Document 12044339

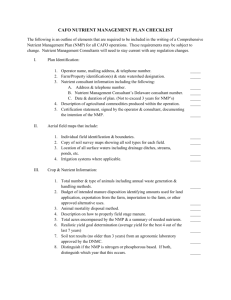

advertisement