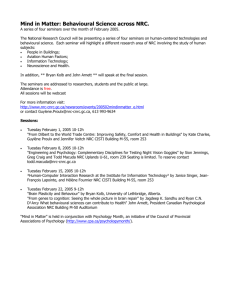

GAO NUCLEAR REGULATORY COMMISSION

advertisement