SEP 1 2008 Tin Yiu Lam

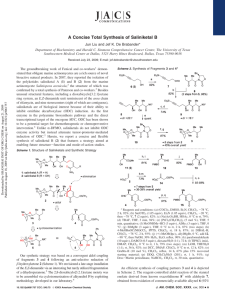

advertisement