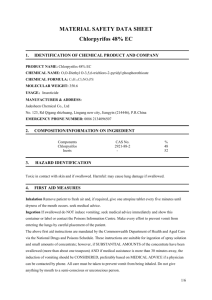

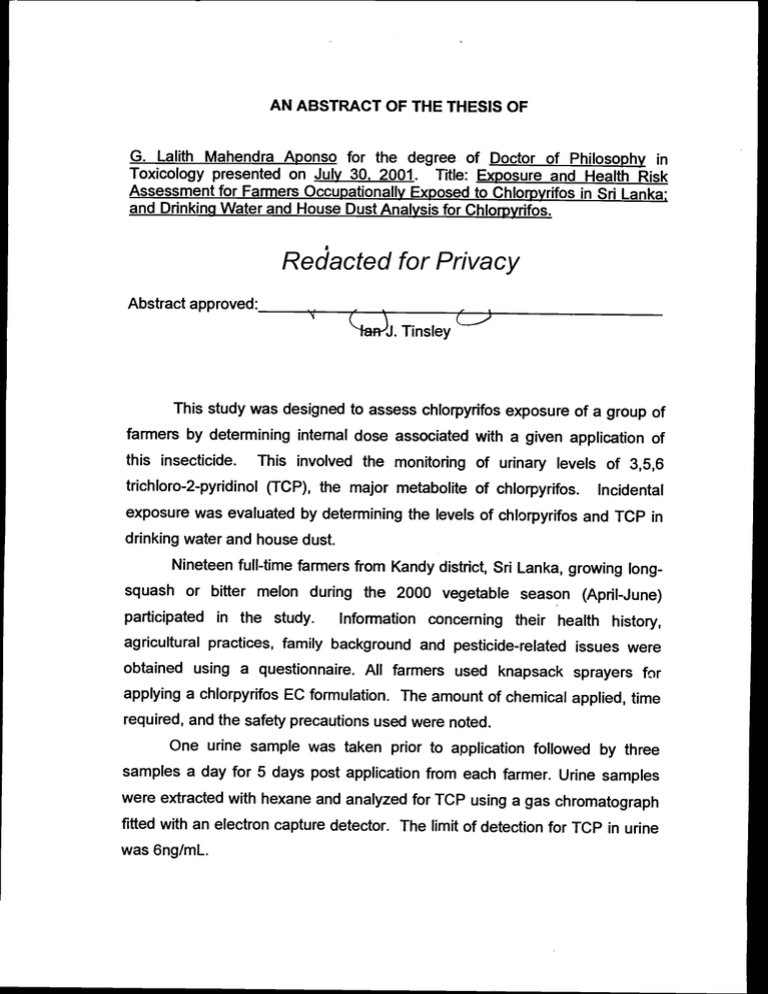

G. Lalith Mahendra Aponso for the degree of Doctor of... Toxicology presented on July 30. 2001. Title: Exposure and Health...

advertisement