BURNOUT NUCLEATE CONVECTION WATER

advertisement

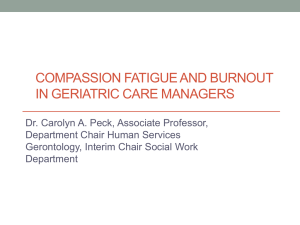

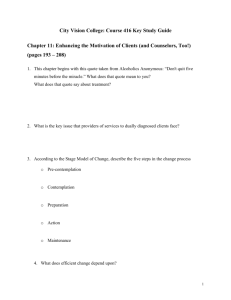

BURNOUT IN FORCED CONVECTION NUCLEATE 80N F WATER BY J. M.. REYNOLDS TECHNICAL REPORT NO. 10 OFFICE OF NAVAL RESEARCH CONRACT N~ori-07894 NONR-1 848(39) D.S.R. PROJECT NUMBER 7-7673 JY 1,1957 HEAT TRANSFER LABORATORY MCANICAL ENGINEERING DEPARTMENT MASSACHUSETTS INSTITUTE OF TECHNOLOGY CAMBRIDGE, MASSACHUSETTS Summary Data are presented for burnout in forced coivection nucleate boiling of water at pressures above 500 psia. A dimensionless correlation is devised for. the M.I.T. data which is found to be valid for certain recent data reported by Argonne National Laboratory. INTRODUCTION The nucleate boiling process is characterized by an unstable maximum heat flux which, if exceeded, results in a large discontinuous increase in surface temperature. The maximum or "burnout" heat flux is naturally of great importance to the designer of apparatus utilizing a b&iling liquid as the coolant. Recent experimental investigations of the phenomenon have yielded sufficiently reproducible data to permit correlation of data from different sources in certain flow regimes and system geometries. Burnout data recently taken at M.I.T. is presented here along with a dimensionless correlation of the forced convection burnout heat flux for water at pressures above 500 psia. Description of the test aparatus The test section used in this program consists of a 9-inch length of "A" nickel tubing, .1805 inches in internal diameter and .2105 inches in external diameter. The tube is vertical and the flow upward. Electrical heating of the test section is accomplished by passing current through the tube wall. The source of electrical power is two 3000 amp 12 volt DC generators in series which can be effectively controlled from zero to maximum output. The system consists of a closed loop with a stainless steel DeLaval Hay~.ward-Tyler circulating pump. Pressure is maintained on the system by a pressure veksel in which water is evaportted by electrical heating. The pressure vessel is also used to degass the water before each run. Distilled water is used in all runs and an ion exchanger is used to maintain the impurity level below 1 ppm NaCl. The test section instrumentation consists of inlet and outlet pressure and voltage taps and nine chromel-constantan thermocouples on the tube outer wall. The wall thermocouples are insulated from the tube by .0015 in. mica. The temperature difference across the tube wall is computed by the method of ref 1. Inlet and outlet fluid temperatures are measured 5-1/2 inches upstream end 9 inches downstream of the test section. -2- The tube is surrounded by four thermal shields, each enclosing the tube for one-quarter of its length. The shields are individually variable resistance heaters wound on aluminum tubing, which are adjusted! to the average temperature of the portion of the test section under each. The requirements of the burnout program necessitate the use of a device to prevent failure of the test section at the burnout point. This device, or burnout detector, must be one which can identify the burnout condition and take action to prevent failure, while allowing the experimentor to actually In principle, the detector relies on the fact that thermodynamic burnout occurs at the test section exit and is characterized by a large temperature rise. Actually, the detector compares the electrical attain burnout heat flux. resistance of the final 1/16" of the test section with that of the remaining These two resistances constitute two legs of a Wheatstone bridge circuit, the other two legs consisting of fixed and variable resistors of tube length. At burnout the resistance of the final length of the test section increases rapidly in relation to the remainder, causing an unbalance in the bridge circuit. suitable ratings. The net voltage at the reference point in the bridge circuit provides the input signal to a four stage DC amplifier. The output of the amplifier fires a triggering circuit which discharges a 7000 volt .10,uAf capacitor through a spark gap in the circuit breaker. The time required by the burnout detector to "decide" when a bona fide burnout has occurred is relatively long, about 6 millisec. At peak pressure and heat flux, this interval is virtually all the time available before the test section allowable overtemperature of 500 F is reached. Consequently, an instantaneous circuit breaker is required to act on the signal from the amplifier. Rapid circuit interruption is accomplished by using the . 1 0 1"f capacitor * discharge to fire an explosive cap which is contained in a hollow copper tube. The test section current flows continually through the copper tube which is one-half inch in outer diameter, 3-1/32" long, and has an .047" wall. The copper tube is restrained by a mechanical device which insures clean circuit interruption when the cap is fired and low voltage drop through the tube and * DuPont X-98-N blasting cap, #6 strength, RDX loaded for 3000 F temperature stability. -3- its connections during the run. Details of the breaker construction as well as a complete discussion of the detector circuitry will be subject of a project report to be issued shortly. The burnout detector has been an effective instrument for the study of the burnout phenomenon and is well suited to the characteristics of the process. During a run, the test section current is increased quite slowly. Therefore, any bridge unbalance due to varying tube temperature can be readily compensated by manual adjustment of the variable resistors. At high heat flux, in the neighborhood of burnout, the test section is normally almost isothermal, so that, while the magnitude of the test section resistance may vary, the resistances of the two portions of the tube remain in a relatively constant ratio to each other. This males manual ad.4pstment unnecessary near the burnout point. Almost without exception, the burnout detector has successfully prevented failure of the test section and permitted the actual attainment of the burnout condition in the test section. The fact that the detector is not firing prematurely is periodically checked by allowing a test section to fail while observing the time between the discharge of the capacitor and the appearance of steam or other evidence of failure. These two events occur simultaneously. TEST RESULTS Burnout data were taken at 500, 1000, and 1500 psia system pressure and at water inlet velocities of 5 and 10 feet per second. These data are presented in Appendix A. The apparatus used in this work has been employed for a number of years in studying the nucleate boiling process, and its limitations have been discussed in references 1 and 2. The following errors are inherent in the measurement and computation schemes: a. Heat flux is estimated to + 3% b. Flow rate is estimated to + 2% c. Inlet and outlet fluid temperatures and test section wall temperatures are estimated to + 20 F. These quantities are interrelated in three measures of heat rejection. Heat rejection may be determined from; a. The difference in inlet and outlet fluid enthalpy as measured by the corresponding temperatures and flow rate. b. The product of current and test section voltage drop. c. Summation of heat release in the nine wall sections based on the current and tube resistivity at each of the nine wall temperatures. These three computations yield the + 3% heat flux variation. Burnout data is recorded on a'l6-point Brown recorder since it is impossible to achieve steady state at the burnout point. A complete set of data extends 16 seconds before burnout occurs so that some temperature readings must be estimated to + 30 F. Current and voltage readings are printed three times during each recorder cycle, so that errors in those readings are not increased. COhiELATION OF THE DATA The Correlation Correlation of the test datta is an obviously desirable goal which, once attained, allows comparison of data from different sources. Unfortunately, the forced convection burnout process is not yet sufficiently well understood to allow one to use experimental and dimensional analysis techniques to full advantage.in determining correlation groups. Nevertheless, it is hoped that some progress may be made toward a correlation by the "brute force" technique of fitting existing data with whatever combination of properties and system parameters reduce scatter to an acceptable level. Later, these groups may be investigated in the light of present knowledge and further experiments specifically designed to tdst the correlation. In attempting to correlate the forced convection nucleate boiling process, one must be somewhat skeptical regarding the usefulness of the normally defined heat transfer coefficient. Those familiar with the forced convection boiling process will recognize that the heat transfer coefficient has meaning only at a point and, when applied to a finite length of heat transfer surface, becomes strongly dependent on the length uner consideration. In addition, a -5useful film coefficient must not strongly depend on heat flux, as it does in nucleate boiling. A further difficulty lies in the measurement of T - Tb at high pressure and high flux. Under these conditions, the temperature change across the test section wall may be 3 or 4 times the wall-to-fluid temperature difference. Such conditions enormously increase the difficulty of obtaining reliable data. For these reasons, the present correlation was undertaken with the surface-toliquid heat transfer coefficient and temperature difference specifically excluded from the list of possibly relevant parameters. In general, the properties to be used for the correlation are restricted to those which do not involve especially sentitive experimental techniques. The problem of correlating the data bec6mes somewhat more manageable if attention is directed to the region of burnout with net exit bulk quality. Under these conditions, large variations in exit fluid properties abe obtained providing an ideal area for testing groups based on properties at the burnout point. At the same time, it appears reasonable to expect that estimates of flow conditions based on average properties are more accurate in the quality region where large temperature gradients do not exist and vapor generation at the surface is at least partially accounted for in the net steam generation predicted by average flow quality. For example, in the region of burnout with subcooled exit conditions it is possible for vapor generation at the surface to significantly increase the exit flow velocity over the value average exit fluid properties. Consequent,y, the primary correlating effort was directed toward burnout with the average exit fluid condition in the two-phase region. The following discussion applies exclusively to the two phase flow regime. If one computes the various exit flow paxameters, it becomes apparent that the average exit velocity, assuming no slip between the phases, exhibits strong potentialities as a correlating factor. Quite simple relations between burnhut heat flux and exit velocity can be devised to correlate data over a reasonably wide range of conditions. For example, a plot of vexit vs. q"/Klg correlates the M.I.T. data reported in Appendix A as well as the more complicated final result presented here. It is not possible, however, to extend such a simple correlation outside the range covered by this particular set of data. A second correlating factor may be found by reasoning that, in the absence of large changes in slip ratio, the quantity of liquid adhering to the wall at -6- the exit section must become small at high quality, Since the boiling process depends on a liquid covered surface, it is reasonable to expect that the average depth of the liquid film on the surface is an important variable when this depth is small. Under these conditions, the maximum bubble diameter would be limited by the liquid film thickness. Computation of the film thickness based on all the liquid in the stream at average exit quality yields encouraging results. This term, , proves to be a strong * correlating factor. Having V0 and $ available as correlating factors, dimensional reasoning leads one to a relation of the following type: IF/D _L Correlation of the data with these groups results in the following specific relation, isq4 . /0I-2 -) (2) Discussion of the Correlation The results of applying the correlation to the M.I.T. and ANL data are shown in Figures 1 and 2. The range of operating points covered by the data correlated is: a) Heat flux from 0.6 x 106 to 2.8 x 106 Btu/hr ft2 b) Flow rate from 0.66 x 106 to 3.6 x 106 lb/hr ft2 c) Pressure from 500 to 2000 psia d) Average exit quality from 0.01 to 0.60 e) Test section L/D 50 and 76 (D of .18" and .306") The correlation may be conveniently broken down to show the predicted dependence of q" on the various flow parameters and water properties. X /) where f( ) where = ( (3) (4) -7From Fig. 3, one can see that the variation of f(x,p) is such that the correlation predicts a continuously decreasing peak flux with increasing pressure (except very near the critical pressure). It is improbable that such a relationship is valid at low pressures. The limit of validity of this particular group of properties has not been fully established; it appears to fit the experimental facts for pressures as low as 500 psia at flow rates as low as 1 x 106 lb/hr ft2 The correlation given by equation (3) indicates an inverse relationship between burnout heat flux and flow rate at constant exit fluid properties. This is contrary to the relationship reported in other operating regimes (ref. 3), specifically, with subcooled exit conditions. Both the direct and inverse variation of q" with G appear well established in specific operating ranges, but the dividing line between the two variations has not yet been clearly defined. The present correlation indicates that the inverse relationship is valid over at least the following very roughly defined region in water systems. a) Average exit bulk quality below 50% b) Pressure above 500 psia c) In the region of inlet subcooling below 2500 F on the M.I.T. test section The effect of approaching these limits may be seen in Fig. 2 in which a systematic deviation from the correlation line is observed at qualities greater than 60% or ! .06. -8Limitations of the correlation The correlation presented in this paper is inherently restricted to the prtdkction of burnout in water systems with vertical test sections and upflow. In addition, it is specifically directed toward burnouts with net exit bulk qualities. The correlation is presently untried for test section hydraulic diameters outside the range .18" to .306", the L/D range from 50 to 76, and pressures below 500 psia. In addition, the data correlated were taken with DC electrical heating and burnout was induced by increasing heat flux at constant pressure, flow rate, and inlet temperature. To date, no data have been taken to specifically test the correlation so that, in its present state, it must be recognized as tentative. In addition to the above limitations of the data correlated, the form of the parameters involved have the characteristic of greatly amplifying experimental errors in certain ranges. These parameters are, to a certain extent, self compensating. For example, a positive error in exit quality produces a negative error in the ordinate and a negative error in the abscissa tending to bring the point back on the curve. In general, increasing over-compensation exists at high quality () 60%) and low pressure. Experimental errors in the determination of exit quality are reflected in the correlating parameters according to the following relations vo ) - 4o * (5) _ (6) - Vo Errors in the direct measurements of heat flux and flow rate are reflected in quality as a function of inlet subcooling. dv (7) p/- Where AH = 1/ - is the enthalpy rise in the test section and t b is the difference between saturated liquid enthalpy (hf) and fluid inlet enthalpy. Prediction of peak heat flux from the correlation Unfortunately, heat flux is implicit in and "'P, so that it cannot be read directly from the curve for a given pressure and flow rate. A trial and error computation is required. However, experience with the correlation indicates that three trials are sufficient for an accurate graphical solution. Convergence on the predicted value is rapid and the value itself clearly defined. References 1. Rohsenow, W. M., Somma, E. H., and Osborn, P. V., "Construction and Operation of Apparatus for study of Heat Transfer with Surface Boiling", Technical Report No. 2, DIC Project No. 6627, Mass. Institute of Technology, July 1, 1950. 2. Clark, J. A., and Rohsenow, W. M., "Local Boiling Heat Transfer to Water at Low Reynolds Numbers and High Pressures", Transactions of the ASME' Vol. 76, No. 4, May 1954. 3. Jens, W. H., and Lottes, P. A., "Analysis of Heat Transfer, Burnout, Pressure Drop and Density Data for High-Pressure Water", Argonne National Laboratory, ANL-4627, May 1, 1951. 4. Weatherhead, R. J., "Burnout with Net Steam Generation in Vertical, Round and Rectangular Channels," Argonne National Laboratory. Presented at the Reactor Heat Transfer Conference, New Yos New York, November 1, 1956. Nomenclature q" G heat flux, ft-lbf/ft -hr specific flow rate, lbm/hr-ft 2 D inner diameter of test section, ft R D/2 V0 test section exit velocity based on average exit fluid condition, ft/hr test section heated length, ft change in enthalpy of a unit mass flowing through the test section, ft-lbf/lbm saturated liquid enthalpy minus test section inlet enthalpy, ft-lbf/lbm heat of vaporization ft-lbf/lbm L A H A h hfg g g conversion factor, ft-lbm/lbf-sec 2 gravitational acceleration, ft/hr2 average outlet density, lbm/ft3 saturated liquid density, lbm/ft 3 (T* surface tension at saturation temperature, lbf/ft /4, saturated liquid 'viscosity, lbm/ft-hr x mass quality, dimensionless y v vf volume quality = xvy/(vf + xvfg), dimensionless saturated vapor specific volume, ft 3 /lbm saturated liquid specific volume, ft 3 /lbm fg g f height of liquid film on heating surface at average exit fluid condition with no slip between phases, ft APPENDIX A MIT Burnout Data Inlet Temp (P) Pressure .(P sia) - 264 249 298 308 540 372 516 400 414 395 380 461 462 249 291 314 356 387 427 394 410 465 462 232 253 279 312 347 409 421 424 542 509 463 476 474 485 259 357 318 545 555 545 565 575 555 585 585 555 535 535 545 565 530 575 545 535 539 527 1035 1010 981 1020 1025 1065 1053 1015 .1020 1020 1025 1005 1005 1035 999 1015 1065 985 343 323 336 436 1015 1040 499 497 420 461 1010 1010 1055 1015 993 Flow Rate 6 (b/rft2) 10" _ Heat Flux .6 (Btu/hr-ft ) 10" Exit uality 2.10 2.12 2.86 2.80 .036 2.13 2.59 2*54 .057 2.04 1.97 2.01 1.93 2.00 1.94 1.86 1.86 1.04 1.02 1.02 1.10 0,962 0.971 0.990 0.936 0.936 0.939 2.13 2.13 2.08 2.05 2.02 1.88 1.91 1.91 1.70 1.80 1.85 1.77 1.64 1.84 1-04 1.00 1.02 0.965 1.02 1.01 0.961 0.886 0.889 0.964 0.950 2.22 2.14 2.12 2*11 2.07 1.90 1.87 2.30 2*19 2.09 2.05 2.01 2.00 1.98 1.92 1.82 1.82 2*81 .029 .089 .153 .157 .180 .173 .139 .237 .230 .260 .297 .312 .325 .393 .454 .418 .422 .470 .466 Sub. 2*56 2.55 2.39 2*18 1.97 -072 1 .82 .053 1-80 1.67 1.62 1.60 1-53 1.53 1.47 2.08 1.84 1.83 1 82 1.81 1.79 1.62 1*52 1.51 1.51 1.49 .062 .196 .208 .123 .145 .155 *138 .142 .238 .160 .196 .183 .190 .291 .440 .428 .254 .354 Appendix A (continued) Inlet Te2,M (OF) Pressure (Psia) Flow Rate 6 (lbM/r-ft2) 10 502 538 396 509 544 388 438 464 434 495 509 530 320 375 352 382 400 454 495 506 516 1009 985 975 1015 1045 1525 1525 1525 1533 1525 1515 1520 1510 1505 1485 1505 1510 1515 1510 1550 1511 0.886 0.866 0.895 0.890 0.859 1.94 1.89 1.88 1.89 1.79 1.76 1.76 1.02 0.990 0.986 0.964 0.954 0.938 0.881 0.882 0.860 Heat gu06 (Bu/rft4) 1.43 1.41 1.39 1.32 1.29 1.97 1089 1.60 10 Exit Quaity .406 .464 *381 .409 .443 Subc. It .006 1059 subc. 1.45 1.37 1.25 1.67 1.61 1.52 1.47 1.45 1033 1.21 1.15 1.14 .056 .076 .112 .019 .122 .059 .097 .127 .196 .270 . 241 .292 APPENDIX B Inlet Temp (OF) 625 613 636 595 633 586 590 627 614 635 608 613 619 587 622 623 616 613 611 612 597 598 581 624 610 624 ARGONNE NATIONAL LABORATORY Burnout Data, .18" Tube 2000 psia, L/D = 64.5 (Ref. 4) Flow Rate Heat Flux (lb/hr-fta) 10~0 (Btu/hr-ft2) 103.50 3.56 3.44 2.57 2.94 3.30 3.68 3.50 3.58 3.47 2.54 2.51 3.00 3.58 2.71 2.68 2.74 2.88 2.94 2.90 3.05 3.10 3.22 2.04 1.89 1.86 0.850 1.00 0.745 Exit Quality .094 .074 .121 0.995 .077 0.682 .118 1.15 .028 .016 .095 .077 .115 1.15 0.820 1.00 0.742 0.863 0.845 0.820 1.14 0.746 0.735 0.805 0.799 0.850 0.840 0.990 1.00 1.15 0.658 0.660 0.660 .091 .104 .090 .014 .101 .104 .091 .071 .072 .075 .048 .049 .019 .136 .102 .151 Appendix B (continued) ARGONNE NATIONAL LABORATORY Burnout Data .306" Tube 2000 psia, L/D = 76 (Ref. 4) 0.186 0.188 0.167 0.210 0.241 0.183 0.304 0.314 0.353 0.230 0.246 0.435 0.268 0.226 0.241 0.398 0.505 0.61W 0.725 0.441 0.176 .495 631 609 628 633 614 632 584 629 525 525 633 510 504 513 599 618 507 523 580 0.169 0.198 0.196 0.215 0.258 0.245 0.275 0.278 0.328 0.327 0.318 0.360 0.357 0.356 0.356 0.346 0.587 0.600 0.393 .574 .676 .580 .580 .840 .515 .407 .491 .619 .560 .470 .525 .670 .620 .459 .384 .262 .218 .403 465 627 0.534 0.550 0.595 0.346 .380 600 23 10 4 * o X 2 - 2000 psi, Argonne Not. Lab. Data 1500 psi M. I.T. Data 1000 psi 500psi / -- / J 2 2 10 6 2 4 e_/#A/ __. 0 + 30 %Z- ,0' 30 % Z I C) 0 b -x 2 -1/- 4 /4/ /s s. 4 IO -9 =|49 x10 Z / / 6 2 /9 x I .01 1. 4 2 6 4 .10 6 !.0 8 /R FIG. I- CORRELATION IN .18" OF BURNOUT 1. D. TUBES. HEAT FLUX FOR WATER 22 10 0 o C \0 21 -o- b N .01 2 4 6 8 .10 2 4 6 8 8/R3 FIG. 2- CORRELATION I.D. TUBE. OF BURNOUT ARGONNE HEAT NATIONAL FLUX WATER LABORATORY IN .306" DATA 1.0 -1I 10 2 b >, x =0.25 10 8 4 0.5 42 1.49xO q"G 1.5 D f(x, p)g, 2 -13 10 FIG. 3- 500 0 DEPENDENCE f (x,p) vs. 1000 Pressure (psia) OF CORRELATION PRESSURE 1500 ON WATER 2000 PROPERTIES