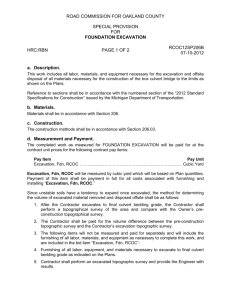

Conceptual Design Construction Plan Toronto Transit Commission - Yonge Subway Extension (YSE)

advertisement

Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design Construction Plan August 26, 2011 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Toronto Transit Commission 5160 Yonge Street Toronto, ON M2N 6L9 Toronto Transit Commission Yonge Subway Extension (YSE) Conceptual Design Construction Plan August 26, 2011 Hatch Mott MacDonald 2800 Speakman Drive Mississauga, Ontario L5K 2R7 Canada Tel: 905 855 2010 Fax: 905 855 2607 john.mcdonald@hatchmott.com John McDonald Contract #Y85-9/001/B Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Toronto Transit Commission Yonge Subway Extension (YSE) Conceptual Design Construction Plan Issue and Revision Record Rev A B Date July 11, 2011 Aug. 26, 2011 Originator J. McDonald J. McDonald Checker Approver Description Draft for Comments Conceptual Design This document has been prepared for the titled project or named part thereof and should not be relied upon or used for any other project without an independent check being carried out as to its suitability and prior written authorization of Hatch Mott MacDonald being obtained. Hatch Mott MacDonald accepts no responsibility or liability for the consequence of this document being used for a purpose other than the purposes for which it was commissioned. Any person using or relying on the document for such other purpose agrees, and will by such use or reliance be taken to confirm their agreement to indemnify Hatch Mott MacDonald for all loss or damage resulting therefrom. Hatch Mott MacDonald accepts no responsibility or liability for this document to any party other than the person by whom it was commissioned. To the extent that this report is based on information supplied by other parties, Hatch Mott MacDonald accepts no liability for any loss or damage suffered by the client, whether through contract or tort, stemming from any conclusions based on data supplied by parties other than Hatch Mott MacDonald and used by Hatch Mott MacDonald in preparing this report. Contract #Y85-9/001/B Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan List of Contents and Appendices 1 2 3 4 5 Page Introduction ................................................................................................................................. 1 1.1 Purpose ........................................................................................................................... 1 1.2 Scope .............................................................................................................................. 1 Contracting Strategy ................................................................................................................... 1 2.1 Contract Strategy ............................................................................................................ 1 2.2 Contracting Options ....................................................................................................... 2 2.3 Contracting Recommendations ...................................................................................... 2 2.4 Contract Interfaces ......................................................................................................... 3 2.4.1 Train Storage Facility ........................................................................................ 3 2.4.2 Richmond Hill Centre Station ........................................................................... 4 2.4.3 East Don River Bridge ...................................................................................... 4 2.4.4 Clark Station ...................................................................................................... 5 2.4.5 Steeles Station ................................................................................................... 5 2.4.6 Early Works Contractors ................................................................................... 5 2.4.7 Systems Installation Contractors ....................................................................... 6 Construction Staging / Methodology .......................................................................................... 6 3.1 Launch Shafts ................................................................................................................. 6 3.2 Tunnel Boring Machines ................................................................................................ 7 3.3 Tunnel Drives ................................................................................................................. 7 3.4 Tunnel Segmental Lining ............................................................................................... 8 3.5 Extraction Shafts ............................................................................................................ 8 3.6 Cut and Cover Construction ........................................................................................... 8 Construction Sites ....................................................................................................................... 9 4.1 Richmond Hill Centre Station and Vicinity ................................................................. 10 4.2 Don River Bridge and Vicinity .................................................................................... 10 4.2.1 Existing Conditions ......................................................................................... 10 4.2.2 Traffic Management during Construction ....................................................... 11 4.2.3 Construction Contracts .................................................................................... 11 4.3 Steeles Station and Vicinity ......................................................................................... 12 4.4 Cummer Station and Vicinity ....................................................................................... 12 Traffic Management .................................................................................................................. 13 5.1 Traffic Lanes ................................................................................................................ 13 5.2 Alternative Traffic Options .......................................................................................... 14 Contract #Y85-9/001 Rev. B, Page i Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 5.3 Road Closures .............................................................................................................. 14 5.4 Turn Lanes ................................................................................................................... 14 5.5 Signing ......................................................................................................................... 15 5.6 Traffic Signal Adjustments/Timing ............................................................................. 15 5.7 Transit Operations and HOV Lanes ............................................................................. 15 5.8 Pedestrians.................................................................................................................... 15 5.9 Private Access .............................................................................................................. 15 6 Construction Schedule .............................................................................................................. 15 7 Critical Path............................................................................................................................... 16 Appendices Appendix A - Drawings Appendix B - Schedules Contract #Y85-9/001 Rev. B, Page ii Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 1 Introduction 1.1 Purpose The purpose of this Construction Plan is to document the contracting strategy and construction methodology for the Yonge Subway Extension (YSE) that meets the challenging needs of this project and to develop an overall construction schedule for planning purposes. The capital cost estimate is based on the methodology and assumptions used in this report. This document is a requirement of the Conceptual Design Phase of the project and will form a basis for a more detailed contracting strategy and construction schedule that would be prepared during the next phase of the YSE project. 1.2 Scope This Construction Plan documents the requirements for the proposed Yonge Subway Extension (YSE) from the existing Finch Station Tailtrack to the Train Storage Facility located north of the Richmond Hill Centre Station in York Region, an extension of 7.416 kilometres; consisting of five new subway stations namely, Cummer Station, Steeles Station, Clark Station, Langstaff Station and Richmond Hill Centre Station. 2 Contracting Strategy 2.1 Contract Strategy For the purpose of the Conceptual Design, it is assumed that the contract strategy adopted for the Yonge Subway Extension (YSE) would be consistent with the strategies previously employed for the construction of the Sheppard Line and that is currently being implemented for the Toronto-York Spadina Subway Extension (TYSSE). These strategies include the following: 1. An equipment contract for the advance owner procurement of earth pressure balance (refer below) (EPB) tunnel boring machines (TBMs). The overall proposed tunnelling length for this project is very similar to TYSSE and consequently, it is likely that four machines would be required. The capital cost estimate will assume that the machines will be purchased new, however the timing of this project could allow for the re-use of the machines currently assigned to TYSSE. 2. A material supply contract for the advance purchase of a precast segmental tunnel lining system (compatible with the TBMs) to line the running tunnels. 3. Where possible, the number of interfaces between adjacent contractors should be minimized. One method of achieving this objective is to include the construction of a station within a tunnel contract particularly for those locations where the tunnel is initially driven through the station footprint. This approach was not used for the Sheppard Project but has been adopted on TYSSE. The experience gained on TYSSE will likely dictate whether this strategy will also be adopted for the Yonge Subway Extension. Contract #Y85-9/001 Rev. B, Page 1 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 2.2 Contracting Options Based on the strategies listed in Section 2.1 above, the following contracting options should be considered: 1. Tunnel drives from a launch shaft (LS1) at Richmond Hill Centre Station crossover south to an extraction shaft (ES1) located within the north approach structure to the East Don River Bridge. This contract could: Include Langstaff Station and Park and Ride lot; Exclude Langstaff Station and Park and Ride lot. 2. Tunnel drives from Steeles Station launch shaft (LS2) north of Steeles Station, north to an extraction shaft (ES2) located within the south approach structure to the East Don River Bridge. This contract could: Include Clark Station; Exclude Clark Station. 3. Tunnel drives from a launch shaft (LS3) at the Steeles Station crossover south to an extraction shaft (ES3) located within an extension of the Finch Tailtrack. This contract could: Include Cummer Station; Exclude Cummer Station; Include 180m of box structure extension to the existing Finch Station tailtrack; Exclude 180m of box structure extension to the existing Finch Station tailtrack. 4. Construction of the East Don River Bridge including approximately 225m of twin box approach structure south of the bridge and 200m of twin box approach structure north of the bridge. 5. Construction of a cut and cover underground train storage facility (834m long for Alignment Bi) including removal and reconstruction of portions of Bantry Avenue Bridge. For construction scheduling purposes and to establish potential requirements for construction sites and haul roads, it has been assumed that this work would be split into two contracts. 6. Construction of Steeles Station, crossover and underground bus terminal. 7. Construction of Richmond Hill Centre Station, crossover and above ground bus terminal. 2.3 Contracting Recommendations The current strategy, based on the Design-Bid-Build approach used for Sheppard and TYSSE projects, that will be used to develop a preliminary construction schedule, is based on the following contract packages: 1. Tunnel drives from a launch shaft (LS1) at Richmond Hill Centre Station crossover south to extraction shaft (ES1) and including Langstaff Station and Park and Ride lot; This contract would also include one EEB and for the re-alignment of the Highway 7 Yonge Street ramp to ensure sufficient cover was provided over the tunnel; Contract #Y85-9/001 Rev. B, Page 2 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 2. Tunnel drives from Steeles Station launch shaft (LS2) at Steeles Station north to an extraction shaft (ES2) and tunnel drives from a launch shaft (LS3) at the Steeles Station crossover south to an extraction shaft (ES3). This contract would also include three EEBs, the construction of Cummer Station and substation and 180m of box structure extension to the existing Finch Station tailtrack; 3. Construction of the East Don River Bridge including approximately 225m of south twin box approach structure and 200m of north twin box approach structure. Two EEBs are included in this package, including all associated road diversions; 4. Construction of the train storage facility from the north end of Richmond Hill Centre Centre Station to 30m south of the Bantry Avenue Bridge Overpass; 5. Construction of the train storage facility from 30m south of Bantry Avenue Bridge to the north end including associated facilities (two EEBs, fan room, electrical services building, change facility and the removal and replacement of the Bantry Avenue Bridge; 6. Construction of Richmond Hill Centre Station, crossover, substation and above ground bus terminal; 7. Construction of the substation and electrical services building at Royal Orchard; 8. Construction of Clark Station and substation; 9. Construction of Steeles Station, crossover, substation and underground bus terminal. 2.4 Contract Interfaces As noted in Section 2.1, the construction schedule and the conceptual design capital cost estimate will be based on the purchase of four earth pressure balanced tunnel boring machines. It has been assumed that the first pair of tunnel boring machines would be used for construction package outlined in Section 2.3 Item 1. The second pair of tunnel boring machines would be used for construction package outlined in Section 2.3 Item 2. The tunnel contractors will install all headwalls at stations and extraction shafts through which the TBM shall pass. The tunnel contractors will be responsible for and complete the excavation, dewatering and temporary works within all launch and extraction shafts. The permanent works within the launch and extraction shafts may also be assigned to the tunnel contractors or they may be assigned to other contractors. For instance, it is proposed that the permanent works for extraction shafts ES1 and ES2 be assigned to the contractor responsible for the East Don River Bridge and the associated box approach structures; refer Section 2.3, Item 4. Key contract interfaces are as follows: 2.4.1 Train Storage Facility The train storage facility will be a large earth moving exercise, with an overall length of more than 830m and a depth of between 21.5 and 23m, the total excavated quantity will be approximately five times that of a typical passenger station. It is therefore proposed to split the work into two contract packages (refer Section 2.3, Items 4 and 5). The scope associated with demolishing a portion of the Bantry Bridge and re- Contract #Y85-9/001 Rev. B, Page 3 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan building the bridge has been assigned to the more northern contract. Drawing SK020 has been prepared to indicate the assigned split between the two contractors. Contractor interfaces therefore include: Train storage contractor (refer Section 2.3, Item 4) and train storage contractor (refer Section 2.3, Item 5) at a location approximately 30m south of Bantry Bridge; Train storage contractor (refer Section 2.3, Item 4) and the contractor for Richmond Hill Centre Station (refer 2.3, Item 6) with the interface being the north end of the station box. 2.4.2 Richmond Hill Centre Station This work area will be quite complex and include the train storage facility to the north, the passenger station and substation, a bus terminal, a crossover and a launch site for the tunnel drives south. In addition, that the interface with the below ground 407 Transitway Station located just south of the bus platform could also be required. For the present, this item will be excluded from the discussion. Drawing SK020 has been prepared to indicate the various areas assigned to the various contractors. Contractor interfaces therefore include: Train storage contractor (refer Section 2.3, Item 4) and the contractor for Richmond Hill Centre Station (refer Section 2.3, Item 6) with the interface being the north end of the station box. The Richmond Hill Centre Station Contractor (refer Section 2.3, Item 6) and the tunnelling contractor (refer Section 2.3 Item 1). As noted, the tunnelling contractor must initially re-shape the existing stormwater pond and re-align the Highway 7 Yonge Street ramp to ensure sufficient cover exists for the tunnelling operation. This contractor will also be responsible for a 45m long launch shaft including excavation, dewatering and support of excavation. The permanent works could be assigned to the tunnelling contractor (per TYSSE methodology) or it could be assigned to the Station Contractor. 2.4.3 East Don River Bridge As noted in Section 2.3, Item 3, this package of work will include the construction of the bridge over the East Don River and the twin box approach structures on either side of the bridge. Due to the reduction in cover, it is necessary to extract the tunnel boring machines at the approach structures. As a minimum, it is assumed that the tunnelling contractors will be responsible for excavation, dewatering and support of excavation including secant pile headwalls for the extraction shafts. For these locations, it is proposed to assign the permanent works at the extraction shafts to the contractor for the bridge and approach structures. Drawing SK022 has been prepared to illustrate the work site implications. Contractor interfaces therefore include: Tunnelling contractor (refer Section 2.3, Item1) that will be extracting the TBM at extraction shaft ES1 at the northern end of the north approach structure and will therefore interface with the East Don River Bridge and approach structures contractor. Tunnelling contractor (refer Section 2.3, Item 2) that will be extracting the TBM at extraction shaft ES2 at the southern end of the south approach structure and will therefore interface with the East Don River Bridge and approach structures contractor. Contract #Y85-9/001 Rev. B, Page 4 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 2.4.4 Clark Station Consistent with the philosophy used for Sheppard Line and the TYSSE projects, the tunnelling contractor is responsible for installing the secant pile end headwalls at a station interface irrespective of the assignment of responsibility for construction of the station. In Section 2.3, Item 8, it was recommended that construction of Clark Station be undertaken by an independent station contractor. This station will have unique water issues (dewatering, contiguous pile cut-off walls for support of excavation) that differentiate this station from other stations required for the expansion. Contractor interface therefore includes: Tunnelling contractor (refer Section 2.3, Item 2) will install secant pile headwalls at both ends of Clark Station and will tunnel through the station. The Clark Station contractor (refer Section 2.3, Item 8) will be responsible for ultimately removing the tunnel lining segments within the station headwalls and will be restricted in the extent of excavation that can be undertaken prior to the completion of the tunnelling contractor’s work for the segment between Steeles Station and the East Don River Bridge south approach structure. 2.4.5 Steeles Station This work area will be extremely complex and include for the subway station and substation, a below ground bus terminal, bus ramps and portals on Steeles Avenue, a crossover and launch sites for the tunnel drives north from Steeles Station to the East Don River Bridge south approach structure and south from the Steeles Station crossover to the extension of the Finch Tail Track. In addition, this work must be undertaken below major urban arteries (Yonge Street and Steeles Avenue). Drawing SK021 has been prepared to illustrate the work site implications. Contractor interfaces therefore include: The Steeles Station Contractor (refer Section 2.3, Item 9) and the tunnelling contractor (refer Section 2.3 Item 2). As noted, the tunnelling contractor will be responsible for a 45m long launch shaft, located adjacent to the northern station box unit, including excavation, dewatering and support of excavation. The permanent works could be assigned to the tunnelling contractor (per TYSSE methodology) or it could be assigned to the Station Contractor. The Steeles Station Contractor (refer Section 2.3, Item 9) and the tunnelling contractor (refer Section 2.3 Item 2). As noted, the tunnelling contractor will be responsible for a 45m long launch shaft, located within the southern end of the crossover, including excavation, dewatering and support of excavation. The permanent works could be assigned to the tunnelling contractor (per TYSSE methodology) or it could be assigned to the Station Contractor. 2.4.6 Early Works Contractors For the purpose of a Conceptual Design discussion, it is deemed to be unnecessary to identify scope that may be implemented by other contractors that would lead to further interface issues with the contractors identified above. For instance, the scope associated with modifying the existing stormwater pond at Richmond Hill Centre Station and re-aligning the Highway 7 Yonge Street ramp from Yonge Street was assigned to the tunnelling contractor. The responsibility for re-location of utilities is not addressed. By default, it is assumed that this work will be implemented by the station contractor and or tunnelling contractor. To minimize the risk of delays to the project, it may become necessary for this work or for Contract #Y85-9/001 Rev. B, Page 5 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan other items of a similar nature, to be assigned to other contractors. These situations will be identified and addressed during detailed design. 2.4.7 Systems Installation Contractors Systems installation includes for: installation of the double-tie track system and isolated slab at special trackwork locations, installation of rail and rail components including rail welding, traction power, signalling and communications and supervisory control. Interface issues between system installation contractors and the station and/or tunnelling contractors are too complex to be addressed at the level of a Conceptual Design. In particular, station construction contracts are generally configured in such a manner that systems installation contractors can obtain free and unobstructed access to the adjacent tunnels for track construction and system installation. Where possible, dropshafts necessary to support this work have been identified and located on the tunnelling general arrangements (refer SK023 and SK024) since these features may necessitate property takes and will influence traffic management planning. In terms of construction schedule, it is assumed that all systems installation will be planned in such a way that the time allocated for construction of structures and finishing of stations, will be sufficient to complete the systems installation. Systems installation, in fact, forms a large component of the structure finishing duration. Commissioning of the system has been indicated on the construction schedule as a unique activity. 3 Construction Staging / Methodology The basic premise behind the methodology developed for the Sheppard Line and TYSSE and proposed for this Yonge Subway Extension Project (YSE) is that where sufficient cover exists, tunnelling by earth pressure balance tunnel boring machines (TBMs), operating in pressurized mode at all times, represents the lowest cost construction methodology for the alignment, with the least surface disruption and consequently, should be maximized to the greatest extent possible. Where there is a need for larger open spaces (stations) or multiple track situations (crossover, pocket track and train storage facility), where tunnelling is not feasible, supported open cut excavation will be used. Tunnel drives indicated on drawings SK023 and SK024 represent 5082m of the overall alignment extension length of 7416m (69%). This includes 510m for stations that are initially tunnelled through and then subsequently constructed by cut and cover. Various components of these methodologies are described below. 3.1 Launch Shafts Launch shafts are the locations where the tunnel boring machines are lowered to track level to commence a tunnel drive and subsequently used to remove spoil from the tunnel and to lower tunnel lining segments and other construction materials. The tunnelling contractor is generally responsible for the design and construction of the launch shaft, the slab that supports the TBM at the secant pile headwall and the thrust frame and TBM cradles. The excavation width for the length of the tunnel boring machine is slightly greater than the minimum width required for station and or twin box construction. The overall length of the TBM and trailing gear is 70-80m; however the launch shaft will be restricted to a length of 45m. In addition, the actual opening at street level will be further limited to 15m and located off-street where possible. Contract #Y85-9/001 Rev. B, Page 6 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 3.2 Tunnel Boring Machines The conceptual design for the tunnels consists of twin tunnels spaced at 13.59m centres with finished internal diameters of 5400mm. Generally, a cover equivalent to 1.5x tunnel diameter (8.1m) is maintained over the tunnels. This requirement will dictate requirements to re-shape the existing stormwater pond prior to commencing the drive south from Richmond Hill Centre Station crossover to provide adequate cover, will dictate the need for approach box structures on either side of the East Don River Bridge and for the extension of the existing Finch Station tailtrack where minimum cover results with the current alignment profile. It is expected that an owner-procured earth pressure balance (EPB) tunnel boring machine contract strategy will be adopted for YSE as it was for TYSSE and for Sheppard. These machines will be specified to operate in EPB mode which is defined as being operated with a filled, pressurized plenum chamber with tunnel spoil removal by means of a screw conveyor. An earth pressure balance tunnel boring machine (EPBM) is a fully shielded tunnel boring machine, which utilizes a full-diameter rotating cutter head equipped with a combination of drag teeth and disc cutters, and which advances using hydraulic rams that thrust against the tunnel initial support erected as a ring within the trailing shield. The machine operates with an active face support system equipped with a screw conveyor, ground conditioning system, and other equipment. The tunnel face support is provided by a highly viscous soil paste formed by the excavated materials mixed with conditioners (bentonite slurry, foams, polymers or other additives). To minimize ground loss, the annulus between the precast tunnel lining and the cavity excavated by the TBM is grouted through radially spaced ports on the trailing shield. 3.3 Tunnel Drives Tunnel drives 1 and 2 (1,937m in length) will launch from LS1 at the south end of the Richmond Hill Centre Station Crossover and mine south through the future Langstaff Station, terminating at extraction shaft ES1 in the north approach box to the East Don River Bridge. Secant pile headwalls will be installed by the tunnel contractor at Langstaff. The tunnelling contractor will also be responsible for the temporary works required at both the launch and extraction shafts and potentially the permanent works at the launch shaft. Up to six weeks is typically allowed between the starts of the parallel drives. Upon completion of the drives, these particular TBMS would no longer be required. Tunnel drives 3 and 4 (1,958m in length) will launch from LS2 located adjacent and north of Steeles Station and mine north through the future Clark Station, terminating at extraction shaft ES2 in the south approach box to the East Don River Bridge. Secant pile headwalls will be installed at Clark Station. Due to the high groundwater levels and groundwater pressures likely requiring cut-off walls to bedrock, Clark Station will be assigned to a station contractor. Upon completion of the drives, these TBMs will be transported back to Steeles Station for Drives 5 and 6. Tunnel drives 5 and 6 (1,187m in length) will launch from LS3 at the south end of the Steeles station crossover and mine south through the future Cummer Station, terminating at extraction shaft ES3 in the extension of the existing Finch tailtrack. Secant pile headwalls will be installed by the tunnel contractor at Cummer Station. Due to the fact that these drives will be the second in the series (following drives 3 and 4), it is proposed to also assign Cummer Station to this tunnelling contractor since the interface management will be more critical. Contract #Y85-9/001 Rev. B, Page 7 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 3.4 Tunnel Segmental Lining The bored tunnels are designed as a complete system. The tunnel lining internal diameter (5400mm), ring length (1500mm) and thickness (235mm) were specified for the TYSSE project as part of the TBM procurement work. Lining design was based on a standard universal six-segment ring (4 trapezoidal segments plus a key and counter-key segment). Geotechnical conditions for YSE would be very similar to those encountered on TYSSE and therefore any changes that would be considered for YSE would likely be as a result of actual experience on TYSSE. For this reason, it is expected that a similar procurement strategy for the tunnel linings would be adopted. 3.5 Extraction Shafts Extraction shafts are the locations where the tunnel boring machines are raised from track level to surface at the completion of a tunnel drive. Responsibility for the design and construction of the extraction shaft is assigned to the tunnelling contractor. The length of the extraction shaft will be 20m; however, where possible, it may be located off-street permitting the TBM to be slid from its final drive position to its removal position so that road traffic is not significantly affected. Alternatively, if the opening must be within the street ROW, the street will be decked over until such time as it becomes necessary to remove the machines. Since the tunnelling drives are staggered by approximately six weeks, the removal of the TBMs will also be staggered by approximately six weeks. 3.6 Cut and Cover Construction Stations, crossovers and emergency exit facilities will be constructed by cut-and-cover methods. This practice was most recently used for the stations along Sheppard Avenue and will also be used for the TYSSE facilities. The majority of the Yonge Subway Extension stations and EEBs are located within the Yonge Street ROW. Cut-and-cover construction for these facilities will therefore require a series of measures to initially divert traffic and utilities to permit installation of the selected excavation support system. Soldier piles and lagging excavation support is typically constructed by installing the soldier piles first within the pre-bored holes, followed by installing lagging boards concurrent with the excavation process. Limits are placed on the extent of open face area permitted to limit the potential for ground loss into the excavation. This option should be considered in conjunction with adequate surface water management. It should also be noted that soldier piles with lagging are a more flexible support system compared with secant piles or continuous concrete diaphragm walls. Soldier piles with lagging are typically considered suitable where ground movements are permitted to some degree, i.e. where sensitive structure or utilities are not located adjacent to the proposed excavation. An internal system of whaler beams and struts are provided to limit the deflection of the soldier piles. The spacing of the struts must also be placed in a manner that does not interfere with subsequent concrete placement. At surface, a system of deck beams will be installed to support the decking required to allow traffic movement during the excavation and construction process. In place of horizontal supports or struts, soil anchors may be used to provide unrestricted access to the excavation areas. Soil anchors are generally designed by specialist contractors, who will supply, install and undertake appropriate tests to confirm that the soil anchors meet the temporary works design criteria. For anchors to be used, temporary construction easements will be necessary. Typically, anchors extend Contract #Y85-9/001 Rev. B, Page 8 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan perpendicularly, or at a predetermined angle, beyond the line of the excavation a distance equal to 1.5 to 2.0 times the excavation depth. For this reason, soil anchors are used less frequently than the internal strut system. The preliminary geotechnical reports for each station based on the current investigation programme provide guidance to when more specific water control measures are necessary to limit the risk of ground loss. These measures may include the installation of multi-stage eductors for dewatering of layered deposits and deep wells for depressurization of underlying aquifers. In the most severe circumstance, contiguous caisson or diaphragm walls installed from surface into the bedrock may be necessary. To permit the installation of current and future utilities, the station structures and other structures such as ventilation shafts and emergency exits are generally positioned in such a manner to typically have 3m of cover from the road surface to the structure (crossovers would have considerably more cover). To minimize potential long term effects on the road systems, specifications mandate the quality and density of the backfill that is placed on the structure to ensure a satisfactory result. Around utilities and in areas where suitable compaction cannot be achieved, unshrinkable fill is specified. 4 Construction Sites The Yonge Subway Extension (YSE) Project is 7.42km in length with 1.61km in the City of Toronto (south of Steeles Avenue) and 5.81km in York Region (north of Steeles Avenue). The project comprises a total of 5.08km of twin-bored tunnel, five stations, five substations, eight emergency exit buildings (EEBs), six dropshafts, six cross passages, one bridge, 513m of twin or triple box structure and an 834m below grade triple track train storage facility north of the Richmond Hill Centre Station. With the exception of the cross passages, all these facilities have a component of cut and cover construction with associated impact on current traffic flows and surrounding property. Each of the contractors has requirements for site parking, site trailers and facilities, equipment storage, materials handling laydown and access. The tunnelling contractor has requirements for power distribution facilities, mechanical and electrical equipment, storage of lining segments and for the possible treatment of spoil that may not be in a state for immediate haulage from the site. The remaining contractors require additional storage space for formwork, reinforcing steel and other materials of construction including cranes. Significant truck movements are required to haul material offsite, deliver and pump concrete on-site and ultimately to bring backfill to the site prior to restoration. The construction contracts for the scopes of work described herein will be structured to minimize, as much as possible, the interfaces between the adjacent contractors to avoid sources of conflict and resulting claims. In addition, it should be noted that there will also be systemwide contractors required for the installation of double ties and isolated slab, track, traction power and signalling and communications requirements that must be installed primarily at track level and whose work must also be coordinated particularly with the station contractors. The four major areas of construction activity are described in more detail below: Contract #Y85-9/001 Rev. B, Page 9 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 4.1 Richmond Hill Centre Station and Vicinity At least four large civil construction contracts are proposed for this 1.25km section of the Yonge Subway Extension (YSE). These include: At the south end of this section, a launch shaft will be required for the North Tunnels Contractor (Contractor ‘A’) to launch the TBMs for Drives 1 and 2 south towards the East Don River Bridge. Prior to commencing the excavation for the launch shaft, this contractor (or an early works contractor) must initially re-shape the existing stormwater pond so that sufficient cover exists to safely begin tunnelling. In addition, it is proposed that the Highway 7 Yonge Street ramp be realigned from its current location situated over the southern half of the crossover to the south of the proposed launch shaft. This re-alignment will limit the influence of on-ramp traffic on construction activity and avoid the need for numerous changes to the on ramp alignment that would otherwise be required. An extension to the stormwater pond intake and the possible adoption of a siphon design will also be required to remove the interface conflict between the launch shaft and the intake. Refer to SK016, SK017 and SK018 for drawings indicating the Highway 7 Yonge Street ramp re-alignment and changes to the stormwater pond profile. The Richmond Hill Centre Station Contractor (Contractor ‘B’) will be responsible for construction of the station including entrances, electrical substation, crossover and above ground bus terminal. There is an option where the southernmost three units (45m) of the crossover structure could be assigned to the tunnelling contractor. Note that the architectural drawing SKA-008A also indicates an underground Highway 407 Transitway Station to the south of the proposed bus terminal. Currently, that station does not form part of the YSE project and is not considered in this Conceptual Design evaluation. Approximately 415m of the below ground train storage facility will be assigned to Contractor ‘C’. It should be noted that this contract would include 2.5 times the excavation quantity of a typical station box, 2.0 times the concrete quantity and 5.0 times the quantity of backfill. The remaining 419m of below ground train storage facility including two EEBs, a fan room, electrical services building, maintenance operators building and a possible dropshaft will be included in Contractor ‘D’ scope. In addition, construction of the train storage facility necessitates the removal and subsequent reconstruction of a significant portion of the existing Bantry Avenue Bridge. Drawing SK020 was developed to show possible contractor site requirements and access. At this time, it would not appear to be possible to isolate construction traffic from traffic used by residents, office workers and mall patrons. It is expected however that a satellite bus terminal facility will be developed such that the current VIVA bus terminal would not remain in operation during the construction programme. 4.2 Don River Bridge and Vicinity 4.2.1 Existing Conditions The East Don River is situated in a valley with wide open embankments on both sides and flows through a 14m span concrete arch culvert under Yonge Street. Yonge Street crosses the East Don River in the Contract #Y85-9/001 Rev. B, Page 10 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Thornhill Heritage District, with the Ladies’ Golf Club of Toronto located on the east side of Yonge Street and the Thornhill Country Club located on the west side. The existing Yonge Street roadway, supported on an embankment across the East Don River valley, consists of two general purpose lanes in each of the northbound and southbound directions and a centre left turn lane. 4.2.2 Traffic Management during Construction The preliminary traffic staging concept involves a 4-lane traffic detour (refer SK022) being built on the west side of Yonge Street adjacent to the bridge and conventional diversions and decking for the bridge approaches and will follow the existing profile of Yonge Street. Care will be taken during construction to minimize environmental effects and to maintain continuous property access. Traffic stages indicated on Drawings SK036 and SK037 consist of: Stage 1 includes a 4-lane traffic detour and a pedestrian walkway constructed on the west side of Yonge Street over the existing East Don River culvert. In Stage 2, the bridge and northbound approaches will be constructed. General traffic will circulate on the 4-lane detour built in Stage 1. Units for the west side approaches immediately adjacent to the bridge would also be constructed at this time to facilitate the next stage of traffic management. In Stage 3, the remaining west side approaches and ultimate Ladies Golf Club access will be constructed. Northbound traffic will use the new bridge; southbound traffic will continue to use the detour. 4.2.3 Construction Contracts At least three large civil construction contracts are proposed for this 0.6km section of the Yonge Subway Extension (YSE). These include: At the north end of this section, a tunnel extraction shaft will be required for the North Tunnels contractor to retrieve the TBMs from Drives 1 and 2 launched from the south end of the Richmond Hill Centre Station crossover. This tunnelling contractor is responsible for dewatering and support of excavation for the tunnel extraction shaft and to retrieve the TBMs. At the south end of this section, a tunnel extraction shaft will be required for the South Tunnels contractor to retrieve the TBMs from Drives 3 and 4 launched from the north end of Steeles Station. This tunnelling contractor is responsible for dewatering and support of excavation for the tunnel extraction shaft and to retrieve the TBMs. The bridge contractor will be responsible for construction of the road detours, construction of the bridge and for both the north and south twin box approach structures including the permanent works at the extraction shafts. Once the tunnel drives are complete, drop shafts are proposed to be constructed within these extraction shaft locations. Contract #Y85-9/001 Rev. B, Page 11 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan 4.3 Steeles Station and Vicinity At least two large civil construction contracts are proposed for this 395m section of the Yonge Subway Extension (YSE). These include: At the north end of this section, a tunnel launch shaft will be required for the South Tunnels contractor to launch the TBMs for Drives 3 and 4 north towards the East Don River Bridge. At the south end of the Steeles Station crossover, a tunnel launch shaft will be required for the South Tunnels contractor to launch the TBMs for Drives 5 and 6 southwards to extraction shaft ES3 located in the extension of the Finch Station tailtrack. The above tunnelling drives, including dewatering and support of excavation for the launch shafts, are assigned to the same contractor. This contractor is also assigned the construction of Cummer Station, the electrical substation at Cummer and the 180m extension of the Finch tailtrack structure. The Steeles Station Contractor will be responsible for construction of the passenger station including entrances, electrical substation, and crossover. There is an option where the southernmost three units (45m) of the crossover structure and the 45m of box structure on the north side of Steeles Station could be assigned to the Soth Tunnels Contractor. The excavation will be decked over, where possible, to facilitate traffic flow and property access. Due to limited depth of cover, decking may be removed to permit construction of the station roof slab. The Steeles Station Contractor’s work will also include the construction of a 16-bay below ground bus terminal with a 185m long bus platform and associated ramps and entrance portals with an overall portal to portal distance of 660m beneath Steeles Avenue. Drawings SK021 and SK031-033 were developed to show possible contractor site requirements and access. 4.4 Cummer Station and Vicinity One large civil construction contract is proposed for this 520m section of the Yonge Subway Extension (YSE) to minimize the potential number of contract interfaces and risk of claims. As noted in Section 2.3, it is proposed to assign this work to the South Tunnelling Contractor responsible for tunnel drives 3 and 4 from Steeles Station north to the East Don River extraction shaft ES2 and for tunnel drives 5 and 6 from the south end of the Steeles Station crossover to extraction shaft ES3. The work at Cummer Station and vicinity will include: A 180m triple box extension of the existing Finch pocket track; At the north end of this triple box section, a tunnel extraction shaft (ES3) will be required for the tunnelling contractor to retrieve the TBMs from Drives 5 and 6. The tunnelling contractor is responsible for dewatering and support of excavation for the tunnel extraction shaft and to retrieve the TBMs. Installation of the secant pile headwalls at Cummer Station so that the TBMs can tunnel through the station; Contract #Y85-9/001 Rev. B, Page 12 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Tunnel drives 5 and 6 will include for 174m through Cummer Station and 166m between Cummer Station and the extraction shaft ES3; Construction of Cummer Station including entrances and an electrical substation. Drawing SK025 was developed to show possible contractor site requirements and access. 5 Traffic Management The Traffic Management Plan will detail vehicular and pedestrian traffic arrangements during the construction of the Project. The analysis of traffic operations in the Traffic Management Plan will generally follow the Traffic Impact Study Guidelines prepared by the City of Toronto and York Region. The complexity of the Traffic Management Plan will also be related to the extent of the construction contract and the nature of the existing traffic congestion issues in the construction zone. The Traffic Management Plan will be developed during detailed design. All elements of a traffic management concept must be approved by the affected road authorities, in consultation with the Police and Fire Departments and Emergency Medical Services, prior to award of a construction contract. Prior to the start of construction, the Proponent will organize information sessions, as required, with the local community and business groups to explain the construction activities and restrictions, as well as to establish lines of communication. Construction and proposed staging procedures will have temporary and/or permanent effects. For each construction site, a specific construction and staging plan will be developed during detailed design and will be implemented during construction based on traffic management principles that have been proven successful on other similar subway construction projects including Sheppard Line and the current TYSSE project. The general guidelines and principles that will be followed for traffic management during construction of the Yonge Subway extension (YSE) include but are not limited to the following: 5.1 Traffic Lanes Where possible, the existing number of lanes will be preserved at an individual construction site. When this cannot be achieved, maintaining current or improvements to transit operations should be the first priority. As a general guideline, where the road surface must be excavated, the minimum number of lanes of traffic as noted in Table 5-1, should be provided at all times. Contract #Y85-9/001 Rev. B, Page 13 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Table 5-1: Minimum Number of Lanes to be Maintained Existing Lanes Minimum Number of Lanes to be Maintained 1 lane in each direction 1 lane with appropriate controls 2 lanes in each direction 1 lane in each direction 2 lanes in each direction 1 lane in each direction 1 centre left (continuous) turn 1 left turn at signalized intersection 3 lanes in each direction 2 lanes in peak direction 1 lane in off peak direction 3 lanes in each direction 2 lanes in peak direction 1 centre left turn lane 1 lane in off peak direction (continuous) 1 left turn signalized intersection 5.2 Alternative Traffic Options Where partial lane closures must occur, traffic operations in the area of the construction, including appropriate upstream and downstream intersections, will be analysed to assess queue lengths, delays and general levels of service. 5.3 Road Closures Where full closure of the road must occur, a suitable road detour will be designated, with the approval of the appropriate road authorities. Temporary closings of arterial roads may occur during designated time periods acceptable to the approval authority. In major commercial areas i.e. Centrepoint Mall, later start times for road closures may be considered for detailed design. 5.4 Turn Lanes Where lane closures are required at signalized intersections and a left turn lane is presently provided, provision for left turning vehicles will be provided. If not possible due to construction, approval for the left turn restriction must be given by the appropriate road authority. If a left turn restriction is allowed, then a suitable detour route for left turns will be designated. Contract #Y85-9/001 Rev. B, Page 14 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Right turn lanes may be closed and need not be accommodated in the traffic diversion, unless traffic volumes dictate their permanent need. This will be coordinated with or dictated by the road authority. 5.5 Signing For all areas of construction, suitable advance signing will be provided. Where lane restrictions will be present for long periods of time, advance signing will also include appropriate alternate routes to encourage motorists to avoid the construction area. 5.6 Traffic Signal Adjustments/Timing Where elements of the traffic signal infrastructure must be adjusted to accommodate traffic diversions or excavations, the physical relocation will be designed for submittal to the appropriate road authority. Where lane closures at a traffic signal must occur, there may be a need to adjust the traffic signal timing. 5.7 Transit Operations and HOV Lanes Maintenance of transit operations are deemed to be the highest priority during any restrictions imposed by construction. Where possible, a dedicated bus lane should be provided. Requirements during construction will be coordinated with the transit operator. HOV lanes will not be provided during construction. 5.8 Pedestrians A minimum 1.2m pedestrian sidewalk will be provided if a sidewalk currently exists. Where a sidewalk must be closed for temporary construction work, alternative pedestrian routes with appropriate signage will be provided. 5.9 Private Access Access will be maintained to all driveways throughout the construction period, unless suitable arrangements have been made with the property owner and the appropriate road authority to provide an alternative access or temporary closure. 6 Construction Schedule Section 2.2 Contracting Options provides a list of basic contracting options that were considered for the implementation of the Yonge Subway Extension (YSE). At this time, no overall project constraint dates have been established or identified. Section 2.3 Contracting Recommendations therefore adopts one potential set of proposed contracts to be applied for the Yonge Subway Extension (YSE) so that an overall construction schedule can be established and approximate durations assigned to various construction activities. Where possible, the objective is to minimize the potential for claims by limiting the overall number of contracts and associated contract interfaces. Drawings SK023 and SK024 provide an overview of the key components needed for the YSE including proposed locations for launch shafts, extraction shafts and direction of tunnel drives. Contract #Y85-9/001 Rev. B, Page 15 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan As noted, the capital cost estimate includes four new TBMs. The assumption is that two tunnelling contracts will be awarded with the first contract including for tunnel drives No 1 and 2 from a launch shaft situated at the south end of the Richmond Hill Centre crossover to extraction shaft (ES1) at the north end of the north approach structure for the East Don River Bridge and the second contract would include for tunnel drives 3 and 4 from the launch shaft located adjacent to and north of the Steeles Station to extraction shaft (ES2) at the south end of the south approach structure to the East Don River Bridge and for tunnel drives 5 and 6 from the launch shaft located at the south end of the Steeles Station crossover to extraction shaft (ES3) at the north end of the extension of the Finch Tailtrack. Tunnels will initially be driven through the footprint for Langstaff Station, Clark Station and Cummer Station. The construction of Langstaff Station will be added to the north tunnel contract. The construction of Cummer Station will be added to the south tunnel contract. The construction of Richmond Hill Centre Station, Bus terminal and crossover, Clark Station and Steeles Station, Bus Terminal and ,crossover would be separate contracts. 7 Critical Path A preliminary design and a preliminary construction schedule have been prepared (refer attached) that documents the adoption of the Section 2.3 strategy for contract packaging. The critical path resulting from the above includes the following general activities: 1. RFP and award of the Geotechnical Investigation; 2. RFP and award for the Design of Cummer Station; 3. Design of Cummer Station; 4. Tender and award for construction of the South Tunnels, Cummer Station and Finch Tail track Extension (refer Section 2.3, Items 2 and 3); Construction of Launch Shaft LS2; Set-up and tunnel drives from LS2 to extraction shaft ES2 located within the south approach structure at the East Don River Bridge; Set-up and tunnel drives from LS3 to extraction shaft ES3 located within the extension of the existing Finch Station tailtrack; Complete excavation, construct structure and finishing for Cummer Station, 5. Installation of systems work, and 6. Commissioning of the system and tie-in to the existing Yonge Subway. Contract #Y85-9/001 Rev. B, Page 16 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Appendix A Drawings Contract #Y85-9/001 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Drawing List Drawing no. Title HMM-SK-016 Richmond Hill Launch Shaft - Preliminary Proposed Road Diversion and Modification of Stormwater Retention Pond HMM-SK-017 Richmond Hill Launch Shaft - Preliminary Proposed Road Diversion and Modification of Stormwater Retention Pond - Cross-sections – Sheet 1 of 2 HMM-SK-018 Richmond Hill Launch Shaft - Preliminary Proposed Road Diversion and Modification of Stormwater Retention Pond – Cross-sections – Sheet 2 of 2 HMM-SK-020 Richmond Hill Centre - Site Areas and Access HMM-SK-021 Steeles Station and Bus Terminal – Site Areas and Access HMM-SK-022 East Don River Bridge – Site Requirements HMM-SK-023 Tunnel- General Arrangement –Sh.1 of 2 HMM-SK-024 Tunnel- General Arrangement –Sh.2 of 2 HMM-SK-025 Finch Station Tail Track Extension & Cummer Station – Site Areas and Access HMM-SK-031 Steeles Station – Traffic Diversion Scheme – Stage 1 HMM-SK-032 Steeles Station – Traffic Diversion Scheme – Stage 2 HMM-SK-033 Steeles Station – Traffic Diversion Scheme – Stage 3 HMM-SK-036 East Don River Bridge – Traffic Diversion – Stage 1 HMM-SK-037 East Don River Bridge – Traffic Diversion – Stage 2 HMM-SK-039 East Don River Bridge – Traffic Diversion – Stage 2 – Sta. 4+900 HMM-SK-040 East Don River Bridge – Traffic Diversion – Stage 2 – Sta. 5+230 Contract #Y85-9/001 Toronto Transit Commission - Yonge Subway Extension (YSE) Conceptual Design – Construction Plan Appendix B Schedules Contract #Y85-9/001 Year 9 Year 8 Year 7 Year 6 Year 5 Year 4 Year 3 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 1 2 3 4 5 6 7 8 9 10 11 12 TBM Available TBM Available Yonge Subway Extension - Construction Schedule Mobilization Excavation Floating Slab Structural Finishing Civil Commissioning Demolition Drop Shaft Utilities Reloc EEB # 8/ Fan Room EEB#7 Train Storage #2 Bantry Bridge Train Storage #1 Crossover Richmond Hill Station Substation Drop Shaft Launch Shaft LS1 Highway 7 on Ramp Utilities Relocation General EEB # 6 Headwall #1 Langstaff Station Headwall #2 EEB #5 Substation R.O. Extraction Shaft ES1 Box Structure #1 East Don River Bridge Box Structure #2 Extraction Shaft ES2 EEB # 4 EEB # 3 Headwall #2 Clark Station Headwall #1 Utilities Relocation General EEB # 2 Launch Shaft LS2 Steeles Station Steeles Bus Terminal Crossover Launch Shaft LS3 EEB # 1 Headwall #1 Cummer Station Headwall #2 Extraction Shaft ES3 Finch Tailtrack Ext Month 16-Jun-11 15:06 Yonge Subway Extension - Detail Design Sched Activity ID Original Start Activity Name 29-Mar-16 642 01-Mar-12 29-Aug-14 0 86 40 240 260 186 191 722 01-Mar-12* 01-Mar-12 02-Jul-12 28-Aug-12 26-Feb-13 05-Sep-13 02-Dec-13 02-Jul-12 29-Jun-12 27-Aug-12 07-Aug-13 05-Mar-14 29-May-14 29-Aug-14 17-Apr-15 80 490 100 490 100 686 02-Jul-12 24-Oct-12 30-Sep-14 21-Dec-12 25-Nov-14 22-Jan-13 23-Oct-12 29-Sep-14 20-Feb-15 24-Nov-14 17-Apr-15 09-Sep-15 110 120 400 400 771 22-Jan-13 26-Jun-13 17-Dec-13 13-Feb-14 16-Apr-13 25-Jun-13 16-Dec-13 14-Jul-15 09-Sep-15 29-Mar-16 120 90 100 440 834 16-Apr-13 04-Oct-13 13-Feb-14 07-Jul-14 04-Jun-12 03-Oct-13 12-Feb-14 03-Jul-14 29-Mar-16 25-Aug-15 90 04-Jun-12 40 10-Oct-12 576 07-Dec-12 09-Oct-12 06-Dec-12 26-Feb-15 Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award 120 120 124 100 100 617 07-Dec-12 29-May-13 15-Nov-13 14-May-14 06-Oct-14 08-Jan-13 28-May-13 14-Nov-13 13-May-14 03-Oct-14 26-Feb-15 21-May-15 Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award 130 130 134 110 100 612 08-Jan-13 11-Jul-13 16-Jan-14 25-Jul-14 02-Jan-15 07-Dec-12 10-Jul-13 15-Jan-14 24-Jul-14 31-Dec-14 21-May-15 17-Apr-15 Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award 130 130 130 110 100 682 07-Dec-12 12-Jun-13 17-Dec-13 20-Jun-14 25-Nov-14 08-Jan-13 11-Jun-13 16-Dec-13 19-Jun-14 24-Nov-14 17-Apr-15 20-Aug-15 Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award 150 147 150 120 100 08-Jan-13 08-Aug-13 10-Mar-14 09-Oct-14 01-Apr-15 07-Aug-13 07-Mar-14 08-Oct-14 31-Mar-15 20-Aug-15 Geotechnical Investigations Project Start RFP and Award Geotechnical Work Plan Geotechnical Investigations (2 or 3 Stages) Geotechnical Design Reports Geotechnical Baseline Report(s) Tunnels Geotechnical Baseline Report(s) Stations Tunnel Design A1060 A1070 A1080 A1470 A1480 Design RFP Award Tunnel Pkg A Design Tender and Award Tunnel Pkg A Tunnel Pkg B Design Tender and Award Tunnel Pkg B Tunnel Boring Machine A1100 A1110 A1120 A1125 Prepare Spec Tender and Award Manufacture (TBM's A and B) Manufacture (TBM'sC and D) Tunnel Segments A1130 A1140 A1145 A1150 Segment Design Tender and Award Plant Mobilization Manufacture Station Design A1160 RFP and Award A1170 Work Plan Cummer A1180 A1190 A1200 A1210 A1220 Clark A1300 A1310 A1320 A1330 A1335 Langstaff A1340 A1350 A1360 A1370 A1375 Steeles A1380 A1390 A1400 A1410 A1460 Summary Milestone Critical Milestone Remaining Work Critical Remaining Work Year 1 Duration 1054 01-Mar-12 Design and Procurement A0010 A1000 A1010 A1020 A1030 A1040 A1050 Finish 2 3 4 5 6 7 8 9 10 01-Mar-12* RFP and Award Geotechnical Work Plan Geotechnical Investigations (2 or 3 Stages) Geotechnical Design Reports Geotechnical Baseline Report(s) Tunnels Geotechnical Baseline Report(s) Stations Design RFP Award Tunnel Pkg A Design Tender and Award Tunnel Pkg A Tunnel Pkg B Design Tender and Award Tunnel Pkg B Prepare Spec Tender and Award Manufacture (TBM's A and B) Manufacture (TBM'sC and D) Segment Design Tender and Award Plant Mobilization Manufacture RFP and Award Work Plan Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award 1 of 5 Actual Work Yonge Subway Extension Project Schedule © Primavera Systems, Inc. 16-Jun-11 15:06 Yonge Subway Extension - Detail Design Sched Activity ID Original Start Activity Name Duration 685 08-Jan-13 Richmond Hill A1420 A1430 A1440 A1450 A1455 Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award Train Storage A1250 A1260 A1270 A1280 A1290 RFP and Award Work Plan Design to 30% Design 30% to 100% Tender and Award Construction South Tunnels Utilities relocation A1490 Utilities Relocation LS2 A1500 A1510 A1515 A1517 LS2 Mobilization LS2 Excavation LS2 Permanent Structure LS2 Drop Shaft Tunnel Boring D2 A1519 A1520 A1530 A1540 TBM Available (A and B) Prepare TBM Tunnel Boring D2-A1 Tunnel Boring D2-B1 Headwalls A1624 Clark Station Headwall 1 A1626 Clark Station Headwall 2 ES2 A1550 ES2 Excavation A1555 ES2 Permanent Structure A2620 ES2 Drop Shaft EEBs A1560 A1570 A1575 A1580 A1590 A1600 A1605 A1610 A1615 EEB # 2 Excavation and Backfill EEB # 2 Permanent Structure EEB # 2 Finishing EEB # 3 Excavation and Backfill EEB # 3 Permanent Structure EEB # 4 Excavation and Backfill EEB # 3 Finishing EEB # 4 Permanent Structure EEB # 4 Finishing Clark Station A1620 A1630 A1640 A1650 Clark Station Mobilization Clark Station Excavation Clark Station Permanent Structure Clark Station Permanent Finishing East Don River Bridge A2470 East Don River Bridge Mobilization A2480 East Don River Bridge Excavation A2490 East Don River Bridge Permanent Structure Summary Milestone Critical Milestone Remaining Work Critical Remaining Work Finish 2 3 4 5 6 7 8 9 10 25-Aug-15 150 150 150 120 100 666 08-Jan-13 08-Aug-13 13-Mar-14 14-Oct-14 06-Apr-15 02-Jul-12 07-Aug-13 12-Mar-14 13-Oct-14 03-Apr-15 25-Aug-15 29-Jan-15 86 40 127 320 81 1454 02-Jul-12 01-Nov-12 02-Jan-13 01-Jul-13 03-Oct-14 25-Nov-14 31-Oct-12 31-Dec-12 28-Jun-13 02-Oct-14 29-Jan-15 19-Jun-20 1390 23-Feb-15 19-Jun-20 205 23-Feb-15 04-Dec-15 200 23-Feb-15 524 23-Feb-15 04-Dec-15 23-Feb-17 40 80 60 40 297 23-Feb-15 20-Apr-15 03-Oct-16 29-Dec-16 15-Jul-15 17-Apr-15 11-Aug-15 28-Dec-16 23-Feb-17 01-Sep-16 0 60 170 170 84 15-Jul-15 12-Aug-15 05-Nov-15 06-Jan-16 10-Sep-15 04-Nov-15 07-Jul-16 01-Sep-16 05-Jan-16 40 10-Sep-15 40 05-Nov-15 412 23-Feb-16 04-Nov-15 05-Jan-16 20-Sep-17 60 60 40 546 23-Feb-16 01-May-17 26-Jul-17 11-Aug-15 16-May-16 25-Jul-17 20-Sep-17 12-Sep-17 60 80 60 60 60 60 60 60 60 1101 11-Aug-15 02-Sep-16 29-Dec-16 04-Nov-15 29-Dec-16 05-Jan-16 24-Mar-17 24-Mar-17 19-Jun-17 08-Oct-15 03-Nov-15 28-Dec-16 23-Mar-17 01-Feb-16 23-Mar-17 28-Mar-16 16-Jun-17 16-Jun-17 12-Sep-17 26-Dec-19 60 270 360 380 1090 08-Oct-15 06-Jan-16 27-Jan-17 27-Jun-18 01-Dec-15 05-Jan-16 26-Jan-17 26-Jun-18 26-Dec-19 03-Feb-20 60 01-Dec-15* 110 25-Feb-16 350 01-Aug-16 Year 1 Design to 30% Design to 60% Design to 90% Design to 100% Tender and Award RFP and Award Work Plan Design to 30% Design 30% to 100% Tender and Award Utilities Relocation LS2 Mobilization LS2 Excavation LS2 Permanent Structure LS2 Drop Shaft 15-Jul-15 Prepare TBM Tunnel Boring D2-A1 Tunnel Boring D2-B1 Clark Station Headwall 1 Clark Station Headwall 2 ES2 Excavation ES2 Permanent Structure ES2 Drop Shaft EEB # 2 Excavation and Backfill EEB # 2 Permanent Structure EEB # 2 Finishing EEB # 3 Excavation and Backfill EEB # 3 Permanent Structure EEB # 4 Excavation and Backfill EEB # 3 Finishing EEB # 4 Permanent Structure EEB # 4 Finishing Clark Station Mobilization Clark Station Excavation Clark Station Permanent Structure Clark Station Permanent Finishing East Don River Bridge Mobilization East Don River Bridge Excavation 24-Feb-16 29-Jul-16 15-Dec-17 East Don River Bridge Permanent Structure 2 of 5 Actual Work Yonge Subway Extension Project Schedule © Primavera Systems, Inc. 16-Jun-11 15:06 Yonge Subway Extension - Detail Design Sched Activity ID Original Start Activity Name A2500 A2510 A2520 A2524 A2526 A2530 A2540 A2550 A2553 A2555 A2560 East Don River Bridge Permanent Finishing Box Structure 1 (East) Excavation Box Structure 1 (East) Permanent Structure Box Structure 1 (West) Excavation Box Structure 1 (West) Permanent Structure Box Structure 1 Permanent Finishing Box Structure 2 (East) Excavation Box Structure 2 (East) Permanent Structure Box Structure 2 (West) Excavation Box Structure 2 (West) Permanent Structure Box Structure 2 Permanent Finishing LS3 A1670 LS3 Excavation A1950 LS3 Permanent Structure A1970 LS3 Drop Shaft Tunnel Boring D3 A1680 Prepare TBM A1700 Tunnel Boring D3-A2 A1710 Tunnel Boring D3-B2 Headwalls A1850 Cummer Station Headwall 1 A1860 Cummer Station Headwall 2 ES3 A1740 ES3 Excavation A2600 ES3 Permanent Structure A2630 ES3 Drop Shaft EEBs A1720 EEB # 1 Excavation and Backfill A1730 EEB # 1 Permanent Structure A1735 EEB # 1 Finishing Steeles Station A1750 A1760 A1770 A1780 A1870 A1880 A1890 A1900 A1910 A1920 A1930 A1940 Steeles Station Mobilization Steeles Station Excavation Steeles Station Permanent Structure Steeles Station Permanent Finishing Steeles Bus Terminal Mobilization Steeles Bus Terminal Excavation Steeles Bus Terminal Permanent Structure Steeles Bus Terminal Permanent Finishing Crossover Mobilization Crossover Excavation Crossover Structure Crossover Floating Slab Cummer Station A1810 A1820 A1830 A1840 Cummer Station Mobilization Cummer Station Excavation Cummer Station Permanent Structure Cummer Station Permanent Finishing Finch Tailtrack Exit A1978 A1980 A1990 A2000 Finch Tailtrack Mobilization Finch Tailtrack Ext Excavation Finch Tailtrack Ext Permanent Structure Finch Tailtrack Ext Permanent Finishing North Tunnels Summary Milestone Critical Milestone Remaining Work Critical Remaining Work Finish Year 1 Duration 350 150 170 150 150 340 130 170 130 170 340 441 18-Dec-17 25-Feb-16 27-Sep-16 30-May-17 04-Dec-17 06-Jul-18 19-May-16 22-Nov-16 26-Jul-17 31-Jan-18 01-Oct-18 23-Feb-16 02-May-19 26-Sep-16 26-May-17 02-Jan-18 05-Jul-18 05-Nov-19 21-Nov-16 25-Jul-17 30-Jan-18 28-Sep-18 03-Feb-20 31-Oct-17 80 60 40 257 23-Feb-16 12-Jun-17 06-Sep-17 16-Jun-16 14-Jun-16 05-Sep-17 31-Oct-17 09-Jun-17 60 150 150 62 16-Jun-16 12-Sep-16 07-Nov-16 12-Sep-16 09-Sep-16 13-Apr-17 09-Jun-17 06-Dec-16 40 12-Sep-16 40 10-Oct-16 321 07-Oct-16 04-Nov-16 06-Dec-16 29-Dec-17 60 60 40 361 07-Oct-16 08-Aug-17 01-Nov-17 14-Jul-16 04-Jan-17 31-Oct-17 29-Dec-17 30-Nov-17 60 60 60 1223 14-Jul-16 12-Jun-17 06-Sep-17 21-Aug-15 06-Oct-16 05-Sep-17 30-Nov-17 28-Apr-20 60 300 350 480 40 300 450 200 40 330 280 60 1006 21-Aug-15 16-Nov-15 24-Jan-17 08-Jun-18 16-Nov-15 15-Jan-16 21-Mar-17 28-Dec-18 11-Mar-16 06-May-16 22-Sep-17 30-Oct-18 12-Aug-16 13-Nov-15 23-Jan-17 07-Jun-18 28-Apr-20 14-Jan-16 20-Mar-17 27-Dec-18 09-Oct-19 05-May-16 23-Aug-17 29-Oct-18 25-Jan-19 19-Jun-20 60 230 300 390 863 12-Aug-16 07-Nov-16 04-Oct-17 11-Dec-18 16-Jun-16 04-Nov-16 03-Oct-17 10-Dec-18 19-Jun-20 07-Oct-19 40 190 260 350 1413 16-Jun-16 12-Aug-16 12-May-17 22-May-18 25-Nov-14 11-Aug-16 11-May-17 21-May-18 07-Oct-19 23-Apr-20 2 3 4 5 6 7 8 10 9 East Don River Bridge Permanent Finishing Box Structure 1 (East) Excavation Box Structure 1 (East) Permanent Structure Box Structure 1 (West) Excavation Box Structure 1 (West) Permanent Structure Box Structure 1 Permanent Finishing Box Structure 2 (East) Excavation Box Structure 2 (East) Permanent Structure Box Structure 2 (West) Excavation Box Structure 2 (West) Permanent Structure Box Structure 2 Permanent Finishing LS3 Excavation LS3 Permanent Structure LS3 Drop Shaft Prepare TBM Tunnel Boring D3-A2 Tunnel Boring D3-B2 Cummer Station Headwall 1 Cummer Station Headwall 2 ES3 Excavation ES3 Permanent Structure ES3 Drop Shaft EEB # 1 Excavation and Backfill EEB # 1 Permanent Structure EEB # 1 Finishing Steeles Station Mobilization Steeles Station Excavation Steeles Station Permanent Structure Steeles Station Perm Steeles Bus Terminal Mobilization Steeles Bus Terminal Excavation Steeles Bus Terminal Permanent Structure Steeles Bus Terminal Permanent Finishing Crossover Mobilization Crossover Excavation Crossover Structure Crossover Floating Slab Cummer Station Mobilization Cummer Station Excavation Cummer Station Permanent Structure Cummer Station Finch Tailtrack Mobilization Finch Tailtrack Ext Excavation Finch Tailtrack Ext Permanent Structure Finch Tailtrack Ext Permanent Finishing 3 of 5 Actual Work Yonge Subway Extension Project Schedule © Primavera Systems, Inc. 16-Jun-11 15:06 Yonge Subway Extension - Detail Design Sched Activity ID Original Start Activity Name Utilities Relocation A2005 Highway 7 on Ramp Civil Works A2010 Utilities Relocation LS1 A2020 A2030 A2200 A2210 Mobilization Excavation Launch Shaft Structure Drop Shaft Tunnel Boring D1 A2039 A2040 A2050 A2060 TBM Available (C and D) Prepare TBM Tunnel Boring D1-C1 Tunnel Boring D1-D1 Headwalls A2180 Langstaff Station Headwall 1 A2190 Langstaff Station Headwall 2 ES1 A2070 Excavation A2640 Permanent Structure A2650 Drop Shaft EEBs A2080 A2090 A2095 A2100 A2110 A2115 EEB # 6 Excavation and Backfill EEB # 6 Permanent Structure EEB # 6 Finishing EEB # 5 Excavation and Backfill EEB # 5 Permanent Structure EEB # 5 Finishing Langstaff Station A2140 A2150 A2160 A2170 Langstaff Station Mobilization Langstaff Station Excavation Langstaff Station Permanent Structure Langstaff Station Permanent Finishing Richmond Hill Station A2220 A2230 A2240 A2250 A2260 A2270 A2280 A2290 Richmond Hill Station Mobilization Richmond Hill Excavation Richmond Hill Permanent Structure Richmond Hill Permanent Finishing Crossover Mobilization Crossover Excavation Crossover Structure Crossover Floating Slab Train Storage A2300 A2310 A2320 A2330 A2340 A2370 A2380 A2390 A2410 A2420 A2430 A2435 Train Storage #1 Mobilization Train Storage #1 Excavation Train Storage #1 Permanent Structure Train Storage #1 Floating Slab Train Storage #1 Permanent Finishing Train Storage #2 Mobilization Train Storage #2 Excavation Train Storage #2 Permanent Structure Train Storage #2 Permanent Finishing EEB # 8 Excavation and Backfill EEB # 8 Permanent Structure EEB # 8 Finishing Summary Milestone Critical Milestone Remaining Work Critical Remaining Work Finish Year 1 Duration 269 25-Nov-14 04-Dec-15 190 25-Nov-14 220 26-Jan-15 586 04-May-15 25-Aug-15 04-Dec-15 31-Jul-17 40 80 80 60 351 04-May-15 30-Jun-15 13-Jan-17 05-May-17 10-Sep-15 29-Jun-15 21-Oct-15 04-May-17 31-Jul-17 12-Jan-17 0 60 190 190 61 10-Sep-15 19-Nov-15 17-Feb-16 13-Apr-16 16-Mar-16 16-Feb-16 11-Nov-16 12-Jan-17 08-Jun-16 40 16-Mar-16 40 13-Apr-16 416 13-Apr-16 10-May-16 08-Jun-16 15-Nov-17 60 60 40 544 13-Apr-16 27-Jun-17 21-Sep-17 22-Oct-15 07-Jul-16 20-Sep-17 15-Nov-17 21-Nov-17 60 80 60 60 80 60 1053 22-Oct-15 13-Jan-17 05-May-17 20-Jan-16 05-May-17 29-Aug-17 16-Mar-16 19-Jan-16 04-May-17 31-Jul-17 12-Apr-16 28-Aug-17 21-Nov-17 27-Mar-20 60 240 350 375 1132 16-Mar-16 09-Jun-16 19-May-17 05-Oct-18 22-Oct-15 08-Jun-16 18-May-17 04-Oct-18 27-Mar-20 21-Feb-20 60 260 360 420 60 240 330 60 1365 22-Oct-15 20-Jan-16 27-Jan-17 27-Jun-18 22-Oct-15 20-Jan-16 29-Dec-16 15-May-18 30-Jan-15 19-Jan-16 26-Jan-17 26-Jun-18 21-Feb-20 19-Jan-16 28-Dec-16 16-Apr-18 08-Aug-18 23-Apr-20 60 350 480 60 380 60 350 460 440 60 80 60 30-Jan-15 24-Apr-15 09-Sep-16 01-Aug-18 25-Oct-18 30-Jan-15 24-Apr-15 09-Sep-16 03-Jul-18 22-Jun-15 09-Apr-18 01-Aug-18 23-Apr-15 08-Sep-16 31-Jul-18 24-Oct-18 23-Apr-20 23-Apr-15 08-Sep-16 02-Jul-18 26-Mar-20 15-Sep-15 31-Jul-18 24-Oct-18 2 3 4 5 6 7 8 9 10 Highway 7 on Ramp Civil Works Utilities Relocation Mobilization Excavation Launch Shaft Structure Drop Shaft 10-Sep-15 Prepare TBM Tunnel Boring D1-C1 Tunnel Boring D1-D1 Langstaff Station Headwall 1 Langstaff Station Headwall 2 Excavation Permanent Structure Drop Shaft EEB # 6 Excavation and Backfill EEB # 6 Permanent Structure EEB # 6 Finishing EEB # 5 Excavation and Backfill EEB # 5 Permanent Structure EEB # 5 Finishing Langstaff Station Mobilization Langstaff Station Excavation Langstaff Station Permanent Structure Langstaff Station Perm Richmond Hill Station Mobilization Richmond Hill Excavation Richmond Hill Permanent Structure Richmond Hill Permanent Finishing Crossover Mobilization Crossover Excavation Crossover Structure Crossover Floating Slab Train Storage #1 Mobilization Train Storage #1 Excavation Train Storage #1 Permanent Structure Train Storage #1 Floating Slab Train Storage #1 Per Train Storage #2 Mobilization Train Storage #2 Excavation Train Storage #2 Permanent Structure Train Storage #2 Perm EEB # 8 Excavation and Backfill EEB # 8 Permanent Structure EEB # 8 Finishing 4 of 5 Actual Work Yonge Subway Extension Project Schedule © Primavera Systems, Inc. 16-Jun-11 15:06 Yonge Subway Extension - Detail Design Sched Activity ID Original Start Activity Name Duration 60 60 60 318 A2440 EEB # 7 Excavation and Backfill A2450 EEB # 7 Permanent Structure A2455 EEB # 7 Finishing Bantry Bridge A2350 Bantry Bridge Demolition A2360 Bantry Bridge Permanent Structure Commissioning A2590 Commissioning Summary Milestone Critical Milestone Remaining Work Critical Remaining Work Finish Year 1 11-Nov-15 27-Apr-17 24-Jul-17 15-Jun-16 08-Feb-16 21-Jul-17 16-Oct-17 01-Sep-17 60 15-Jun-16 130 02-Mar-17 194 03-Feb-20 08-Sep-16 01-Sep-17 29-Oct-20 194 03-Feb-20 29-Oct-20 2 3 4 5 6 7 8 9 10 EEB # 7 Excavation and Backfill EEB # 7 Permanent Structure EEB # 7 Finishing Bantry Bridge Demolition Bantry Bridge Permanent Structure Commissioning 5 of 5 Actual Work Yonge Subway Extension Project Schedule © Primavera Systems, Inc.