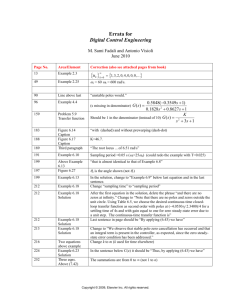

/?&

advertisement