Document 11559666

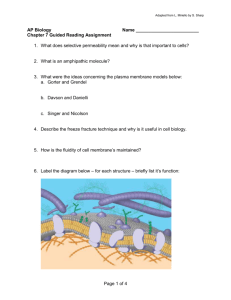

advertisement