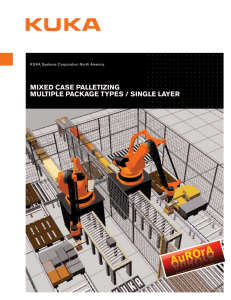

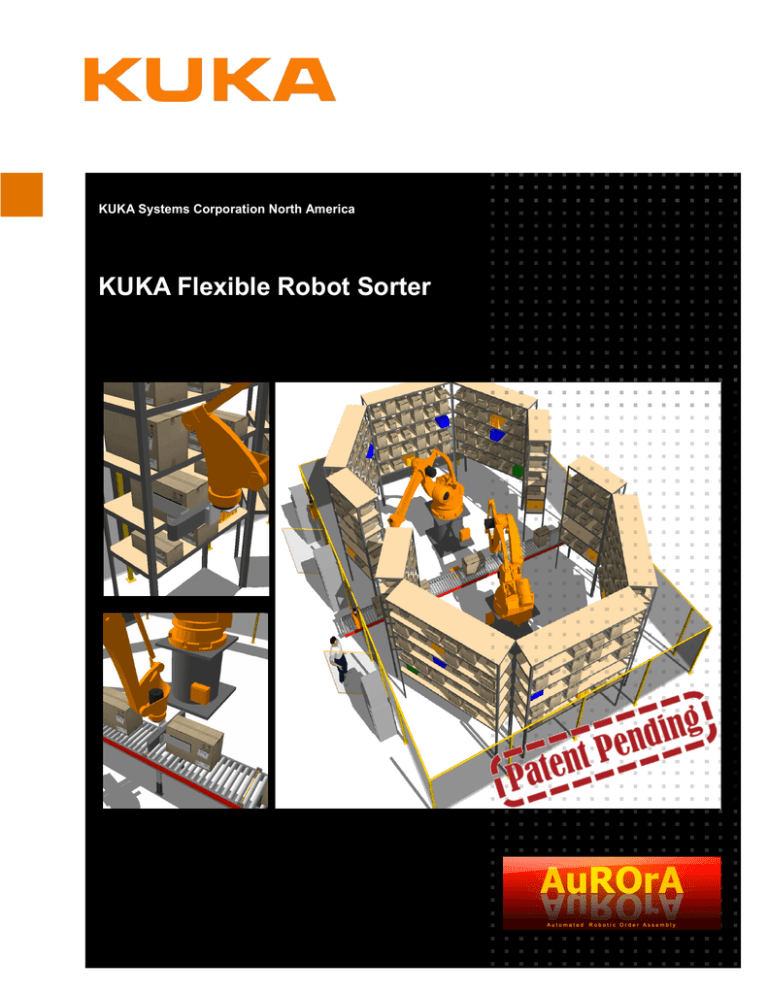

KUKA Flexible Robot Sorter KUKA Systems Corporation North America

advertisement

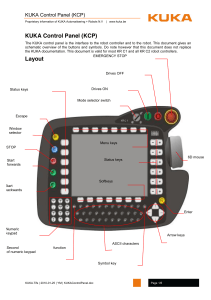

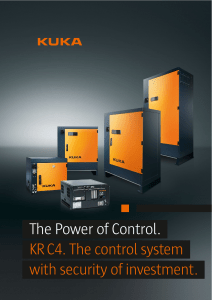

KUKA Systems Corporation North America KUKA Flexible Robot Sorter KUKA SYSTEMS CORP. FLEXIBLE ROBOT SORTER Flexible Robot Sorter … if you require a dedicated sequence to your product stream, but currently have no way to make it happen. … if you currently have a large amount of floor space taken up with large case sortation systems and need a lower maintenance and floor space solution. Example Scene … if you currently have a pick-to-sticker or wave pick system that needs a lean cost-effective way to provide a palletizing cell product in a dedicated sequence The KUKA Flexible Robot Sorter solution is a concept designed for buffering, sorting, or customized stacking of various products. With today’s SKU proliferation, more and more order lines are becoming very diverse. With such diversity, it is sometimes difficult in traditional automated systems to sequence the order lines properly for palletizing. However, with KUKA’s innovative Flexible Robot Sorter (FRS), this is no longer a challenge. With the FRS, order flow can be random without any degradation to the integrity of the mixed pallet building process. The KUKA.PalletMix Software evaluates the order line and determines the proper palletizing sequence based on the customer’s stacking rules. The SKUs are then released into the system either in sequence or random, depending on the automation upstream. The FRS tracks each SKU and if they are in sequence, then they are passed through to the palletizing cell for palletizing. If SKUs are presented out of sequence, the FRS robot will pick the SKU and place it into an intermediate storage shelf until such a time that the order sequence requires it to be placed back on the conveyor. Example Scene Example Scene Corresponding 3D result Corresponding 3D result Corresponding 3D result THE BENEFITS Single-source solution, from planning to the world-wide after sales support Seamless flow of information between systems Standardized industrial robots Random or sequenced flow of order lines The flexibility and security of continuous operation the FRS solution provides is invaluable in today’s warehouse and distribution operations where uptime and accuracy are critical components to a successful and productive distribution facility. Scalable to your production needs Free-standing cell with robot & shelves take up minimal floor space & are easy to maintain / clean Easily modified for additional SKU capability and new product types KUKA SYSTEMS CORP. FLEXIBLE ROBOT SORTER MAIN SYSTEM COMPONENTS Picture of KR 100 A B A KUKA Robot (KR 100 PA or KR 180 PA) for picking objects B KUKA Wing Gripper to accommodate different object sizes C Variable Shelves for Intermediate Storage D Cell Controller with Teach Pendant & Safety Control E KUKA.PickControl Application Software with interface to superior Warehouse Control System (WCS) F KUKA Robot Control THE SYSTEM CONTROLLER C D The system control includes the KUKA.PickControl software of KUKA AuROrA™ application framework and is the communication and control interface to the operator and superior Warehouse Control Systems (WCS). It connects to the robot and directs the work load to the different picking robot in the work cell. It features many support functions to simplify the commissioning process and the system diagnostics. THE FLEXIBLE ROBOT SORTER F E TECHNICAL DATA Picking Performance Up to 6 picks / minute (depending on layout / packaging) Temperature Range 0 - 110°F Maximum Case Weight Variable Energy Supply 480 VAC or Local Voltage and frequency 1 In-feed pallet conveyor 2 Shelves for intermediate storage 3 Picking Robot 4 Outfeed case conveyor 2 4 3 1 KUKA Systems Corporation North America WOULD YOU LIKE MORE INFORMATION ABOUT HOW KUKA SYSTEMS CAN HELP YOU REDUCE YOUR COSTS, OPTIMIZE YOUR OPERATIONS, AND IMPLEMENT A FLEXIBLE SOLUTION FOR NOW AND THE FUTURE? CONTACT US AT LOGISTICSSOLUTIONS@KUKANAO.COM OR CALL +1 586 795 2000. KUKA Systems Corporation, North America 6600 Center Drive | Sterling Heights, MI | 48312 | USA Phone 586 795 2000 | Fax 586 649 4434 | info@kukanao.com | www.kukanao.com WM - Nr. 996000/1102/USA/1© ROBOGISTICS™. ROBOTICS IN LOGISTICS.