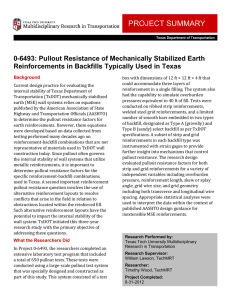

Multidisciplinary Research in Transportation

advertisement