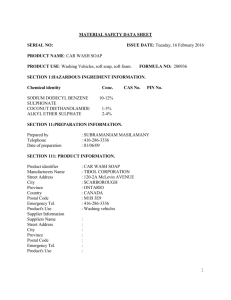

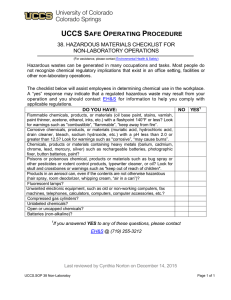

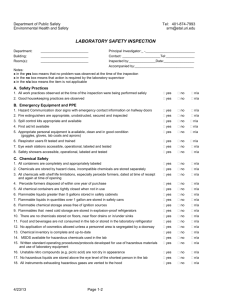

Chemical Hygiene Plan

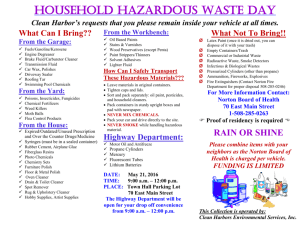

advertisement