Document 11269345

advertisement

Process Characterization of a PMMA Hot Embossing System

by

Katharine Luginbuhl

Sc. B. Mechanical Engineering

Massachusetts Institute of Technology, 2012

Submitted to the Department of Mechanical Engineering

in partial fulfillment of the requirements for the degree of

Master of Science

at the

MASSACHUSETTS INSTITUTE OF TECHNOLOGY

AC4N'ES

June 2014

MASSACHUSET , INSTITUTE

OF T~cN~G

D Massachusetts Institute of Technology 2014.

All rights reserved.

AUG 15 201

L

RA. E S

R

Signature redacted

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

Author .............................................

Department of Mechanical Engineering

May 9, 2014

Cetiid byySignature

...... S i

Certified

n t

r

redacted

e a t d .........................................

David E. Hardt

Ralph E. and Eloise F. Cross Professor of Mechanical Engineering

Thesis Supervisor

A ccepted by..

Signature redacted ...........................................

David E. Hardt

Ralph E. and Eloise F. Cross Professor of Mechanical Engineering

Graduate Officer

2

Process Characterization of a PMMA Hot Embossing System

by

Katharine Luginbuhl

Submitted to the Department of Mechanical Engineering

on May 9, 2014, in partial fulfillment of the

requirements for the degree of

Master of Science

ABSTRACT

Microfluidics devices are important both for research use and medical application. To create

these microfluidics devices, the hot embossing process is commonly used. In order to

characterize this process to enable cycle to cycle control, a small-scale system was developed,

using a hot embossing machine, taping machine, and functional tester previously created. Parts

were moved between these machines with an Epson GlO SCARA robot, which provided the

appropriate efficiency and accuracy. This system was able to produce embossed parts with a takt

time of less than 135 seconds, and over 1000 of such parts were produced. The system was

analyzed to determine potential sources of variance, considering both things that would alter the

part and things that would alter the measurements. This enabled the system to be run in a state of

statistical control, which in turn allowed for a designed experiment to be done on the system.

This designed experiment determined that the forming temperature, forming force, forming time,

as well as the square terms for the forming temperature and forming force and the cross-terms of

forming force with forming temperature and forming time with forming temperature, were all

statistically significant in the formation of parts. With this data, cycle-to-cycle control can be

enabled in the future.

Thesis Supervisor: David E. Hardt

Title: Ralph E. and Eloise F. Cross Professor of Mechanical Engineering

3

4

ACKNOWLEDGEMENTS

There are a number of people without whom this thesis would not be possible:

First, many thanks to my advisor, Professor David Hardt, who is excellent at both making

sure that the technical details are always clear while keeping focus on the overall project. His

enthusiasm and dedication kept everything interesting, and his broad knowledge base made him

always able to find an answer.

I want to thank Maia Bageant, whose knowledge, hard work, and overall good company

made her a delight to work with, and who was willing to help me figure out how to make the

robot behave even when it meant altering her precisely-designed hot embosser. I want to thank

Caitlin Reyda for the amazing suggestion that I get involved in this project, and for her

wonderful machine designs without which the system would not have existed. I would like to

thank Joseph Favella both for his machining expertise and for his ability to always find the

potential dangers of the system.

I would like to thank Nadege Zarrouati for the excellent selection of robotic arm that I got

to use, as well as for the prescient ability to pick something that could interface with our other

machines. I would also like to thank everyone else who worked on the many iterations of this

project prior to me.

I want to thank my friends Chris Carignan, Hannah DuBose, and Lucretius Williams for

their ongoing support and encouragement throughout this project, as well as their tolerances of

the resulting sleep schedule.

I would like to thank my family, especially my parents, Erica Turner and William

Luginbuhl, without whom none of my work would have been in any way possible, and who have

always been confident in my abilities. I would also like to thank my younger sister, Jessica

Luginbuhl, who is always willing to listen to me explain my latest projects.

Finally, a tremendous thanks to the MIT-Singapore Alliance, for their generous funding

of the project and making everything possible.

5

6

7

TABLE OF CONTENTS

1

2

3

4

5

Introduction .........................................................................................................................

19

1.1

M icrofluidics ................................................................................................................

19

1.2

Hot Embossing...........

20

1.3

Precision Manipulation.................................................................................................

22

1.4

Process C ontrol .........................................................

22

1.5

Project Motivation.................................................................................................

............................................

..............................................

.................................................

23

Previous Work...........................................................................

25

2.1

The Part ...

........................................................................

25

2.2

Hot Em bossing M achine............................................................................................

26

2.3

Taping M achine..............................................................................................................

29

2.4

Functional Testing......................................................................................................

31

2.5

Epson Robot ........... .oo.....................................................................

34

Robotic Handling System ..................................................................................................

37

.. ~.. . .

3.1

Safety ... o........................................................................................

38

3.2

End Effector Design....................................................................................................

39

3.3

Precision Part Manipulation.............................................

40

3.4

Autonom ous Programm ing ........................................................................................

48

3.5

System Comm unications.............................................................................................

56

3.6

System Failure Modes........ooo ..o...............................

...... o................. 59

Minimum System Cycle Time..........................................................................................

4.1

Simulation ...........

4.2

Results..........................................................

.............................................

63

63

........... 66

Initial Experiments of System Characterization ..............................................................

73

5.1

Experim ental M ethod................................................................................................

73

5.2

Blank Parts .. .................................................................................

74

5.3

Hot Embossing M achine ............................................................................................

78

5.4

Functional Tester........................................................................................................

82

5.5

Taping Machine..................................................

89

8

6

Statistical Process Control Results and Discussions.....................................................

6.1

7

Statistical Control......................................................................................................

91

91

Process Characterization Using Designed Experiments ................................................

101

7.1

M easurem ent Errors .....................................................................................................

101

7.2

DOE Results.................................................................................................................

103

Conclusions.........................................................................................................................

111

Next Steps ....................................................................................................................

113

A

Robot Sam ple Code ...........................................................................................................

115

B

Robot Points .......................................................................................................................

125

C

DO E Data ...........................................................................................................................

129

D

M ATLAB Simulation........................................................................................................

137

9

References...........................................................................................................................

157

8

8.1

9

LIST OF FIGURES

Figure 1-1: The four steps of the hot embossing process for microfluidics devices. By applying

pressure to a plastic at or near its glass transition temperature, the plastic will locally flow into

the shape of the mold, after which it can be cooled and separated. A bonding layer over top seals

the m icrofluidics channels. [3].................................................................................................

20

Figure 1-2: The resulting cross-section of a microfluidics channel, based on the forming force

applied. Higher forces cause more localized flowing of the plastic, resulting in sharper channels

with steeper walls. This data corresponds to PMMA parts formed at 110 C. [5]..................... 21

Figure 2-1: The tool used to make the part. Two input ports combine via a mixing pattern using

50 pim to a single output port. Additional markers have been placed on the part in case additional

measurem ents were needed. [12]............................................................................................

25

Figure 2-2: The first version of the hot embossing machine, showing the forming platens in the

Instron ...........................................................................................................................................

27

Figure 2-3: The current hot embossing hardware, with key features labeled. [12].................. 28

Figure 2-4: The taping machine, showing the path of the tape as the parts are moved linearly

along the belt. Parts will be sealed with one piece of tape, which is then separated by the adjacent

cutter. [13].....................................................................................................................................

30

Figure 2-5: Three parts that have been embossed, with the tape placed overtop of them. The

dotted lines show where the tape will be cut to separate the parts, and the arrow shows the

direction the parts move within the machine. [13] ...................................................................

31

Figure 2-6: A zoomed-in image of a part in the functional testing machine, and that image with

the data from the functional tester recorded on it. The average width and standard deviation

measures in the upper-left corner are based on the four measured channel widths. The

information in the upper-right corner is used to determine the presence of the part. The TRUE

label in the lower-right corner indicates that the part may have fluid flow through it. ............ 32

Figure 2-7: The standard deviation of the intensity across both an unmixed and a mixed channel.

The mixed channel has a much lower standard deviation because of the more uniform intensity.

[13]................................................................................................................................................

33

Figure 2-8: The four joints of a GlO Epson robot, which enable it to move in all three

dimensions, with one axis of rotation. Hard stops may be applied to joints 1 and 2 to reduce the

range of motion. [21]....................................................................................................................

35

Figure 3-1: The manufacturing cell layout. Parts go from the dispenser (1) to the hot embosser

(2), then are transferred to the taping machine (3) and cutting machine (4). From there, they are

placed in the functional tester (5) and finally the finished parts bin (6).................................. 37

Figure 3-2: The robotic end effector, formed from a hollow vacuum channel with holes to create

a seal against the part. The talon or hook on the end of end effector allows for part manipulation

independent of the vacuum. The two ports on the end effector allow for the simultaneous

transportation of two parts. [13]...............................................................................................

39

10

Figure 3-3: The three degrees of freedom of the part on the effector head. Parts may be shifted in

either of the two planar dimensions (a) (b) with respect to the effector head, or rotated. (c) Parts

cannot be shifted or rotated perpendicular to the planar effector head, as this would cause the

vacuum holes to not adhere to the part, and the part to be dropped. ......................................... 41

Figure 3-4: The part dispenser, holding approximately 20 parts. The spring forces the parts to the

top of the dispenser, from where they can be removed. ...........................................................

43

Figure 3-5: An example part in the dispenser, showing the variation in x, y, and orientation

which m ay result from the dispenser. .......................................................................................

43

Figure 3-6: The alignment of a part when being retrieved from the dispenser. The location of the

talon is indicated with the dotted line. The part starts unoriented in the dispenser, with the

effector head lowered over it. (a) The part is then pulled straight out of the dispenser, aligning it

against the talon on the end-effector and orienting it. (b) The vacuum is then activated and the

part is moved against the side of the dispenser, which causes its location to be fully known. (c)45

Figure 3-7: The initial method of part alignment against the three pins. Parts are placed

sufficiently far away from the pins such that, given the variance in their location, they will never

overlap with the pins. (a) Parts are then pushed towards the back pins. (b) Finally, parts are

pushed against all three pins. (c)...............................................................................................

45

Figure 3-8: The orientation of a part using three-pin alignment. The part is first brought against

the two farthest alignment pins, which involves some intentional overshooting on the part of the

robot. The part is then moved diagonally with respect to the three pins, causing it to orient and

rest against them , fully fixing its location..................................................................................

46

Figure 3-9: The precision of the robot when placing parts in the functional tester over 50 trials.

For these higher-resolution images, a two-pixel margin of error corresponds to slightly more than

1 pm, allowing the actual part variance to dominate. The maximum linear displacement can be

seen to be approximately 30 gm in x and approximately 20 pm in y, and the maximum angular

displacement about 0.3 degrees. As it is uncertain which position is correct, all errors have been

shifted to have a m ean of 0 im.................................................................................................

48

Figure 3-10: The top-level priority system for the actions of the robot. Each time the robot

completes an action, a new action is selected based on this priority system............................

51

Figure 3-11: Detailing the task the robot will select for a given system state, assuming the

dispenser has blank parts remaining. By starting at the indicated blue square and accurately

answering each question about the state of the system, it can be determined what action the robot

will perform, indicated by a green square, or how the robot will wait, indicated by a yellow

square. Red squares indicate that the system has stalled, and correspond to states that cannot

norm ally be achieved....................................................................................................................

53

Figure 3-12: Detailing the task the robot will select for a given system state, assuming the

dispenser does not have blank parts remaining. By starting at the indicated blue square and

accurately answering each question about the state of the system, it can be determined what

action the robot will perform, indicated by a green square, or how the robot will wait, indicated

by a yellow square. Red squares indicate that the system has stalled, and correspond to states that

cannot norm ally be achieved. ....................................................................................................

54

11

Figure 3-13: A sample task structure where the robot performs tasks sequentially, rather than

55

based on the state of the system ............... ...............................................................................

Figure 3-14: A top-level view of the system communications. The mechanism by which the

communication occurs is indicated by color. Locations labels include the data stored at that

location. The data communicated at each junction is listed at the bottom. ..............................

57

Figure 3-15: Dye contamination occurs due to the back pressure in the functional tester causing

bubbles of both water and dye to form (a). When the part is inserted into the functional tester, it

makes contact with the red dye bubble (b), and, as it is inserted, drags that bubble into the bubble

of water (c). When the part is placed, the water inlet has red dye in it (d)............................... 60

Figure 4-1: Showing the consistency between cycles and average cycle time for the system, as

67

determined by the functional tester..........................................................................................

Figure 4-2: The takt time of parts after slight modifications to the hot embossing and functional

testing code to increase efficiency. The overall cycle time has decreased by almost 7 seconds,

69

and there are fewer outliers......................................................................................................

Figure 4-3: The simulated system cycle times as a function of the functional testing time. Cycle

times increase linearly with the functional tester while the robot completes its task shortly before

the hot embosser opens. The peak corresponds to the robot performing an action while the hot

70

embosser is waiting for a part .................................................................................................

Figure 4-4: The system cycle time as a function of the functional tester processing time, using a

different priority set for the robot. While similar to Figure 4-3, the cycle times after the peak are

71

lower. ............................................................................................................................................

Figure 5-1: A run chart showing parts made from two different orders of the PMMA blanks. The

red dotted line indicates where the run switched from the first order to the second. A small but

75

noticeable drop in the average channel width occurs at this point. ..........................................

Figure 5-2: The box plots of and the results of an ANOVA test on the mean channel widths the

parts immediately preceding and immediately following the switch in part orders. The

probability of a mean shift occurring given the data is greater than 98%. ............................... 76

Figure 5-3: The average channel width of parts J61 to J120, where parts J91 to J100 have both a

higher average value and a significantly higher variation than the rest of the parts. Each ten parts

came from its own packet, although only one of the six packets used appears to be distinct...... 77

Figure 5-4: The boxplot and ANOVA test for the group of ten parts which appear to be outliers.

Based on this run data, something almost certainly changed. However, whether this was due to

78

the ten part group or some other factor is uncertain. ................................................................

Figure 5-5: The force applied by the actuator on the part during forming, over many cycles.

While slightly noisy, the applied force is highly consistent between cycles............................

80

Figure 5-6: The upper heater temperature of the hot embosser over 60 part cycles. There is

increased variance during the heating and cooling steps. During the forming step, temperature is

consistent to within about 1 degree Centigrade. No clear trends are shown. ........................... 81

Figure 5-7: The temperature of the lower heater during part forming over 60 part cycles. Because

of its lower power, the lower heater had a lower overall temperature than the upper heater, as

82

w ell as a longer rise time. .........................................................................................................

12

Figure 5-8: The measurements taken by the functional tester when the same part was placed into

it repeatedly. These measurements are the average of the four channel widths visible to the

functional tester. The grand mean is 65.33 gm, with a standard deviation of 0.31 m............ 83

Figure 5-9: A normal probability plot for the functional tester repeatability test. The data is not

completely normally distributed, as higher values are more likely than would be expected. ...... 84

Figure 5-10: The averages of each of the four channels measured during the functional tester

repeatability test. The error bars shown correspond to one standard deviation. The inter-channel

variation is greater than the variation in the measurements for a given channel...................... 85

Figure 5-11: Part El 1 with the light source on a lower setting (left) and a higher setting (right).

The higher light setting has reduced the amount of shadow around the channel, which caused the

edge detection software to measure the right picture as having a channel 4 pm narrower. ......... 85

Figure 5-12: The channel widths recorded by the functional tester under two conditions with the

primary lighting source. When the lighting was increased, the average part width decreased by

about 4 jm, owing to a decrease in the number of shadows seen by the optical measurement... 86

Figure 5-13: Measurements from the same part at varying times of day, as well as with the

overhead lighting off. These tests show that the secondary lighting conditions do not

significantly impact the part measurements...............................................................................

87

Figure 5-14: A portion of the optical target, as seen from the functional tester. This image was

used to confirm the calibration of the functional tester. The lines on the optical target are exactly

50 m wide. ..................................................................................................................................

88

Figure 5-15: The measured spacing of the 50 gm lines and between those lines on the optical

target image, at 25 distinct points along the image. The line width is 80 pixels, indicating that 1

pixel corresponds to .625 gm ....................................................................................................

89

Figure 5-16: The test for taping machine variability. Six parts were put through the taping

machine 10 times each, with the resulting measurements then recorded. The mean and standard

deviation for each part are indicated. The taping machine is a non-negligible source of system

variation . .............................................................................................

,......................................... 90

Figure 6-1: The run chart for the first run of the system to make a statistically significant number

of parts. While the system was in control for the first 60 parts, a mean shift occurred at the end.

.......................................................................................................................................................

92

Figure 6-2: The CuSum chart for the initial process run, using groups of n = 3. With this chart,

the process mean shift can clearly be seen...............................................................................

93

Figure 6-3: A run chart for the second of the long runs, again showing a mean shift. In this

process, the mean shift starts at the beginning and then levels off...........................................

94

Figure 6-4: The run chart for the first 60 parts of the J Series, or third long run. The initial

portion of the run shows what appears to be a startup transient, which then levels off, with the

rest of the run being largely uniform. A slight discontinuity occurs between parts J19 and J20,

where the blank parts were switched from the initial batch ordered to the second batch. However,

this switch does not coincide with the end of the startup transient........................................... 95

Figure 6-5: A run chart after the system appeared to be in control. While the process is almost in

control, there is a mean shift for approximately ten parts between J90 and J100. There is also a

13

significant mean shift between parts J60 and psrts J61, although the only change was that the

system was left on for a little over an hour between the parts..................................................

96

Figure 6-6: The run chart for the K series, with the forming temperature set to 120 C instead of

115 C. This caused the parts to have a much lower channel width, which was the desired effect.

The process continues to be in contrql.....................................................................................

97

Figure 6-7: The high outlier from the K series, part K4. The tape has not properly adhered to the

part, causing large amounts of bubbling, which may have prevented the part from being properly

97

measured.......................................................................................................................................

Figure 6-8: The process run again with the high temperature at 120 C after a number of minor

hardware tweaks. The L series pictured provides the same data from the K series run before the

minor hardware tweaks, indicating that the process is still in control...................................... 98

Figure 6-9: The ANOVA test done between the K series and the L series, which shows no

significant m ean shift....................................................................................................................

99

Figure 6-10: The normal probability plot for the combined K and L series. The process is not

normal, largely due to the number of outliers with narrower channels. The cause for these

99

outliers is not currently known. ................................................................................................

Figure 7-1: One measurement error incurred during the DOE. The left image shows the

measurements of the four channels from part DOE 2. The left-most channel clearly has a much

narrower measurement than the other three, and upon closer examination, as seen in the image

on the right, the software has measured the distance from the outside of one channel to the inside

of the other, rather than the distance between the outside of both channels............................... 102

Figure 7-2: The pattern used by the image matching software to determine that a part is present

(left) and a part which the measurement software had trouble detecting, owing to how narrow its

102

channels were (right)...................................................................................................................

Figure 7-3: A part where two of the channels have been measured, and a close-up of the two

channels that were improperly measured. The edge-finding has recorded the channels as being

103

w ider than they actually are........................................................................................................

Figure 7-4: The average channel widths of parts formed at 115 C, as a function of forming force

and forming time. Parts formed at 115 C in this range have a much higher width than the forming

parts, as the PMMA only begins to flow at 114 C. Increased form time and force both result in

106

sm aller channels..........................................................................................................................

Figure 7-5: The average channel width for parts formed at 120 C. Parts at this temperature, given

higher form times and forming forces, get closer to ideal channel width of less than 60 pm, but

do not reach it at these parameters. Increased forming force and form time both decrease channel

width, except at the highest forming force when increasing the form time from 30 seconds to 40

seconds........................................................................................................................................

107

Figure 7-6: The average channel widths of parts formed at 125 C. Here, many of the parts are

below 60 gm in channel width, and the graph starts to level off at high form times and forming

10 8

forces...........................................................................................................................................

Figure 7-7: The average channel width as a function of forming temperature and forming strain.

Forming strain is given by the forming force times the forming time. In this region, forming

14

strain has a much larger impact on the part at temperatures close to the glass transition

temperature of the part................................................................................................................

109

Figure 7-8: The impact of each term and cross-term, along with the probability that the given

parameter is statistically significant. All parameters except for the force curvature term are

highly significant. .......................................................................................................................

110

Figure 7-9: The residuals for the least-squares fit model of the DOE data. The predicted fit is

highly correlated with the data....................................................................................................

110

15

16

LIST OF TABLES

Table 3-1: The information communicated between the robot and the hot embossing machine

and functional tester during the course of system operations. The hot embossing machine and

functional tester have the same communication scheme. Data flags are listed in the order that

they will occur in a typical cycle, first triggering the machine, then communicating that the

machine is done, then resetting the machine to ready it for a new process trigger. ................. 58

Table 4-1: The operation times for each of the tasks of the robot while operating in low power

mode. Both ports had to be taught their points separately, resulting in slightly varied cycle times

between the ports. Operating in high power mode could reduce these speeds by a factor of 5 or

m ore. .............................................................................................................................................

64

Table 4-2: The travel times of the robot between the machines of the system. These times are

largely consistent between ports that are far apart, but for ports close together the time to turn the

effector head starts to dominate .................................................................................................

65

Table 4-3: The part numbers and corresponding cycle times for parts with much lower cycle

times than normally displayed by the system. These cycle times are between 1.5 and 2.5 seconds

lower than expected from the rest of the data. These lower cycle times likely result from

computer communications discrepancies. ...............................................................................

68

Table 6-1: Showing the different part runs done to attempt to achieve statistical control, along

with the letter used to designate each of those runs. Unless specified otherwise, each run had a

forming temperature of 115 C, a cooling temperature of 60 C, a forming force of 1000 N, a

heating time of 60 seconds, a forming time of 30 seconds, and a cool time of 20 seconds. ........ 92

Table 7-1: The parameters to be altered during the designed experiment, as well as the values

selected for those parameters. A full 33 factorial test was selected for this experiment, with each

point having five repetitions.......................................................................................................

101

Table 7-2: The results of the hot embosser DOE. Five parts were made at each of three levels of

the forming temperature, forming force, and forming time. The average channel width, standard

deviation, and number of parts at each parameter are shown. Two parts were removed owing to

being significant outliers.............................................................................................................

105

17

18

CHAPTER

1

INTRODUCTION

Microfluidics devices, which have a large number of applications in the medical industry, can be

manufactured in a variety of ways. Soft lithography, micromachining, hot embossing, and

injection molding are just a few of the ways these devices can be created. However, as discussed

by Perez [1], the hot embossing system has a number of advantages over other methods currently

in use, including a much higher flexibility and a much lowers startup cost. The system in

question uses PMMA blanks and a hot embossing machine, along with tape, to create a part

which acts as a simple microfluidics mixing device. The part can then be tested for quality by

both measuring the width of the mixing channels and by determining the location where the fluid

is deemed "mixed." Once this data relayed to the hot embossing machine, the system can be kept

in control, using the type of feedback selected by the operator.

1.1

Microfluidics

Microfluidics is the science of dealing with small quantities of fluid, on the order of 10-9 to 10-18

liters, using devices with channels from tens of microns to hundreds of microns width. These

microfluidics devices have a wide variety of applications in research, including the evaluation of

protein crystallization, drug development screening, and bioanalysis. [2] In spite of the number

of applications, commercial usage is currently limited, in part owing to costs of fabrication of the

microfluidics devices. Until cheap, large-volume production of these devices is available, widescale healthcare applications will be limited.

While many of the initial microfluidics devices were made using PDMS1, it is not an

optimal material for biological testing. Owing to the tendency of PDMS to swell in the presence

of organic solvents or to deform under high pressures, PMMA 2 is often selected as the material

for microfluidic devices. [3] PMMA, like glass, has desirable optical properties, but can be

1Polydimethylsiloxane, a cast elastomer

2 Poly(methyl methacrylate), a thermoplastic

19

fabricated using hot embossing or micromilling, rather than glass etching. While micromilling

can be used to create appropriate width channels, the resulting surface roughness and required

post-processing to achieve the desired optical results often make hot embossing preferable.

Injection molding is also an option, and while it allows for sufficiently high-volume and low-cost

manufacturing for the desired market, the it has a much higher initial cost and lead time than hot

embossing, making it undesirable for prototyping and testing, especially compared to the rapid

tooling changes allowable by hot embossing. [1]

1.2

Hot Embossing

The hot embossing process involves raising an amorphous plastic to slightly above its glass

transition temperature and then applying a mold at high pressure to cause the plastic to deform to

the desired shape. Plastic is cooled around the tool, then removed. To create microfluidic

channels, an additional, optically clear layer is then bonded overtop the plastic. Because the

overall flow is small, hot embossing tends to result in lower residual stresses than fabrication

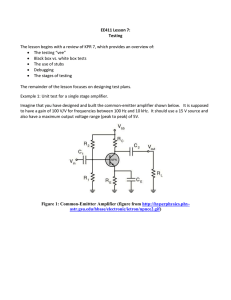

techniques such as injection molding. [4] The hot embossing process is shown in Figure 1-1.

mold

Heating

Pressing

tttttttt

Cooling and

separating

Bonding

Figure 1-1: The four steps of the hot embossing process for microfluidics devices. By applying pressure to a

plastic at or near its glass transition temperature, the plastic will locally flow into the shape of the mold, after

which it can be cooled and separated. A bonding layer over top seals the microfluidics channels. [31

20

The pressing step of the hot embossing process causes the heated thermoplastic to flow

around the mold, creating the desired shape. In this step, the forming force used can cause

variations in the final shape of the part. While high forming forces result in an ideal negative of

the mold, lower forces may not cause sufficient flow. Figure 1-2 shows the resulting crosssections of a microfluidics channel after the application of various forces. At lower forces, the

channel is shallow and wide compared to the mold, as seen replicated under higher forming

forces.

F-

PF=10N

N

Z

F=30N

F=1I

SN'

Figure 1-2: The resulting cross-section of a microfluidics channel, based on the forming force applied. Higher

forces cause more localized flowing of the plastic, resulting in sharper channels with steeper walls. This data

corresponds to PMMA parts formed at 110 C. [51

There are a number of different bonding methods used in conjunction with hot

embossing. Adhesive bonding places a layer of viscous liquid over the thermoplastic, or uses a

lamination film. Lamination films in particular are both inexpensive and scale easily to higherrate processes. Thermal fusion bonding and solvent bonding both cause intermolecular bonding

between the embossed part and the bond material, with thermal fusion using high temperatures

and pressures and solvent bonding using a chemical to which both components are soluble. [6]

Various problems arise from these methods. Using a layered adhesive can often block the

microfluidic channels. Thermal fusion bonding is time-consuming, and solvent bonding may

change the surface properties of the part. For these reasons, lamination films are often considered

as a suitable mass-production bonding process. [7]

21

The hot embossing process is, compared to injection molding, high-flexibility, low-cost,

and medium-rate. The comparatively longer cycle times arise from the need to heat and cool both

the mold and part during each cycle, something not always necessary in injection molding.

However, hot embossing allows for the creation of aspect ratios greater than two, which is

difficult in micro-molding. [8] Because the tool used for the hot embossing process can be

quickly changed, hot embossing provides both low start-up times and high flexibility.

Additionally, the ability to easily switch out for a new tool coupled with the comparative cost of

the tools makes the process cheaper than injection molding. [4]

1.3

Precision Manipulation

Because of the small scale of the microfluidics channels, the hot embossing step must occur with

high precision. This requires a precision placement of the parts into the hot embossing machine,

which in turn necessitates a form of high-precision manipulation. When moving parts, location

errors are introduce both during the pick-up and the placement, which must fall below a certain

acceptable threshold based on the system in question. Adhesive forces between the part and the

manipulator may add locational errors during the placement step, as do any methods of forceful

removal of the part from the manipulator. [9]

When dealing with small parts, suction can be a highly precise method of placing parts. A

suction gripper uses vacuum pressure to lift a part. Suction grippers, in conjunction with optical

measurement, have been shown to be able to reach 10-micron tolerances, and, using a physical

boundary for the part such as grooved channels, suction grippers have also been able to reach 2

micron tolerances. [10]

1.4

Process Control

For parts to be created in any volume, process control is needed to ensure the quality of those

parts. There are a wide variety of potential alterations that a system can undergo, including

changes to the material type, alterations to the system equipment, and even variations in the

surrounding environment, all of which can alter the final part quality. To keep the parts produced

of an acceptable quality, feedback is needed throughout the system. Generally, this feedback

22

control will take one of two forms; high bandwidth feedback within the system machines, and

sampling of the final parts produced by the system. [11]

To create appropriate system feedback, one or more quantifiable measures of part quality

must be determined. These measurements can then be made on completed parts, and the results

compared to the expected process value. If the measurements do not fall within an acceptable

error, or if a series of measurements show a trend over time, the system has displayed evidence

of no longer being in control. When this happens, troubleshooting must take place to determine

what has changed or is in the process of changing for the system, so it can be corrected. This

enables the system to continue to make appropriate-quality parts.

Machine variables for a hot embossing system can include the temperature, pressure, and

displacement at each point during the hot embossing process. These values inform on the overall

deformation of the part, which indicates how well the microfluidic channels have been informed.

The glass transition temperature can also be computed, which provides information about the

material of the part in question. This information can then be used to detect shifts in material

quality. [12]

1.5

Project Motivation

This thesis will, using previously-created embossing, adhesive bonding, and functional testing

machines, detail the creation of a small factory capable of producing parts at a rate pre-defined

by the hot embossing cycle. The sources of part quality variation and data necessary for the

creation of a cycle-to-cycle control scheme have also been detailed.

Prior to this thesis, ongoing research has been done to create a controlled system for the

production of hot embossed microfluidics devices. A hot embossing machine, measuring

forming force, displacement, and temperature, which could produce parts with a cycle time of

110 seconds, was created. [12] A separate device for applying laminate tape to the embossed

parts was built, as was a testing machine which could optically measure the resulting channel

width of the embossed parts. [13] To move parts between these machines, a precision

manipulation system was developed. [14] To create the controlled system, the system had to be

fully utilized and an appropriate process control had to be identified.

To fully utilize the system, parts had to be moved between machines rapidly enough that

the 110 second cycle time on the hot embosser was the system bottleneck, and precisely enough

that the optical measurement could be made. Rapid part movement required the creation of time23

efficient movement paths as well as an appropriate prioritization for the various actions which

could be performed by the singular part movement machine. This precision required, in addition

to the previously developed manipulation system, the identification and reduction of all the

additional sources of part location variation within the system.

To implement process control on the system, a number of factors were identified. The hot

embossing machine needed to be verified to be in a state of statistical control. A design of

experiment needed to be done to determine the exact effect of the various process parameters on

the final part. The optical measurement had to be communicated to the hot embossing machine,

and the hot embossing machine had to be taught the appropriate action to take based on the data

received. Once these things were done, the system would be controlled based on a feedback loop

from part quality.

24

CHAPTER

2

2.1

PREVIOUS WORK

1

The Part

To demonstrate process control for a hot embossing system, a suitable part had to be designed.

The part needed clear microfluidics channels, which could be easily measured to demonstrate

proof of concept for the system. A simple mixing device was selected, with two input ports and

one output port. The channel width on the embossing tool was selected to be 50 gm, and the

depth was selected to be 40 Rm. Figure 2-1 shows the features on the tool used to make the part.

Additional features, including a grid of squares 20 gm on a side, were included on the tool to

increase the amount of data that could be gathered from a completed part. The tool used to create

the part was made of bulk metallic glass by Henann [15]. Henann chose bulk metallic glass for

the tool after it was shown to be both robust and accurate for use in the hot embossing process

for microfluidics devices.

Figure 2-1: The tool used to make the part. Two input ports combine via a mixing pattern using 50 pm to a

single output port. Additional markers have been placed on the part in case additional measurements were

needed. 1121

25

Parts are made from PMMA, using rectangular injection-molded blanks. Originally,

PMMA was laser-cut from flat sheets into the desired shapes. However, owing to the high

variation in the thickness of the PMMA and associated handling issues, blanks were injectionmolded by an independent contractor.3 Before embossing, blanks are 1.52

0.01 mm thick and

approximately 35 mm x 25 mm in area, with three 2 mm-diameter holes where the fluid will

flow into and out of the embossed part. A slight indentation in one corner provides an orienting

mark.

2.2

Hot Embossing Machine

2.2.1 Previous Versions

The first version of the hot embossing machine, created by Ganesan, [16] used an Instron Model

5869 to supply the forming force, with copper platens dispersing the heat supplied via heating

cartridges. The cooling system would then run cold water through the platens to cause them to

reduce the system cooling time. After poor results with a copper tool, a silicon tool was used.

The cycle time took about 30 minutes, consisted of about 10 minutes of heating, 17 minutes of

forming, and 3 minutes of cooling. Force and displacement data for each run was recorded. The

heater temperature was also recorded, although the distance of the heaters from the part caused

this data to not be a truly accurate representation of the system. Figure 2-2 shows the initial

hardware.

3 http://www.quickparts.com/

26

Figure 2-2: The first version of the hot embossing machine, showing the forming platens in the Instron. 1161

For the second version, Dirckx [17] built on Ganesan's work. Using the same Instron,

forced heat transfer via heated and cooled fluid was able to reduce the cycle time to 6 minutes,

consisting of two minutes of heating, two minutes of forming, and two minutes of cooling. This

machine included features to demold the completed part from the tool. However, this method

was required a much larger machine to sufficiently heat and cool the fluid, and the resulting

cycle time was still higher than desired.

In the third version of the hot embossing machine, Hale [18] further reduced the total

cycle time to 2 minutes by minimizing the thermal mass between the heaters and the part. The

part size was also standardized, to the creation of 1"x 3" parts, rather than the variable-sizing the

prior machines were capable of producing. This enabled the tool to be switched to the current

one, made from bulk metallic glass. The load application was switched from the instron to a

smaller Mead Fluid Dynamics DM-600 x 1" stroke pneumatic cylinder with an integrated load

cell. This also helped to significantly reduce the equipment cost.

27

2.2.2 Current Version

The current version of the hot embossing machine, built by Bageant, [12] has a cycle time of 115

seconds. Of this time, 30 seconds are used for heating, 30 seconds are used for forming, 20

seconds are used for cooling, and 5 seconds are used for unclamping. The machine includes PIDcontrolled heaters and force provided by a pneumatic bellows, or air spring. A linear air bearing

limits the motion to one dimension. The combination of the air spring and air bearing provide

low friction, precision linear motion, and eliminate any potential motion outside of the desired

dimension. Force and temperature are recorded from the actuators, and an LVDT measures and

records the displacement of the system. Figure 2-3 shows the current hot embossing hardware.

Key features, including the LVDT, the air bearing, and the air spring (pneumatic actuator) have

been labeled.

Planar

adjustment

flexure

Thermal

stack

LVDT

Air

bearing

Load cell

Pneumatic

actuator

0-frame

structure

Figure 2-3: The current hot embossing hardware, with key features labeled. [121

28

2.3

Taping Machine

A separate machine was created to perform the bonding step of the hot embossing process, as

seen in Figure 1-1. This bonding, using a laminate adhesive, or tape, over top of the part,

required a method that was both rapid and robust. Our collaborator, at Nanyang Technology

University in Singapore, built a machine which semi-automated the taping process by placing a

part on a moving stage, which could then be sealed with individual pieces of tape. [19] [20]

However, a fully-automated process was desired. A method of continuous taping, with the piece

of tape cut into appropriately-sized pieces once it had adhered to the part, was selected and built

by Reyda [13].

In the taping machine, tape is unspooled via a series of rollers, then laid overtop parts

placed in the taping machine. Parts are moved linearly through the machine while the tape is

applied using motor-actuated belts. Force is then applied via spring-loaded rollers to the top of

the parts to ensure good bonding between the tape and the parts. Figure 2-4 shows a side view of

the taping machine, indicating the path the tape takes as the parts move through the machine.

29

Take-up reel

Tape reel

Motor

removes

liner

Exposed tape

Roll applies pressure

4B

@@@@

Motor drives

belt

4%

Figure 2-4: The taping machine, showing the path of the tape as the parts are moved linearly along the belt.

Parts will be sealed with one piece of tape, which is then separated by the adjacent cutter. [13]

Once the parts have been taped, the tape is cut to separate the parts from each other. This

cutting is done by a separate device next to the taping machine, which parts are pushed into by

the stiff tape. Once parts have reached the cutting device, an air cylinder forces two rotary blades

over the edges of the last two parts in the machine, cutting them apart. The part that has been

separated from the tape ribbon is then removed from the taping and cutting setup by the part

manipulator discussed in Section 2.5. An additional effector pushes the cut portion of the tape

out of the device. [13] The path of the blades over the taped parts is shown in Figure 2-5. Note

that no portion of the remaining tape will hang over the edge of the parts.

30

Figure 2-5: Three parts that have been embossed, with the tape placed overtop of them. The dotted lines show

where the tape will be cut to separate the parts, and the arrow shows the direction the parts move within the

machine. [13]

2.4

Functional Testing

A crucial part of the process control for the automated system is an automated way to measure

the parts produced. To this end, a machine was designed and built by Reyda to determine the

quality of the parts produced by the system. This machine has a cycle time of 85 seconds for a

full functional test, or a shorter cycle time of 17 seconds for just the preliminary optical test.

The functional tester takes a zoomed-in image of a part, then analyzes it to determine if it

has been properly formed. This analysis first determines the minimum light intensity of the part

and the overall standard deviation of the light. If the minimum light intensity is below a

threshold value and the standard deviation is above a threshold value, the part is determined to be

present. Key features of the part are matched to a pre-recorded pattern, which is also used to

determine whether or not the part is present. If the part is present, the pre-recorded pattern is

used to determine whether or not the part is sufficiently oriented. If the part is more than 4'

rotated, the fluid ports will not properly line up, and the part is recorded as being improperly

oriented. [13]

If the part is present, the channel widths are measured using this zoomed-in image. Edge

detection is used in the regions where the channels are expected to be, based on the pre-recorded

pattern. This edge detection finds the outer channel widths at several locations and averages

them to find the width of each of the four channels. These four widths are recorded, as is the

average and standard deviation of the four widths. Figure 2-6 shows a raw image from the

zoomed-in camera, as well as an image with the functional tester's data recorded on it.

31

Figure 2-6: A zoomed-in image of a part in the functional testing machine, and that image with the data from

the functional tester recorded on it. The average width and standard deviation measures in the upper-left

corner are based on the four measured channel widths. The information in the upper-right corner is used to

determine the presence of the part. The TRUE label in the lower-right corner indicates that the part may

have fluid flow through it.

32

If the part is both present and oriented, red dye and water are flowed through the two

input ports, and a less-zoomed image taken of the resulting fluid mixing profile. Red dye was

selected because of its strong visibility, given a green filter over the main light source and a

grayscale image. By looking at the standard deviation of the light intensity across a channel, the

extent of the mixing at that location could be determined. Figure 2-7 shows images of both the

mixed and unmixed channels before and after the standard deviations were labeled. The unmixed

channel has a much higher standard deviation than the mixed channel.

94

18

31

42

01

_99,

0

9

9

4WO4

-0

7

Figure 2-7: The standard deviation of the intensity across both an unmixed and a mixed channel. The mixed

channel has a much lower standard deviation because of the more uniform intensity. [131

The mixing data from the functional tester encountered a few problems during testing.

Because the fluid from the ports had a tendency to slightly bubble up from out of the o-rings

where the ports interfaced with the functional tester, inserting the part tended to cause red dye to

get into the source for the water. This caused the water to be slightly mixed when it entered the

part, interfering with the mixing location measurement. Additionally, the mixing location was

much sooner in the channels than was expected. More mixing occurred at the bends than was

expected, which caused problems because of the lack of data gathered at the bends. However, the

initial channel width measurements still provided the necessary data for the process control of

the system.

33

2.5

Epson Robot

For this system, an Epson G10 [21] materials handling robot was used. The choice of a robot

was based on a combination of flexibility and precision4 over many cycles. Because of the nature

of both the hot embossing process and the part testing procedure, parts were required to be

accurately placed in a number of locations. However, owing to the ongoing development of the

system, those locations were subject to change as machines were introduced or modified.

Because of these potential changes, a conveyor belt or other fixed approach of part movement

was ultimately deemed impractical. The selected robot requires only a simple reprogramming to

accommodate a new machine, a machine redesign, or the movement of an existing machine

within the system. Because the parts would remain horizontal for all processes, a 6-axis robot

was not needed, so a 4-axis SCARA (Selective Compliant Assembly Robot Arm) could be used.

This also eliminated the variability that would have arisen from the additional, unneeded

dimensions. Of the available SCARA options, an Epson GlO was chosen because its range and

precision were deemed the best for our system. [14]

The Epson GlO contains four distinct joints, enabling the manipulator to move within

three dimensions with angle of the end effector controlled by the fourth joint. Joint one rotates

the links of the manipulator around its base parallel to the floor. Joint two rotates the remaining

links about the end of the first link, again parallel to the floor. This enables the end of the

manipulator to obtain any position within that plane. Hard stops can be added to each of joints

one and two to limit the total rotation, as well as the position of the end effector. The third joint

controls the height of the end effector, and the fourth joint rotates the end effector to allow it to

be positioned at the desired angle. The four joints of the G10 Epson robot are shown in Figure

2-8.

4 The Epson GlO has a working radius of 850 mm. It has a precision of 10 pm in joints 1 and 2, 25 pm in joint 3,

and 0.005 degrees in joint 4.

34

Joint#2

(mlbing)

Jokt#3 and #4

Joint #1

Ami #1

++

((rots")g

Ann

)

MOM~

Figure 2-8: The four joints of a G10 Epson robot, which enable it to move in all three dimensions, with one

axis of rotation. Hard stops may be applied to joints 1 and 2 to reduce the range of motion. [211

The Epson G 10 robot is responsible for the transportation of parts between the machines,

as well as into and out of the system. Once blank parts have been loaded into the dispenser by an

operator, the system can run autonomously, with the robotic manipulator keeping track of the

location of all parts within the system as well as moving those parts when necessary. By keeping

track of the part locations as the parts were moved, the robotic manipulator was able to

determine the optimal action for the system at any given time, and then perform that action.

Owing to the precise nature of both the embossing of the parts and the image acquisition

during the functional testing, parts need to be loaded into machines with a precision of less than

0.5 mm. Because of the lack of feedback surrounding the system, part location needed to be

well-controlled at all times. Additionally, because of the introduction of slight variations at

various points into the system, a three-point alignment system is used at all critical steps to verify

that part location is within the required margin of error. This three-point alignment consists of

35

three pins, which anchor two sides of the parts as well as preventing them from rotating. The part

alignment is further discussed in Section 3.3.

This robot enables the system to be fully automated, removing any variance that might

arise because of differences in human manipulation. The full automation is also beneficial in that

it allows the system to consistently operate at peak or close to peak capacity, without relying on

an operator at all times. For the purposes of system rate, the hot embossing has been determined

to be the bottleneck process, and thus the prioritization of the robotic manipulator is heavily

weighted towards keeping the hot embossing machine running at all times. System prioritization

is discussed in Section 3.4, and system efficiency is discussed in Chapter 4.

36

CHAPTER

3

ROBOTIC HANDLING SYSTEM

Within the system, the robot was required to move parts to achieve the highest possible

production rate. The robot would pick up parts from the part dispenser and step them through the

system, to the hot embosser, the taping machine, and the functional tester. After removing parts

from the tester, they would be place in the finished parts bin. The parts needed to be placed in

both the hot embosser and the functional tester with less than 0.5mm error during each cycle.

Figure 3-1 shows the system that the robot interacts with. The part dispenser, hot embossing

machine, taping machine, cutting machine, functional tester, and finished parts bin are all

labeled.

Figure 3-1: The manufacturing cell layout. Parts go from the dispenser (1) to the hot embosser (2), then are

transferred to the taping machine (3) and cutting machine (4). From there, they are placed in the functional

tester (5) and finally the finished parts bin (6).

37

3.1

Safety

In order for the Epson G10 to be safely used, operators and observers must remain at least 1

meter from the work envelope at all times. To enforce compliance with this safety standard, a

Sunx Type 4, SF4B series laser curtain is used in conjunction with a SF-C13 Sunx Safety

Control Unit. The system was placed in the corner of a room, with the emitter and receiver for

the laser curtain placed at each of the two walls forming the corner. A mirror was erected

between the emitter and receiver to create a sensor along the two free edges of the system. The

control unit was then wired into the Epson G 10 emergency stop, causing the system to enter an

emergency stop state whenever the laser curtain was interrupted at any point. By placing the

laser curtain at least one meter from the work envelope of the robotic manipulator, safe usage of

the robotic manipulator can be ensured.

An additional concern is contact with existing machines, especially during a system startup. While the robot has a series of hard stops, which can drastically limit the work envelope, the

system's machines are, by necessity, within the work envelop. During the system steady-state, all

paths are known, and programmed to avoid cgllisions with the existing machines. However the

position of the robotic manipulator at startup is unknown, and thus a specific path cannot be

assumed.

To avoid this issue, the location of the robot is determined at system start-up. The

manipulator is then moved at the slowest possible speed, in low-power mode, to a predetermined location. This movement path takes into account the location of the manipulator,

with specific paths being generated should the effector head be located within one of the

machines in the system. This enables the manipulator, starting from anywhere in the system, to

move to a given starting location safely. The starting location is used any time the system is run,

including after a sudden disconnect or emergency stop. The programming which governs these

movement paths is included in Appendix A.

38

3.2

End Effector Design

The end effector design selected included both a talon for part alignment and vacuum holes to lift

and hold the parts. The end effector is shown from the side and bottom in Figure 3-2, along with

the location of the part relative to the vacuum holes.

Hook

Milled area

Vacuum holes --

Figure 3-2: The robotic end effector, formed from a hollow vacuum channel with holes to create a seal against

the part. The talon or hook on the end of end effector allows for part manipulation independent of the

vacuum. The two ports on the end effector allow for the simultaneous transportation of two parts. [131

This end effector design was selected to allow multiple parts to be carried and to allow

interface with all of the machines in the system. The long, narrow end of the effector head is able

to fit into the functional tester and the hot embosser.

39

The double-ended nature provides an effective buffer, allowing the robot to remove a

completed part and insert a new part at a given machine without traveling to a different machine.

This is greatly beneficial at the system bottleneck, the hot embossing machine. With only one

effector head, the robot would have to pick up a finished part, place it at the next station, pick up

a new part, and place it in the hot embossing machine. With the addition of a second effector

head, placing the embossed part and retrieving a new blank part are eliminated from the

sequence of events. This shortens the time the hot embosser is not in use by eliminating several

required actions. With one effector head, a part must be removed from the hot embosser, placed,

a second part picked up, and that part then placed in the hot embosser. With two effector heads,

if the robot is already holding a blank part, the number of necessary actions is reduced to simply

removing a part from the hot embosser and placing the next part. Thus, the amount of time the

robot would spend placing the first part and picking up the second part is eliminated from the

maximum cycle time.

The vacuum is transmitted from the vacuum ports on the G10 robot to the effector head

of the robot through vacuum tubing. The effector heads are hollow, allowing them to retain the

vacuum when parts are placed against the vacuum holes. The vacuum is sufficient to hold one or

both parts simultaneously. Even if a part is dropped, the vacuum loss does not cause sufficient

lack of pressure for the other part to fall.

3.3

Precision Part Manipulation

In both the embossing machine and inspection station, the positioning of the workpiece in the

machines is critical. This alignment effects everything from where the device channels are on the

substrate to where the inlet and outlet ports are for the functional test. Precise placement also

makes the measurement more repeatable.

3.3.1 Requirements for Precision

The robot must be able to consistently pick up parts from each location. As the effector

heads on the robot have only four vacuum holes, the parts must be in such location that those

vacuum holes are able to come into contact with the parts. The precision for the robot is thus

dependent on the range that the vacuum holes can cover while attempting to pick up a part from

a given location. However, large amount of variance within the potential range of the vacuum

40

holes are still undesirable, as they then require excessive alignment times to make sure that the

vacuum holes have achieved proper contact.

With respect to part location variation, there are three degrees of freedom. Parts can be a

varying distance along the effector head, considered to be variation in the x dimension.

Perpendicular to that, parts can be to one side or the other of the effector head, which is variation

in the y dimension. Parts can also rotate in one dimension, in-plane with the two position

variations. Parts cannot be in varying positions in z, nor can they rotate in either of the other two

dimensions, as any of these location variations will prevent the vacuum from connecting with the

part, causing the part to be dropped immediately. Figure 3-3 shows the three degrees of freedom

of the part on the effector head.

(a)

(b)

(c)

Figure 3-3: The three degrees of freedom of the part on the effector head. Parts may be shifted in either of the

two planar dimensions (a) (b) with respect to the effector head, or rotated. (c) Parts cannot be shifted or

rotated perpendicular to the planar effector head, as this would cause the vacuum holes to not adhere to the

part, and the part to be dropped.

Once the robot is able to pick up parts, it must be able to place parts within the hot

embosser for the purpose of accurate embossing. The hot embosser has two main constraints on

placement. If the part is poorly positioned in y, the robot will be unable to place the part within

the hot embosser, as the part will contact one of the demolding fingers rather than slotting

between them. The other constraint is relevant to the accuracy of the embossing process. If the

part is placed imprecisely, the pattern will be embossed onto the wrong location of the part. This

can lead to a part that the functional tester is unable to properly process, or, in extreme cases, a

part that is defective and cannot allow fluid flow.

The robot must also be able to place parts within the functional tester for the purpose of

accurately analyzing the finished part. Like the hot embosser, a poorly positioned part can result

41

in the inability of the robot to place the part within the functional tester. The functional tester

uses a camera with a very narrow field of view. Because of this, the image matching software is

unable to match the patterns on the part images if the embossed pattern is misplaced by more

than 500 microns. This 500 microns is cumulative between the positioning at the hot embosser

and the functional tester. Additionally, poor alignment within the functional tester will cause the

ports on the part to not line up with the ports in the functional tester, preventing fluid flow.

The taping machine requires the least accuracy within the system. The machine is built

with high robustness to part placement, of up to several millimeters in both x and y, as well as

rotations of several degrees. As long as the part is placed within this range in the input area, it is

oriented and funneled into the precise location required by the taping rollers. Once it is

appropriately located, the precision is maintained until it reaches the cutting step, where a hard

fixture ensures a consistent cutting location, as described by Reyda. [13]

The final placement of the part is within a tray used to collect completed parts. As such,

precision lower than that required by the robot to pick up the part on the vacuum holes is needed

to place the part.

3.3.2 Sources of Variance in Part Placement

Each time the part is moved, a small amount of position uncertainty is introduced. Variation also

occurs from the operations of the different machines, as well as being introduced at the start of

the system.

At the start of the system, the blank parts are stacked in a dispenser. The dispenser,

shown in Figure 3-4, has a stack of parts that are moved to the top via a spring. As each part is

removed, another rises to the top to take its place. Because the dispenser needs to provide

minimal friction to allow for the sliding of the parts, the exact location of the blank parts within

the dispenser is uncertain. This uncertainty exists in the angle of the part relative to the dispenser,

as well as where the part is located in both x and y within the dispenser. Figure 3-5 shows an

example of a part in the dispenser with unknown x, y, and orientation.

42

Figure 3-4: The part dispenser, holding approximately 20 parts. The spring forces the parts to the top of the

dispenser, from where they can be removed.

Figure 3-5: An example part in the dispenser, showing the variation in x, y, and orientation which may result

from the dispenser.

Position variation is also introduced when the hot embosser raises the part against the

demolding fingers as the platens open. This causes the part to fall a slight distance when it is

removed from the tool. This can cause motion in both x and y, as well as to rotate. Although the

functional tester does not have demolding fingers, the abrupt nature with which it opens also

causes some movement of the part in a similar manner.

The largest source of location variation within the system comes from the cutting that

takes place after the part is processed by the taping machine. Because pressurized air is used to

43

move the cutting device, and because it must be able to quickly slice through the tape ribbon, a

large amount of force is applied to the base of the cutting device during each operation. This

causes vibration in the base, resulting in a large movement and rotation of the part in question.

Once the part has completed the functional testing process and is no longer needed within

the system, it is dropped into a tray from a height of approximately 10 centimeters, resulting in

an extremely high position uncertainty. However, because the part no longer needs to be

retrieved for further operations, this variation does not have a negative effect on the system. A

system of final placement that leaves the parts in the correct production order would be best, but

currently the retention of part order is accomplished by labeling the parts before they are put in

the dispenser.

3.3.3 Reduction of Variation

Reduction of variation takes place both when picking up and when placing a part. This reduction

is focused on parts immediately prior to and during their placement in the hot embossing