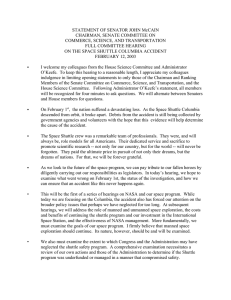

COLUMBIA

advertisement