STUDY PNEUMAT CAISSON PISCATAQUA

advertisement

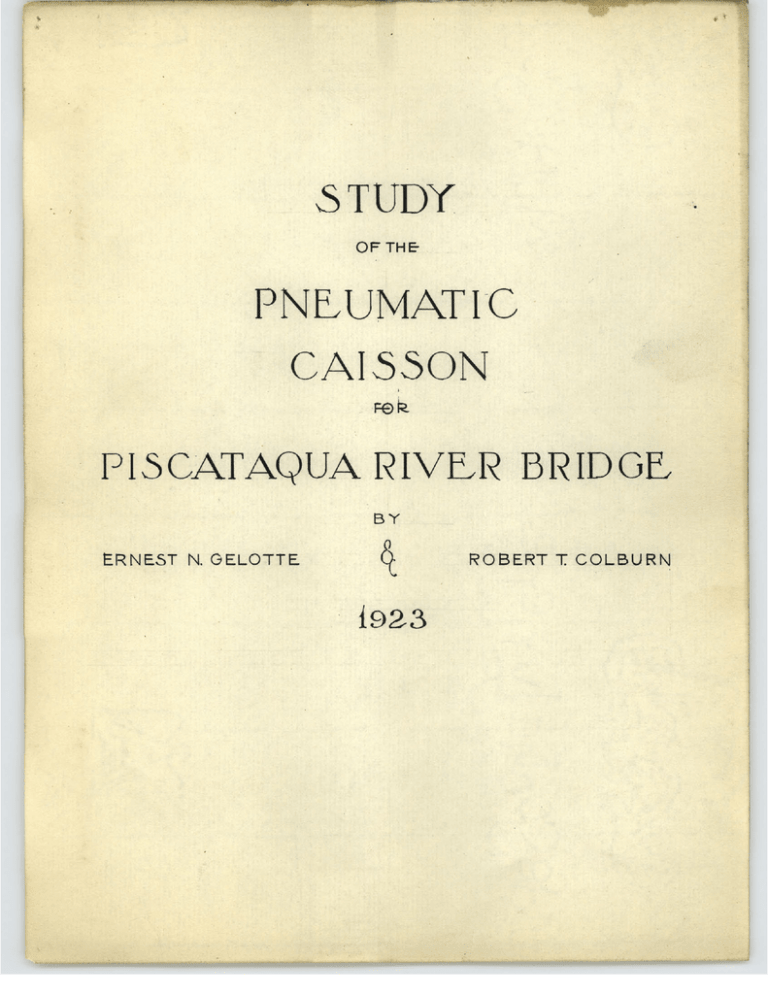

STUDY

OF THE

PNEUMAT I C

CAISSON

FO

PISCATAQUA RIVER BRIDGE

BY

ROBERT T COLBURN

ERNEST N. GELOTTE

192-3

TABI.

Oi

rap-e

loreword ---------------------------------------3

Notation -nd refererces --------------------------

Case 3.----

4-20

Calculatior of neutral axi.- rd monent of

6-7

inertia ----------------------------------8

Calculation of weirht of cheerb------Calculation of weiTht of superstrtcture----9

Shear and moment curves-----------10-11

Determination of loads------------12-15

ibre stresses----------------6

treses--------------------------7

eri

18

Vertical rod -----------------------------19

Bond stre.sses -----------------------------Surmar

20

------------------------------------

Case 2.------------------------------------------21

~ener] theory (H"orizontal re-erorc-rent)--22-27

ricLticnal reitance-----------------------29

cp--------------------------------0

Irevsi:re

32

-----------------------Jolution of eruti

Fibre stresses in 'hcori zcrth xe-or'c rcerent-32-33

e-narcvn

3

Jtresses :nvertico

ctresses--------------------------------35-38

hoof

-

Case 3------------------------------------

39-40

Surierstructure ---------------------------------

41-43

Conclusion----------------------------------------44-46

Caissor charter of Piscatagua

-

iver Eridge-------late

Caisson superstructurc---------------------------Plate

DiagraF of section showir;

neutral axis--------

B

ure 1

FOREWORD.

Owing to the increased use of compressed air

work in deep foundations, and the very limited amount of

accurate knowledge on the subject at the present time,

we have chosen for our thesis, a study of a deep foundation using a pneumatic caisson. Rather than attempt to

design a caisson chamber, which, owing to the small

amount of available data, could be done intelligently

only by a person with experience in that line, we decided to take a design which had already been built, and

make a thorough investigation of it. This investigation

is a complete analysis of the stresses set up in the

caisson during critical periods of construction and

placing. We can thus check up the present methods of

design and can perhaps show where the design could be

improved. In doing this we learn all the principles of

design just as thoroughly as if we designed one of our

own, and furthermore we are able to study what is considered a good design, which has already been tried and

found to be safe. We are also able to study the practical

problems and difficulties which arise on an actual job,

which would be impossible in an artificial problem.

Through the kind offices of the firm of

Holbrook, Cabot and Rollins, we were able to obtain the

drawings for the reinforced concrete caisson used for the

piers of the new Piscataqua River Memorial Bridge, at

Portsmouth, New Hampshire. We are indebted to Mr. Rollins

and to Mr. Harkness of the same firm, for valuable data

pertaining to thesek particular foundations.

There were a number of practical difficulties

in this case which make it unique. The river bottom was

of gravel overlaying solid rock at a depth of ten to

fifteen feet. The water was about sixty to sixty-five

feet in depth making a total of about eighty feet.

Owing to the slight depth of the gravel, it was impossible

to drive piles with which to guide the caisson, and this

forced the use of special means. The caissons were built

on shore on ways, similar to a ship, and then launched

and floated into place, where they were anchored and sunk.

Owing to the great weight of the concrete caisson, two

sections of the wooden superstructure were built on top

of it before launching, in order to insure it's floating

in the water. Another difficulty was here encountered.

The water at the place whure they were built was shallow.

In order to prevent the caisson from touching bottom and

upsetting, it was necessary to lighten it in every way

possible. This was done by making the roof of the chamber

..............

........

...

..

only six inches thick before launching. When floated to

deep water, the extra three and one half feet were added.

Enough of the pier was also built to sink it to the

river bottom. It was then carefully lined up and anchored

by cables both ways, because the tide fbowed in both

directions. When in placeit was then sunk in the usual

manner, and the pier built inside. Plate A and B show

the complete caisson and superstructure with dimensions.

For a proper analysis of this structure, it is

necessary to consider three critical cases.

1. During launching when very considerable stresses

- are set up especially if some of the ways should

fail to function. It would normally be supported

by five ways.

2. During the sinking and when in place at the

maximum depth. In this case the air pressure

and hydrostatic pressure combine to set up

stress in the chamber.

3. The possibility of uneven bearing, as for instance

when a boulder obstructs one edge, causing most

of the weight to come at one point.

A fourth part which will be investigated, is the wooden

superstructure. Each of these cases will be taken up

separately and the stresses calculated in each case.

This will give a complete analysis of the structure and

show it'"s strong and weak points.

We must concede at the start, that this problem is a very indeterminate one, and certain assumptions

will have to be made, but in every case the assumptions

are explained and in our opinion justified, and coincide

as nearly as possible to ordinary concrete assumptions

used in practical work.

We feel that this problem will be of value

both as a study of deep foundations, and also as a

further study of the theory of concrete.

NOTATION.

Fs

Fs'

Fo

S

v

u

Tensile unit stress in steel.

Compression unit stress in steel.

Compression unit stress in concrete.

Total shear.

Shearing unit stress.

Dond unit stress.

Modulus of elasticity of steel.

Modulus of elasticity of concbete.

Es

n fEe

Be

Es

Ec

M

As

Zo

Q

Bending moment.

Area of steel.

Sum of perimeters of bars.

Statical moment about N. A.

REFERENCES.

"Applied Mechanics Vol 2"K

"Concrete Engineers' Handbook"

"Foundations"

"Beton und Eisen"

Fuller and Johnston.

Hool and Johnson.

Jacoby

and Davis.

Dec. 4, 1919.

Oct. 4, 1920.

CASE 1

This case takes up the consideration of the

stresses in the caisson chamber during launching. The

caisson will be considered under the two worst conditions

Case 1-A. Balanced in the center, acting as a canttlever, all ather ways having failed.

Case 1-B. Supported at both ends, acting as a simple supported beam, the center ways

having failed.

Theses cases are somewhat analagous to the "hogging"

and "sagging" of ships, and are calculated in somewhat

the same manner.

It is obvious from the start that these are

very extreme cases and that it is highly improbable

that they would ever be realized. Naturally, every precaution would be taken to have the ways all on the same

level, and to prevent any one of them from failing. It

is necessary, however, to investigate them to forestall

any emergency. In view of the fact that if an accident

should happen, the stress would be a maximum for only a

fraction of a minute while the caisson slid into the

water, it would be perfectly justifiable to allow a high

fibre stress for this case, as long as it came within

the elastic limit.

In this case we are really considering a concrete beam reinforced in both tension and compression,

and of very complicated cross section. As such it is

necessary to consider the maximum fibre stresses, shearing stress, and bond stress.

The assumptions that are made are the ordinary beam theory assumptions for concrete beams, and also

that the concrete takes no tension. While this last is

not strictly correct, it is very nearly so for high stress

and as it is used in most work in practice, it seems a

logical one to make.

As this caisson has a very complicated cross

section, the only reasonable method of figuring is the

equivalent area method. This substitutes for the steel

an equivalent area of concrete. The caisson is 1-2-4

concrete and therefore n=4-15, and the equivalent area

area of.concrete is 15 times the area of the steel.

Figure 1. shows a cross section giving these qquivalent

areas for both case 1-A and 1-B. The roof in the center

can hardly be considered as acting as part of the beam,

inasmuch as the supports and most of the weight are on

the edges. It seems logical to use the Joint Committee

ruling for the width of tee beam flanges to determine

how much of the roof to consider.

Flange width (2 X s/ab thicknessjtidd

or I A-SPA N

of stem

This eliminates the central portion of the caisson from

the calculations (see fig. 1). The position of the neutral

axis as calculated by the equivalent area method, is

shown for both case 1-A and 1-B in fig. 1.

CALCULATION of the neutral axis and moment of inertia.

Let g:=distance from extreme compression fibre to

the neutral axis.

dedistance from extreme compression to extreme

tension fibre.

It is necessary to assume a trial position of

the neutral axis between any two sets of rods. If the

calculated value of y shows it to be in a different place

them a recalculation is necessary, using the new position

between a different set of rods. Only the correct calculation is shown here. To give the others would be merely

reptition.

For convenience the calculation is tabulated

in tables I and 2.

Col. A gives the areas or equivalent areas.

Col. B gives their distances from the neutral axis

in terms of d and y.

Col. C gives the statical moment of the areas about

the neutral axis, from which y may be calculated.

Col. D gives the squares of the distances in col. B

Col. E gives the moments of inertia about the N. A.

Table I gives values for case 1-A.

Table 2 gives values for case 1-B.

The values in columns A and B are taken from

figure 1.

Wid16

of /?af to consider as

-.

padrt of Beam

74

I

A

(d=

TA BLE /.

X=

qFEA

04

(C)

(a)

(A)

oJsrAjTcz

/OMa.

ANEV1.

AX/3

1,46 j

(E)

(D)

AX= SrATICAL

AfNwr

Ao,r0~~

N

AX/3

NE#T.

-60 y

-/6 y

04

/440 -- /65y

- 29 70 - 336y

'-

8700

/800

d-y -J

d .Y - 28

d-y -S2

/J-

/

Yb d-y -9

25340

/960

/2O

d -y -70

d-y -ae

d-y-94

JO

jo

JO

28

20

28

y- 3

y - 6

y -/ 6

20

y-Y

28

y-42

7

y

/120

460

2/82700

y0i,0/ar

.xg

Y

N.)

604000

8500

J7,000

65O

35M00

13800

2700

47800

/930

5970

170

tZ/40

t/oy

,ory?

8Z1

.)0

1,4800

5"

y

(I

3.ty

y

31~

40

*

41-4L /7/0

84 -23y

l 4 70

Y8,4

y

-/6 -26

190

24.4

- -04 +2d y

2/0

/44

e gy

-8-40

(0o

2.4

-//176 +2

-2772

__

75 7

2440

33

21.(=

14=

y

- 3y

-30

9730 -2

/0,00

4 41

tiZeMCT/A

/MENr

1N.) (/N.

60

Case I-A

49/~

;p *#4Tet

2/8'=

-4749~

trag

e

a

y= -

2/8)000

4/0

3

/Y

~X

CAI/cu/ate y

E4aating the Statical moment of +steel

-concr-ete

to that-of -s-teel and

297Ja-273:Y y

-2772

t.140Y

5, o 2 + -y

2iV2

=

y

4/J

, 0J2y' ,fyat

3

"

y= 444

=

TotA/

I = x

a/, 06 74

- 0,0.0

;740,00

w-

TAB E 2. (d-- /47")

(W)

(A)

4I4 A

DSrANCE

X v

ot

11v*

(_

g

'RON

N&117 AXIS

(N.)

.)2

y .-

4

d

d-Y -3

d-y -2

30

3

30

0

JO

3.

6

6T,

.

/4

(D)

AX = 374T/CAL

No/IET Aaour

2

NEI7

d-y-27

0

324

/'02

63=f

M-y

d- y -J/

y-2

26y -280

X

/45

/4 y-420

y-30

4__

425=

-1/2

J6y

y-

-

__ __ __,___ __ __

/01g000

87000

/8m

= C.0o

2/4

/.

2900

-812

.190900

223'

6yJ*

p

120000

795oo

2 &ir

/x4S

46800

22roo

750

?700

290

9"0 /400

-, '=

Iyr'2Z t

-3'.Y:6y /7 ,

8r 2060

d- yd,

-1$y

8/0

d-y-~93

99&0 -288.t y

toI

/60

4000

-3oy

-y3y

-JYy

2580

d-y.-T

2zO

d- y-75r 2/6

avINE/itrA

(11_)

O 3070

J'= /02

95qJ'= 9900 297000

7620 228,60o

87,F'

171,Ooo

$70

7,*.

-Jo y

-3 Yy

-3 y

-yg

4410

430o

3960

3600

2

foMdP/

N)

_3

d--y-39

y-

(E')

4x

(i

4X/3

N

30

30

(c)

Case I-D

/eey-/'2O

/

jr

49

260

/20,p

2

0o

358,00

____

__

__

____

____

___

____

Calculale y

Fgruating

the statical moment

of -steel -and - concrete

3y +/80y +1Z4y-3 -.Z41=

y*a+ 594.6y

y

7a / I = 2 X /,

ooo=

2996

___

__48330

of ,teel

-28,evy

445

O0;6

= ,0 , is4

to that

0

WEIGH/T OF CA.3OIV

CHAAN8ae/t.

A

A

COAXC)T

B

4

PA N

d~~X/X/279289

,4cd /X/8=28a

24Xfr

4Are-d

StCC77ION

,SiCdes

Cross

/1740

02 i&=/d/ M

A1

.178*~2s9,r~z/a,80 w

2Z

7,m2oe(2xr Z)'so2 7J-, rd

,zz(. xr xF//4J)(/rO)V

W

7 f0

S5ECT/CoA' z3

7iita

xY.r-xib.)0/6e

4t,

6.f

PCW7O

0

SECT/IOA/ A -f-S

s4

8=

7T07*,lL.

2O~roo#

,,p 7 4 ~ 9 ii

~ ~2#O ~

7

wz.

2XY2?44

#

4664jOO

;X4,4-00 -* ,

taA

8 Y27..A

~__

__

V

1

I-

.

'

2.r. 'I

2>v'-. /4'-

I

I

-I

no

tmtmm

9j4

28'

WEIGHT

OF

SECTION

WOODEN

5UPERSTRUCTURE

A

t/g.

Vo/,me

No,

(47X22Xf)

Plan

Wa les

(47X/)

/5

24 (zz x r)

Stvds

ims/'(28sX i

Csj

Other 4cecessaries

InOS

WeigAt,

4r45-

/ ro0

J/#ova#

4JIf-

//90

18080

7;

ste n/oN

SEC TION A

P/an|

Wa les

StodS

Crdo

Bs.

i5

(59 X2X g)

(j9 x)

ZZ (2z x4

( 9 .)

4l.44

Toa4

1

/0

Othep accessoric3

Dr

7f'

JOro

l 1 - t 467

SECTION

TTAL

A-+B

62,8o

+-3;3orO

5ECTION (zzr: hisA)

=

279600 *

A

/0.

SHEAR AND MOMENT

A c tua/

Loading

0570

CURVE5.

CASE I-A.

Ate

&48

7040

Caison alone.

trueciare.

/Supers

3Aear

CAdmber a/one

Mh

4f

/omeni

=

=

I/874OX7= OJI2oA

2o4iQ

9if-,45400

7

00070

p5,erstrueture

An -2x6treoX7=

794040

NAl = 2xrror(wJe)#344 000

642tjao

607q 000

Lad

Considered

Uniform.

J2 7. 00

27;9600

CAamAer alone

Ma=327Yd0sx

Metnenet

=

ji/40:sA

AJuperstruetore

ANm =2X3.goXJ 424@W0

trror

(with

4,140-40

uniform

deadd)

-

.' In fgurming deflecions vse uniform load,

Cham her

IS4-e 1.

CA amr--- Juaperstractiure

"

Lsago oe

or

SA edJ46900

000

CA amber alo'ne

A/,4av //&74,OX7t &TyOot

--

204~~~7,

&t0/6*-24,e00

.t /#cim in

-fperi trvc tur-e

Xa= m Z;( 5*7,4X

Aote

Chamb~er a lone

p -. ers 1.*uc tore

7=

Af.

Ov ". all40p~4

zo(5204600 #

-80400

W.6 -2 xr7oj-o

x.54 S-T 3400ooa

-2 X82,doox,/8=/,94qaoo

+

,ON

'140 000

Cham7,be,I. L96 Oa A

CA a mhe,- * J Svpers tr-vc tvq-e

2'. 3.T0 0

ETERIJNATION OF LOADS.

Before it is possible to determine the fibre

stresses due to bending, it is necessary to ascertain

what part of the weight of the wooden superstructure is

carried by the caisson chamber. It is evident that the

caisson will not take the full weight, especially as the

superstructure is water tight, and necessarily must be

made very stout. Obviously it has some degree of stiffness itself, and will help carry part of its own weight.

To find what part this is, is a difficult Phing.

Any method will be more or less approximate,

but it is better than making an arbitrary guess.

The method which I will use is as follows.

Find the deflection of the caisson chamber and superstructure separately and under there own weights. The

ratio between the two, will give some idea of the % of

the load of the superstructure, which the caisson must

carry. To find either of these deflections accurately

would be impossible for such a complicated section.

Inasmuch as the deflection theory for concrete beams is

from 5 to 30 % in error, it seems justifiable to depart

from it for such a complicated problem as this. I am

therefore going to keep to my original ass ution of no

tention in the concrete and also use equivalent areas

of concrete for the steel. This reduces then, to a

homogenious beam 'f uniform cross section and will be

treated by the ordinary detlection formulas for each

case.

Given in Vol.2

General formula. EIv=Jidx.afJMdx.dx. Fuller and

Johnson.

In considering the superstructure it seems

that the studding and cross beams will add no material

amount to the stiffness of the structure, as they are

merely fastened to-gether at right angles to each other.

The plank itself is what gives it its stiffnessit being

very firmly built and water tight. The question comes up

as to how deep a section to take acting independently.

If we take a quarter of one section or 5.5feet, we have

good proportions for ordinary beams of the same length.

This method gives deflections for the caisson

chamber alone as follows.

Case 1-A..... 1/2"

Case 1-B..... 0'

These cannot be taken as exact, but we can probably say

that for case 1-A, the deflection is something under an

inch, and for case 1-B, it is under a 1/2 inch.

I

*

/I.

The deflection of the superstructure taking

a section 5.5 ft. high is as followos

Case 1-A.....1.3"

Case 1-B.....O"

Taking a whole section of 22 feet in height as acting

to-gether the deflection for case 1-A is only .162"

As this is so small it seems that the first is nearer

right. We can infer from these results that the deflection for case 1-A is under 2", and for case 1-B

from 1/2" to 1".

It is seen that very little confidence can be

placed in these results. However it seems obvious that

the tendency for the superstructure to deflect is greater than that of the caisson itself. From the results

it would seem that the caisson carries about 1/2 the

weight of the superstructure in case 1-A and,perhaps,

a little

less in case 1-B.

Recognizing the fact that this is only one

step better than an arbitrary guess, I am going to

assume that the caisson takes 1/2 the load of the superstructure as being the nearest to the correct one that

we can make. In order to make a more complete investigation, the fibre stresses for three different cases

will be calculated. The first case using only the weight

of the caisson itself, then using the full weight of the

superstructure, and lastly using the assumption of 1/2

the weight of the superstructure. The first two give..

the maximum and minimum values possible, and the third

gives a value between these which is probably more

correct than either.

The resulting fibre stresses indicate that

case 1- A is very highly stressed. The minimum condition

is not unsafe, but the condition when 1/2 the weight of

the superstructure is considered gives-stresses beyond

the elastic limit of both steel and concrete, and the.

maximum condition is decidedly unsafe. If tais case

of balancing in the center had ever occured (which

actually did not, and probably would not in any other

case) it seems certain that serious results would have

followed. We could allow stresses up to the elastic limit

for such an extreme case but it is hardly safe to go

far beyond this.

For case 1w-B, even the maximum posible

stresses are under the working stresses for both steel

and concrete by a wide margin. The probable stresses

are less than this. If this case actually,happened it

seems certain that the caisson is absolutly safe as far

as bending is concerned.

Following are the calculations resulting in

the determination of the fibre stresses.

47

O~PLECT/ON Of' cA1,5 ON

LOFF? ITJ5

OW4N

WEIGH-T

CA45E I-A870

"r-r

1hi3 caae

d erived( 1n k6Iff

Vi---

PvllerandS John,5on

CX 2 , 006OOOj

77,15

040

CA5E 4:

Eli

-4;,T/jzOmx */04,e7xt- /~fX4I?

EIS&W

*,

4br+3J4770/ - JA70X4 +

x

C, 4/40/2

CA

o(/8d

Mx~?

'

+fz/O9Oag4ood2J#08O/-40d

-q

ly

a, ado-864'#,oof

i

I

/5.

DEFLECT/ON OP 3VPER3TRLCTVRE.

ir'S OWN WEIG/VT

UNDER

lDIII

CASE I-A

/.37;$

T= 2X4X(X2=

p/ coo

12

A'-= /, 6,00,000

Wy

= 3j-e

=3xA93/

W

E

ov

3J;0 (x(375"x/2)

-

8x

'4

,040O/9Xa

s#'

lx

2

X4X(

22

4"~

X2)t= /2,2 0aoa

12

W = 376X 7450

2:79;Ovotx

V= .-

279,040

(37~xIZ)

I000

ox / G0a0OX /2,20

i:980,

CA 5Z1-8

2oeoto+ 6280Ox-

-

EIr

d

+ 4/,400xz /47* +* C,

g5ox+.8Ogc37x4 + CX + C1

20q00o 1

/

-

=0O

=

S0c

C, = ,oqugoo - /43J0f/4-//

lr=4n

ax

Ef.r

=-- 2.T00/+4 72Y('- 2

2,6

J4+7/,-

O 3,4

O+24;O0 * JC0*

cz =o

+rg00if 5--/76/'+9to4

o

=-26:TOg3en

Et-

/9/

- ..

000

oc

/,beg0coX/2

. .....

....

..............

-/6a00

2(aooo0,OOOA/x

-

-

006r

= /&800

-

~

11

de

/6.

F bre

f3reasez,

41

A=k

* fj'=

(d-~J'~r

2~

A~l(~s-3)/J~~

I

CA.3E I-A

chamber alone

4 /40OX#44X/2,

3 77.4 oo

fJ=4, /490

,60%j

Kx4/X/2XRf

#/3O g

3,774000

chamber + supersfrvetwre.

6

-RAtio = //31400

f , /4400

fc

= r'9

Ab~ass

=

&5 X /2,140

cAfj

E

__244___7_

s upcrtratv fvre

e e

Ratiow b,/44uo+2,62oa

4

#

fe = ,43x&60

fs

= /,4X340o0

fs' = /

2Iwo

C A3Et /--5

chamber d/one,

=/,9oo4

Ae

3664

coo000 A.__

940 42.4X/2 x,

f

000

564

33240S

ck&AdIA i + superstye tfre

7/

Rafio =j72 4 00, fe = 7/X230

0f

Z Z7/ X 6

fs

7/ X 33240

fs' =

cAamber +

Ratio

/92.7ea

A4 sperstructfre

=/,3X

.9at7

/ -94 0o

fc

fs' =

As

/

X 2 O

3

3K

AT~

-X

3620

330

JT

h/D 04

-

1

P

i

___________________________________________________________

17

.3TRE356E.3

H1/EARING

The shearing stresses cannot be calculated ac.curately by the formula vr. V because this assumes that

all the tension steel is c ncentrated at it's center of

gravity. This is not the case and since it is distributed

over the section, the shear will vary. The value of b

is not constant either which makes variations. We will

go back to the homogenious beam theary using equivalent

areas.

V=

Derived in"Vol

'.

Fuller and Johnson.)

Q= Statical moment of the area obove the section

about the neutral axis.

S Total shear on the aes Men, cross section.

b Width at the section.

I= Moment of inertia.

One point of maximum shear is of course at the

fneutral axis. Where this does not come at the narrowest

section, as in case I-A, it is necessary to investigate

another section as XX.

Case /-A (at netiral axia)

Z(2973T-27j6444)-J{20

camioi alone ."197x32,3Td

-=r04

774#

-: X.Y

-,1-

t.j

i'

47z77

d'"

3

d

_

(sea tio,

S-

j

-ZA

92

.dd/P7462/00

=009.

rX)

ood -t0,y

/440 - I.y

202A-/roy

2/4/74

4

. 0412X 32);304 =

caissen? aer

*

=z/4/7

X

Z=377

-4g{5

= /

,oo/7

77 4

A-

Super .9d0/z7r6,4

*Z

,e62

46/s

97r

= Ad]4O

4

0eaA

Case ,-z9 (at neutr /dax5)

34200

b= A X,

=/

Tw .§44

Oo -2

"

ca9~o

issen~a/one

S

.000 78 2.8Zoa

suprY .

WA

0oo07dX

574200

,ooorax

007X2S4x0=

/

=oo

|,/9

226

=14&

While some of the stresses ruh over the present

allowable of the Joint Committee of 120#/sq. in., they are

not excessive in view of the fact that it has been debated

2 40jf/sq.in.

is not'"safe f or a working stress. In this extreme case therefore it seems perfectly safe in shear even

if the stresses are rather high.

Wv

~a

VERTICAL RODS WHICH IN THIS CASE ACT AS STIRRUPS.

These are 1" square rod.a, 6" c. to c.

As before we will keep to the assumption of no

sion in the concrete.

ket' Pz

tension in

ren-

stirrapoa

3 x dist. aptcrt

b

width of bedm

tf

rrotegt par-

P='vb3

Then

and

Civen in

0,afs As

aut P

. v(abI

.'

~//ep-and

.45A

fs

.( A,

C&se I-A.

{s ect xX)

,vXIzx6

Qr

&K

caisson aone

a * food.-.

i

pE

f=O/(20-

/

,-xyda

f, =7~X9=

7S

Case1-8 (sect N-4)

. vxI2 X

f5 ,XxXdz

4 =_ gr

caisson alone

* super

U

-)t

a

4, w4X

f~=to

/42

=.ZQ7

X2_9/ -__

fs POX.224

=L(S_

These values are the maximum values of the

&tress in the verticals and are seen to be within safe

values. Of course in positions where v is small, the

atress in the verticals willeless, and therefore could

have been spaced farther apart, as far as their action

as stirrups are concerned. However as they were put in pri

primarily to reinforce the cutting edge as a cantilever,

their use as stirrups in this case is only secondary in

importance. The other case will limit them and is treated

elsewhere.

1.9

BOND

J 7RE3.3.

As in the case of shear, the ordinary bond formula

is not correct. unless. modified, because all

u

the tension steel' is not concentrated at a point.

We will modify it to correspond to the shear formula

S'/4-w6

A/ow

s SStitv te for Lr, if>

9

a

S-= Xb

SQ

4Z

,61

.

Za=Zperimeter of rods outseide section.

Q0=Statical M of those rods about N. A.

S =Total shear.

As in the case of a rectangular beam, the greatiest

bond stress 1s in the tension steel and, since the most

stressed rode are the farthest from the neutral axis,

these will have the greatest fibre stress.

C4se /,4

Q= /20X /oY3;t-= /2,40

7'

e =418 =X2

Z ~ .! 77045'av7

12,440a

-

.00/033

"S X .7 7 40

caisso ai/ne

I

,

+)j,

?2?'/A =

.

OOpr

IO3Xt9d

A

j2i7

t0

2

=

S7

-48

.On/4'3/oo

Case I-B.

Q=

fOQ/2.5~=

(/.'V

=7-,44 ,0000

CI3Son

dIfloe ,o/

r, * A10 e,

Ii

IDZ

oopr-4

X.322?34

,a0/0fX467/O0 =

..

4

.*4

z

tr5s

All these values are below the working boni

of a0,/sq.in. for plain rods recommended by the Joint

Committee. It seems that the caisson is safe as far as

bond stress is concerned.

I

_J

11

or RiE5ULT3.

SUMMA/RY

J T/

Z333

IN Lo. PE?

sQ. //V,

CA S4E /-A

F'

F

A.

L Oad

v (C.k)

44.V

/Z,/6o

OaJsi*J Ja4ae 46(0 3000

/rp0 .rpJre 244dd

, + sp~er;

42410 /7T3

'0 /3'

e

1 +4$

Load5

COWDw alone

S osper

-+

A

2y3O

92

CASE

-6

Fs

F'

v6MA.)

8104

Y320

6.700

JIaI 29/

40

29

3.94

3/0

//

/6QdO

vtxX)

2470

3AO

293

ve)-t. Iods

A-

34

4Z

40

/200

2 JDO

/ 50O

ert. rods

9720

4

/62

MA.

CASEI-iB

-

-

#.1~-

-'

I

/

N.4.

-

CA W I-A

7

-

I

-

I

I

I

/73400

'T

E

'i:.

|

mR

33

DjAGRAMA.

.

:

-.

:

.

.

2/

CASE 2.

The purpose of this investigation is to make an

analysis of the probable stresses in the working chamber,

when the cutting edge is at elevation 25. This was the

elevation to which the structure was sunk, and according,

ly, the stresses under possible conditions at this elevation

will cause the maximum fibre stresses.

The first condition is that due to the sudden

dropping of th pressure in the working chamber, which

acts as a blo n the top, causing the structure to sink

against the f iction on the sides of the caisson. This

method as well as loading the structure is used in practice

to overcome frictional resistance.

However, in case the air compressors should cease

to be in operation, or in case the material through which

the structure was being sunk should be of such a consistenby that it caused a blow out, so that the compressor

would not be able to furnish enough ai:b, then the structure

would be subjected momentarily to a pressure almost as high

as full hydrostatic pressure.

To facilitate the investigation under these

conditions, the analysis will be divided into three parts

as follows,

1. The calculation of the fibre stresses in the horizontal reinforcing, when the pressure is dropped

so as to allow the caisson to sink.

2. The calculation of the fibre stresses in the vertical reinforcing under the same conditions as in 1.

and also the stresses under the condition of a

blow out.

3.dAn investigation of the roof.

In the first part , the slope deflection method

shown in Section 10 of Hool and Johnson's "Handbook on

Reinforced Concrete", will be used to derive the necessary

formulas for the moments at the corners and connections

of the cross bracing.

In patt 2 the ordinary formula for the figuring

of a cantilever beam will be used, while in part 3 the

slab and beam formulas will be used.

/

r

-

-

-

-

OOI/o*

-

-

-

-

-

-1-

ce

6

8

9'/

is

Deflectiona

about B3.

-4/

7)~

SZ

A

le

+_

g

.t

.1af

E5,z

3 is

6

~ciu~

I

.~o ~ ~ ~oz.

.

6EZ

E[-7'

7A

v /

.3

-~

XfAJ

a~LZ'

Y2/

Difference in slope between the two tanxents at

equal to the area of the moenerve.

(e~-o~)

=

mN

8 .I

z ez

AZ

zez

i/4Mi6#

+2

Jx

,f2

6c

A and

2zz

from equations I and 2.

Eliminating

equation 1 by 3 and equation 2 by 2-.

11(,-a,

[M,,

0a

Multiplyin6

4

7t"

Subtracting equation 4 fromn 3.

f-7

2

2

O~f

by

Multiply both sides of the equation by 2 and divide

49

M

In

74

a

.

n

Ez

= 2/(E(zO+e-se)7+ j

the saue nannor

E-

/-

6

Applyint, this tua the end section

ABC and assutaing theC two the tvo

corners 2 and 3 to be fixed.

The deorrmation a ases~aed to be

A C

as&shown in tne ske~ ye

Then the angles

h lueoRisequl

proxiately to the deormtion

C

due

th

appii

o

trally applied lod of wl/2

4of

Then:..cu-

IZX;'Z3

7

Z 4X 56

variable thIckness of te caisson wall.

X

Zo equivalent area of concrete for two one inch square

rode when n 15.

p

Deformation:

(z4X+56)

(24x+-56.)E

Substituting in equations 5 and 6

~ZE413

-1

S(-3

) -. /*

*7

4X4 f56

/Z X

7.

/2

x

Ora

/Z

26

/

If, however we assume that the corners B and C are

not fixed and that relatively they hold the same position

after the load is applied the value of R is zero

Then

and the deformation will be as shown in the

accompanying sketch.

7

Then:

a -

/2

la"

also

Shear at A and B.

/*

/2

i w/2

2

_

12

.8

L

..............

. ..

.......................

. ...............

j

N/ 0

na7pee3

or

e

Pei

C

.8C

0

10

/

/7'

/

Since in equation 9 the ament at A is the saae as

that for a beam fixed at the ends, we can assume that

A and F are fixed, and concider the structure shown by the

full lines.

It

is

also assumed that the ends G H I J are

fixed.

Then the equations for the moment at each end of the

members can be written:

Mo

6

m

Ny

a

zE,

(,+-

= zR,

a>.2

aG)

G,+, 742

)

7 Me2I'E~

2,+,3

e,+

x ,(Z

MA

BC

MIT

Mp

M

-0

zE4

Me, -9~

,

~ O'

+-3IV,)

(9n3

Z

EX

z=209

29/G)

)+' /2

.Z

oIents at iJny joint equal zero

Since the sum of the

"

Als"

O

Le

=

0

From which we Set:

G(4,

4k,4,+kG-k

19a

.

(6x, 4ks

9,

/

)+zt2* , sz R,2-*,r>&

0, (k

k,

- A- 1/

c

7%K)+z

ks

74,44

c2

kZ 9,-6

7 Q/ 0

coI (

A0 - 6 AG ' al=

of

Also the sum of the moments at the top ard bttm

slazar multipIl

. by the height.

columns are etqual to the

86

C

D/

66

YU.0

But

/

2

4X,'4Agf4 ZXk

2K

.3

2

4

5

6K+4X

-

+-z4no'-o

MaConsA

67

K

K/r>

/2

'/eayE.-

/2

Z-k

KZ

2K

z

/WO

/C

/

4K

ZX-5_Z

4/g4W t,4k -6

/

-24r>

Using these general equations it is possible to solve

'tre'e at

and the moments and fib'e

izna

4 ections of the struc-

for the values of

the various pointo

The same type of general equations as are shown on

can be derived for the case when the points B and

page

E-are assumed to be fixed. Figure

I

I

2

/

I

2

-I----,/

AZ

K,

/

/

N

L~

/1~74~

lop

8

+ ,

/

~1/

I

I

a /8 zC.

= (2

/

1-

~2{2~JO~r3~e)

.(ZOc.4 OOL cv-e

t.Z

=zx,

A7DC ~2EX

N,,R,

p1 ,e

/2

(2O9,,-yQ)

w2EKJ

29D+9,)

-jtZ

A~wix

Also*

If,+

z Ek, (

4zx, (z 0,

,

-0

7,,-C

,,-a

,1=o0

zEX

4K z,+,3)zE

=6--2

z,9-

0

.........

1

2

2i'WA3

fVl 5

5 e c /1 *0

r."

MeMoe/6

464F

BC CD

I

o~'

D

B6C/D/*1-,

5c/1*

.

5.

228

55>Z6

-6/(3,

447 *

z5lz

,,/7c he.5

4412

ZA4X

Covo03/

.zI

5 I

cof7s/a

&

52

/66

/Z258.96

6.77

/66

216.4

1162

.304

575-2

31L

F89 .0Qo.52q

.5ec/,or, /Alcc cro-ll>-ac1?,

3o4

*Ot-eco5eaa

.4roae"

5 75.2zI

6-9 1.oo-2.9

I/.3c

e /L

Pa,?e4d~ ize

0aI0,oo one/boc.

Q4 o',A OsecA 'o.'j:.

-

the

te~i

der'i~the

lw

uaitreatl

Before cl

horzotalcet~;, i

pressLare on the cilsson.

.i .

u n~mryto

/3/ro

7.

-37

c~n~7Z

Area of-" VoIo

1-.7t.94

"9'

'Fle Y.Ot,

/30

3010

-17Ar

~I

v/e-

Li plac- ,31,, e: er in wtr

I

on

O/Q 4

Z4x

6 7 rec7 0/' sw'/ace

6 7 3$QmZIy

6 01//om.

31v ale /0~ OC7.rl C/ocv CAC

3~do

.77A5

-9 4 - zx

.

ii ., /( "12 550 -#4

a5.9.4 x55o

~ /0

'C/

472 67o#i

n

C CZ"Crl0/,

p"/Oe1

so

4726~7o

7o-lal I/*oae/.

76053,9ZO

wve.,9 A

A'r'17-e

cc

(j

/Ae

COC':t*

Wvez7

otwe4

A/ o~

9

C012AtCZ /00/?

c/r,~,

~5415oo

22"5eimon Odewooa/es-7 3cvoePa al oirn

Z7~A 4oo&

7

i6.14eo 0,0/ cve/ 124/ 0//'O0O/' ad /edW a Ac4rZ445X4ZGX-9S-W

('' S. -)

/OU.0C,4i;1.

CV'

252d/~/~O

~4~/weig/

0 1A cc/.

-,Z

Xq3.4)

0%//0 o

-1e

4

.h IYo

10r

3/i, 3cc

eV/

3~ZZJe7

o~

/po/ur

G.94Z74

34

I

From to difference in weight and displacement it

would seem that the caisson would have a tendency to r

is

in

the actual case was not true, for in placing the

pair in alignment enou

weight was added to

tracture

ie

at high tide so that the cutting ecies were arely off th

bottomn and when ta

proper location.

ime wen

p ie

duwn t.

na

n

It

It is safe to assume thrfore

that t 1 e only drop in

pressure needed is that necessary to over come a frictional resistance of 472,670 .

To arrive at a rational estimate of the ressure

drop necessary to sink tho structure, concider the amount

of water that should be allowed to enter the c"isson to

make it sink under its own weight.

Pneozi re

a/b o

472

G 706

the working chamber.

,Theoretically water should fill

2'/ev.

C&6/er' w oa/Y! tv'e /o

PpeavcJ('c afsec

W

af

C7/

N:o/er-

cl7

o Eom&er 7(52o v

wor^CA 2

w

=70

2.

. 7375

B=

.32

oa 47 (.5z--zG)X

2.5 -375#/sy./Ed

?.d

4.eA.

A difference in pressure of 375 # per sq.

equal to a drop in -age pressure of about 2.6

ft.

is

# which is

about that used in actuaal practice.

ubstitutin

we can sol ve f~

....

.....

....

..

......

these values in

the equations for

thnbending moments and fibre stresses.

....

..

............

..........

.............

11

t 1hus in to tabuiur f orm so wn on pag ZG

o

t-.

The vrluc of a will b

of w at

zero inice there can not be any horizontal movement of the

structure when it is symetrically loaded.

Subs ti~

with the 'v

Values of 9 for section A.

L9a

_____on

5.72

/3.:5*4

3

/A.-54

£1.72

S

2

I

e

is4

32

2.6

54.7 roz

o4.

-.

/

44.556

/

4

-4.2/7

/

/

.3

/e

4.18

-2.37

+'.o oOO 4

4.55$

/

4,928d

/

/

.Za/

4

/

4.18

4 - >C315

-oo4

SuLstitutinG

9 in the first

tion, however,

zero.

2000:z

cs

Ioc2.4

6

Yales oIG

62Z5

/3.54

13.72

13.54

-.

Cons3/anl

--.

4

5,

$

-o0o1Z

.00

-- ocooxi

Aolr

+,o 004/6a

Aoo4-

In the e 1ution

on page 45 te values

fo

assumption can be calculated,.

An inspecshow thmt bh 9 at C and D are equl to

The vjal e of the m ets for the several points can

can now be found for sections A and

arid are tabalated

with the fibre stresses on page.3Z

g5

/

Z

3

4

I

4I7Z

/3. S4

-. o 377

r35

61/.72

/3. 54

/3. f4

5<,.7'Z

4.555

/

/

f4

/

55

3,

+. oo 37

'.ooooCG

.238

/

Coa 3 /cO$

s

13.54

.7

/3.54

/

Go

O4

Ga

6qgoa~/on

/

-oaoz 7

48

A-000

2'/Q4-1

/

3'

-ooo/57

.237

4 55

/

/

'-a4 328

4'

4olue o 0

/N

6'

foooozj-:oooo

422

37

3i 2o

320

2.9z2o0

a3o

/2500

z 4 _34r 0

z35 2/1Q

So

295

27

Soo o

7.3 3G

397

S9Zo

2/ I00

422

31 20

12 900

51

7.96

7oo

54o

3600

3370

2 Goo

2600

G6

540

7oo

75

790

3600

S06 oo

.o675

5930

D3,38 /:5S1

2or,7

P

V.00007

D 4 340

/3,ooo

C,

f.ooa76

en/

3 5.ooo

/7 36

8

8

4./8

o oo

fAootoo/G

C

CO

-.

93.95

:ooo7

--.000 067

.Z31

/

c

0

?.3Goo

75

6e

6/

3370

The moen

at A witt

will not b~e f'i4ured eInec

hor

uL

e a

mtion that B nde

ta

the moments at the other pont

caees less than

0..0, i all

3

/

5.4C.

IfoI

A6

6q

6

55

/,-

/2 X +38

qB

E

omen'

/35,6o5

425

comnp

3/3o

38'7

72

Lntiria

.6$Zo

3800

5her,

Tae corner A will have the :aaxi(mu

invetisat~e t11at secio.G

at we shll

<w/

~onuula U

.3ec. OPA

"2

.~7 5X/9.~Z

2

325

.5525

/2 ~ /0.4.3

4A10.43

.Yec.

88

G .x /3.4.

2

/ op- 2 776

~06

GOG

GdOG7

I.

i ,:ac~i~cerwt

ch~rberone foot wl1 d

a-wswnend t.3 be

th ctyoi

C

C/

c

.1

Fo~t/Y 0/c2 Ad-m

//oo/ q' Yo0k>n3on

L

L7,aeer3//&B

Coi-cle

FWS e4 ~zPay

-I7-=o

34

Akjco AVO 4oyo// ?/C eyuiv-

Y/n

c/e

=h735

0 44

2X65611/

C

.2/GX.934XIZ

4/

G7.O

-.

5leqrt

34"X-.9567,

-a6

7

/5A~6X2G5j

-o

34e."

Me rb, qC al

laooe -7Z2

c 0 mo.a

o n o1 o. ( ' a

/e~

/ 1?

caip

Aa.,e

/'9omenA

'~~

2/00

A2 .9.34 x 3

Th c)lio

vestI~~~atc

o

s~x

2

~~ j 0/ CO3

o A

2/00 -#

A

the

~

O

>i~v!

I jcJu

6tos uiide t L.ctdt~orfll~abo

A~

.5

N/ev.

of co///n

5e

eo07 e

/00

Ppe ssure o/-32 -4-250

P7

Fre

a40e /0

oafrm' /oao/ 0f 41250

s/resses ae

/o

/3

7

//G,

57

of' /06 257

/06 Z57ZX /Z X

G X94zz/2

XC

X3 44x. .95G7

/000

- 54 Soo

Yer/c

,/t

VZ. 75o-/4,35o=

in resist

retLsio

corr-p.

o/

stress es

3A..

c orrop r'oo

/5400#

oo'~o

Ip"-hecEzra:_Ireabv

In the investigallon o~ tone stresses in the root it

will be concidered that ':m six inch slab is ofec tive

in resisting the upward pressure, and the concrete above

act onl; as de~a veicht.

the

However-, vin

t- e

wrn in the;:working is reccd,

concete atove the slab will be assumed to be self austaining.

It was shown on page tha6 the difference in the weight o f

the structure and the displaceneent was 7,884,00c. 6,947,150

per.

or 936-850 1 which was bullt up in sol

Thisacting

ivin/

evation 45.

ta

over an area of 816 sq./ft.

fills the pter solid to about el-

Actually however the concrete was filled to about elevation 57.

e2yat~1v,

~~ndor~~~W 1~l rsuewth thte cutl

~~Z

S~.

J.

Of

C

t

3,the upward preur -i

Opposinic thi's the-re s /M,1t

4; ft. -Slab at60

4 Al

c'-

72/.r

/440~

Pci 6 -)

6A~Wy

04'. QOO/O ?Ysena

~ec/,oz~ 6?4~

I

I

-

-

~

Iz

41

Tr=-

~ A?

~

~

-~-

A04i c074;U3l

Lao c/4'~/e

~/If

e~'a(~~le/eo

ec~

ZocyS/efl/e~~

-- "/75

cot 2 ~8O 17d 7

/2

/AI.

C

p-.0o.9.37

A ~40O7

60176

Z 2A

.o4XZZ

./

- 56S40C

#

:/5z

Goo

=3.9,

R=625

5*6

0063.94

X

/{6-6 44

.d

=/2g.

5

~i.17

97

5

ec-n

o

o/ al/56/

-L

/o

a srip

oa

I.O

c

-

/2*

p-.0//

2XY70-901

-4o7X.85GX/ZX/6

2x7000

16

7030/

3

.85SGX425X.5S S

6$94.

56 x 425

12 x.

.46

2.5

S6 X 4

ca7 OtS-oOfm

-

CC

68 27

pe7- -oo

4/3O435SX 8557

16, 076

/.9 6

.eeoz

s

/AtVru CC

A,

0/2,30

/-

/2Soo

.

The value of tP-e 'I~ bre strsesco at the enas will obviousl -r

b :nuc

and since those at D ar not on

t4he sfe

siac those at ' will not be figured.

.36,

TIt

czse

'a

0ii

conu

JzC T1/OAJ 4e7

r

c53.

df

>&

CASE 3,

This case takes into account unequal bearing.

If we take the case of a boulder obstructing one edge,

we will have the worst. case. Undoubtedly, if this -boulder

were considered as located either at the extreme end or

in the center of one side, we have the worst condition.

Die 4

tWag

Z;

Diag 3

These diagrams illustrate the results due to

this cause. Owing to the fact that the caisson is supported laterally on all sides by the material through which

it has penttrated, it seems almost impossiblu for there

to be any tilting of the structure. This means that the

assumption is made that vertical lines remain vertical

after deformation. This gives us the case of a fixedended beam. In diagram 1. we have a fixed-ended beam with

uniform load, and the supports on different levels. In

diagram 2. we have the same but with the end supports

on the same level, and an extra support in the canter

on a higher level.In the latter case we have bending in

a direction perpendicular to the paper also if the stone

comes only under one edge.

This particular case is not very serious if we

werely consider the boulder as having a vertical reaction.

When sunk as deep as this, the chamber including a four

foot roof, as well as the pier itself and three sections

of the superstructure, will act as the beam. Moreover,

the friction on the sides &f the caisson is, according to.

reliable data, about 600#/sq.tt. and would thus support

a large part of the vertical load. I beleive then that

merely taking a vertical reaction of the boulder will

not give high stresses. In practice too, it would be a

simple matter to remove a boulder of this type and reduce

it's effect to nothing.

This case becomes serious, howevmr, if the

boulder or ledge has a slanting surface and has a tendency to crush in the cutting edge. It is this horizontal

concentrated thrust which is dangerous. Diagram 3

illustrates. It would be a very difficult thing to remove

an obstruction of this type, because it would be

necessary to get behind the cutting edge, and this is

almost impossible.

This last case will be calculated,thenas it

is the worst possible condition.

Fro,~,

CaseZZ

Case ff

/~j.

~

we have

we

,F

=

e

c =

/1-;' (b

c,,da,. <.9?W7'

7.Y4

odd

.2/( X;

Al = rA'X7X ;/.

,

2AA

,z'

rf_

. aaorI.Af~l= .a651

x- q934

X3w

?-AF,4/

Y)~. 1

lYf-x

('d

t7

2%':'

IIl

d

b

93'4 X /-

A/ax

tpCC

ZX

-x

c-#it

fK

Xi7.(7y

x 4

144ax),= ---oxt.zo

,

/,Or-w

=

-16=

Z .4XZ

14,0O

X.?Y

/2

-

- IF

,YR-0

=4Jre-o A

It.4e tensjen streel limnits and

7 TAjs

is

can centfraited /Odid

t~ze m8.zimom

doci

7pof talVe into dac,007t' rAe horizobtal itel

whicA would vndoobtedly r-arry 30ome of the load.

741.;j, ~A owi

....

..

....

..

tha f

0-

00

WOODEN SUPERSTRUCTURE ABOVE CHAMBER.

While the wooden superstructure is entirely

separate from the concrete caisson chamber as far as

design is concerned, it seems worthwhile to investigate

it, in order to complete the analysis. It is readily

seen that it is a very important part of the caisson as

a whole and would have to be figured carefully. It can

be figured to a greater degree of accuracy than the

chamber itself.

There is some uncertainty as to just how much

bracing was put in. The main braces are shown in PLATE B

at the first of the thesis. There were however a number

of auxiliary braces placed after part of the pier was

built, which braced agr.st the pier. The number of these

is uncertain and their* f uncertain depending on how

tight they were placed. They would certainly add to the

strength and cut down the stress in the braces. We will

figure it as if only the main braces were in place and

modify the results to take into account the auxiliary

braces. The load will be taken as full hydrostatic

pressure as there is a possibility that this may occur.

The following calculations show the stresses

in the plank, studs, longitudinal bracing, and cross

bracing. If we take 1300#/sq.in. fibre stress and 120#/sq

in. longitudinal shear as the safe working stresses we

can compare the results. The studs and plank are within

safe values with the exception of a high shear stress in

the studd. The braces, however, are decidedly unsafe

if the effect of the auxilliary braces is omited. We must

therefore assume that enough braces were added to reduce

the high stress in the main braces to safe values.

We can therefore conclude,that with sufficient

extra bracqing,that the superstructure is safe.

4Z

The

of spans and,

a 12" lap, it

a 1

plank is a continuous beam over a number

as it is securely fastned at the ends with

can be considered as fixed at the ends,

*

12."

I'

2'

2.V

'

2'

2

/yo'rostat i c presspre

P= -"O

1=

Af Z

(utiderilu$

lY2OX

2

1_ _4X

-

Az

S=

=

i

4/2OXZ

4 2 X=4/.2o'

O

4/2 X24

-

/z X44'

JTtvd's

12-

The studs are vertical, continuous

beams with five spans (1 section).

As they are vertical they are subjected to a uniformly varying load as

the hydrostatic pressure varies with

the depth. It will be close enough for

this calculation to take an average

load on each span.

The beam is solved by the use of

the three moment equati~n.

4F

A);

+4#x+A&y= -Zui-2mi.

A,2+

-o- -2 W.;

-A 2u

Af,+4s+ Af - --

2e9AM,

-65s

-oo

-6a0'00

/ 7,'OOO

4000

-t

fGA000

Af

4

0

r *-2*

I

-,z

I~pZ000

Nx 6 X s'. F

2

**&~v

4N /d M4

/JAf4 +t6O6b-t+/'k =-3Jor -you',

/AMz

+J' M,

=-7~6-22w 4.d-2

+, ZLAI .454M -/12w -112 wj

26.Ms -/2

..........

....

..

a

-

21e

*2w.--!*

Lr

+2''

f

4.53

stad s (a

t.)

Afa

4JA-/

A

-a@

=W 42

...

4-

43040 -4S.20

,x

$652ao

/

74000/6

,~

= 768,V0004. /2

x/-*- 664i 4

r 7660 -74/S

J.

J

4

Qw

/141.

./J20~4/YO

r-= ie o

= Ma

- 7,

.yX3=

a _ y

G9Xe64

/08

Iongilvdinal Braces

/niforn load= 4X4/20= /4460A

/4so AA

2

+ 4 IA 4 J44I4~LLLLLLLLLAJ

4 1 i 141

,"

1141

4 4 4 it 411

9'

Kq4braces

q'

I

IMxA

f

are continuous beams and may be

These

cons idered as uniformly loaded, as the studs are only

two feet c. to c.

From Hool and Johnson "Concrete Eng. Handbook."

we have that the

/2 ,oooF?*=|/4 ###i.

ax A = - /0r x /648OX 9'

IX123, /72a

/2.

= .f2J0

/728

S

A- X /540eX-9= 8 4OAe'w

Ja

72x3 = 2/

69A0X2'6

/2 X/728

1''

"

0

Crosj Brace

9X4.4/A.

4 Leaad-

/44 000

*x- 722..

Acteal

(~AR.F.A.

1

F. //oo(/-,37= 7o 710

AlowaYe 4 =

if

//po~A

6

Aowever tAere is

Ma x allowa4le a- 2/ c

Sum maty

race in center

A. A E.A,

Pc

ri-a n r1

4sny' Dra ces.

Feorinv

963.

X4 Y

ae

F

-

/

d4

CONCLUSION.

Having calculated the stresses in this caisson

under the worst possible conditions that it would ever

be subjeeted to, we are now able to point out both the

strong and weak places in its construction, and suggest

improvments in the design.

Inasmuch as the stresses in nearly every case

which has been considered are below the elastic limit of

the material, and in view of the fact that these maximum

conditions in all probability would never occur, it seems

justifiable to say that the caisson is within safe limits.

In looking over the results, however, it is possible to

poimt out the good and bad features of the design. This

will be done for each case separately.

Case 1.

The results in this case seem to me to be very

satisfactory. In case 1-B the stresses are within safe

working values even under the absolute maximum condition.

Sn case 1-A the concrete and tension steel have rather

high stresses, but owing to the remote possibility oft

this case ever being realized and then only momentarily,

it would be justifiable to allow a higher stress.

Referring to the diagrams on page

it will be

seem that the stresses in the steel which comes between

the positions of the neutral axis in the two cases is very

small. It would seem that it would be better to have bunched

the rods at the top and bottom where thbir maximum strenghh

could be utilized. This point is further emphisized in

case 2, where the same conclusion is reached.

It is not possible to criticise the section of the

caisson which acts as a beam because the section is determined for an entirely different purpose, and this case

is not the limiting one.

CASE 2.

It is seen from this analysis that the fibre

stresses in the horizontal reinforcing due to the pressure

drop necessary to sink the caisson, are well on the safe

side and this in spite of the fact that no account was

taken of the resistance that would be offered by the vertical reinforcing.

In fact , the rods at section B and one or two

below this section might well have been omitted.

In the calculation of the stresses in the vertical

section, assumed to be under full hydrostatic pressure,

it was found that the stresses in both the steel and the

concrete are excessive, but here again, no account was

taken of the horizontal rods. The later will have a tendencyto resist the deformation and so help by carrying some of

the load. Even under this improbable condition of full

hydrostatic pressure, which could only last an instant, the

combined resistance of the horizontal and vertical reinforcing would probably be strong enough.

Under this condition, if we assume that the horizontal reinforcbmgnt takes the the pressure necessary to

sink the caisson, against friction, the stress in the

vertical section will be those shown on page3Y. However,

it is fair to assume that the horizontal reinforcement will

carry a greater percentage of the total load, thus reducing the stresses in the vertical sections.

The analysis of the sides of the working chamber

seem to indicate that even under the severesttconditions

it would not fail.

In the analysis of the roof, no real satisfactory

results were obtained when the six inch slab was considered.

Undoubtedly the mass of concrete above the slab resists

the upward pressure by punching shear or arch action.

Assuming that it resisted this upward pressure in shear

at the perimeter of the working chamber and allowing

40#/sq. in., the area necessary would be the total upward

pressure of 936850+5760 or 163/sq." ft. This gives a depth

of concrete of about 1.22 ft. with'the perimeter equal to

133 ft.It is on the safe side then as far as punching

shear is concerned. No analysis will be attempted on the

probable arch action, but it does seem to the authors,

that it would be possible to design an inverted arch above

the working chamber, which would have withstood the upward

pressure. This it seems,could have been done by placing

the curved rods in position before pouring the skeleton

caisson.

Case 3.

This case is extremely important as it one which

is often met with. It is not very easy to determine the

value of the load in this case, and it seemed better to

Find the maximum load which the caisson could stand concentrated on the cutting edge in this manner, and then

use our own judgement as to whether this was a value large

enough to be safe. While it is difficult to say what load

it ought to carry, the loads obtained seem to be as high

as it would seem possible to obtain actually. This load

is carried by both the cattilever and the horizontal reinforcing rods and would thus be even safer.

General Conclusion.

It seems to the authors that the value of this

analysis, is not simply the determination of the stresses

in this particular caisson, but rather an introduction to

the methods used in deep foundation work, and an insiht

into the difficulties encountered with the methods of

overcoming them. The fact that this particular caisson

was shown to be a safe structure is reatively unimportant,

but the conclusions which were obtained which would be of

use in designing another similar structure, are important.

This problem has necessitated the study of the

theory of concrete to an extensive degree, not only relative to foundation structures, but involving a number of

other subjects as well. As a study of the concrete theory

then, this thesis has been of great importance, even if

incidental to the main object.

. ...

...

..

.

.........

...

........

............

.....

...

CA J5E /-A

CA13501N 3UPPORTED IN

CENTER

CAOEI-8

CA1530N iUPPORTED AT

BOTH END3

FIG./

I

3CALE !

'

-

3UPPONrED

rkHE CA133ON WAS

ON SWAY

DURING

TWO WOR4T

LAVNCJING.

CAJEZ

TH1E

TO CONSIDR APtE

SJUPPORTING WAYJ FAIL

T(

T71 TWO CA3Z A5OVE

AN IN

ITACT5

aNetIrHICJ CON70IYON3

Wit

A,3 A

5 EAMP

-3E PAGE 6-7 FOR

DiTERMIN

COMPUTATIONS

TO

NEZUTRAL AXI3_

caeNCT!*4-2 -4

M.RUIVALENT AREA-

nli-

AXAs

OF CA /3O.50N

3 TEEL

TEQUIVALENT AREA3 OF CONCgETE

CT/ON

CRO33,5E

5

LONGITUDINAL

JHOWING

CENTER

AND /T'S

"WN-No"

'

en

00

0o

0

II

0~l-

' .! "

A

N

PLATE B

~qAcr~Iz7Iz

~4~z

31

14 0

I4

$$$$*

to"

PL..A N

ev 375

U'

ATAQ UA

RUCTU/?E

LOCATION

3CALE

RIVER ,BRIDGE

!ON

CA3ODAL

BUILT

&DEPrH

46./*

0110mo

*

1 111,

![Applied Strength of Materials [Opens in New Window]](http://s3.studylib.net/store/data/009007576_1-1087675879e3bc9d4b7f82c1627d321d-300x300.png)

![Strength of Materials [Opens in New Window]](http://s2.studylib.net/store/data/009980952_1-af573ee3f319ca71dbd5b53d99fdf436-300x300.png)