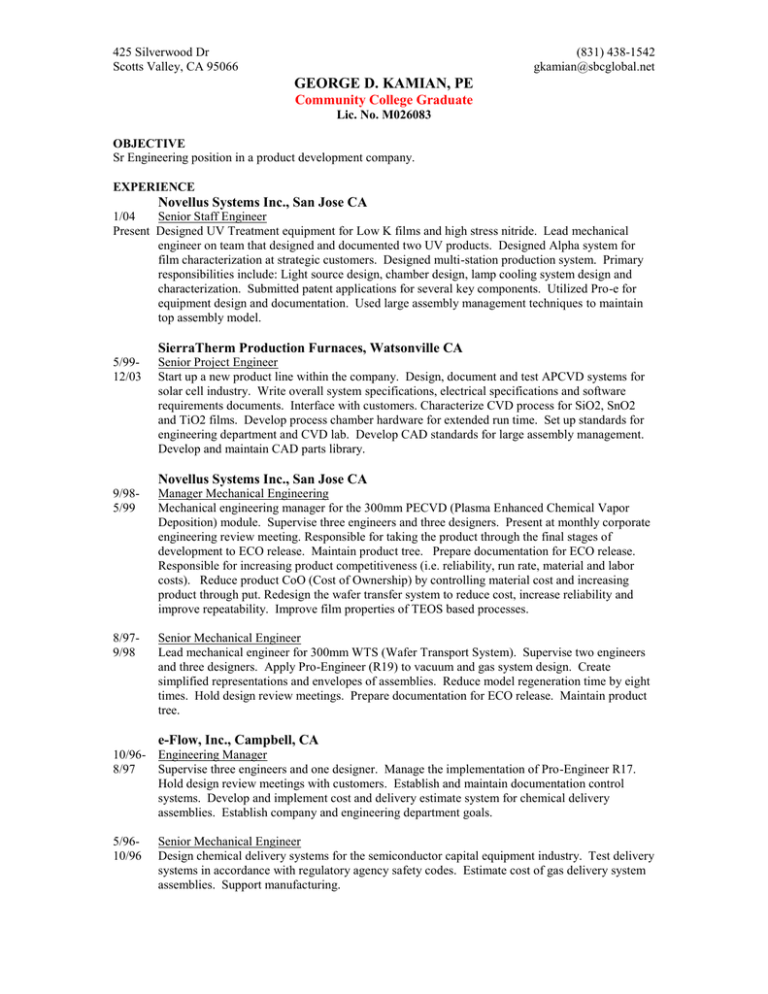

GEORGE D. KAMIAN, PE Community College Graduate

advertisement

425 Silverwood Dr Scotts Valley, CA 95066 (831) 438-1542 gkamian@sbcglobal.net GEORGE D. KAMIAN, PE Community College Graduate Lic. No. M026083 OBJECTIVE Sr Engineering position in a product development company. EXPERIENCE Novellus Systems Inc., San Jose CA 1/04 Senior Staff Engineer Present Designed UV Treatment equipment for Low K films and high stress nitride. Lead mechanical engineer on team that designed and documented two UV products. Designed Alpha system for film characterization at strategic customers. Designed multi-station production system. Primary responsibilities include: Light source design, chamber design, lamp cooling system design and characterization. Submitted patent applications for several key components. Utilized Pro-e for equipment design and documentation. Used large assembly management techniques to maintain top assembly model. SierraTherm Production Furnaces, Watsonville CA 5/9912/03 Senior Project Engineer Start up a new product line within the company. Design, document and test APCVD systems for solar cell industry. Write overall system specifications, electrical specifications and software requirements documents. Interface with customers. Characterize CVD process for SiO2, SnO2 and TiO2 films. Develop process chamber hardware for extended run time. Set up standards for engineering department and CVD lab. Develop CAD standards for large assembly management. Develop and maintain CAD parts library. Novellus Systems Inc., San Jose CA 9/985/99 Manager Mechanical Engineering Mechanical engineering manager for the 300mm PECVD (Plasma Enhanced Chemical Vapor Deposition) module. Supervise three engineers and three designers. Present at monthly corporate engineering review meeting. Responsible for taking the product through the final stages of development to ECO release. Maintain product tree. Prepare documentation for ECO release. Responsible for increasing product competitiveness (i.e. reliability, run rate, material and labor costs). Reduce product CoO (Cost of Ownership) by controlling material cost and increasing product through put. Redesign the wafer transfer system to reduce cost, increase reliability and improve repeatability. Improve film properties of TEOS based processes. 8/979/98 Senior Mechanical Engineer Lead mechanical engineer for 300mm WTS (Wafer Transport System). Supervise two engineers and three designers. Apply Pro-Engineer (R19) to vacuum and gas system design. Create simplified representations and envelopes of assemblies. Reduce model regeneration time by eight times. Hold design review meetings. Prepare documentation for ECO release. Maintain product tree. e-Flow, Inc., Campbell, CA 10/96- Engineering Manager 8/97 Supervise three engineers and one designer. Manage the implementation of Pro-Engineer R17. Hold design review meetings with customers. Establish and maintain documentation control systems. Develop and implement cost and delivery estimate system for chemical delivery assemblies. Establish company and engineering department goals. 5/9610/96 Senior Mechanical Engineer Design chemical delivery systems for the semiconductor capital equipment industry. Test delivery systems in accordance with regulatory agency safety codes. Estimate cost of gas delivery system assemblies. Support manufacturing. George D. Kamian, PE (831) 438-1542 gkamian@juno.com Watkins Johnson Company, Scotts Valley, CA 1/955/96 Project Manager HDP Design Engineering Design project lead for HDP (High Density Plasma) reactor. Design and build a complete process module in 4-month time frame. Duties include project management, chemical delivery & vacuum system schematics, mechanical design at sub-system level and hands-on assembly of module. 6/931/95 MTS Chemical Delivery and Process Exhaust Design chemical delivery systems involving Silane, Phosphine and Diborane for use on APCVD reactors. Design exhaust systems for APCVD reaction chambers including injector vents, shields and exhaust flow control devices. Develop extended run time exhaust system resulting in increased equipment up time. 19906/93 Head Semiconductor CVD Processing Chamber Engineering Supervise four mechanical engineers and eight technicians. Manage projects. Define customer requirements. Coordinate mechanical, electrical, software and process engineering efforts. Chair design review meetings. Schedule and interface with design drafters. Produce project schedules. Research and development of CVD process chambers. Design chemical injectors and exhaust systems for APCVD chambers. Manufacturing engineering for chemical injectors and exhaust systems. Watkins Johnson Company, Scotts Valley, CA (cont’d) 19831990 MTS R&D Engineer Design and testing of key deposition and exhaust system components for an APCVD Tungsten Silicide reactor. Develop a patented chemical injector and a patented self-cleaning flow control orifice. Mechanical and electrical design of atmospheric chemical vapor deposition systems for the semiconductor and solar and display industry. Design electrical system for APCVD reactor including component selection, schematics and PLC programs. Additional responsibilities: Production planning, cost estimations, customer interface, documentation and ECO’s. Conduct group training seminars. Travel domestically and abroad for installation and service of equipment. EDUCATION Santa Clara University MS, Mechanical Engineering, 1995 California Polytechnic State University BS, Mechanical Engineering, 1983 Cabrillo College AS, Engineering, 1981 COURSES SEMATECH DOE (Design of Experiments) Project Management AFFILIATIONS ASME Member 5774815 SKILLS Pro-Engineer Wild Fire, AUTOCAD R2000, SolidWorks 2003, Microsoft Word, Project, Excel, Shop skills (milling machine, lathe, tig & mig welder) Page 2