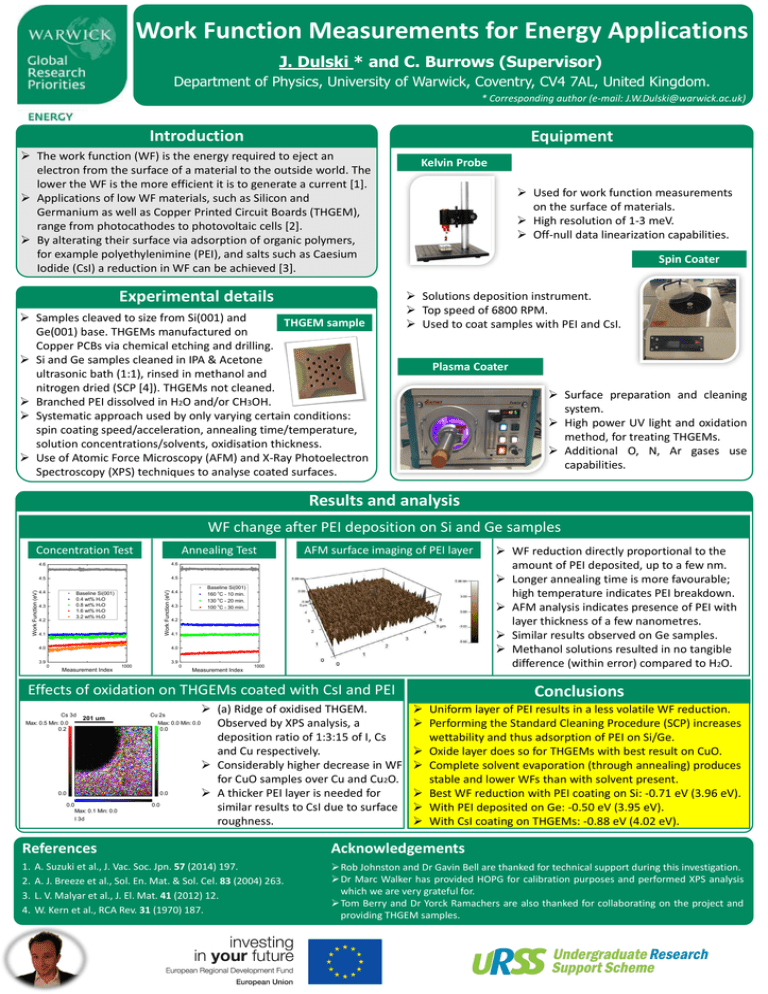

Work Function Measurements for Energy Applications Introduction Equipment

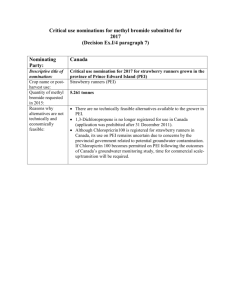

advertisement

Work Function Measurements for Energy Applications J. Dulski * and C. Burrows (Supervisor) Department of Physics, University of Warwick, Coventry, CV4 7AL, United Kingdom. * Corresponding author (e-mail: J.W.Dulski@warwick.ac.uk) Introduction Equipment The work function (WF) is the energy required to eject an electron from the surface of a material to the outside world. The lower the WF is the more efficient it is to generate a current [1]. Applications of low WF materials, such as Silicon and Germanium as well as Copper Printed Circuit Boards (THGEM), range from photocathodes to photovoltaic cells [2]. By alterating their surface via adsorption of organic polymers, for example polyethylenimine (PEI), and salts such as Caesium Iodide (CsI) a reduction in WF can be achieved [3]. Experimental details Samples cleaved to size from Si(001) and THGEM sample Ge(001) base. THGEMs manufactured on Copper PCBs via chemical etching and drilling. Si and Ge samples cleaned in IPA & Acetone ultrasonic bath (1:1), rinsed in methanol and nitrogen dried (SCP [4]). THGEMs not cleaned. Branched PEI dissolved in H2O and/or CH3OH. Systematic approach used by only varying certain conditions: spin coating speed/acceleration, annealing time/temperature, solution concentrations/solvents, oxidisation thickness. Use of Atomic Force Microscopy (AFM) and X-Ray Photoelectron Spectroscopy (XPS) techniques to analyse coated surfaces. Kelvin Probe Used for work function measurements on the surface of materials. High resolution of 1-3 meV. Off-null data linearization capabilities. Spin Coater Solutions deposition instrument. Top speed of 6800 RPM. Used to coat samples with PEI and CsI. Plasma Coater Surface preparation and cleaning system. High power UV light and oxidation method, for treating THGEMs. Additional O, N, Ar gases use capabilities. Results and analysis WF change after PEI deposition on Si and Ge samples Annealing Test 4.6 4.6 4.5 4.5 4.4 Work Function (eV) Work Function (eV) Concentration Test Baseline Si(001) 0.4 wt% H2O 0.8 wt% H2O 1.6 wt% H2O 3.2 wt% H2O 4.3 4.2 4.1 AFM surface imaging of PEI layer Baseline Si(001) 160 oC - 10 min. 130 oC - 20 min. 100 oC - 30 min. 4.4 4.3 4.2 4.1 4.0 4.0 3.9 3.9 0 Measurement Index 0 1000 Measurement Index 1000 Effects of oxidation on THGEMs coated with CsI and PEI Cs 3d Max: 0.5 Min: 0.0(a) 0.2 201 um 0.0 0.0 Max: 0.1 Min: 0.0 I 3d (a) Ridge of oxidised THGEM. Max: 0.0 Min: 0.0 Observed by XPS analysis, a 0.0 deposition ratio of 1:3:15 of I, Cs and Cu respectively. Considerably higher decrease in WF for CuO samples over Cu and Cu2O. 0.0 A thicker PEI layer is needed for 0.0 similar results to CsI due to surface roughness. Cu 2s WF reduction directly proportional to the amount of PEI deposited, up to a few nm. Longer annealing time is more favourable; high temperature indicates PEI breakdown. AFM analysis indicates presence of PEI with layer thickness of a few nanometres. Similar results observed on Ge samples. Methanol solutions resulted in no tangible difference (within error) compared to H2O. Conclusions Uniform layer of PEI results in a less volatile WF reduction. Performing the Standard Cleaning Procedure (SCP) increases wettability and thus adsorption of PEI on Si/Ge. Oxide layer does so for THGEMs with best result on CuO. Complete solvent evaporation (through annealing) produces stable and lower WFs than with solvent present. Best WF reduction with PEI coating on Si: -0.71 eV (3.96 eV). With PEI deposited on Ge: -0.50 eV (3.95 eV). With CsI coating on THGEMs: -0.88 eV (4.02 eV). References Acknowledgements 1. 2. 3. 4. Rob Johnston and Dr Gavin Bell are thanked for technical support during this investigation. Dr Marc Walker has provided HOPG for calibration purposes and performed XPS analysis which we are very grateful for. Tom Berry and Dr Yorck Ramachers are also thanked for collaborating on the project and providing THGEM samples. A. Suzuki et al., J. Vac. Soc. Jpn. 57 (2014) 197. A. J. Breeze et al., Sol. En. Mat. & Sol. Cel. 83 (2004) 263. L. V. Malyar et al., J. El. Mat. 41 (2012) 12. W. Kern et al., RCA Rev. 31 (1970) 187.