consumption, energy use (EV) > How to get help