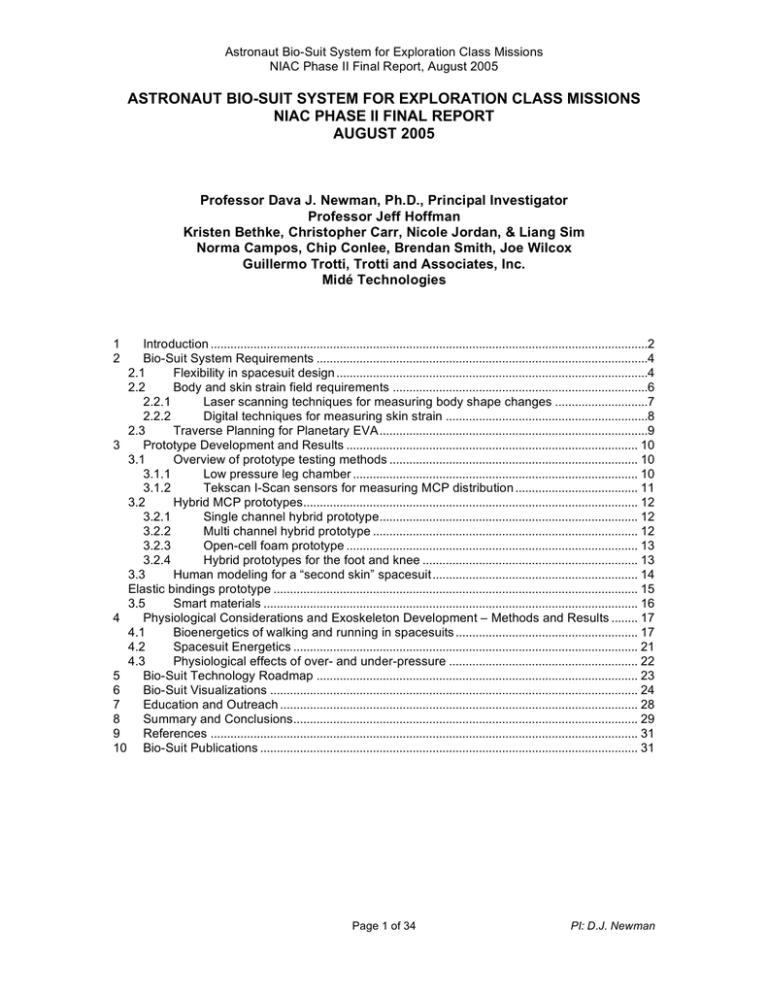

ASTRONAUT BIO-SUIT SYSTEM FOR EXPLORATION CLASS MISSIONS AUGUST 2005

advertisement