Spectral properties of liquid-core Bragg fibers Please share

Spectral properties of liquid-core Bragg fibers

The MIT Faculty has made this article openly available.

Please share

how this access benefits you. Your story matters.

Citation

As Published

Publisher

Version

Accessed

Citable Link

Terms of Use

Detailed Terms

Rowland, K.J. et al. “Spectral properties of liquid-core Bragg fibers.” Lasers and Electro-Optics, 2009 and 2009 Conference on Quantum electronics and Laser Science Conference.

CLEO/QELS 2009. Conference on. 2009. 1-2. ©2009 IEEE.

Institute of Electrical and Electronics Engineers

Final published version

Wed May 25 23:20:25 EDT 2016 http://hdl.handle.net/1721.1/60289

Article is made available in accordance with the publisher's policy and may be subject to US copyright law. Please refer to the publisher's site for terms of use.

© 2009 OSA/CLEO/IQEC 2009

CThE2.pdf

Spectral Properties of Liquid-Core Bragg Fibers

Kristopher J. Rowland 1* , Shahraam Afshar V.

1 , Alexander Stolyarov 2 , Yoel Fink 2 , and Tanya M. Monro 1

[1] Centre of Expertise in Photonics, School of Chemistry & Physics, University of Adelaide, South Australia, Australia, 5005

[2] Photonic Bandgap Fibers and Devices Group, Massachusetts Institute of Technology, Cambridge, Massachusetts 02139, USA

* kristopher.rowland@adelaide.edu.au

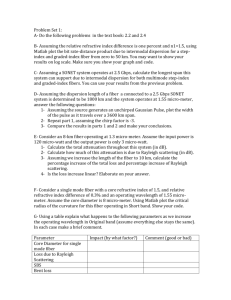

Abstract: We demonstrate significant shifting of the fundamental bandgap of a hollow-core

Bragg fiber by systematically filling the core with liquids of various refractive indices.

Comparison with theory demonstrates the importance of considering material dispersion.

©2009 Optical Society of America

OCIS codes: (060.2400) Fiber properties; (230.4170) Multilayers; (060.4005) Microstructured fibers;

1. Introduction

Air-core Bragg fibers (cylindrically symmetric photonic bandgap fibers with a 1-D binary layered cladding and a hollow core) have recently attracted much interest for their suitability for applications such as precision infra-red high-power delivery [1]. However, until recent work on surface-emitting fiber lasers (SEFLs) [2], Bragg fibers have primarily been considered only with an air core. As recently discussed [3], the structure of this type of fiber permits bandgap guidance within any core material with a refractive index from 1 up to that of the lowest cladding layer index. By increasing the refractive index of the core by, say, filling it with various liquids, the core light-line is able to intercept different regions of the cladding bandgap spectrum, typically shifting the transmission window to shorter wavelengths and altering the supported bandwidth [3].

These principles also apply [3] to hollow-core Integrated-ARROW planar waveguides [4] which have attracted much interest recently. The dimensions of these waveguides make them ideal for applications to sensing and microfluidics [4]. By virtue of the similarities of the two types of waveguide [3], any results pertaining to the spectral properties of filled Bragg fibers will translate similarly to Integrated-ARROWs.

To the best of the Authors' knowledge, there has not yet been a systematic study on the effect filling the hollow core of a Bragg fiber with liquids of various refractive indices. Here we present such a study and demonstrate how the spectral behavior of a particular Bragg fiber is altered when filled with various liquids. The results are in reasonable agreement with that expected from theory. Such low-loss liquid-core fibers would have applications in sensing [4], microfluidics [4], novel nonlinear devices [5] and SEFLs [2].

2. Experimental Results

The 15cm lengths of Bragg fiber used consist of a large (330µm diameter) hollow core, surrounded by a periodic cladding with 9 pairs of alternating layers of Arsenic Trisulphide (As

2

S of approximate thicknesses 76nm and 124nm respectively. The cladding was terminated by a thick jacket of PEI producing a total outer diameter (OD) of 585µm. The first and final As

2

3

) glass and Poly-Ether Imide (PEI) polymer

S

3

layers of the cladding are designed to be half the thickness of the others in an attempt to minimise surface states. Importantly, in the regimes of interest here,

As

2

S

3

and PEI have non-negligible material dispersion, Fig. (1). Figs. (2)(a) & (2)(c) show the calculated bandgap spectrum (effective modal refractive index vs. wavelength) with and without the layer material dispersion incorporated; the TM gaps lie in the white regions whereas the TE gaps lie in the white and grey regions.

In order to fill the fiber and measure the transmitted spectra, we employed a hermetically sealed filling setup in which, once the fiber itself is filled, the fiber ends are suspended in a reservoir of the liquid. The reservoir is terminated by transparent windows permitting free-space in- and out-coupling of light to and from the filled fiber.

The light lauched into the fiber was from a supercontinuum white-light source from Koheras (the SuperK TM

Compact). The liquids used to fill the fiber were 'Immersion Liquids' from Cargille with refractive indices 1.4019,

1.4620 and 1.5780 (all standardised at a wavelength of =589.3nm).

Fig. (2)(b) shows the measured transmission spectra of the fiber when filled with each liquid (peaks 1 through

3) and when empty (peak 4). There is a clear trend followed by the set of peaks: as the core index increases the transmission wavelength monatonically decreases, almost covering the whole visible spectrum (peaks 1 through 4 are centered on wavelengths of approximately 500nm, 533nm, 555nm and 700nm, respectively), and the peak width initially decreases then increases again. This behavior coincides with what is qualitatively expected of the fundamental TM bandgap, such as in Figs. (2)(a) and (2)(c). It is expected that the TM gap dominates the transmission spectrum since the input source is randomly polarised; light beyond the edges of the smallest bandgap will thus be attenuated most (the TM gap always lies within the TE for modes in the region of interest here [1,3]).

978-1-55752-869-8/09/$25.00 ©2009 IEEE

CThE2.pdf

© 2009 OSA/CLEO/IQEC 2009

Fig. 1. The refractive indices of the cladding layer materials, (a)

As

2

S

3

and (b) PEI, versus wavelength. The curves are actually optimised fits to independently measured datapoints [6] and are used in the evaluation of the bandgap spectrum in Fig. (2)(a). Only a spot point of the indices (at = 700nm) is used to generate Fig. (2)(c).

Fig. 2. (a) Bandgap spectrum of the Bragg fiber used where the layer material dispersion has been taken into account. (b) Transmission spectra of the fiber when empty (peak 4) and after filling with liquids of various refractive indices (peaks 1-3). (c) The same as Fig.

(2)(a) but where layer material dispersion has been neglected.

3. Comparison with Theory and Conclusion

It is well known that the cladding of a Bragg fiber can be approximated as a planar Bragg stack [1-3] with the cladding bandgaps obtained from a Bloch-wave analysis [3]. However, such analyses typically assume the cladding layer indices are constant. We demonstrate that in the regimes discussed here, the material dispersion is nonnegligible, Fig. (1), and must be taken into account for any meaningful comparison with experiment. Fig. (2)(a) incorporates the dispersive indices of As

2

S

3

and PEI whereas Fig. (2)(c) assumes constant indices corresponding to those of the layers at =700nm. The constantn bandgap map [Fig. (2)(c)] clearly flattens out faster at shorter than the dispersiven map [Fig. (2)(a)], artificially shifting the bandgap considerably (the left-most band edge of peak 1 is beyond the scale shown). The substantial disagreement of the band edges between the two cases, and the degree of variation in the indices at these wavelengths [Fig. (1)], implies that dispersion can not be neglected. Dispersion of the filling liquids should also be taken into account and is approximated here (in the absence of independent measurents) by the dotted lines in Figs. (2)(a) & (2)(c), representing a potential 2% increase in n core

; the highest and lowest band edges from both the original and perturbed n core

-light-line intercepts are shown (vertical solid lines).

Close agreement is achieved between the TM band edges (with layer material dispersion), Fig. (2)(a), and the transmission peaks of the filled and unfilled Bragg fiber, Fig. (2)(b). The agreement of the middle two peaks is poorer than that of the outermost, likely due to insufficient precision of the estimated fiber layer thicknesses and dispersion properties of the liquids (each liquid is only standardised at =589.3nm); the smaller gaps in that region are relatively more sensitive to perturbations to fiber parameters.

In conclusion, we have experimentally demonstrated the shifting of a Bragg fiber's transmission spectrum by filling the core with liquids of various refractive indices. Reasonable agreement with what is expected from a

Bloch-wave based analysis was achieved only when the material dispersion of the layers was incorperated. A more precise analysis will be presented following detailed measurements of the fiber and liquid properties as discussed.

These results verify some of the key features of liquid-filled Bragg waveguides discussed in [3] which are important for the application of liquid-core Bragg fibers to sensing, microfluidics, novel nonlinear devices and SEFLs.

References

[1] B. Temelkuran et al., “Wavelength-scalable hollow optical fibres with large photonic bandgaps for CO

2

laser transmission,” Nature 420,

650-653 (2002)

[2] O. Shapira et al. “Surface-Emitting Fiber Lasers,” Opt. Express 14, 3929-3935 (2006)

[3] K. Rowland et al., “Bandgaps and antiresonances in integrated-ARROWs and Bragg fibers; a simple model,” Opt. Express 16, 17935 (2008)

[4] D. Yin et al., “Optical characterisation of arch-shaped ARROW waveguides with liquid cores,” Opt. Express 13, 10564–10570 (2005).

[5] S. Yiou et al., “Stimulated Raman scattering in an ethanol core microstructured optical fiber ,” JOSA A 14, 741-755 (1997).

[6] Refractive index data used is available from the site: http://mit-pbg.mit.edu/Pages/DataBase.html