Optical Diagnostics for Velocity, Temperature and

advertisement

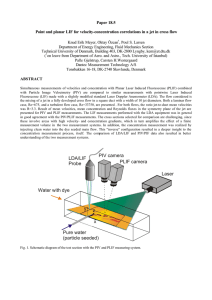

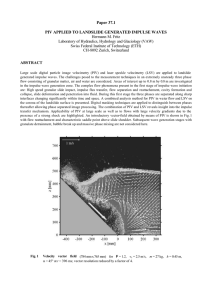

Proceeding of ’99 Korea-Japan Joint Seminar on Particle Image Velocimetry pp15-31 Optical Diagnostics for Velocity, Temperature and Species Measurements of the Flow Field Toshio KOBAYASHI, Hui HU and Tetsuo SAGA Institute of Industrial Science, University of Tokyo Roppongi 7-22-1, Tokyo 106-8558, Japan Abstract The basic concept and principles of the optical techniques for the velocity, temperature and spice measurements of the flow field, which include Particle Image Velocimetry (PIV), Thermos-Chromic Liquid Crystal (TCLC) and Planar Laser Induced Florescence (PLIF) techniques, were briefly introduced in the present paper. The current development states of these optical diagnostic techniques were overviewed and illustrated with examples picked up from recent published journal and conference papers describing both the developments and applications of PIV, TCLC and PLIF techniques. The highlight areas for the future development were also suggested in the present paper. Keywords: Optical diagnostics, Particle Image Velocimetry (PIV) technique, Thermos-chromic Liquid Crystal (TCLC) technique and Planar Laser Induced Florescence (PLIF) technique Introduction With the rapidly development of the model optical techniques and digital image processing techniques, optical diagnostics is assuming an ever-expending role in the diagnostic probing of fluid mechanics by supplying the fluid mechanics researcher with the capability for remote, non-intrusive, in-situ, spatially and temporally precise measurements of important parameters of the flow field like velocity, temperature and species. This means that, optical diagnostics provides the fluid mechanics researchers and engineers not only with the more accurate measurements but also with completely new capabilities. Spatially precise, instantaneous measurement at high rates permits the flow field to be frozen and tracking with high frequency response. Measurement at many locations simultaneously along a line, over a plane or in a volume permits spatial correlation to be obtained providing new phenomenological insight into fundamental behaviors of flow phenomena. The application of these new and exciting techniques is so promising that it is expected to impact fluid mechanics science and technology in a very significant fashion. Although various optical flow field diagnostic techniques had been developed, the context of present paper will just focus on the techniques of Particle Imaging Velocimetry (PIV), Thermos-chromic liquid crystal (TCLC) and Planar Laser Induced Fluorescence (PLIF). These techniques can be used to measure the velocity, temperature and spice of the flow field instantaneously and globally. Compared with other traditional velocity, temperature and species measurement techniques, PIV, TCLC and PLIF techniques have following characteristics: 1. Non-intrusive measurement techniques: In contrast to techniques for the measurement of flow velocities and temperature employing probes as pressure tubes, hot wires, thermos-couple or other traditional methods, PIV, TCLC and PLIF being optical techniques work non-intrusively. This allows the application of PIV, TCLC and PLIF techniques even in high-speed flows with shocks or in boundary layers closed to the wall, where the flow may be disturbed by the presence of probes. 2. Whole field measuring techniques: PIV, TCLC and PLIF are techniques, which allows to record image of large parts of flow fields in a variety of applications in gaseous and liquid media and to extract the velocity, temperature and spice information out of these images. For the velocity measurement, this feature is unique to the PIV techniques except to Doppler Global Velocimetry (DGV), which is a technique particularly appropriate for high-speed air flows (the error of DGV is almost bigger than 5m/s(Meyer, 1995), which made it is unacceptable for the most low speed case). For the flow field temperature measurement, although infrared (IR) imagery technique can also get globe results, it suffers from the poor spatial resolution and measurement accuracy. Other techniques for velocity, temperature and spice measurement methods only allow the measurement of the flow at a single point. The instantaneous image capture and high spatial resolution of PIV, TCLC and PLIF systems allow the detection of spatial structure of even in unsteady flow fields. Due to the above advantages, numerous researches had been reported about PIV, TCLC and PLIF techniques in the past two decades. The applications of PIV, TCLC and PLIF almost touch upon all the fluids-related fields, range from the fluid mechanics fundamental study of shear flow and turbulent transition to the engineering field of turbo- 15 - machinery, automobile and aircraft designing. Many famous review papers and textbooks about PIV (Adrian 1991, Grant, 1997, Wernet 1997, Reffel et al. 1998), TCLC (Dabiri et al. 1991) and LIF (Hesselink, 1988 and Eckebreth, 1995) are also available commercially. In the following context, some basic principles of PIV, TCLC and PLIF techniques will be brief introduced. The recently development of these techniques will also be reviewed by giving some examples of the velocity, temperature and spice measurement results of the flow field by using these techniques. 1. PIV Technique The technical basement of the PIV to do velocity measurement is to measure the displacement of the tracer particles seeded in the flow in the settled short time interval. A typical set-up of a PIV system always consists of several subsystems (Fig.1), which including particle seeding, flow field illumination, particle image acquisition and image processing. In most PIV applications, tracer particles have to be added to the flow. These particles are illuminated in a plane or in a volume of the flow at least twice within a short time interval. The light scattered by the particles is recorded either on a single frame or a sequence of frames by either photographic film or CCD camera. It is assumed that the trace particles move with the local flow velocity between the illuminations. With the settled time interval of the illuminations and the displacement of the tracer particles between the two or more light illuminations determined through PIV image processing, the velocity of the flow field is constructed. 1.1. Seeding As the same as Laser Doppler Velocimetry (LDV), PIV technique measures the velocity of the fluid field indirectly by means of the measuring the velocity of tracer particles within the flow. The kinematics of the local fluid field was estimated by analyzing the motion of the tracer particles recorded on the photographic film or CCD camera. In order to insure the tracer particles can follow to the flow motion accurately, the tracer particles should be chosen carefully to be neutrally buoyant and to be efficiently scatter the illumination lights. Since the obtained particle image intensity and the contrast of PIV images is directly proportional to the scattered light power. It is often more effective and economical to increase the image intensity by properly choosing the scattering tracer particles than by increasing the illuminating laser power. The light scattered by small particles is a function of many factors, such as the ratio of the refractive index of the particles to that of surrounding medium, particle size, particle shape, particle orientation and angle of observation. For spherical particle with diameters larger than the illumination light wave length, the scattered light by the particle can be estimated by Mie's scattering theory (Van de Hulst, 1957). Figure 2 shows the normalized scattered intensity of different diameter glass particles in water according to the Mie theory. From these figures, it can be seen that the scattered light intensity will be increasing as the particle diameter increases. It should also be noted that the scattered light intensity is not blocked by the tracer particle but spread out in all directions. Therefore, for a large number of particles inside the light sheet, massive scattering will appear. So, the light intensity which is focused by the recording lens is not only due to direct illumination but also due to fraction light which have been scattered by more that one particle. These imply that not only larger particles can be used to increase the scattering efficiency but also the number density of tracer particles. The scattering efficiency of the trace particle also strongly depends on the ratio of the refractive index of the particle to that of the fluid. Such as, the refractive index of water is considerably larger than that of air. The scattering of particles in air is at least one order of magnitude more powerful than particles of the same size in water (Raffel et al. 1998). So, the larger particles have to be used for water flow experiment, which can mostly be accepted since the density matching of particles and fluid is usually better than that in air. 1.2 Illumination system The illumination system of PIV is always composed of light source and optics. Lasers, such as Argon-ion laser and Nd:YAG Laser, are widely used as light source in PIV systems due to their ability to emit monochromatic light with high energy density which can easily be bundled into thin light sheet for illuminating and recording the tracer particles without chromatic aberrations. The optical system is always consisted by a set of cylindrical lenses and mirrors to shape the light source beam into a planar sheet to illuminate the flow field. 1.3 Particle Image acquisition The widely used recording medium for PIV particle image acquisition is either photographic film or Charge Couple Device (CCD) camera. The development of digital CCD camera has encouraged to the development of Digital Particle Imaging Velocimetry (DPIV) (Willert et. al. 1991). Comparison with the photographic film based PIV techniques, DPIV system has the many advantages. (1). It is fully digitized, so avoids expensive opt-mechanical devices and tedious interrogation processes. (2). Various digital techniques can be implemented to handle noise and improve processing speed. (3). It allows for the cross-correlation of two independent video frames and removes problems associated with the self-convoluted images. (4). Conventional auto- or cross- correlation techniques combined with special framing techniques can be used to measure higher velocities. While, the disadvantages of the DPIV in current stage are the low - 16 - temporal resolution (defined by the video framing rate, always 30 Hz from 512 by 512 CCD camera and much lower for the other high resolution camera) and the loss of the spatial resolution (the CCD camera used in current stage is almost 512by 5122, 1024 by 1024 or high to 2048 by 2048 pixel, which is still at least one or two order lower than that by using photographic film.). These disadvantages are expected to be improved in the future with the development of the computer technology. 1.4. Image Processing Many algorithms or methods had been proposed for PIV image processing. All of these methods or algorithms can be conclude into three catalogues based on the particle image density. When the tracer particles seeding density is low, the trajectory of the individual particles can be identified in the series of images. The algorithms or method based on identification of the trajectory of the individual particles are always called Particle Tracking Velocimetry (PTV) method. The most common used PTV method including 4T-PTV (Kobayashi, et al.1989), Binary correlation method (Uemura et al. 1990), spring-model method (Okamoto, 1993) and Super-Resolution Method (Keane et al.1995) et al.. As the seeding density increasing, the detection of individual particles becomes difficult. In this case an alternative approach named correlation method can be used to tracking the patterns of particles instead of individual particle. By using correlation method, The PIV recording images is divided into small sub-areas called "interrogation area", the local displacement vector for the images of the tracer particles at the first and second illumination is determined for each interrogation area by means of statistical methods. The correlation function is always used to judge the corresponding pairs of the interrogation areas in the first and second illuminations. The correlation methods may also be divided auto-correlation method and cross correlation method. When the two exposure were recorded in one frame, auto-correlation method was always used. For the auto-correlation method, it will always have the problem of direction ambiguity, which may be cured by using image shifting (Adrian et al. 1986) or other techniques (Shen, 1997 and Marzoak, 1998). When the two exposures were recorded on two frames, the crosscorrelation method can be used. Since it did not have the problem of direction ambiguity, cross-correlation method is the most popular method for PIV image processing in the current stage (Hu et al. 1998). When the tracer particle concentration is so dense that individual particles are not longer distinguishable, the pattern is formed through the variation in the speckle intensity variations on the image. It was always named as Laser Speckle Velocimetry (LSV) for this case. The most common used method for LSV image processing is Young's fringe analysis method (Grant et al. 1989). 1.5. The expanded application range of PIV technique Since PIV technique can measure the velocity of whole flow field instantaneously without disturbing to reveal the global structures of a complicated and/or unsteady flow field quantitatively, the application of PIV technique almost touch upon all the fluids-related fields. The application range of the PIV technique has be expanded quite a lot in the recent years. PIV technique hand been used to study either steady flow or unsteady flow, low speed flow (subsonic flow) or high speed flow (supersonic flow); single phase flow or multi-phase flow; macros scale flow or micro scale flow. PIV technique had been used successfully to study many complex unsteady flow phenomena to reveal the evolution of the vortex and turbulence structures in the flow field. Figure 3 shows the PIV measurement results in a self-induced sloshing flow field (Hu et al 1999). The changes of the global flow pattern and vortices evolution during the selfinduced sloshing can be revealed very clearly from the PIV velocity vector field. PIV technique has also been used to study many high-speed (supersonic) flow phenomena. Figure 4 shows the PIV measurement result of a transonic flow field (the velocity range is from 280m/s to 520m/s) around a NACA 0012 airfoil (Raffel et al., 1993). The structure of shock about the airfoil can be revealed very clearly in the velocity vector field. PIV technique had also been used to research many multi-phase flow phenomena in recent years, which include gasliquid flow, gas-solid flow and liquid-solid flow. Since the PIV images can not only used to construct the velocity fields of the multi-phase flow, but also can be used to get information about the geometry and concentration distributions of the bubbles or solid particles in the multi-phase flow field through image processing. The interaction of the flow field with the gas bubbles or solid particles can be revealed more easily and directly than other techniques. Figure 5 shows the PIV measurement results of a liquid-gas two-phase flow. The effect of the gas bubbles rising on the water flow field was analysis based on such kind of PIV results (Lindken et al. 1999). In recent years, one of the most promising and challenging research topics is the study about MEMS (MicroElectronics Machine System). In order to study the flow behavior inside MEMS (the scale of the flow field is always in the order of オ m), Micro PIV techniques have also been developed. Figure 6 shows the PIV measurement results of a Hele-Shaw flow around 30オ m abscale (Santiago et al. 1998 ) and a supersonic flow in a micro-nozzle (Meihart et al. 1999), more details can be got from their papers. 1.6. Three Components and Three Dimensional PIV techniques The "classical" PIV technique is just two dimensional method, which is only capable of recording the projection of - 17 - velocity into the plane of the laser sheet, i.e the out-of-plane velocity component is lost while the in-plane components are affected by an unrecoverable error due to the perspective transformation (Nisino 1999). For highly three-dimension flows, this can lead to substantial measurement error of the local velocity vector. In order to get the out-of plane velocity component, some three components PIV (3C-PIV) and three-dimensional PIV (3-D PIV) techniques were also be proposed. They include stereoscopic PIV technique (Parsad, 1993), Dual-plane PIV technique (Raffel et al.1996), 3D PTV technique (Suzuki et al. 1999) and Holographic PIV (HPIV) (Barnhart et al. 1994, Zhang et al., 1997). Stereoscopic PIV technique is a most straightforward, but not necessarily easily implemented, method for the three component velocity measuring PIV technique. It used two cameras at different view axis to do PIV recording (Fig.7, Saga, 1999). By doing the view reconciliation (Soffol et al., 1998), the corresponding image segments in the two views are matched to get three component of the velocity vector in the laser sheet plane. Dual-plane PIV technique is a quasi three component PIV technique, which is implemented by offsetting the light sheet a small amount between the recordings to obtain the out of plane velocity of the flow field in the laser sheet plane. Based on the measuring change of the respective correlation peak height from one recording to the next, the out-of-plane displacement component was estimated (Raffel et al. 1998, Fig. 8). The Dual-plane PIV technique was has the problem of the poor accuracy for the out of plane velocity in the current stage. 3D-PTV and HPIV are real three-dimensional measurement technique, which can get the three components of the flow velocity in a volume simultaneously. Three cameras are always used to record the positions of the particle tracers in the measurement volume from three different view directions for 3D-PTV technique (Fig. 9, Suzuki et al. 1999). Through there-dimensional image reconstruction, the locations of the tracer particles in the measurement volume are determined. By using particle-tracking method, the three dimensional movement displacements of the tracer particles are calculated. Up to now, 3D-PTV method may suffer from the low spatial resolution (always less than 1,000 instantaneous velocity vectors can be got simultaneously by using common used CCD camera), which is expected to be improved by using high resolution CCD-camera. Holographic PIV (HPIV) uses holography technique to do PIV recording, (Fig. 10), which enables the measurement of three components of velocity throughout a volume of flow to be obtained. Of the existing three-dimensional PIV methods, HPIV is capable of the highest measurement precision and spatial resolution. However, HPIV is still at its stage of development and not well suit for experiment, where set-up time, optical access and observation distance are important factors (Okamoto, 1999). The further efforts should be needed to make the HPIV technique as a more practical technique for fluid mechanics experiments in the coming years. 2. Micro-Capsulated Thermos-chromic Liquid Crystal (TCLC) Thermometry Liquid crystal, which is thermos sensitive, can change its color with the changing of temperature. Since the first using of liquid crystal in the field of fluid dynamics by Klein et al.(1968) in determining the location of laminar and turbulent boundary layer transitions on a flat plant placed in a supersonic air stream, the development of the digital image processing technology in the past two decades had enabled Thermos-Chromic Liquid Crystal (TCLC) to be used not only a qualitative indicator to indicate the hot and cold region but also as a quantitative tool to visualize the temperature of the flow field quantitatively. The cholesteric liquid crystal is composed of layers of liquid crystal sheet (Fig. 11), and in each sheet the molecules are aligned in a slightly different orientation with respect to their adjacent layer. When unpolarized light hits the liquid crystal, it is split into two linear polarized components. Due to the anisotropy of the liquid crystal, the polarized plane of the light will be rotated. When the optical wavelength is equal to the wavelength of the incident light, the circularly polarized light in the same direction as the helix is reflected, while the circularly polarized light in the opposite direction is transmitted through the liquid crystal. As the temperature of the liquid crystal changes, the distance between the sheet of liquid crystal layers changes tending to increase the pitch of the liquid crystal. And the angular direction of each layer of liquid crystals increases with respect to its adjacent layers tending to decrease the pitch. Due to these effects, the color refection of the liquid crystals is not only sensitive to the temperature but also to the viewing angle, shear stress and magnetic field as well. However, by encapsulating the liquid crystal and using them in the non-magnetic environment, the effect of the shear and magnetic field can be eliminated. The temperature response time of liquid crystal is also an important consideration since a slow response time would result in erroneous temperature values. Since the liquid crystal is encapsulated, the response time of both the liquid crystal and encapsulating shell should be take into account (Doh, 1995). By choosing the correctly sized neutrally buoyant liquid crystals, the temperature field of the interested flow may be measured accurately and responding quickly. To measure the temperature of the flow field by using Thermos-Chromic Liquid Crystal (TCLC), the calibration process to get a quantitative relation of the color to temperature must be conducted before the experiment starting. For color-to-temperature relation calibrating, the visualized images of the micro-capsulated liquid crystal particle at settled temperatures were captured by color CCD camera in R, G and B color space. By using the acquired R, G and B values, the other optical parameters such as Intensity, Saturation and Hue of the color can be computed. Fig. 12 gives the typical measured optical characteristics of the micro-capsulated liquid crystals (R23CW3, D=0.3mm), which including the acquired normalized R, G, B values and Hue in relation to the temperature. Since their - 18 - relation to temperature is non-linearity, a neural network method (Ozawa et al., 1992) was suggested to construct the color to temperature calibration profile with higher accuracy. By using the calibration profile or look-up tables of the color-to-temperature relation, the temperature of the flow field can be calculated. Figure 13 shows an example of temperature measurement results by using TCLC. By scanning the illumination light sheet, three-dimensional temperature distributions of the flow field can also be constructed. 3. PLIF technique for spice (concentration) and temperature field measurement Florescence process is a radioactive decay process that occurs by electronic transitions in molecules of fluorescence material. After a fluorescent dye molecule is exposed to an electromagnetic field or exactitude by laser beam. Photons entering the fluorescent dye molecule will cause displacements of electrons from one energy state to another. The displacement of the electrons results in increased potential energy of the molecule from the ground state to the excited state. When the electrons return to the ground state from excited state, fluorescent light will be radiated. Fig. 14 shows an example of the spectrum of a fluorescent dye. The intensity of the laser induced fluorescence measurement at any arbitrary point (x0,y0) along the excitation beam can be expressed as: H f ( x0 , y0 ) = I ( x0 , y0 ) AΦ εLC ( x0 , y0 ) (1) where Hf ( x0,y0) is the measured fluorescence intensity at the point (x0, y0), A is the fraction of the fluorescence light collected by camera. Φ is the quantum efficiency, L is the length of the sampling volume along the path of excitation beam, ε is molar absorptivity, and C(x0,y0) is the molar concentration of the fluorescent dye. I(x0,y0) is the intensity of excitation light beam at the point (x0,y0), which can also be expressed as: I ( x0 , y 0 ) = I 0 e − εlc (2) Where I0 is intensity of the laser beam at the inlet of the measure flow field, l is the length of solution the excitation laser beam traveled through before reaching the point (x0,y0), and c is the concentration of the fluorescent dye. From the equation (2), it can be seen that, since the intensity of the excitation light I(x0,y0) is the function of the position and the concentration distribution of the fluorescent dye along the excitation beam before reaching the measurement point B. This means that concentration distribution of the fluorescent dye may attenuate the intensity of the excitation beam. This attenuation effect will be increasing with the increasing of the concentration of the fluorescent dye. Fig.15 shows the attenuation effect in the disodium fluorescein solution with different concentration (Hu et al. 1999). It can be seen that, in the low concentration condition, the attenuation effect is very small, which can always be negligible. 3.1. The spice (concentration) measurement by using PLIF From the equation (1), it can be seen that, if the temperature of the flourecent dye is kept in constant, the intensity of induced fluorescent light will be change linear with the concentration of the fluorencent dye in the flow field for low fluorescent concentration case with the attenuation effect being negligible. So, by measurement the intensity of the fluorescent light, the concentration distribution of the fluorescent dye in the flow field can be calculated. Before the measurement starting, the calibration procedure to get the quantitative relationship of the normalized intensity of the florescent light to the concentration of the fluorescent dye should be conducted firstly. Figure 16 shows a typical calibration profile of normalized intensity of the florescent light to the concentration of the fluorescent dye (Hu et al. 1998). By using the above calibration profiles, the concentration distribution of the fluorescent dye in the flow field can be measured. Figure 17 shows some examples of the concentration measurement results in a lobed jet mixing flow by using PLIF technique (Hu et al. 1998). 3.2. The temperature measurement by using PLIF For some fluorescent dyes, the molar absorptivity is temperature dependent. Therefore, equation (2) can be rewritten as follows: H f ( x0 , y 0 ) = I ( x0 , y0 ) AΦ ε (T ) LC ( x0 , y 0 ) (3) If the concentration of the fluorescent dye is now kept in constant, the temperature of the flow field can be calculated by measuring the intensity of the fluorescent light. To do the temperature measurement by using PLIF, the calibration procedure to get the quantitative relationship of the normalized intensity of the florescent light to the temperature should also be conducted firstly before the measurement beginning. By using the calibration profile of the normalized intensity of the florescent light to the temperature (Figure 18, Sakakibara et al. 1993), the temperature distribution of the flow field can be constructed. 3.3 Dual emission laser induced fluorescence technique The PLIF temperature measurement method described in the above section just used a single dye as fluorescent dye. In order to insure the measurement result has a good accuracy, a set of the calibrations have to be done to eliminate the - 19 - errors due to the non-uniform distribution of light sheet, the laser light reflection and the attenuation effect. One way to by pass these issues is to use a dual emission PLIF technique which normalize the fluorescent light intensity of temperature dependant dye with a temperature independent dye. According to the equation (3), when the laser light passed through a homogeneous fluorescent solution containing two dyes (both with a constant concentration through out the solution), the fluorescence ratio at any point can be expressed as: H 1 f ( x, y ) H 2 f ( x, y ) ∝ ε1 (T )c1Φ1 ε 2c2 Φ 2 (4) Where H1f (x,y) is the fluorescence intensity of the temperature dependent dye and H2 f (x,y) is the fluorescence intensity of a temperature independent dye. From equation (4), it is evidence that the fluorescence ratio is only a function of a few physical properties of the dyes, not the excitation intensity. Assuming that both fluorescence are present in constant concentration everywhere in the flow field, these physical properties can be normalized through a calibration ratio of fluorescence ratio versus temperature. That is the ratio of the physical properties of the two fluorescent dyes is a constant and does not influence the change in the ratios with temperature. Note that the fluorescence intensity of the temperature dependent dye contains the temperature information, while the temperature fluorescence intensity of independent fluorescent dye contains the excitation intensity information at every point in the laser sheet. If the florescence intensity from each dye is measured simultaneously, the fluorescence ratios will be independent of laser light alignment, distribution, and intensity. Figure 19 (Coppeta et al. 1998) shows the comparison of the two (flourescein and rhodamine B) and single dye (flourescein) system's ability to predict temperature. It shows that the change in single dye absorption with temperature causes the error to increase in the direction of light sheet propagation while the dual system is immune to the changes in absorption. An example of the temperature measurement result by using dual emission laser induced fluorescence technique were shown on the Figure 20 (Sakakibara et al. 1999). By scanning the illumination laser sheet, the three-dimensional isosurface of the temperature in the flow field was shown in the figure. 4. Simultaneous measurement of the velocity and temperature/spice fields As mentioned above, PIV technique can be used to do vector field (velocity) measurement of the flow field, while TCLC and PLIF techniques can be used to measure the scalar (temperature and spice) distributions in the flow field. In many engineering applications like combustion phenomena, the relationship between the vector transfer processing and scalar transfer processing may also be very important and interesting. So, the methods to combine PIV technique with TCLC or PLIF techniques to measure the velocity and temperature (or spice) distributions of the flow field simultaneously have also been suggested in the recent years. A method named as Particle Image Thermometry and Velocimety (PITV) was suggested by Doh, et al. (1995) with the combination of PIV technique with TCLC technique. PITV method uses micro-capsulated thermos-chromic liquid crystal particle as tracer particles seeded in the flow flied. The spatial position information of the micro-capsulated liquid crystal particles was used to construct the velocity field by using PIV technique, while the temperature distributions of the flow field was measured by the color-to-temperature relationship of the micro-capsulated liquid crystal particle. The PITV technique had been successfully used to conduct the temperature and velocity measurements in a vertical buoyant jet flow (Doh et al.1995), a typical measurement result were shown on Figure 21. The ideals with the combination of PIV and PLIF to resolve the velocity and temperature (or spice) distributions in the flow field have also been suggested (Grissino et al. 1999, O’Hern et al. 1999). The flow field was seeded with small spherical tracer particles embedded with fluorescent dyes. The laser-induced fluorescent light and the laser light scattered by tracer particles are separated by using optical filters and detected by camera separately. The information from the scattering Laser light was used to construct the velocity distribution of the flow field by using PIV image processing. While, the signals from the laser induced fluorescent light are used to calculate the scalar distributions (either temperature or spice concentration) in the flow field. A typical results of the velocity and temperature simultaneous measurements from a PIV/LIF system was shown on Figure 22. 5. Conclusions and highlighting areas of future development Recent advances of model optical techniques and digital image processing techniques are leading PIV, TCLC and PLIF techniques to pay ever-expending roles in the research fields of fluid mechanics and thermodynamics. Evolution of these techniques had been the principal activities of a number of laboratories over the last twenty years. These techniques are now well established with its limitations and strengths being understood and well documented as indicated in the many referenced papers in this paper and elsewhere (Adrian, 1996) Although much progress had been made in improving the processing speed of PIV, TCLC and PLIF techniques by using ingenious software and complex hardware, the sustained development in this field should still be need in the coming years. The processing speed problem will become more serious for the stereogrammetry and Holographic version of these techniques. Besides the need to develop more powerful hardware for the techniques of PIV, TCLC and PLIF, considerable efforts - 20 - are also still need for the image processing algorithms development in the future to increase the accuracy and resolution (both spatial and temporal resolution) capability of the measurement results by using these techniques. Such as, two major problems can be identified with current image processing techniques related to PIV are (1). Limitation on spatial resolution of the estimated displacement field. (2). Limitation on the dynamical range of displacements (i.e., the difference between the largest and smallest displacement) that can be accurate measured. Although some progress have been made in recent years (Keane et al, 1995, Kumar et al. 998, Hart, 1999 and Hu et al 1999), sustained efforts should still be made in future. The relationship between the development of experimental techniques and Computational Fluid Dynamics (CFD) simulation methods is being one of the most popular topics in the recent days. With the fast development of the modern experimental techniques, in particular, the appearance of the field measurement techniques, like PIV TCLC and PLIF techniques, it has become possible to reveal the flow field turbulent structures instantaneous and globally by using experimental tools. The measurement results of these techniques will allow not only for simultaneous valid comparison between CFD simulation results and experiment data and more importantly will enable the development of robust and reliable turbulence models for CFD simulation (Moser et al., 1998). With the accumulating of a sufficient body of turbulence data got by optical diagnostics like PIV, TCLC and PLIF techniques, the prospects for developing reliable turbulence models are indeed bright. The need to understand the complex flow phenomena are reflected in many sponsors of the researches of PIV, TCLC and PLIF techniques with the interests coming from civil engineering companies, automobile and aircraft manufacturers, energy producers and defense agencies. The necessary and importance of the flow field optical diagnostic techniques like PIV, TCLC and PLIF have been well recognized. It is not doubtful that these optical diagnostics will pay more and more important roles in the fluid-related researches with the continuos development of these techniques in the future. Reference 1. Adrian R. J. 1986, "Image Shifting Technique to Resolve Directional Ambiguity in Double-Pulsed Velocimetry”, Appl. Optics 25, PP3855-3858. 2. Adrian R. J. 1991, "Particle-image techniques for Experimental Fluid Mechanics ", Ann. Review Fluid Mechanics, PP261-304. 3. Adrian R. J. 1996, "Bibliography of Particle Imaging Velocimetry Methods: 1917-1995”, TAM Report No.817, UILU-ENG-96-6004. 4. Barnhart, D. H., Adrian, R. J. and Papen G. C., 1994, “Phase-conjugate Holographic System for High-resolution Particle Image Velocimetry”, App. Optics, 33-33, pp7159-7170 5. Coppeta J. and Rogers C, 1998, "Dual emission laser Induced Fluorescence for Direct Planar scalar behavior measurements " Experiments in Fluids, Vol.25 No. 1, pp1-15. 6. Dabiri, D., Gharib M., 1991, Digital Particle Image Thermometry: the Method and Implementation." Exp. Fluids Vol.11. pp77-86 7. Doh. D. H. Kobayashi. T. and Saga T. 1995, "Experimental Study on Vertical Bouyant Jet Using 3-D Particle Imaging Therometry and Velocity. ASME FED -1 1995, pp63-70. 8. Doh D. H., 1995, "A Study on three dimensional particle image thermometry and velocimetry using lique crystal", Ph. D. thesis, University of Tokyo. 9. Echebreth A.C., 1995, "Laser Diagnostics For Combustion Temperature and Spice ", ISBN 2-88449-225-9, Gordon and Breach Publishers. 10. Grant I. 1997, "Particle image Velocimetry: a review" Proceedings Institute of Mechanical Engineers Voll.211 Part C, pp55-76 11. Grant I. Owens, E. H. and Smith G. H. 1989. "The Effect of Flow Turbulence and Interrogating beam Profile on Particle image Velocimetry Fringes." Optics and laser in Engng. Vol. 11 pp.115-128 12. Grissino A.S., Hart D.P., and Lai. W. L. 1999, “Combined Dual Emission LIF and PIV to Resolve Temperature and Velocity”, Proceeding of 3rd International Workshop on Particle Image Velocimetry, Sept. 16-18, Santa Barbara, U.S.A. 13. Hart. D. P. “The Elimination of Correlation Error in PIV processing”, Proceed of 9th International Symposium on Application of Laser to Fluid Mechanics (Lisbon), (1998b). 14. Hart D. P..Super-Resolution PIV by Recursive Local-Correlation", Proceedings. of VSJ-SPIE'98, Yokohama, (1998a), CD-ROM paper No.AB149. 15. Hellseink L. 1988, "digital Image processing in Flow Visualization." Ann. Review Fluid Mechanics, PP261-304. 16. Hesselink L. Digatal Image Processing in Flow Visualization" Annual Review Fluid Mechanics vol. 20.1988 pp421-484 17. Hu H., T. Saga, T. Kobayashi K. Okamoto and N. Taniguchi, "Evaluation of the Cross Correlation Method by Using PIV Standard Images "Journal of Visualization, Vol.1, No.1. pp87-94, 1998 18. Hu H., Kobayashi T., Saga Tetsuo, Taniguchi N., Segawa S., Nagoshi M. and Okamoto K., 1999 "A PIV Study on the Self-induced Sloshing in a Tank with Circulating Flow" (CD-ROM Paper No. PF152), Processing of The 2nd - 21 - Pacific Symposium on Flow Visualization and Image Processing, Honolulu, U.S.A. 19. Hu H., Kobayashi T., Saga T., Taniguchi N., Segawa S.and Ono A., "Research on the Mixing Enhancement Performance of Lobed Nozzle By Using PIV and PLIF "Proceedings of 1998 ASME Fluids Engineering Division Summer Meeting, FEDSM98-4994, June 21-25, 1998, Washington, D.C. U.S.A 20. Keane R. D., Adrain R J. and Zhang Y., 1995, “Super-resolution Particle Image Velocimetry”, Measurement Science and Technology, Vol.6. pp754-768. 21. Klein E. J. 1968, “Application of Liquid Crystal to Boundary Layer Flow Visualization.” AIAA paper 68-376. 22. Kimura I., Hyodo T. And Ozawa, M., 1997, “Temperature and Velocity Measurement of #-D Thermal Flow Field Using Thermos-Sensitive Liquid Crystals.” Proceeding of 2nd International Workshop on Particle Image Velocimetry, Sept. 16-18, Fukui, Japan 23. Kobayashi, T. Saga. T, Haeno T, Tsuda m, N. 1991, "Development of real time velocimetry measurement for high Reynolds fluid flow using digital image processing design. ASME FED-1 1991, pp9-14. 24. Kobayashi T., Saga T., Segawa S., and Kanda H. 1989,"A 2-Diminsional Real-time Digital Image Processing System for Flow Field Measurement.", Transaction of the JSME vol. B(5-509), pp.107-114. 25. Kumar S. and Banerjee S. 1998, “Development and Application od a Hierarchical System for Digital Particle Image Velocimetry to Free-surface Turbulence”, Phys. Fluids, Vol.10, No.1, pp160-177. 26. Lindken R. And Merzkirch W. 1999, “Velocity measurements of Liquid and Gaseous for a System of Bubbles Rising in Water”, Proceeding of 3rd International Workshop on Particle Image Velocimetry, Sept. 16-18, Santa Barbara, U.S.A. 27. Marzouk Y. M. And Hart D. P., “Asymmetrical Auto-correlation Function to Resolve Directrion Ambiguity In Images”, Experiments in Fluids, Vol.25, pp401-408. 28. Meinhart C.D., Gray M.H.B. and Wereley S.T., "PIV Measurements of High-Speed Flows in SiliconMicromachined Nozzles," Submitted to J. Fluids Eng (1999). 29. Meyers J. F. , 1995, “Development of Doppler Global Velocimetry as a Flow Diagnostics Tool”, Measurement Science and Technology, Vol.6, No.6, pp769-783. 30. Moser R. D. And Adrian R.J, 1998, “Turbulence Data for LES Development and Validation” Proceedings of 1998 ASME Fluids Engineering Division Summer Meeting, Washington, D.C. U.S.A 31. Nishio. K. 1999, “PIV Measurement and Data Analysis of Axisymmetric Impinging Jet Flow – Is Threecomponent Velocimetry Measurement Needed? ”, JSME FED conference, No.99-19, pp353-354, Tottori, Japan. 32. O’Hern T. J., Tieszen S.R., Schefer R. W., Gerhart A. L., Young C.and Weckman “Simultaneous Measurement of Velocity and Concentration Fields Using a High-Speed Motion Picture PIV/PLIF System in a Buoyant Helium Plume” Proceeding of 3rd International Workshop on Particle Image Velocimetry, Sept. 16-18, Santa Barbara, U.S.A. 33. Okamoto K., Hassan, Y. A., Schmidl, W. D., 1993, "New Tracking Algorithm for Particle Image Velocimetry. Experiments in Fluids. 34. Okamoto K, 1999, “Holographic Particle Imaging Velocimetry”, The textbook of the workshop of threedimensional PIV, VSJ-PIV-S2. (ISBN4-906497-21-9), pp97-112, Yokohama, Japan. 35. Ozawa, M., Muller U., Kimura, I. And Takamori, T., Flow and Temperature Measurement of Natural Convection in a Hele-Shaw Cell Using a Thermos-sensitive Liquid crystal Tracer, Exp. Fluids, Vol. 12, pp213-222. 36. Prasad A. K. and Adrain R. J.,1993, " Sterescopic Particle Image Velocimetry Applied to Liquid Flows.", Exp. In Fluids. Vol. 15, pp49-60 37. Raffel M, C. Willert and Kompenhans J. 1998, "Particle Image Velocimetry", ISBN 3-540-63683-8, Springer 38. Raffel M. Westerweel J., Willer C., Gharib M. And Kompenhans J. 1996, Analytical and Experimental Investigations of Dual-plane Particle Imaging Velocimetry”, Optical Engineering, Vol.35, pp2067-2074. 39. Reffel M. and Kompenhans, J. (1993), "PIV Measurement of Unsteady Transonic Flowfield above a NACA 0012 Airfoil" Proc. 5th Int. Conf. On Lasers Anermnotry, Veldhoven, Netherlands, pp527-535. 40. Saga T. 1999, “Three Dimensional Particle Image Velocimetry”, The textbook of the workshop of threedimensional PIV, VSJ-PIV-S2. (ISBN4-906497-21-9), pp41-61, Yokohama, Japan 41. Sakakibara, J., Adrian, R.J., 1999. “Whole Field Measurement of Temperature in Water using Two-Color Laser Induced Fluorescence”, Experiments in Fluids, Vol.26-1/2, pp.7-15. 42. Sakakibara J., Hishida. K. and Meade M. 1997, "Vortex Structure and heat transfer in the Stagnation region of an impinging plane jet ( Simultaneous measurements of velocity and temperature field by digital Particle Image Velocimetry and Laser Induced Fluorescence) " J. of heat and Mass Transfer Vol. 40 No. 3 pp3163-3176. 43. Sakakibara J. 1995, "Research on the vortex and heat transfer mechnism of the impinging jet by using digital image processing method." Ph. D. Thesis. Keio University. 44. Sakakibara, J., Hishida, K. and Maeda, M. 1993; Measurements of thermally stratified pipe flow using imageprocessing techniques. Exp. Fluids 16, 82-96. 45. Santiago, J.G., Wereley S.T., Meinhart C.D., Beebee R. T, and. Adrian R.J, 1998, "A Particle Image Velocimetry System for Microfluidics," Experiments in Fluids, Vol. 25, No. 4, pp316-319. 46. Shen G. X. 1997, "Fleasibility and usability Study on the Shifting for PIV " Proceedings of the second International - 22 - Workshop on PIV'97-Fukui, pp185-192. 47. Soloff, S. M., Adrian R. J. and Liu Z. C., 1997, “Distortion Compensation for Generalized Stereoscopic Particle Imaging Velocoimetry”, Measurement of Science and Technology, Vol.8, pp1441-1454. 48. Suzuki Y. “Three-dimensional Particle Tracking Velocimetry”, The textbook of the workshop of three-dimensional PIV, VSJ-PIV-S2. (ISBN4-906497-21-9), pp79-96, Yokohama, Japan 49. Van de Hulst. H. C. (1957). "Light Scattering by Small Particles", John Wiley and Sons Inc. 50. Wernet M. P. 1997, "PIV for Turbomachinery Application." SPIE'97-3272 51. Willert C. E. and Gharib M., 1991, Digital Particle Image Velocimetry Experiments In Fluids, Vol.l0, ppl8ll993. 52. Yoda M., Hesselink L. and Mungal M. G., “Instantaneous Three Dimensional Concentration Measurement in the Self Similar Region of a Round High-Schmidt Number Jet , J. Fluid Mech., Vol.279, PP3l3-350 (1994). 53. Zhang, J., Tao, B. and Katz, J., "Turbulent flow measurement in a square duct with hybrid holographic PIV," Experiments in Fluids, vol. 23, 373-381, 1997. 54. Uemura T., Yamamoto F. And Koukawa M., “High Speed Algorithm for Particle Tracking Velocimetry”, Journal of the Visualization Society of Japan, Vol.10. No.38, pp58-64 - 23 - Flow field with tracer particles Illumination system display Synchronizer camera computer Figure 1. A typical PIV system a. d=1オ m b. d=10オ m c. d=30オ m Figure 2. The light scattering by glass particle in water (Raffel et al. 1998) -30.00 -24.00 -18.00 -12.00 -6.00 0.00 6.00 12.00 18.00 24.00 30.00 150 Spanwise Vorticity ( Z-direction ) Y mm 200 Spanwise Vorticity ( Z-direction ) Y mm 200 -30.00 -24.00 -18.00 -12.00 -6.00 0.00 6.00 12.00 18.00 24.00 30.00 150 Re =6,700 Re =6,700 Uin = 0.33 m/s Uin = 0.33 m/s 50 50 0 0 -50 -50 0 50 100 150 U out 100 U out 100 X mm 200 250 300 -50 -50 a. t=t0 0 50 100 150 X mm 200 b. t=t0+1.0/7.5s Figure 3. PIV measurement result for a self-induced sloshing flow field (Hu et al. 1999) - 24 - 250 300 Figure 4. PIV measurement result for a transonic flow field above a NACA 0012 airfoil (Raffel et al.1993) 7 Figure 5. PIV measurement result of a multi-phase flow (Lindken et al. 1999) a. Hele-Shaw flow around 30オ m obscale (Santiago et al. 1998) b flow in a supersonic micro-nozzle (Meinhart et al. 1999). Figure 6. PIV measurement result of micro flow fields - 25 - Laser Sheet d x1 x1 d x1 d x1 1 2 α1 x3 d x3 α2 V x2 β β 1 x x d x2 d x 1 1 Camera 2 Camera 1 2 V dx d x3 22 x2 x3 a. Optical arrangement Y 20 0 -10 -20 -30 -20 -30 -10 Y mm 10 Z X 30 W m/s 21.0896 20.0605 19.0314 18.0023 16.9732 15.9441 14.9149 13.8858 12.8567 11.8276 10.7985 9.7694 8.7403 7.7112 6.6821 5.6530 4.6238 3.5947 2.5656 1.5365 0.5074 20 10 0 -10 -20 -30 -20 -30 -10 0 Xm m Y mm Z 30 Y 0 10 Xm m 20 30 b. instantanous results 10 20 30 c. time average results Figure 7. Optical arrangement and measurement results of a Stereo PIV system (Saga, 1999) a. optical arrangement b. measurement results Figure 8. Optical arrangement and measurement result of Dual-plan PIV system (Rafel et al. 1998) - 26 - X W m/s 21.0896 20.0605 19.0314 18.0023 16.9732 15.9441 14.9149 13.8858 12.8567 11.8276 10.7985 9.7694 8.7403 7.7112 6.6821 5.6530 4.6238 3.5947 2.5656 1.5365 0.5074 b. system arrangement b. measurement results Figure 9. System arrangement and measurement result of 3D-PTV system (Suzuki, 1998) a. recording system b. reconstruction system c. 3D velocity distribution Figure 10. Optical arrangement and measurement result of a Holograph PIV system (Barnhart et al. 1993) - 27 - Figure 11. The cholestric liquid crystal structure (Dabiri et al. 1991) a. Normalized R, G, and B color values vs. temperature b.Hue value vs. temperature Figure 12. The optical characteristics of thermal-chromic liquid crystal (Doh, 1995) Figure 13. Temperature measurement results by using thermos-chromic liquid crystal thermometry (Kimura et al. 1997) - 28 - Figure 14. The Spectrum of fluorescence dye Rohdamine B (Sakakibara, 1995 ) 1.2 H(X)/H(0) 1 0.8 0.6 c0:1g;1250l 0.4 laser power 2.5w c0:1g:100l 0.2 0 0 50 100 150 200 250 L length (m m ) Figure 15. Attenuation effect of the laser light (HU et al. 1999) (I-Ib)/(I0-Ib) 1 0 .8 L a s e r p o w e r = h ig h L a s e r p o w er= m iddle L a s e r p o w e r = lo w T h e o r y V a lu e 0 .6 0 .4 0 .2 C /C 0 , C 0 = 0 . 3 m g /l 0 0 0 .2 0 .4 0.6 0.8 1 Figure 16. The calibration profile for the concentration measurement by using LIF technique (Hu et al. 1998) - 29 - Figure 17. Spice concentration measurement result in a jet mixing flow by using PLIF (Hu et al. 1998) Figure 18. The calibration profile for the temperature measurement by using PLIF technique (Sakakibara et al. 1997) Figure 19. A comparison of single and dual florescence dye system for temperature measurement (Coppeta et al. 1998) - 30 - Figure 20. A typical temperature measurement result by using dual emission LIF technique (Sakakibara et al. 1999) Figure 21. A typical measurement result of a PITV system (Doh et al. 1995 ) Figure 22. A typical measurement result of a PIV-PLIF system (Grissino et al. 1999) (velocity vector from PIV and temperature distribution (background) form PLIF ) - 31 -