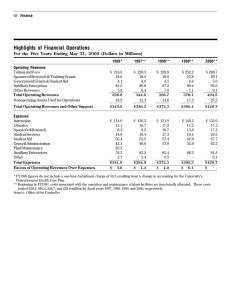

Assignment of New Products Under Classified Pricing: A Conceptual Dynamic

advertisement