C 2 P D

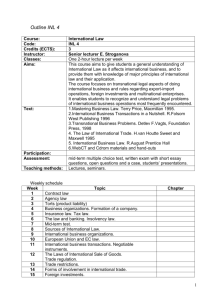

advertisement