Cost Decision Making for Managers

advertisement

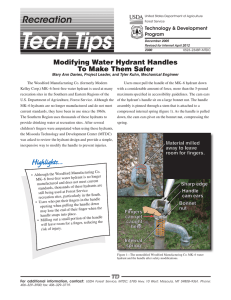

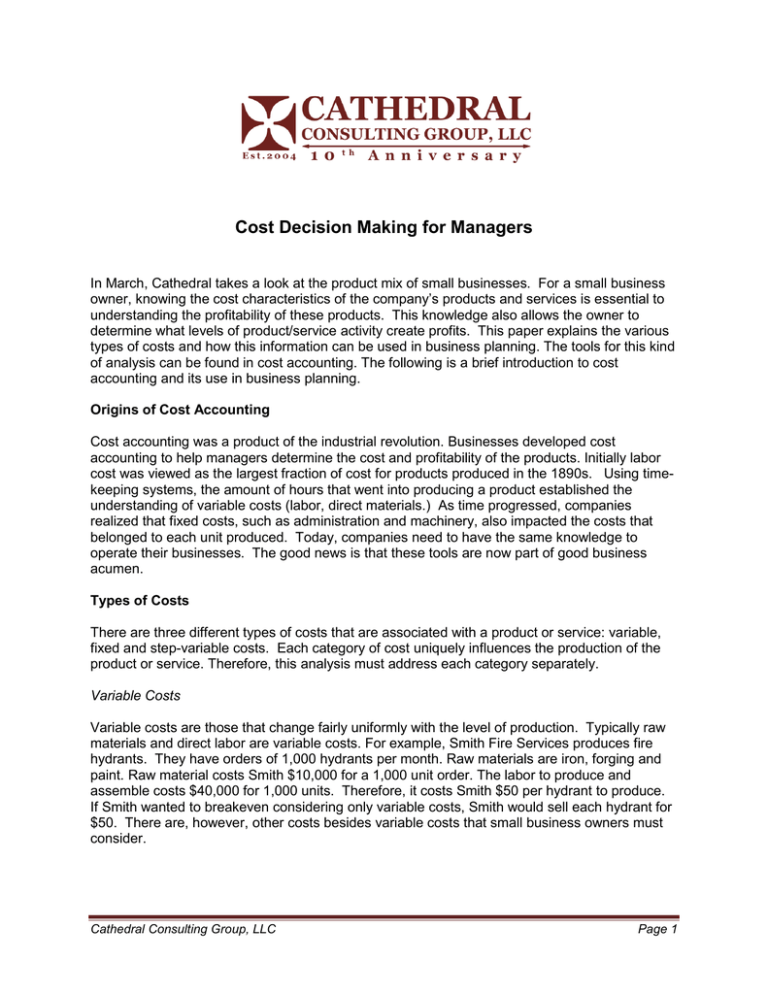

Cost Decision Making for Managers In March, Cathedral takes a look at the product mix of small businesses. For a small business owner, knowing the cost characteristics of the company’s products and services is essential to understanding the profitability of these products. This knowledge also allows the owner to determine what levels of product/service activity create profits. This paper explains the various types of costs and how this information can be used in business planning. The tools for this kind of analysis can be found in cost accounting. The following is a brief introduction to cost accounting and its use in business planning. Origins of Cost Accounting Cost accounting was a product of the industrial revolution. Businesses developed cost accounting to help managers determine the cost and profitability of the products. Initially labor cost was viewed as the largest fraction of cost for products produced in the 1890s. Using timekeeping systems, the amount of hours that went into producing a product established the understanding of variable costs (labor, direct materials.) As time progressed, companies realized that fixed costs, such as administration and machinery, also impacted the costs that belonged to each unit produced. Today, companies need to have the same knowledge to operate their businesses. The good news is that these tools are now part of good business acumen. Types of Costs There are three different types of costs that are associated with a product or service: variable, fixed and step-variable costs. Each category of cost uniquely influences the production of the product or service. Therefore, this analysis must address each category separately. Variable Costs Variable costs are those that change fairly uniformly with the level of production. Typically raw materials and direct labor are variable costs. For example, Smith Fire Services produces fire hydrants. They have orders of 1,000 hydrants per month. Raw materials are iron, forging and paint. Raw material costs Smith $10,000 for a 1,000 unit order. The labor to produce and assemble costs $40,000 for 1,000 units. Therefore, it costs Smith $50 per hydrant to produce. If Smith wanted to breakeven considering only variable costs, Smith would sell each hydrant for $50. There are, however, other costs besides variable costs that small business owners must consider. Cathedral Consulting Group, LLC Page 1 Fixed Costs Fixed costs are those that remain unchanged regardless of whether the activity level increases or decreases. Rent, depreciation, insurance, maintenance, indirect labor costs, and administration are examples of fixed costs. For example, Smith Fire Services has building rent of $2,000 a month, insurance of $1,000 a month and $2,000 of indirect wages for a total of $5,000 a month in fixed costs. Those costs will remain constant whether or not Smith manufactures 1 or 10,000 fire hydrants. Step Variable Costs Step variable costs have elements of both fixed and variable costs. Step variable costs are costs that stay fixed over a range of activity and change after this range is exceeded. For example, Smith Fire Services can produce 500 fire hydrants with 5 employees. Each additional employee can produce 200 hydrants. If Smith’s activity increases to 1,000 hydrants, Smith would need to hire 3 employees to fill this, thus increasing payroll costs in steps. The challenge for Smith is the cost increase caused by the order that requires the next step. This increase in business may actually not be profitable. 10 8 6 4 2 Number of Employees Step Variable Cost Graph 0 1 201 401 601 801 Fire Hydrants Produced Capacity Pricing: The Problem of Fixed Costs As mentioned, every business has fixed costs such as rent, insurance, maintenance, taxes, and administrative costs that must be covered. Combining this with the variable cost of each product, we can rightly deduce that the overall cost for each unit changes with the activity level. Thus, the more activity increases, the lower the overall costs for a unit of product decrease. For example, Smith Fire Services produces fire hydrants. They have variable costs of $50 per hydrant and monthly fixed costs of $5,000. If Smith produces 1,000 fire hydrants a month, the average unit cost per hydrant would be $55 per hydrant ($50 + ($5,000/1,000)). If Smith has been operating at 60% capacity in producing the 1,000 hydrants then increasing the production by 30% to 90% of capacity, the company produces 1,300 hydrants per month. These hydrants would have a unit cost of $53.84 ($50 + ($5,000/1,300)) which is a reduction of $1.16 per unit. Cathedral Consulting Group, LLC Page 2 Putting it all Together: The Break-even Analysis Let’s assume that Smith Fire Services management wants to determine the price they need to charge per fire hydrant. In trying to determine a new price point, it is important to establish a break-even point for the business. The break-even point is the number of units at a given price that produces sufficient revenue to cover all of the costs to operate the business. Below is the current model for Smith with a price point of $100 per fire hydrant sold. Using the facts noted above, Smith has $50 of variable costs per unit. Therefore, each unit contributes $50 to offset the fixed costs. The fixed costs are $5,000 a month, causing the break-even point to be 100 fire hydrants. It is at that point where fixed costs have been covered. Every fire hydrant above that point allows the business to produce a profit. Please note that step variable costs and variable pricing increase the complexity of the analysis, but it is essentially the same exercise. $14,000 $12,000 Dollars $10,000 $8,000 Contributed Profit $6,000 $4,000 Loss Fixed Costs $2,000 $1 51 101 151 201 Fire Hydrants Sold Recommended Actions: 1. Prepare a breakdown of costs between variable and fixed and step variable. 2. Using a standard product or service, prepare the cost to deliver based on the variable costs. 3. Using the standard product’s price and variable costs, determine the break-even level of activity. 4. Consider the capacity of the business and the percentage of activity needed in the break-even analysis. 5. Reflect on the level of activity needed, the profitability of each product and model the break-even benefit of different levels of product/service and prices. Phil Clements is CEO of Cathedral Consulting Group, LLC and a Managing Director in the New York Office. Drew Dillard is a former Associate in the Midwest office. For more information, please visit Cathedral Consulting Group LLC online at www.cathedralconsulting.com or contact us at info@cathedralconsulting.com. Cathedral Consulting Group, LLC Page 3