Chapter 4—Design Elements, Considerations, and Tools

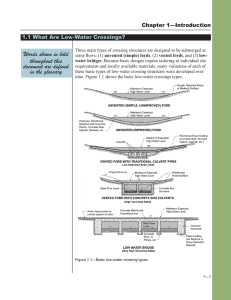

advertisement