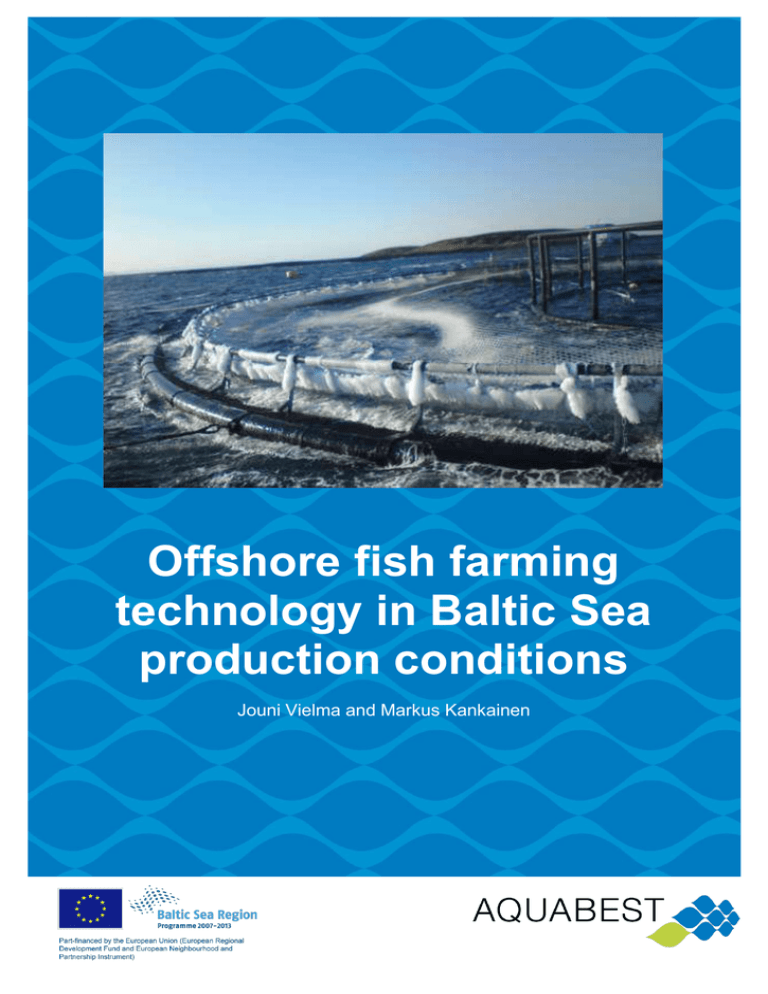

Offshore fish farming technology in Baltic Sea production conditions

advertisement

Offshore fish farming technology in Baltic Sea production conditions Jouni Vielma and Markus Kankainen Finnish Game and Fisheries Research Institute, Helsinki 2013 ISBN 978-952-303-064-0 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea production conditions Jouni Vielma and Markus Kankainen Finnish Game and Fisheries Research Institute Description Authors Kankainen, M. & Vielma, J. Title Offshore fish farming technology in Baltic Sea conditions Year Pages ISBN 2013 23 978-952-303-064-0 Abstract In coastal regions, spatial planning often leads to the conclusion that the best new cage farming sites are located in open or semi-open areas with harsh production conditions. It is apparent that, under such conditions, conventional cage farming technology faces high risks of failure due to high wind speeds, high wave heights and strong currents. In addition to tolerating high-energy and harsh conditions, systems need to be cost-efficient, safe to work in and must suit the fish species in question, in order to avoid fish welfare problems. In addition to farming sites, harbors for service vessels, transport of fish to processing and over-wintering sites need to taken into account during the planning. This brief review introduces the technologies that have been used in cage aquaculture farming in open or semi-open water areas. We also discuss what challenges conditions in the Baltic Sea may pose to offshore fish farming. Fish farmers have identified the following product development challenges to offshore aquaculture: 1. Vessels must be safe and usable in harsh conditions. 2. Safety on board vessels and in handling the aquaculture structures under harsh conditions. 3. Cage technology. Cages must retain their shape and size and must be durable but lightweight in relation to their volume. 4. Cage handling operations and technological solutions. It should be possible to lift, install and clean cages under difficult conditions. 5. Technological solutions for monitoring, such as information transfer and energy production, must be further developed. Keywords Aquaculture, technology, offshore, Baltic Sea, spatial planning Publications internet address http://aquabestproject.eu/reports.aspx Contact Markus Kankainen, markus.kankainen@rktl.fi Additional information Contents Description 4 1. Introduction 6 1.1. Definition of offshore aquaculture 6 1.2. Production conditions measurement and equipment standards 7 2. Offshore aquaculture technology 2.1. Cages, nets and mooring 2.1.1. Floating flexible cage systems 8 8 8 2.1.2. Floating rigid cage systems 10 2.1.3. Submerged and semisubmergable systems 11 2.1.4. Nets 14 2.1.5. Mooring 14 2.2. Feeding systems 15 2.3. Vessels and equipment 17 2.4. Environmental monitoring equipment, early warning systems and electricity 18 2.5. Project design and turnkey operations 19 3. Special characteristic of production conditions in Baltic Sea 19 3.1. Winter conditions 19 3.2. Waves and depth 20 3.3. Adaptation of production cycle 20 4. Competitiveness and challenges of offshore farming 21 4.1. Competitiviness 21 4.2. Challenges for research and development 21 References 23 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 1. Introduction In the worldwide expansion of aquaculture, a key issue lies in locating suitable locations for farming. Due to the eutrofication of the Baltic Sea, the nutrient load of aquaculture is controlled, in order to avoid further environmental damage and diminish conflicts with other uses of the sea. Sectoral interests and their impact on the environment are managed through spatial planning. Within Northern Europe, maritime spatial planning has been the subject of several research and development projects, such as COEXIST (www.coexistproject.eu) PartiSEApate (www.partiseapate.eu) BaltSeaPlan (www.baltseaplan.eu) SUBMARINER (www.submariner-project.eu) AQUAFIMA (www.aquafima.eu) Project “Coastal futures” at Alfred-Wegener Institute, Germany. AQUABEST (http://www.aquabestproject.eu/) In the coastal areas of the Baltic Sea region, aquaculture spatial planning processes have already been conducted in Denmark in 2002-2003 (Anon. 2003), and in Finland during 2010-2013 (Anon 2013). Lack of suitable space within traditional farming areas is also motivating Norway to look towards more open sea areas (Karlsen 2012). A similar discussion on directing new aquaculture into federal waters at open sea is currently ongoing in the USA and Australia, among many other countries. As a final example in Europe, Turkey and Portugal have drawn up a maritime spatial plan and allocated zones for mariculture, often leading to offshore sites (Deniz 2012). In coastal regions, spatial planning often leads to the conclusion that the best new sites are located in open or semi-open areas with harsh production conditions. It is apparent that, under such conditions, conventional cage farming technology faces high risks of failure due to high wind speeds, high wave heights and strong currents. In addition to tolerating high-energy and harsh conditions, systems need to be cost-efficient, safe to work in and must suit the fish species in question, in order to avoid fish welfare problems. This brief review introduces the technologies that have been used in cage aquaculture farming in open or semi-open water areas. We also discuss what challenges conditions in the Baltic Sea may pose to offshore fish farming. Our two other, related reports present production conditions (wind, wave and ice) in the Finnish coastal areas (Kankainen et al. 2013) and a case study of the cost-structure of the investment and operational costs of fish farms located in semi-open conditions (Kankainen and Mikaelsen, in prep.) 1.1. Definition of offshore aquaculture Various definitions are applied to offshore aquaculture. Sometimes, conventional but robust cage farming technology withstanding harsh wave conditions is termed offshore technology, such as in the case of Ryan (2004). This definition is most often used in connection with activities such as salmon farming in semi-open coastal areas. On the other hand, the term “offshore aquaculture” sometimes refers to unconventional or even futuristic marine aquaculture or open ocean aquaculture techniques, where such systems are quite different to mainstream commercial cage aquaculture. On these 6 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions occasions, offshore aquaculture has mainly been piloted for farming valuable marine fish species such as cobia and tuna. In many cases, even distance forms part of the definition of offshore farming. Offshore technology is used both far from the coast, such as around 40 km off the coast in the Bay of Mexico in the United States, or in exposed and deep sites very close to the shoreline. In both cases, similar cage technologies can be used, whereas high distances from the shoreline pose a variety of challenges to logistical systems and have varied effects on operating costs. 1.2. Production conditions measurement and equipment standards Because the risks and investments involved in offshore aquaculture are substantial, the conditions at potential locations, such as currents, wave climate and seabed profile, are often assessed in advance in the planning of investments and production methods. Various regional studies are used in the selection of locations and tools for offshore fish farming facilities. A Norwegian standard, NS 9415, is used in the classification of sea areas according to their wave height and currents (Standards Norway 2008). This standard also includes recommended technological solutions for conditions of various kinds. It is expected that the classification of sea areas presented under this standard will be adopted beyond Norway. The highest classification, Ee, is for areas where the momentary significant wave height exceeds 3 m and the water flow exceeds 1.5 m/s. Significant wave height is the average height of the values among the top third results, based on a series of measurements. The highest individual wave is usually around twice the significant wave height. Many manufacturers and quality systems classify fish farming equipment and mooring systems similarly, according to the conditions for which they are designed. The technology selected for a particular application must be able to withstand strong waves and/or water flows, but must also have a safety margin for momentary extreme conditions. For instance, facilities farming Atlantic salmon in the Faroe Islands are sited at locations where the significant wave height (over a measuring period of 3 hours) has varied from 3.4 m to 7.4 m in a 10-year period. The highest ever recorded significant wave height in the Baltic Sea was almost 8 m, with the highest individual wave being 14 m high (northern Baltic Sea, December 2004). There are unprotected areas in the Finnish outer archipelago, where individual waves can attain a height of 10 m, with an average height of more than 3 m. Wind and wave conditions on the Finnish coastal areas are presented in detail in Kankainen et al. (2013). 7 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 2. Offshore aquaculture technology Adopting offshore aquaculture may require structural changes and new technology in all phases of production prior to fish gutting. In this report, we discuss offshore aquaculture technology under the following headings: Cages, nets and mooring Feeding systems Vessels and equipment Environmental monitoring equipment, early warning systems and electricity 2.1. Cages, nets and mooring Equipment used for offshore aquaculture includes traditional floating cages and various semisubmerged or wholly submerged units. Cages may have flexible or rigid frames. The following is a discussion of various offshore aquaculture solutions based on commercially available products. Some have never progressed past the experimental stage, while others are used in thousands of facilities around the world. 2.1.1. Floating flexible cage systems The most familiar type of floating cage in offshore aquaculture is based on a circular frame made of polyethylene tubing. This tubing is generally 200 to 300 mm in diameter, but 500 mm tubing is also used (Figure 1). There may be one to three such tubes making up a frame. A narrow working platform can be built on top of the load-bearing circular frame and the tubes can be filled with a floating filler. Within the load-bearing frame and above the water, a floating structure supports the net, preventing birds from accessing the cage and fish from leaping out. There may be a further circular frame underwater, to prevent cage deformation. Underwater frames can also be used to hang sealproof nets. Flexible cages are produced by manufacturers such as AKVA Group (PolarCirkel), Aqualine, Fusion Marine, Corelsa, Refamed, AquaSURE and Ocea. Frame manufacture may also be subcontracted out to local entrepreneurs. In the Baltic Sea, the largest cages are 100 metres in circumference. In Atlantic salmon farming, the new frames currently being installed have a circumference of at least 100 m in general. In the Mediterranean, the most common cage frames have a circumference of 40 to 50 m, but cages with a circumference of around 200 m are used for tuna farming. As cage depth in open sea areas is at least 20 m, such frames have a growth volume of more than 50,000 cu.m and yield a harvest of about 1,000 tonnes. In open sea areas in the northern Baltic Sea, floating cages must be removed for the winter, because their structures cannot be built to withstand the movement of thick ice floes. This restricts the circumference of the frames, because the largest frames and cages are difficult to tow with the available equipment. The sea does not freeze over in Norway, Chile or Scotland, so floating cages are not necessarily removed for the winter in these areas. 8 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Figure 1. Circular PE-tube frame is the most widely used technology for cage farming at exposed sites. Companies such as AKVA group, Aqualine, Corelsa, AquaSURE, Ocea, Refamed and Farmocean are producing or have been producing circular cage frames. On the right hand side picture, the model from 90’s (Gigant) on the right, and next to that one modern tubing for exposed sites made of 500 mm tubes. Pictures by AKVA group. The Japanese manufacturer Bridgestone has produced frames suitable for offshore aquaculture from the mid-1970s onwards. These are made of the rubber hoses used for transferring oil from tankers to terminals (Figure 2). Rather than being circular, the frames usually have 4 to 8 corners. The largestknown frame of this kind had a circumference of 160 m and was shipped to Ireland. In some cases, conventional PE frames have been installed within such frames, which then function as breakwaters as well as aquaculture cages. There are at least 300 units in use worldwide, but their manufacture was discontinued in the early 2000s. A similar technology is used in Dunlop Tempest frames (by Bonnar Engineering Ltd from Ireland), introduced on the market around the year 1990. Figure 2. Dunlop frames are based on rubber tubing used for oil pumping in oil terminals (Picture on left by Bonnar Engineering Ltd.). Bridgestone has used similar technology (Picture on the right by Bridgestone). Floating flexible cages can be built to withstand sea conditions with the highest rating, Ee, i.e. a significant wave height of more than 3 m. There are plenty of size options available, and frames can be installed in close proximity to one another, to form clusters that can be fed from a single feeder platform, for instance. Under harsh conditions, the movement of the frames and the mooring system cause wear and tear on the joints of the structure and the cage, and they thus need to be replaced more frequently than in sheltered locations. Frames have been known to break in harsh conditions if feeders are attached to the cages, because this prevents the strain of heavy seas from being distributed evenly across the frame. Because the structures are rather lightweight, in heavy seas maintenance must be carried out using a vessel that can be held steady, so that it does not damage the frames. 9 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 2.1.2. Floating rigid cage systems Metal frames are used in some applications, particularly in sheltered locations. In such systems, access bridges, which in some cases are large enough to support a forklift truck, are built between the cages. Perhaps the best-known brand name in this area is Wavemaster (AKVA group), which has sold more than 4,000 frames worldwide (Figure 3). The largest, 20 x 20 m frames have been used in rather exposed locations; if rigid frames are used in offshore aquaculture, they must be remarkably robust (Figures 4–5). For instance, the Scottish-made Cruive was developed jointly by shipping companies and salmon farmers, but this facility is apparently prone to storm damage and ice accumulation. Structures above the surface accumulate ice, which can considerably increase the weight of the unit. Figure 3. Wavemaster is probably the most sold rigid cage system. Picture by AKVA group. Figure 4. Farming systems by Spanish company Marina System Iberica. At least four systems like the one shown in the picture have been built in the Mediterranean Sea. At the deck there are a feed storage, electricity generator and small cabin for workers. The pillars reach appr. 10 m below the water surface. Picture by Marina Systems Iberica. 10 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Figure 5. First ever semi-submerged Farm Ocean was built in Sweden in 1986. Thereafter, at least 40 such units have been used worldwide. Picture by Farmocean. 2.1.3. Submerged and semisubmergable systems Submerged systems have become common in open sea areas. Submerging cages would enable the avoidance of storm effects close to the water‟s surface. In addition, in certain marine areas toxic algae blooms could be avoided by submerged systems. Various shapes and structures of submerged cages types have been designed (Figures 6-11). Submerged cages require a system for raising and lowering the structures into the water column during maintenance. Submerged farms have not been installed as frequently as, say, surface flexible plastic rings, for reasons such as high investment cost per volume, the relative impracticality of feeding and handling the fish, and potential problems with fish welfare (Karlsen 2012). For example, Atlantic salmon do not thrive throughout their ocean growth phase in systems where they are unable to reach the surface to fill their air bladders. Fish also may suffer from pressure differencies or stress while lifting the submerged system to the surface. Submerged systems do have some benefits; for instance, the water temperature is steadier deeper down, and the cages do not need to be cleaned as often as those on the surface. Moreover, heavy seas do not stress the fish, which may improve their growth, mortality and feed efficiency. There is the additional benefit of submerged systems not being visible within the seascape, which may make them less controversial from the perspective of recreational activities. 11 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Figure 6. SeaStation farms by company Ocean Spar have no floating collar structures, but are based on wires attached to mooring systems. Over 25 such systems are being used in e.g. Puerto Rico and Hawaiji. Pictures by Ocean Spar. Figure 7. AquaSpar units by Ocean Spar are used e.g. in Canada and Spain. Pictures by Ocean Spar. Figure 8. Refamed TLC (Tension Leg Cage) farms change shape and depth with currents. Picture Refamed TLC. 12 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Figure 9. Ocean Farm Technology is the manufacturer of Aquapod systems. It is composed of a rigid frame and a globe shape net cage within the frame. The technology is being used at extreme offshore sites for e.g., cobia farming in Puerto Rico and Panama, and for yellow tail farming in Hawaii. Pictures by Ocean Farm Technology. Figure 10. A Russian SADCO system can be partly or completely submerged. They are currently used e.g. at Mediterranan Sea, Caspian Sea and Black Sea. System includes technology for fish feeding and monitoring (pictures on the right). Pictures by GosNIORH Leonid Bugrov. Figure 11. PolarCirkel has in addition to regular frames a cage system that can be submerged. Picture by AKVA group. 13 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 2.1.4. Nets Nylon is the most common net material used in cage aquaculture. New materials include PET (Polyethylene terephthalate) marketed as EcoNet by AKVA group (Johnson 2012), or Dyneema marketed by DSM. Copper and stainless steel mesh solutions are also available. These have several benefits; they offer more protection against storm damage and predators. They also enable the net to maintain its shape better in heavy currents. This affects the maximum capacity of fish per cage, as well as fish welfare. However, such materials are also more expensive, even if they have a longer shelf-life. They also weigh more, which may further complicate the handling of large nets. Net cage shape is maintained by separate weights, or by a heavy bottom ring/sinker tube. Maintaining this shape is important, not only due to its effect on the net‟s capacity but also to protection against seals, which push against the net wall in order to attack the fish inside. Chains maintaining the sinker tube may abrade the net in heavy waves and should therefore be replaced by other, strong material such as Dyneema ropes. In sum, small engineering and material selection details become important in harsh conditions. Fouling of the net increases its weight and decreases the water flow in and out of the cage. For this reason, antifouling and/or frequent cleaning are important. Cleaning can be carried out using divers, or by using specific remote controlled cleaners. If the entire cage system is towed close to the shoreline in order to harvest fish, nets can eventually be removed and washed in special net washing drums. When the fish are delivered for harvesting with wellboats, the nets can be removed for washing and antifouling. 2.1.5. Mooring The number of mooring points, the material chosen for anchors and lines and how they are attached to the frame are important factors in structural durability. Large units are often moored using several orthogonal moorings. In many cases, double anchors and more durable lines are installed in the direction of the highest prevailing winds and water flows. Mooring lines and solutions require sufficient flexibility to ensure that even large movements of the net structures do not fully stretch the lines and thereby generate a full load (Karlsen 2012). A dense network of mooring lines and buoys makes it difficult for the maintenance vessel to manoeuvre around the facility. Manufacturers of large aquaculture cages offer expert services for mooring planning. Anchorage design depends on the quality of the seabed: in fine sediment, fluke anchors are usually used, since traction embeds them in the seabed. If the seabed is rocky, screw anchors may be drilled into the rock. In particularly deep water, a single-anchor anchorage is sometimes used, with several aquaculture units attached to a single main mooring line. In Finland, water depth is not as much of an issue as in many other offshore aquaculture locations, where the depth may be more than 100 m. Partly for this reason, there is a tendency to locate units in the immediate vicinity of islands, so that in some cases they can even be anchored to the shore. One option for assisting in mooring and protecting from waves would involve integrating fage farming with wind farms or oil platforms. In such cases, specific consideration would need to be given to structures, including mooring, together with the other functions and structures (Buck 2013). In addition to stable stations with mooring, drifting or even self-propelled farms have been suggested and developed for open ocean conditions. 14 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 2.2. Feeding systems Fish may be fed using automated feeders, either unsupervised or with someone supervising the process at the cages. During the growing season, it is preferable to feed the fish on a daily basis, or even several times a day, in order to maximise growth. Exceptions to this are periods in which the weather is particularly warm or cold and the fasting periods before the fish are transferred, gutted or subjected to other stressful handling. In offshore aquaculture, circumstances may limit the use of various automation systems and feeders. On the other hand, circumstances may also hamper or make it impossible to visit the cages every day. The feeder types currently in use in Finland would not necessarily withstand the heavy seas involved in offshore aquaculture. For example, traditional pendulum feeders are unsuitable for offshore conditions due to instability and possible overfeeding in strong waves. Another type of traditional feeder, which is attached to the cage collar, is questionable due to the strong forces placed on the cage collar structures. Feed barges have become common in feeder systems in offshore fish farming facilities. Their capacity may be anything up to hundreds of tonnes (Figure 12). Feed barges are generally placed beside the cages, or in the middle of a cage cluster. The feed is propelled through pipes by pressurised air fed from the barge to the cages. The largest barges have a control room and staff facilities for employees. Feed barges are generally unpowered; they need to be towed to the location and anchored. They can be refilled directly from feed producers‟ cargo ships. The largest feed barges, which can be found in Norway, are designed to withstand waves up to 7 m high. Thus, these systems do not appear to tolerate as harsh conditions as the most robust regular cages. Feeder platforms, particularly cage-specific feed transfer pipes, may be damaged or compromised by harsh conditions. In open-sea areas, it is common for fish to be fed from a boat. In such cases, personnel visit the cages whenever circumstances allow. Although boat feeding reduces the risk of storm damage and avoids major investments in feeder platforms, it is not necessarily the most efficient approach. Every unit has to be fed separately, and the feeding does not occur automatically. Since the distance from feed storage to the aquaculture facility may be long, the feeding process takes a great deal of time and fuel (Kankainen & Mikaelsen 2013). Feed efficiency may also be lower than with automated, continuous feeding, because the fish are fed less often, and in many cases to the point of satiety. Fish growth may be compromised if the fish are not fed every day. A submerged aquaculture facility must be raised to the surface for feeding from a boat, unless there is a system in place for underwater feeding. Using underwater feeding pipes from a feeder platform is a possible solution for avoiding feed pipe damage on the surface. The challenge in underwater feeding lies in distributing the feed evenly, so that all fish are fed sufficiently. It is also more difficult to monitor the fish. 15 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Figure 12. Feed barges have become more common in cage farming. Barges by AKVA group may have capacity between 100 to 700 tons of feed. (Top left). On the bottom left, feed barge in Turkey, snd on the right in Norway. Alhaalla, vasemmalla ruokintalauttoja Turkkista, oikealla Norjasta, Pictures on top by AKVA group, on bottom by M. Kankainen FGFRI. 16 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 2.3. Vessels and equipment Work vessels are needed for day-to-day management of fish farming units: transporting feed and fish, and handling the cages, nets, buoys and anchors. It is becoming common to use vessels 10 to 20 m long, fitted with cranes for lifting nets and feed bags (Figure 13). These have a carrying capacity of a few dozen tonnes. Depending on their size, speed and fittings, seaworthy vessels of this kind cost an estimated EUR 0.5 to 2 million. However, it has been questioned whether the work vessels currently in use would be useful or safe in open-sea areas. A maintenance vessel for a major salmon farming facility near the open sea may be 40 m long and have a carrying capacity of up to 100 tonnes (Figure 14). Investments in vessels may easily be many times higher than investments in all other production equipment (Project „Service Vessel 2010‟, Heide et al. 2012). Smaller seaworthy service boats are usually used for briefer inspections. Sometimes, it is cost-effective to feed the fish directly from a vessel. In such cases, feed tanks and a feeding system are usually installed in the vessels themselves, and the feed is blown out to the fish. Boat feeding is used at locations where feeders cannot be attached to the cages, because they cannot withstand the conditions in question. Boat feeding may also be sensible if the units are small and investing in a feeding system in situ would not be cost-effective. The drawback of boat feeding is that only one or two visits can be made per day, and bad weather may prevent visits altogether. Boat feeding also takes up a great deal of working time. Various specialised vessels can be used in addition to work vessels. For instance, if large feeder platforms are used, it may make sense to have the feed delivered in large quantities, by feed vessels, directly from the feed plant. This would make the related logistics more efficient, as it would not be necessary to transport the feed in small batches on work vessels. Also, on-shore feed storage would not necessarily be needed if the feed were delivered directly from the plant. Such a delivery service would probably best be outsourced, unless the aquaculture enterprise were very large. Fish can be transported for processing in vessels that are fitted out with tanks and pumps for fish transport, or in well boats. Another option is to use work vessels to tow the cages and frames to the shore as they are and extract the fish for gutting there. There are specialised vessels for using various devices, such as cage-cleaning robots. The vessels and equipment required by any particular enterprise depends on what action needs to be taken regarding the fish and the aquaculture facility during growing. It is basically unnecessary to obtain new equipment for tasks such as the removal of dead fish or the transfer or sorting of fish in offshore conditions, but heavy seas, the size of the cages, the structure of the frames and the feeding methods chosen do have an impact on the choice of equipment and tools. 17 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Figure 13. 20 ton catamaran boats are often used for various daily routines at Norwegian salmon cage farms. Cranes are used to lift feed bags and nets. Feeding systems can also be installed on such working boats. Figures by AKVA group. Figure 14. Remote farms at exposed sites may be maintained by up to 40 m long vessels. Picture by Aceaquaculture. 2.4. Environmental monitoring equipment, early warning systems and electricity In offshore aquaculture, because it is not always possible or feasible to visit the cages daily, monitoring and measurements are carried out automatically and remotely, for instance at an on-shore control unit. Feed control requires real-time information on fish behaviour, the water temperature and water oxygen levels. Systems for monitoring these comprise well-established technology at modern aquaculture facilities. Feeder control systems are available that monitor the appetites of fish. These systems observe whether any feed is being left uneaten: if so, they discontinue feeding. Cage monitoring or observing fish activity using cameras reduces risks and may even improve the feed efficiency of fish. Information can be wirelessly transferred to the control room, if the distance is not too great. In the case of cages that are distant from the control room, relay stations may be needed for 18 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions information transfer. Solar panels or wind turbines are sufficient for minor power needs, but generators are needed to provide electricity for feeder platforms. 2.5. Project design and turnkey operations Major manufacturers provide a range of products that covers all needs associated with cage aquaculture, including frames, cages, anchors, mooring lines, feeder systems, metering, monitoring and even the work vessels required. Most manufacturers also provide services such as location assessment, to assist in the selection of technology. In challenging conditions, all technological components must integrate seamlessly and be suitable for the routines of the aquaculture operation. In addition, consultant enterprises in the sector conduct wave and cage movement modelling based on data from the facility location (e.g. the Riflex modelling used by Det Norske Veritas). 3. Special characteristic of production conditions in Baltic Sea 3.1. Winter conditions In the Baltic Sea, winter conditions pose challenges to offshore aquaculture technology (Kankainen et al. 2013). Ice cover, the thawing season and pack ice must be taken into account in equipment and production cycle design. At cage aquaculture facilities in the northern Baltic Sea, the cages must be brought in, from open-sea locations to sheltered locations, for the winter so that the structures are not damaged by moving ice masses. If there are fish in the cages, the wintering locations should be chosen in such way that the cages can be monitored. During the thaw season, maintenance of the cages and fish is difficult if the units are not directly adjacent to the shore. Vessels that can cope with thin ice in early winter and ice floes in late winter are needed to cope with the thaw season. If the ice cover is strong enough in the winter, monitoring can be performed using motor vehicles such as snowmobiles, hydrocopters or quad bikes. In the autumn, pack ice can break or tear loose even robust structures, down to a depth of several metres. The durability of feeder platforms used in offshore aquaculture has probably not been tested in conditions where pack ice is formed or large ice masses move around, even if they are known to withstand some degree of freezing. One option proposed for protecting cages or structures against ice in open-sea areas involves submerging the structures beneath the reach of the ice cover. However, it is risky to leave structures unattended for the winter or the thaw season, and leaving fish without daily monitoring is against animal welfare regulations. Empty aquaculture structures can be left in situ if the water is deep enough for this purpose. However, pack ice can build up to a depth of several metres. The benefit of submerging empty cages is dubious, particularly if the cages are also used for transferring the fish. So far, aquaculture entrepreneurs have found sheltered locations for unit storage next to islands, where pack ice does not form and ice masses do not move around. In the winter, these units do not conflict with other uses of water areas in the inner archipelago to the same extent as in the summer, because there is no nutrient load and fewer people spend their leisure time in the archipelago. 19 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions In the spring, the ice melts faster in open-sea areas in the Baltic Sea than near the shoreline. However, because deeper and larger waters warm more slowly than the waters of the inner archipelago, the best growing season offshore begins later than closer to shore. Similarly, in the autumn offshore aquaculture facilities must be removed earlier than those closer to shore, in order to avoid the risks posed by the thaw season and storms. However, the growth season is not necessarily any shorter, because the rise in water temperature in midsummer is rarely too great. 3.2. Waves and depth When selecting the appropriate technology, other wave climate characteristics may be just as important as wave height. In the Baltic Sea, wave lengths are shorter and the waves are sharper than in the oceans (Kankainen et al. 2013). Because the wave length is short, aquaculture cages do not ride the waves; the waves thus stress the structures in a different way. For instance, a cage with a circumference of 100 m has a diameter of 32 m and a typical depth of 10 to 20 m. In heavy seas, the waves wash over the cages, and the frames can „hang‟ on the waves. The principal advantage of submerged facilities is protection against heavy seas. However, such facilities require a water depth of at least 20 to 30 m, so that the structures can be submerged deeply enough. Areas with water of such depth are rare in Finnish archipelagos. On the other hand, the relative shallowness of the Baltic Sea makes it easier to moor aquaculture facilities. 3.3. Adaptation of production cycle Not all production phases can be located in the open sea (Kankainen et al. 2013). Nursery facilities are not located in the open sea, because juveniles and the required production technology are more vulnerable to harsh conditions. For instance, cages made of nets with a denser mesh tend to deform in areas where the water flow is strong. Because juveniles are more susceptible to stress, they should be grown where they can be monitored continuously. There must therefore be sufficient brooding facilities on shore or inland, from which the fish are then moved to offshore facilities. Similarly, winter storage locations and storage facilities for fish ready for gutting must be close to shore, so that fresh fish can be continuously brought to market, especially during the thaw season. A production cycle has been proposed for offshore rainbow trout farming, where the juveniles would be grown at existing facilities in the inner or intermediate archipelago, or on shore to such a size that they can attain the market size for a traditional large rainbow trout within one growing season, when transferred to an offshore facility. If the production cycle for processing-ready fish were to be delayed by one growing season, more winter storage locations would be needed and the risks and production costs would considerably increase. In addition, lengthening of the production cycle would increase risks such as mortality. In Baltic Sea conditions, the ability to leverage the entire growing season would therefore be important. Installations of offshore aquaculture facilities and the transfer to them of fish should be performed quickly in the spring as the growing season begins, and it should be possible to remove and store the units quickly before winter, so that none of the relatively short growing season is lost. 20 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions 4. Competitiveness and challenges of offshore farming 4.1. Competitiviness When adopting offshore farming, many factors affecting production competitiveness change. Investments and logistics costs increase, as production is moved further out to sea and into more challenging conditions. Production equipment such as cages, feeders and vessels that can withstand open-sea conditions are more expensive than equipment suitable for inner-archipelago locations (Kankainen & Mikaelsen in prep.). When maintenance distances are longer, fuel costs rise and more working time is spent. Also, the length of the growing season, the water temperature, the weather at the location and the organisation of feeding may contribute in various ways to the growth rate, mortality or feed efficiency of fish. Whether a new technology is productised depends on whether the investments required will yield a competitive advantage compared to conventional production technology. Because offshore farming technology requires more investments, a competitive advantage has been sought by increasing the size of production facilities. In Atlantic salmon production, facilities for farming millions of kg of fish – which have many of the features of offshore farming technology (dozens of km from the shore, robust PE frames) – are economically competitive. In the largest salmon-producing countries, Chile and Norway, no fish farming facilities have so far been located in completely open sea, being instead located where some protection is afforded from islands or fjords. These more sheltered locations have enabled the use of traditional aquaculture technologies, albeit in more robust versions, and production has become more efficient as unit sizes have been increased (Asche et al. 2013). It would appear that submerged solutions are not competitive, compared to other technologies, in the farming of salmonoid fish, judging by the fact that no investments in such solutions have been made in the major producer countries, even though they have been tested there. Submerged systems have so far only been used in wide open sea areas and in relation to the more valuable fish species. Because the major production species in the Baltic Sea, the rainbow trout, competes in the same market as Atlantic salmon farmed in Norway and Chile, the average size of facilities in the Baltic Sea should be increased substantially to improve competitiveness. Production should thus be principally relocated to the edges of the open sea, in areas partly protected by islands, so that conventional technology and the existing enterprise infrastructure can be used in these offshore facilities. 4.2. Challenges for research and development It has been postulated that offshore aquaculture represents the only way of responding to increased needs for protein and increased demand for fish (FAO). There is plenty of room in the world‟s seas for production facilities, since most of the Earth‟s water surface area is not used in any way. In fish farming as much as in other forms of animal production, in the search for production growth it has become necessary to take account of sustainable development factors: the wellbeing of fish, environmental factors, the safety of employees, and economy (Willumsen 2012). In product development supporting offshore farming, solutions must be found to the challenges posed by these factors, so that production can grow sustainably. 21 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions Several worldwide challenges have been acknowledged in terms of the proliferation of offshore aquaculture. The fish cannot be observed in situ full time, in order to ensure their wellbeing. A long distance from the shore and local weather conditions may mean that a facility cannot be accessed quickly, or at all if the weather is bad. Long distances would also complicate the information and energy transfer needed to improve fish monitoring, reduce environmental impacts and render production more efficient. Distances would also affect maintenance operations and their costs. Challenging conditions would have an impact on occupational safety and investment costs. Environmental impacts would have to be assessed and production equipment designed so as not to jeopardise the ecosystem of the growth environment. All of these challenges would have to be met in such a way that offshore aquaculture became sufficiently profitable to attract investment by entrepreneurs (Willumsen 2012). Fish farmers have identified the following product development challenges to offshore aquaculture (Willumsen 2012): 1. Vessels must be safe and usable in harsh conditions. Transfers must be swift, and the vessels must be equipped with technological solutions facilitating aquaculture operations and have sufficient carrying capacity. 2. Safety on board vessels and in handling the aquaculture structures under harsh conditions. 3. Cage technology. Cages must retain their shape and size and must be durable but lightweight in relation to their volume. The cages should also protect the fish against predators, particularly seals. 4. Cage handling operations and technological solutions. It should be possible to lift, install and clean cages under difficult conditions. 5. Technological solutions for monitoring, such as information transfer and energy production, must be further developed. Offshore facilities in the Baltic Sea should be large enough to be cost-effective, but on the other hand must not generate excessive local nutrient loads. Such facilities will most probably have to be removed to the safety of the shore for the winter. Installation of facilities in the spring and their removal in the autumn should be well planned, rapid and practical. For unprotected offshore locations, an estimate should be made of the amount of stress placed on the facilities by the shorter wave length in the Baltic Sea. In deep water where particularly heavy seas are likely, semi-submerged systems may be feasible. 22 Reports of Aquabest project 10 / 2013 Offshore fish farming technology in Baltic Sea conditions References Anon. 2003. Havsbrugsudvalget. Udvalget vedr. udviklingsmulighederne for saltvandsbaseret fiskeopraet i Danmark.Ministeriet for Fødevarer, Landbrug og Fiskeri. 105 + 100 pages. Anon 2013. The national aquaculture spatial plan in Finland. (In Finnish: Vesiviljelyn kansallinen sijainninohjaussuunnitelma). 42 pages. Ministry of Agriculture and Forestry of Finland. Asche, F., Guttormsen, A.G., Nielsen, R. 2013. Future challenges for the maturing Norwegian salmon aquaculture industry: An analysis of total factor productivity change from 1996 to 2008. Aquaculture 396, 43-50. Buck, B.H., 2013. Upscaling aquaculture operations in offshore environments - challenges and possibilities in Europe. Presentation at SUBMARINER conference,6.9.2013 Gdansk, Poland http://www.submariner-project.eu/index.php?option=com_jdownloads&Itemid=0&view=finish&catid=86&cid=369 Deniz, H., 2012. Turkey‟s successful spatial planning policy story which includes turning crises to our advantage in offshore mariculture. Presentation at Offshore Mariculture Conference 2012. Izmir, Turkey 17.-19.10.2012. Heide, M.A., 2012 Service vessels for operation of exposed salmon sites. Presentation at Offshore Mariculture Conference 2012. Izmir, Turkey 17.-19.10.2012. Kankainen, M., Niukko, J., Tarkki, V., 2013. Fish farming production conditions in Finnish coastline of the Baltic Sea. Reports of Aquabest project, manuscript.45 pages. Karlsen, L., 2012. Strengthening of cage components. Presentation at Offshore Mariculture Conference 2012. Izmir, Turkey 17.-19.10.2012. Ryan, J. 2004. Farming the Deep Blue. 82 pages Standards Norway 2008. Preliminary new work item proposal: Cage fish farms - Requirements for design, dimensioning, production, installation and operation. ISO/TC 234 / SC. 82 pages.. Willumsen, F.V., 2012. Exposed industrial salmon farming – experience and needs for development. Presentation at Offshore Mariculture Conference 2012. Izmir, Turkey 17.-19.10.2012. 23