Ruggedness Assessment and Experimental Design in the Biofilm Laboratory Center for Biofilm Engineering

advertisement

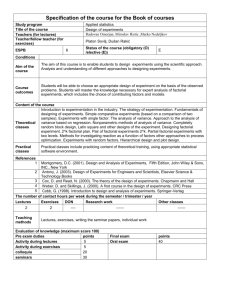

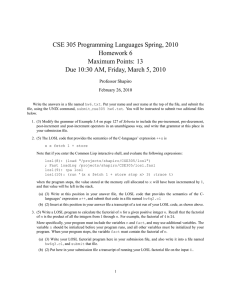

Center for Biofilm Engineering Ruggedness Assessment and Experimental Design in the Biofilm Laboratory Al Parker Statistician and Research Engineer Montana State University CBE workshop – July 2009 Acknowledgments Colleagues in the CBE; esp., the SBML team Funding US EPA Montana Board of Research, Commercialization and Technology Industrial Associates of the CBE Big Sky Statistical Analysts LLC Statistical thinking Data Ruggedness Testing 2p Factorial versus One-at-a-time design Uncertainty assessment Statistical thinking Data Ruggedness Testing 2p Factorial versus One-at-a-time design Uncertainty assessment Grow: CDC biofilm reactor Sampling 1. Rod is removed from reactor 2. Coupon is removed from the rod 3. Rinse Treat: disinfecting an established biofilm Sample: harvest from coupon, disaggregate K. Moll 2008 harvest biofilm by scraping with a wooden applicator stick K. Moll 2008 homogenize to disaggregate clumps Sampling and analysis Treated coupon Dilution series; plate in duplicate or triplicate Biofilm is scraped & rinsed into the dilution tube; the suspension is disaggregated Drop plate: Viable cell density (cfu/cm2) A. Hilyard, 2008 Statistical thinking Data Ruggedness Testing 2p Factorial versus One-at-a-time design Uncertainty assessment Ruggedness A standard laboratory method is said to be rugged if the outcome is unaffected by slight departures from the protocol. Parameters in the protocol Disaggregation: sonicated or homogenized Nutrient (TSB, continuous flow): 50, 100, 200 mg/l Rotation (stir plate): 125, 225, 325 rpm Temperature: 20, 23, 26 oC Time in batch mode: 3, 18, 24 hr Ruggedness Is efficacy testing using the CDC reactor rugged with respect to changes in the batch time over which the biofilm was grown? Viable cell density (log scale) Ruggedness with respect to batch time > 18 hours 107 105 103 0 18 Time (h) © 2002 CBE Performing a ruggedness test 1. Conduct a minimal number of experiments to: Identify unimportant parameters: Is the biofilm significantly influenced by all 5 parameters? Check for interactions among parameters 2. Conduct another series of experiments using only the influential parameters and interactions. Ruggedness Is efficacy testing using the CDC reactor rugged with respect to changes in stir plate rotation and temperature? Full factorial design: 2 factors, each at 3 levels Temperature (o C) 26 23 20 125 225 Stir plate rotation speed (rpm) 325 © 2002 CBE Statistical thinking Data Ruggedness Testing 2p Factorial versus One-at-a-time design Uncertainty assessment One-at-a-time: Study temperature Temperature (o C) 26 23 20 125 225 Stir plate rotation speed (rpm) 325 © 2002 CBE One-at-a-time: Study rpm Temperature (o C) 26 23 20 125 225 Stir plate rotation speed (rpm) 325 © 2002 CBE One-at-a-time design for 2 factors Temperature (o C) 26 23 20 125 225 Stir plate rotation speed (rpm) 325 © 2002 CBE 22 factorial design Temperature (o C) 26 23 20 125 225 Stir plate rotation speed (rpm) 325 © 2002 CBE A factorial design is superior to a one-at-atime design: Factorial design can detect an important interaction between the two factors; the one-at-a-time design can’t Factorial design has greater precision when estimating the main effects of each factor than the one-at-a-time design True Mean log(cfu / cm^2) True mean log(density) increases with temperature; slope depends on RPM 8.5 RPM 125 8.0 225 325 7.5 20 23 Temperature 26 © 2002 CBE True Mean log(cfu / cm^2) One-at-a-time design can estimate these four points only 8.5 RPM 125 8.0 225 325 7.5 20 23 Temperature 26 © 2002 CBE True Mean log(cfu / cm^2) One-at-a-time design cannot detect the fact that the slope depends on RPM 8.5 RPM 125 8.0 225 325 7.5 20 23 Temperature 26 © 2002 CBE True Mean log(cfu / cm^2) Factorial design can estimate these four points only 8.5 RPM 125 8.0 225 325 7.5 20 23 Temperature 26 © 2002 CBE True Mean log(cfu / cm^2) Factorial design can detect the fact that the slope depends on RPM 8.5 RPM 125 8.0 325 7.5 20 23 Temperature 26 © 2002 CBE However … the factorial approach requires more experimental effort Batch time One-at-a-time © 2002 CBE Temperature However … the factorial approach requires more experimental effort Batch time One-at-a-time © 2002 CBE Temperature Factorial Batch time Can use fewer factorial runs; however, can’t estimate all interactions © 2002 CBE Temperature ½ Fraction of 23 Factorial For Five factors, instead of three: how many experimental runs? 25 factorial design: 25 = 32 One-at-a-time design: 2*5 = 10 ¼ fraction of the 25 factorial design: 32* ¼ = 8 Statistical thinking Data Ruggedness Testing 2p Factorial versus One-at-a-time design Uncertainty assessment Differences among experiments is the major source of variation 67% attributable to between experiments 33% attributable to within experiments Formula for the SE of the mean LR, averaged over experiments 2 Sc = within-experiment variance of control coupon LD Sd2 = within-experiment variance of disinfected coupon LD SE2 = between-experiments variance of LR nc = number of control coupons nd = number of disinfected coupons m = number of experiments SE of mean LR = 2 Sc nc • m + 2 Sd nd • m + 2 SE m Where to invest effort to get the most precision? 2 experiments; 6 coupons each; SE of mean log density (12 coupons) = 0.24 4 experiments; 2 coupons each; SE of mean log density (8 coupons) = 0.19 The precision is increased by running more experiments with less effort per experiment Summary It is important to do an arm-chair experiment first Use 2p (fractional) factorial design to determine ruggedness of the protocol to changes in parameters Rely on multiple, independent experiments, each with few samples, in contrast to one experiment with many samples Fin Reliable laboratory methods