Philip G. Cutino, P.E. Engineering 10 Presentation Chabot College, Hayward CA

Philip G. Cutino, P.E.

Engineering 10 Presentation

Chabot College, Hayward CA

September 29, 2008

Today’s Agenda

A little about me.

Stanford Linear Accelerator Center (SLAC)

Linac Coherent Light Source (LCLS)

My role at SLAC / LCLS

Some recent tasks

I am not a typical engineer

Mechanical Engineer

Register Professional Engineer in CA

Returned to school late in life

20 years hands-on work experience before engineering school

Diverse background . . .

20+ years with the same employer

I am currently enrolled at Chabot College!

Stanford Linear Accelerator Center

Location: Menlo Park, CA

Type: Multi-program Laboratory

Contract Operator: Stanford University

Website: www.slac.stanford.edu

Physical Assets:

426 Acres

145 Buildings

1.8M GSF in Active Operational Buildings

Human Capital

Employees: 1,496 FTE as of 4/15/08

Users, Visiting Scientists and Grad Students: 3036 Head

Count

SLAC Mission

Primary mission focus is designing, constructing, and operating state-of-the-art electron accelerators and related experimental facilities to advance the boundaries of scientific understanding.

Areas of Research

Development and application of ultrafast X-ray science

X-ray probes of the electronic and atomic structure of matter

Understanding the fundamental forces of nature and the physics of the birth and evolution of the universe

Advancing the world’s electron accelerator capability

Major Facilities at SLAC

The Linac Coherent Light Source (LCLS), currently under construction.

LCLS, the world’s first X-ray free-electron laser, positions SLAC to become the world leader in the exciting new field of ultrafast X-ray science.

The Stanford Synchrotron Radiation Laboratory (SSRL)

SSRL provides a resource to the user community for probing the electronic and atomic structure of matter.

The B-Factory

An electron-positron collider, completed operations in FY08, but an intensive data analysis program will continue for several years.

The Fermi Gamma-Ray Space Telescope (FGST)

SLAC is home to the Instrument Operations Center for the Large Area

Telescope instrument on FGST formerly know as the Gamma Ray Large

Area Space Telescope (GLAST)

Linac Coherent Light Source

Ultrafast X-ray science

Directly observe the motions of atoms on ultrafast time scales

Investigate dynamics, bonding, heating and melting, at atomic and nanometer length scales

Create and observe extreme new conditions in atoms and materials

Imaging of nonperiodic molecules and nanostructured materials

World’s first X-ray free electron laser

Producing 100 femtosecond pulses of photons in the energy range 800-

8,000 eV

10^ 12 coherent X-ray photons/pulse

Potential for sub-femtosecond pulses

Lead nanoscale science revolution

Master control of energy-relevant complex systems

Lead the world in the investigation of dynamics of atomic transitions, chemical bonding, catalysis and heating

Source: Wikipedia

LCLS

Linac 1003 meters

708 devices

Total Machine* : ~1750 meters of beam line 1242 Devices

Injector: 28 meters of beam line & 95 devices

LTU & Dump

408 meters

176 Devices

*Electron Beam Line Only

Does not include Photon Beam Lines

LCLS Construction Photos

LCLS Construction Photos

LCLS Construction Photos

LCLS from Google Maps

My Role at SLAC/LCLS

Primary responsibility is mechanical support for delivery of electrons from Linac to Beam Dump for

LCLS

Mechanical support for physicists, technicians and users

Diagnostics, BPMs, OTRs, Dumps

Magnets

Vacuum Chambers

LCW (water cooling systems for magnets, collimators, dump)

Recent Tasks

Commissioning Engineer for Injector through L3

4 RODs ranging from 2 days to 2 weeks

Commissioning Engineer for LTU & Dump areas

Design LCW distribution to devices in LTU

Flow Restrictors

Design LCW cooling system for the RF Gun

$1.2M project

2 new water systems

Tight temperature control requirements

High reliability design

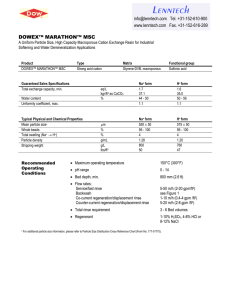

Calculate Pressure Drop

Pressure Drop Calculation Continued

Flow Restrictors

Injector Vault – RF Gun

Injector Vault Work

RF Probe Change

Diagnostics Repair

New Laser Cooling System (LCS)

Serves lasers and RF Gun cooling system

Replaces temporary chiller outside Sector 20 laser room

System Flow: 40 GPM @ 70 PSIG

Supply temperature 56 °F (13.3 °C) ± 0.5 °F (0.9 °C)

Temperature based on dew point just outside of Laser Room Envelope (68

– 72 °F; 50% RH ± 5%)

Chiller Optimized to Run at Part Load.

N+1 pumps and compressors – automatic lead/lag

Heat Rejected to CT1202

Control System: CEF DCS except Chiller (DDC)

Both systems make data available to EPICS

Location: South Side Klystron Gallery between columns 9 & 12

Power source: new 480 V outdoor dist. panel Sector 21

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Requirements Driving LCS Design

Drive Laser

Maximum Load: 11 kW (with 2 Lasers)

3 ThemoTek Chillers per laser

1 Cryomech Compressor per laser

Initially only about 1 kW

No Condensation Inside Laser Room

Dew Point < 56 °F at 72.9 °F DB; 55% RH

14.2 GPM

RF Gun Cooling System

25 GPM

RF Gun LCW Setpoint as low as 64.4 °F (18 °C)

Up to 24 kW heat load as low as 9 kW

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Laser Room Cooling System (LCS)

CTWR

85 °F

CTWS

75 °F

10 Ton Chiller

(optimized for part load operation)

N+1 Compressors

48

°F

Chilled Water

Buffer Tank

30 GPM

30 GPM

September 8, 2006

LCLS Injector through BC1 Process Water FDR

TT-2

56 °F

40 GPM

40 GPM

To/From

Process

2.5 to 10 tons

Phil Cutino pcutino@slac.stanford.edu

New LCLS Injector Water System (ICS)

Two Pumps, each capable of ~80 GPM @ 125 PSIG

Base-line design is for 60 GPM incl. polishing loop

One will run at a time with automatic lead/lag

Supply Temp 78.5 ± 0.5 °F (25.8 ± 0.9 °C)

Plate Heat Exchanger sized to reject 480 MBH

Heat rejected to CT1202

Control System: CEF DCS (AB Control Logix PLC)

All input values available via EPICS

Location: south side of Klystron Gallery between col. 5 & 7

Power Source: new 480 V outdoor dist. panel

Operational by December 1, 2006

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Requirements Driving New LCW System

RF Gun

4 KW heat rejected

SP range 64.4 °F to 113 °F (18 to 45 °C)

Temperature Stability ±0.45 °F (0.25 °C)

Flow 9.2 GPM

Magnets

~45 GPM

80 to 100 PSID

Load Lock / Work Area

80.6 °F (27 °C) maximum

RF Hut

95 °F ± 0.13 °F ((35 °C ± 0.07 °C)

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Injector Cooling System (ICS)

TT

78.5 °F

TT

TT

75 °F

CT1202

Surge

Tank

78.5 °F

2 New Pumps each ~80 GPM

@ 125 PSIG

10 micron filter

New Pump Pad

Heater

93 °F

TT

97 °F

TT

95 °F

±0.13 °F

Sector 20 Klyston Gallery

Continued on next slide

September 8, 2006

LCLS Injector through BC1 Process Water FDR

TT

88.5 °F

TT

84 °F

15 GPM

To RF Hut

Electronics

Heater & Valve

Mounted East

Wall of RF Hut

(Outside)

Phil Cutino pcutino@slac.stanford.edu

Continued from previous slide

DPS

Injector Cooling System (cont.)

BX01

0.52 GPM

BX02

0.52 GPM

QB

0.7 GPM

BXS

1.42 GPM

BX11

1.69 GPM

Sector 21 Linac Housing

BX12

1.69 GPM

BX13

1.69 GPM

BX14

1.69 GPM

Load Lock Area

3 GPM

Loading & Work Area

3 GPM

Sector 20 Laser / Injector Facility

Continued on next slide

Laser Room LCW

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Injector Cooling System (cont.)

Continued from previous slide

Set Point = A + 3

Cooling

Heat Exch.

TT

Set Point = A - 3

Heat

Recovery

Heat Exch.

TT

Heater

DPS

TT

56 °F

TT

DPS

Chilled Water

~ 25 GPM

TT

** LCLS Controls to provide setpoint signal only

Set Point (A) Reset on RF Gun Power

RF Gun Cooling – 10 GPM

64-113

± 0.45 °F

(18-45

±0.25 °C)

Gun Solenoid

3.6 GPM

September 8, 2006

Future

LOA Solenoid

2 GPM

BXH1

1.1 GPM

Sector 20 Injector Vault

LCLS Injector through BC1 Process Water FDR

BXH2

1.1 GPM

BXH3

1.1 GPM

Phil Cutino pcutino@slac.stanford.edu

BXH4

1.1 GPM

RF Gun Simple Scheme

SP –2°C

Set Point (SP)

Range: 18-38 °C

TCV-1

TT-1 TT-2

TCV-2

CHWR

13.3 °C

Process Water to / from RF Gun

HTX-1

CHWS

7.8

°C

Injector Water

10 GPM

SP +2

°C

TT-3

Electric

Heater

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Simple Temperature Profile for Control Valve

103

°F

100.2

°F

(38

°C)

97

°F

97

°F

93

°F

78.5 °F

(25.8 °C)

Leaving

Heater

Leaving

3-way Valve

Leaving

Htx 1

(27 kW added)

64.4

°F

(18 °C)

16

°C

64.4 °F

(18

°C)

RF Gun Water Set Point

September 8, 2006

LCLS Injector through BC1 Process Water FDR

93

°F

(33.9

°C)

100.2

°F

(38

°C)

Phil Cutino pcutino@slac.stanford.edu

Chilled

Water

Supply Temp

56

°F(13.3°C)

~25 GPM

RF Gun Water Control

Set Point (SP)

Range: 64.4-113 °F

(18-45 °C)

SP -4.5 °F

(2.5 °C)

TT

Process Water to / from RF Gun

4kW (max)

TT

Heat

Recovery

HTX-2

HTX-1

SP +4.5

°F

(2.5

°C)

TT

20 kW

Electric

Heater

Injector

Water

10 GPM

78.5

°F

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

103

°F

100.2

°F

(38

°C)

97

°F

Improved Temperature Profile

93 °F

96

°F

90 °F

78.5 °F

(25.8 °C)

Leaving

Heater

Leaving

3-way Valve

Leaving

Htx 1

6.6 kW Heating

4.4 kW Cooling

~11 kW Total

64.4

°F

(18 °C)

61.4

°F

64.4 °F

(18

°C)

RF Gun Water Set Point

September 8, 2006

LCLS Injector through BC1 Process Water FDR

93

°F

(33.9

°C)

100.2

°F

(38

°C)

Phil Cutino pcutino@slac.stanford.edu

RF Gun Cooling System Response

Modeling by Claudio Rivetta

September 8, 2006

LCLS Injector through BC1 Process Water FDR

Phil Cutino pcutino@slac.stanford.edu

Photos of Water System

Construction

More Water System Photos

Finished Pump Pads

My Advice to Perspective Engineers

Effective Communication is very important

Credibility is your most important asset

First impressions are important

Engineering design, like life, is a series of compromises, you need to balance the priorities of the project with available resources

Engineering IS problem solving

Questions?

Links to More Information:

http://www.slac.stanford.edu

http://lcls.slac.stanford.edu

http://www2.slac.stanford.edu/vvc/