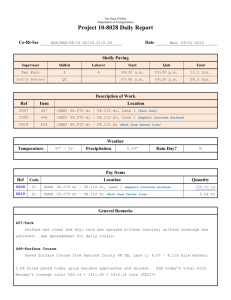

Tack Coat Testing – Measuring Field Bond Strength

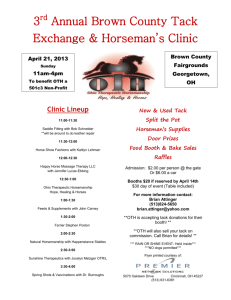

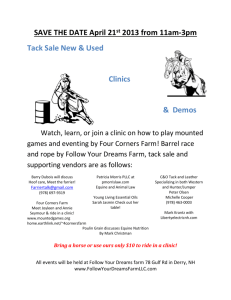

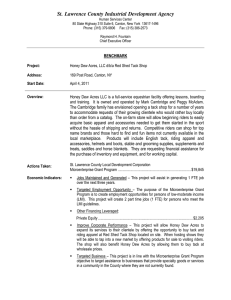

advertisement