Document 11070421

advertisement

HD28

.M414

8'^

|OCT 191989

ALFRED

P.

WORKING PAPER

SLOAN SCHOOL OF MANAGEMENT

"A Product Design Problem

in Semiconductor Manufacturing"

Florin

Avram

and

Lawrence M. Wein

NOT

Sloan School Working Paper #3075-89-MS

August 1989

MASSACHUSETTS

TECHNOLOGY

50 MEMORIAL DRIVE

CAMBRIDGE, MASSACHUSETTS 02139

INSTITUTE OF

"A Product Design Problem

in Semiconductor Manufacturing"

Florin

Avram

and

Lawrence M. Wein

MIT Sloan School Working Paper

August 1989

#3075-89-MS

OCT

1 9 1989

A PRODUCT DESIGN PROBLEM

IN

SEMICONDUCTOR MANUFACTURING

Florin Avrani

Department of Mathematics, Northeastern University

and

Lawrence M. Wein

Sloan School of Management, M.I.T.

Abstract

We

consider the product design problem of allocating the chip sites on a semiconduc-

tor wafer to various types of chips.

in sets (a specified

facility is to

number

maximize the average production rate

a reliable fashion.

A

facility sells chips to its

of several different types of chips),

rication process, in particular

sign,

The manufacturing

random

yield, poses

stochastic analysis

and to measure the improvement

traditional single-type wcifer.

The

in

is

of sets.

customers

and the objective

of the

Variabilitj' in the wafer fab-

a major obstacle in producing sets

employed to develop an

in

effective wafer de-

performance of the multi-type wafer over the

analysis reveals that multi-type wafers regularize the

production flow of non-defective chips of each type and cause these flows to be positively

correlated, both of which help to improve performance.

A

numerical example

that illustrates the analysis and demonstrates the design's effectiveness.

August 1989

is

provided

A PRODUCT DESIGN PROBLEM

IN

SEMICONDUCTOR MANUFACTURING

Florin Avrani

Department of Mathematics, Northeastern University

and

Lawrence M. Wein

Sloan School of Management, M.I.T.

It is

well-known that reducing variability

in

mance. Some of the conventional waj's to reduce

production systems

will increase perfor-

variability include the reduction of set-up

times, greater use of preventive maintenance in lieu of lengthy

machine breakdowns, the

regulation of job releases, the cross-training of personnel, and the use of statistical process control. This

paper provides an example from the semiconductor industry where the

design of the product can also reduce variability, and hence improve performance.

The key

step in semiconductor manufacturing

is

wafer fabrication, which consists of

the production of disc-like wafers about four to six inches in diameter.

the wafer

is

same

surface of

partitioned into chip sites in a grid-like fashion, and each wafer typically has

between 20 and several hundred

the

The

type.

Such wafers

technological developments

will

is

Traditionally,

all

chips on a given wafer are of

be referred to as single-type wafers.

now permit

same wafer. This development

allocate the chip sites

chips.

different types of chips to

However, recent

be produced on the

the catalyst for the wafer design problem:

on a wafer to the various types of

chips.

The

how does one

resulting wafer will be

referred to as a multi-type wafer.

This paper addresses two issues concerning the wafer design problem. The

is

to find an effective design for a multi-type wafer,

improvement

in

performance a multi-type wafer

1

and the second

is

to assess

first issue

how much

offers over a single-type wafer. In order to

define the performance

measure used

environment of the particular

this

environment

analysis

is

in this paper,

facility that

we

will first describe the

manufacturing

motivated this study; however, we believe that

typical of large semiconductor manufacturers. Moreover, although the

stimulated by a specific industry, some of our results apply to more genreal

is

production settings.

Because of the complexity of the technology and the fast-changing nature of the semiconductor industry, the yield of non-defective chips in wafer fabrication can be low and

very erratic.

Average yield rates can vary from several percent up to eighty or ninety

percent, dependiivj; r,poT;

^lie m.'3t'tnty

on wafers, and wafers are produced

and

fifty.

and complexity

in lots,

of <:he product.

where the

lot

Chio'^ pvc

size is typically

made

between

five

In this paper, three different possibihties for producing defective chips will be

explicitly considered:

an entire

lot

can be defective, an entire wafer in a non-defective

lot

can be defective, and finally an individual chip on a non-defective wafer can be defective.

As

will

site

be described in Section

1,

the yield of a particular chip type in a particular chip

depends upon both the location of the chip

In the

site

on the wafer and on the type

manufacturing environment under study, customers order chips

a set of chips consists of a specified

our particular application, a

number

set of chips are

of chip.

in sets,

where

of chips for each of several chip types.

In

required to build a circuit board, and thus

the customers are unable to assemble a circuit board until they receive a set of chips.

The

variability in yield described in the previous

paragraph makes

manufacturer to provide reliable delivery performance to

The wafer

fabrication facihty, or fab,

queues (see Kelly

[4]),

and the

is

its

modeled here as

ol>jective of the design

it

difficult for

the chip

customers.

a

problem

network of quasi-reversible

is

to

maximize the long-run

expected average number of non-defective sets produced by the wafer fab. This objective

will get the sets of chips to the

which

is

customers faster and

an overriding objective

in the

turing facility under consideration

will

hence increase customer

service,

semiconductor industry. The particular manufac-

makes chips

2

for several types of boards; however, in

order to gain insight into the natvire of the problem,

one multi-type wafer for use

in

we

restrict

our analysis to designing

assembling one type of board.

In order to produce a wafer of a particular design using traditional photolithographic

equipment, a mask

set

for a particular design

is

Therefore, the chip

be produced that dictates the circuitry design that

first

A mask

appear on the wafer.

set.

must

on the order of $20,000, and thus once a mask

set costs

produced,

desirable to produce

it is

problem described

site allocation

problem, as opposed to a dynamic control problem.

the lithographic process, then

there

is still

mask

sets

ar-r

design in this

way

in

is

K electron beam

truly a static design

machines are used

in

problem being considered by the designers

each of several hundred

Instead,

it

site.

The main

is

to

constraint that restricts the

not technological in nature, but informational. To keep track of which

in a constructive way,

is

sites

on a wafer (and then to use

such as for process control)

more

is

Our

considered too large an informational

analysis remains essentially

allocates chip sites or rows to the chip types,

problem as one of allocating chip

sites.

and we

will

is

in

each of

unchanged whether one

continue to refer to the design

To summarize, the problem considered

to allocate the chip sites (to various chip types) on a wafer that

in a highly stochastic

this information

desirable to just keep track of which chip type

ten or twenty rows on a wafer.

is

is

not necessary for wafer production. However,

allocate the rows of a wafer to a particular chip

burden.

earlier

mask

wafers with that

decision has been described as one of allocating the chip sites on a wafer

to the various chip types. Currently, the

is

many

set

the need in this case for a simple and effective mechanism to design the wafers.

The design

chip type

will

is

in this

paper

to be mass-produced

environment (a network of queues with three manners of defects)

with the objective of maximizing the long-run expected average number of non-defective

sets

produced.

This appears to be the

first

process flow of finished goods.

our knowledge

is

Singh

et al.

study that has related the design of a product to the

The only paper

[5].

They

related to the wafer design problem to

allocate the chip sites of a single wafer

3

among

cliip

types in order to maximize the probability that a non-defective set can be produced

from one wafer. Unlike our study, they assume that the yield of a chip type

is

a Bernoulli

location.

number

random

They

variable that depends only on the chip type

how

also determine

of wafers

produced

is

in a chip site

and not on the

site

the probability of completing a set increases as the

increased. Although the design derived there

may maximize

the probability of obtaining a single set from a single (or several) wafers, the resulting

wafer,

if

mass-produced,

may

not be effective in the long-run because each chip type

may

not be produced (after accounting for defectives) in the same proportions a^ the demand.

Consic'^ifir^ the cost involving ir

for the

making

a

mask

^et.

and the

fac; that the lnne-n.ir;

computer boards appears to be steady, the long-term view

demand

more appropriate

is

for

our setting.

A

deterministic analysis that considers only long-run averages

is

employed

in Section

2 to address the wafer design problem. There are two cases to analyze, depending

assumption made with regard to yield of wafers on a

Let

chip.

fi^k

upon the

equal the probability

that a type k chip allocated to site 5 on a non-defective wafer will be non-defective.

there exists positive

k.

numbers

Cg

and

^i^

such that

//jj.

=

Cgfj^ for all sites 5

H

and types

then the yield will be called multiplicative; otherwise, the yield will be referred to as

non-multiplicative. Although the yield was thought to be multiplicative in our setting,

know

of no published data analysis that addresses this issue.

The wafer design problem

variable Xgk

is

is

the fraction of site

formulated as a hnear program in Section

s

2;

the decision

devoted to type k chips; thus, the integrality constraint

that each site consists of a single chip that

The

we

of a single type

is

zero-one constrained version of the proposed

LP

is

ignored in our formulation.

will lead to

an

effective

and

feasible

wafer design; however, ignoring this integrality constraint allows for a tractable stochastic

analysis. Since there are typically

many more

sites

than chip types, very few of the optimal

Xak variables will have values other than zero or one. Thus, the performance of the integer

and non-integer solutions

will

be very

close,

4

and the LP solution could be implemented

directly for the

row allocation problem currently under consideration, without the

fear of

causing an information "explosion".

The

results of the deterministic analysis are the following:

under multiplicative yield

(non-multiplicative, respectively) the multi-type wafer will perform the

same

as (better

than, respectively) the traditional single-type case (under the appropriate mix of wafers

entering the fab). Furthermore, imder multiplicative yield, there are

mal designs. Thus, under the multiplicative

yield assumption that

practice, the naive deterministic analysis cannot distinguish

designs, or between the best iriulti-type wafer

A

stochastic analysis

is

employed

number

random

yield.

of non-defective sets completed

for renewal processes

is

A

We

Slepian inequality (see Slepian

minimum

account the variability

derive the point process

up to time

i

for

an arbitrarily-

In each case, the central Hmit

used to reduce the asymptotic (as

point process to the analysis of the

possible wafer

singlf'-type wafer.

designed multi-type wafer and for the single-type wafer.

theorem

possible opti-

believed to hold in

is

among many

in Section 3 that takes into

inherent in the queueing network and in the

that counts the

and the

many

of a multivariate

t

-^ oo) analysis of the

normal random

variable.

then employed to show that a particular multi-

[6]) is

type wafer will perform better than the single-type wafer, and to give sufficient conditions

under wliich one multi-type wafer design

condition

is

will identify

used to develop a surrogate objective function for the

an

effective wafer design.

production up to time

proportional to

The

dominate another design. This dominance

will

t

We

also

show that the

LP

in Section 2 that

difference in cumulative set

between a multi-type policy and the single type policy

is

directly

\/i.

stochastic analysis shows that

duced, and hence to maximize the

if

one wants to maximize the number of sets pro-

minimum

of a multivariate normal,

it

is

desirable to

have the covariance matrix of the multivariate normal contain large off-diagonal elements

(that

is,

positive correlation

among

the elements) and small diagonal elements. Under the

traditional single-type wafer policy, the resulting departure streams of non-defective chips

5

of each type are independent

and thus the covariance matrix has zeroes on the

ofF-diagonal,

whereas the muUi-type wafer leads to a covariance matrix that has positive ofF-diagonal

The reason

elements.

for the positive correlation

is

that entire wafers

and

wafers can be defective. Furthermore, the single-type wafer policy leads to

entire lots of

much lumpier

departure streams of non-defective chips of each type (departures of a particular type occur

whenever a non-defective

lot

of wafers of that type exits the fab) than under the multi-

type wafer pohcy (where each non-defective wafer of each non-defective

some non-defective chips

of each type),

lot

may

contain

and hence the corresponding covariance matrix has

larger diagona' elements.

In addition to offering an effective multi-type wafer design, the stochastic analysis

developed in Section 3 can also be used to plan production.

the algorithm of Clark

correlated)

mean

to approximate the

[2]

normal random

of the

In particular, one can use

minimum

of a set of (possibly

variables. This will allow the production planner to predict the

cumulative production of sets as a function of the rate at which

into the fab. Thus, a simple one-dimensional search can

lots of wafers are released

be used to find the appropriate rate

of lot releases that will attain a specified average output rate of sets.

A

naive deterministic

analysis of the production rate, which uses only average yields, ignores the time that

completed

cliips

wait to form sets, and hence overestimates the production rate of sets for

a given input rate, thereby leading to

tool

is

poor customer

not specific to the problem at hand.

variable yield that can be

modeled

service.

This production planning

For any stochastic production system with

as a quasi-reversible

network of queues, we can estimate

the cumulative production of sets as a fiuiction of the start rate of individual units that

make up

the set.

In Section 4. a numerical study

is

undertaken to assess the effectiveness of the proposed

multi-type wafer design and meas\ire

The numerical example

its

relative

assimies that yield

is

advantage over the single-type wafer.

multiphcative, and a simulation model

is

used to measure the production rate of sets for the single-type policy and several multi6

type policies.

The numerical

results

show

that, after roughly 70,000 sets

were completed,

the single-type policy had only produced SS.7% of the naive deterministic estimate of

the production rate, whereas the proposed multi-type design had produced 98.6% of the

Other multi-type

deterministic production rate.

policies

among

deterministic production rate, axid thus choosing

produced

the solutions to the

Slepian inequality has only a marginal effect on performance.

analysis did provide an accurate estimate (typically within 2

of the observed cumulative production in the single-type

stochastic analysis

is

at over

96%

of the

LP

via the

However, the stochastic

— 3%

of the simulated values)

and multi-type

Thus the

cases.

impact of a multi-type wafer design

a useful tool to assess the relative

and to plan production under any wafer design.

It

interesting to contrast the results of the detenninistic

is

Although the naive deterministic analysis

yield case,

it is

offers

an

more importantly,

analysis.

effective design in the non-multiplicative

not detailed enough to distinguish

multiplicative yield case and,

and stochastic

is

among many competing

designs in the

imable to detect the large difference

in

performance that exists between the single-type and multi-type wafers. Thus, although

the deterministic analysis of yields can be useful,

performed here

remdom

will

urge

rest

it is

our hope that the stochastic analysis

archers and practitioners to delve deeper into the problems of

yields in manufacturing, as

opposed to only analyzing

yields in terms of long-run

averages.

of

1.

The Model

A

wafer consists of

n-i

type

wafer fab

1

is

chips,

772

S

chip sites, indexed by

type 2

chips,...,

and

rtj^-

5

=

1,

...,

S,

and a

type A' chips.

set of chips is

As mentioned

being modeled as an open network of quasi- reversible queues.

composed

earlier, the

We

assume

that the network possesses a stationary distribution (which amounts to assuming that the

network

is

not loaded

stationary distribution.

up

to or

The

beyond

its

capacity),

and that

it

is

initialized

with

its

individual customers in the queueing system represent a lot

7

of wafers,

and the nodes

particular,

of the queueing network represent the workcenters in the fab. In

assumes that, under a multi-type

tiiis

policy, lots of multi-type wafers (all of

which have the same design) arrive to the queueing system according to a Poisson process

with rate

A.

For the single-type pohcy, type k

have

lots (i.e., lots consisting of wafers that

only type k chips on them) arrive according to independent Poisson processes with rate

fk\, for k

we

=

1,

...,

A',

where fk

is

the fraction of lots that are of type

derive the fraction fk that causes the average

produced to be

will

be assumed

in the

f-'^r

same

number

k.

In the next section

of non-defective type k chips

This mix of entering

relative proportions as ni,...,n/\-.

the basis of comparison, and the resulting production policy

lots

Vv-ill

be

referred to as the single- type policy.

Readers are referred to Chapter 3 of Kelly

[4]

for a definition

works of quasi-reversible queues. One possible scenario

number

of identical machines, the machines at each workcenter have the

each workcenter.

FCFS

and

same exponential

(first-come first-served)

For the single-type policy, type k lots have their

terministic route through the workcenters of the fab,

of net-

that each workcenter consists of a

is

processing time distribution, and individual lots are served

at

and examples

own

arbitrary de-

for the multi-type wafer policy,

all lots

have the same arbitrary deterministic route through the fab. As

Section

3,

will

be seen

in

the only performance measures of the queueing network that are required in our

study are the various departure processes.

For both the single-type and multi-type policies,

wafers

is

service,

defective with probability

all

independent of

will

all

be assumed that each

other

and routing information. This type of defect can occur

s£ an oven,

wafers,

5,

it

where the entire

and a wafer

lot

is

processed at once.

in a non-defective lot

other wafers in the

lot.

Tliis

is

Each

lots,

at a

and

lot of

of the arrival,

batch operation, such

lot consists of

L

identical

defective with probability p, independent of

type of defect can occur

when

wafer- by- wafer operations

are performed.

Let

Y'ak

be a random variable that takes on the value of one

if

a type k chip allocated

to site s of a non-defective wafer

(When

non-defective, and takes on the value of zero otherwise.

considering the problem of allocating rows of wafers, the variable

values larger than one.)

Hsk and

respectively.

(7^1^,

independent for

defective chips

The random

where

is

=

fik

Friedman

=

5

Then

the expected value and variance of

It will

1,...,S

Y^i; will

be given by

and k

=

1,..., A'.

Let Y^

=

5Z,=i ^sk be the number of non-

on a non-defective type k wafer (a wafer consisting only of type k

X]^_j

//»*:

and al

=

example) have

for

X^,=i ^Ik-

Many

and

studies (see Stapper

cr^,

[8]

chips).

respectively,

and Albin and

verified that the defects generated in wafer fabricaLion

tend to cluster, causing the variance of the random variable

n:iuch larger

can take on

be assumed that the random variables Ysk are mutually

variable Yk has expected value and variance given by ^k

[1],

1\,^

Y'k

to

be very high, sometimes

than the mean.

The assumption

analysis; however,

it

multi-type policies.

of

independence across

sites of

a wafer

is

not crucial to our stochastic

does allow for a convenient comparison between the single-type and

Moreover, this does not appear to be an overly stringent assump-

an entirely defective wafer has already been

tion, especially considering that the effect of

captured.

Recall that the decision variable for the wafer design problem

fraction of site

.s

[0,t]

under the single-type (respectively, multi-type)

goal

is

is

to solve the wafer design problem,

2.

The

policy.

to choose x^t to

is

process F{t)

maximize hm,_oc

and to compare

optimal design with ]init^oo t~^ F[N{t)], which

under the

which

is

the

number

have departed from the fab during the time interval

dependent, and the wafer design problem

Our

Xgk,

Let N{t) (respectively, F{t)) be the

allocated to type k chips.

of sets of non-defective chips that

is

is

design-

t~^ E[F{t)].

lim^-^oo i~^F[F{t)]

under an

the corresponding performance measure

single- type policy.

Deterministic Analysis

In this section, a deterministic analysis

9

is

undertaken that ignores any variablility

—

in the

'

production process and in the yield process, and looks only at long-run average

values.

We

begin with the single-type case, and then proceed to the multi-type case. The

single-type case

is

considered primarily as a basis for comparison against the multi-type

case.

In the single-type case, each lot of wafers consists of only a single chip type. In order

to analyze the performance of

tliis

case, a

product mix must be specified; that

is,

the

proportion of lots that are released into the fab that are of a given chip type.

Recall

non-defective type k chips are required to form a set, and the average

number

that

nic

of non-defpclive chips

on average,

it

on

a

non-def?ctive type k wafer

Uk for

is

/:

=

1

K. Therefore,

takes n^/ fik non-defective type k chips to form a set, and thus the average

fraction fk of starting lots that are of type k should be

^.i^^-

=

/.

(2.1)

Notice that the average total number of non-defective wafers of

form a

all

types that

it

takes to

set is Ylk=ii^^k/ fJk)-

In the multi-type case, the product design problem can be formulated as the linear

program (LP)

1

max min

T,k

{

l<k<h

771-

^

"S^ Hsk^sk}

(2.2)

'^—

K

subject to

/^

*.

where Xsk denotes the fraction of

The multi-type

=

1

xsk

>

0,

for

=

.s

(2.3)

1,...,5,

(2.4)

site 5 that is allocated to

type k chips.

case will be further distinguished between the multiplicative case and

The expected

the non-multiplicative case.

exists a set of

^ai

=i

5 nonnegative

Hsk

=

constants

Cs

c^fjk for all

yields

/j^jt

summing

.<!

=

10

1, ...,

will

to

be called multiplicative

if

there

one such that

S]k

=

1,

...,

A'.

(2.5)

If

condition (2.5) does not hold, then the yields will be referred to as non-multiplicative.

Since X^g_i Cg

=

1, it

follows that the term

a non-defective type k wafer,

The two

/Vjt

appearing in (2.5)

which was defined

it

factors that affect the expected yield ^sk are the circuit density of type

becomes more

difficult to

As the

versus location surface

is

circuitry of a chip

rehably produce the chip. Also, for

more apt to

are certain parts of the wafer that are

assumes that these two

independent fashion

this condition

test this

in

tells

The

yield

us that some sites

and

location, behave in an

determining the resulting yield of a type k chip in

was thought to hold

in

our setting,

it is

assumption when possible. See Stapper

(2.5) holds, then

LP

max

yield

and

(2.2)-(2.4) can

clear that

[7]

site s.

one wants to

Although

collect

and references therein

for

data

more

location.

be rewritten as

(2-G)

y

y,i,k

Condition

regardless of the chip type.

sites,

factors, circuit density

on the complicated relationship between

When

chip types, there

donut-shaped, with the lowest probability of success occuring in

achieve inherentlj- higher yields than other

(2.5) effectively

all

A-

becomes more

yield non-defective chips.

the middle and at the periphery of the wafer. This yield surface

and

the expected yield for

in Section 1.

chips and the location of site s on the wafer.

dense,

is

s

subject to

\

y

s

—

<

Cg^sk

for k

=

1, ...,.

1

K

^x,, =

1

for.s

=

(2.S)

l,...,S,

*r=l

>

:csk

Let

TT

(2.7)

=

(tti,

and

...,

TT/^)

and

')

=

(2.8), respectively.

(2.9)

0.

(71, ...,7s)

be the dual variables corresponding to constraints

Then the dual LP

is

S

mm

in 5^7.

(2-10)

3=\

subject to 7,

>

^'^^^""^

iov s

11

=

l,...,S;k

=

l,...,K,

(2.11)

Y.^k = h

(2.12)

it=i

^k

If

the constraints (2.11) are

>

0.

summed

(2.13)

over s

=

1,

...,

S, then

we obtain the relaxed dual LP

s

minVi,

(2.14)

s=l

S

subject to

y"7^ > ^^^

=

for k

1,...,A',

(2.15)

*

3=1

K

Y.^k =

(2.16)

l.

>0,

TT,

(2.17)

which can be rewritten as

mm

ni,

max

(2.18)

i<k<K nk

K

=

subject to J^TTjt

k=\

TTjt

The

solution n* to this

LP

>

(2.19)

1,

(2.20)

0.

is

K

= "''^"'^~'forJl- =

-(E-

<.

and thus the optimal objective function value

l,...,7^,

to the relaxed dual

Therefore, an optimal solution to the original dual

LP

(2.21)

LP

(2.10)-(2.13)

is

{^k=i[nk/ ^ik))

is tt*

and

A'

i:

Since

tt^

>

for h

=

= Cs{V'^)~'iovs =

all

binding in the optimal

l,...,A,

(2.23)

the A' primal constraints (2.7) are

1, ....A',

(2.22)

\,...,S.

solution. Since the set of equations

^Vc.x., = (V^)-^forA- =

s=\

k=\

K

^x,;. = Ifor

k

=

.s

\

12

=

1,...,5,

(2.24)

are rediiiidaiit. there

aiT,

in general

many

solutions to the primal LP.

Thus we have proven

the following.

Proposition

all

Notice that (a)

tells

mix

(2.2)-(2.4) is (X^t=i(^*;//u

))

,'

(2.1), the

not unique.

us that the optimal

equal to (X^;t=i("*//^'^'))

uct

LP

the constraints in (2.7) are binding; and

(c) the solution to (2.2)-(2.4) is

is

(2.5),

optimal objective function value of the

(a) the

(b)

Under condition

1.

average

number

of sets

from a non-defective wafer

Recall that under the single-type policy under prod-

•

number

of non-defectiv? wafers rf^qr.ired to obtain a

=:pt

wa?

Thus, under the multiplicative yield assumption, there appears to be no

^;._j(njt//-'A)-

advantage in using multi-type wafers. This

various chip types behave similarly across

is

because the relative expected yields of the

sites.

However,

this deterministic analysis ig-

nores the variabilij' in the production process and the queueing of chips that takes place

The

before they are assembled into sets.

lem, and will indeed

show that there

is

next section will take a closer look at this prob-

a significant difference

between the single-type and

multi-type policies. Furthermore, the analysis in the next section

which of the many solutions to the

Before finishing this section,

tive

assumption that

better in

some

sites

is

feasible for

which

is

the

LP

(2.2)-(2.4)

sites relative to

non-multiplicative case

is

the non-multiplica-

other chip types. Observe that

.>.

=

l,...,S-k

=

1,...,A',

(2.25)

and achieves the objective function value (X^,=i("j/^'j

))

'

as the single-type case. Thus,

The optimal objective function value of LP

2.

under the single-type

LP under

In this case, certain chip types can perform

for

same performance

Proposition

us return to the original

"^^'"^

= /^=

choosing

(2.2)-(2.4) will yield the best design.

(2.5) does not hold.

than other

a-,;.

let

LP

will aid us in

(2.2)-(2.4)

under the

greater than or equal to the corresponding performance measure

policy.

13

3.

Stochastic Analysis

The

stochastic analysis in this section assumes that the multipUcative assumption

(2.5) holds.

However,

in the non-multiplicative case, a similar analysis

compare the performance

of the optimal multi-type policy

to the single type policy.

If

(i.e.,

can be used to

the solution to (2.2)-(2.4))

LP

there happens to be multiple solutions to the

in the non-

multiplicative case, then the analysis can also be used to help decide which solution will

lead to better performance.

Single-Type

3.1

Poiic;,'.

We

bf>gin this :>ection

—

Recall that under this policy, lots of type k

by cmalyzing the single-type

1,...,A' enter the fab

pendent Poisson processes with rate /^A, where fk was defined

an open network of quasi-reversible queues,

non-defective type k lots from the fab

pound Poisson process Dk{t)

= ^,=i

Since the fab

in (2.1).

=

Wi, where Wi,i

(1

—

q)fk^-

Our assumptions

= ^^^

is

a com-

aie independent

and

variables with parameters £, the lot size,

and

1, ...,Ak{t),

Let Nk{t) be defined by

p, the probability of a non-defective wafer.

Nk(t)

is

follows that the departure stream Ak{t) of

Poisson with rate

random

identically distributed (iid) binomial

—

according to inde-

imply that the departure process of non-defective type k wafers

in Section 2 also

1

is

it

policy.

^—J >

0, for

k

=

A',

1

(3.1)

no-

where y\

For k

=

,i

=

!,...,!?<..(/),

1,...,A',

it

are iid

random

follows that E[Nk(t)]

=

variables having the

at

and

Var[A'jt(/)]

=

same distribution

sit,

as Yk-

where

{l-q)\Lil-p)

and

'1

=

11k-

^^\

\Lil- Pyi +

^^iL{\

Furthermore, notice that the A' processes {Nk{t),t

pendent.

14

-

P)P

> 0},k =

+

L'{1

- pYf,i

1,...,A", are

I

.

(3,3)

mutually inde-

Recalling that

of sets

njt

type k chips are required to form a

produced by time

is

t

mini<t</v-

[A''jt(/)J

,

where

[x\

—

For simplicity, we choose to analyze the process N*(t)

set,

it

number

follows that the

denotes the integer part of

which

mini<j.</^- Nkit),

x.

will lead

to a negligible error since

min \Nk{t)\-N*(t)\<liovallt>0.

(3.4)

I

It

follows by the central limit theorem for renewal processes that, for k

Nkit)

-

at

^,

=> Ajt as

j:

—

<

=

1,

...,

A',

^

cx),

>

^

(3.5)

y/t

where A't

~

^'(0. si),

normally distributed with mean zero and vaiicince

i.e.. A';, is

^^., aiivi

=> denotes convergence in distribution. Thus,

<

lim Pr{N*(t)

+

x\fi

ai)

=

\

- hm TT Pr{Nk{i) > xVi +

k

at)

:3.6)

=\

= (i-n('-*(^)))where $

is

(S'-)

the cumulative distribution function of the standard normal.

Thus we can

analyze the asymptotic performance of the single-type policy by studying the

A' independent

normal random

Notice that

relatively

s^.

in (3.3)

few chips in a

variables; this point will

decreases as

increases,

77;-

be pursued further

minimum

in

of

Section 3.4.

and thus the chip types that have

tend to cause the burstier, or more variable, departure

set will

streams, since these chip types will not be produced very frequently.

3.2.

type policy.

lots

Multi-Type Policy. A

By

similar analysis will

from the queueing network

= ^,=1

to the multi-

the quasi-reversibility assumption, the departure process of non-defective

is

a Poisson process A{t) with rate A(l

the departure process of non-defective wafers

D{t)

now be apphed

W'j,

where

variables with parameters

H',,

?

=

L and

is

given by the

—

q).

Therefore,

compound Poisson

l,...,A{t), are again binomially distributed iid

I

—

p.

E[D{t)]

process

random

Thus,

=

X{1

-

15

q)L{l

- p)t

(3.8)

and

= HI -

Var[I>(<)]

Recall that the wafer design

A",

1

where x^k

is

q)t[L{l

- p)p + L^l - P?].

defined by the decisions Xgk,s

is

(3.9)

=

1,...,5,

and

the fraction of site 5 allocated to type k chips. Define the

=

k

random

variables Vgk by

il^

=

Vsk

=

for 5

1,

...,

S;k

=

\,

...,

K.

(3.10)

nk

Then

these mutually independent

random

variables,

^-^^^-^

and Var[F,,]

which are dependent upon the design,

have

E[V,k]

-

^^^.

=

=

Define Tk

Yjs=i

^

'«'-'

^^ *^^*^

s

= 5]

E[Tk]

Let F(t)

=

(Fi(/),...,FA.(f))

variables distributed as Tk/.

It

follows that E[Fk{t)]

Sji-f for j

^

k,

(3.11)

nj^

rik

=

:^

s

and Var[r,]

be defined by Fk{t)

=

Then mini<jt<A' [•f"fc(OJ

bkt, Var[F^.(f )]

=

=

J]

2

^2

:i^.

EJ^i^^I''' ^^^ere

is

the

Eu-^ for k

number

=

1, ...,

(3.12)

T^.''

of sets

A',

are iid

random

produced by time

and Cov[F,(/),

Fkit)]

=

where

s

bk

=

A(l

- q)L{l-p){y

^

S

+

A(l

2

f:iMiliL),

(3.13)

"'^

2

- q)[Lil-p)p + L'{l-p)']{J2 ^^^^^)\

(3.14)

and

S

^^k-Hl-q)[L(l-p)p +

LHl-p?]{Y.^){Y.-^^Ik

Recall that one of the goals of this section

case (2.5), an effective design x^k from

S

among

16

is

the

(3.15)

to choose, for the multiplicative yield

many optimal

solutions to the dual

LP

In the rest of this section,

(2.2)-(2.4).

LP

(2.2)-(2.4)

under condition

we

will restrict ourselves to designs i^jt that solve

However, as noted

(2.5).

performed under the non-multiplicative yield

Proposition

for k

—

1,

...,

limit

where a

A',

is

LP

=

(fej

theorem

,

..., 6fc ),

in (3.13) satisEes bk

=

a

defined in (3.2).

which equals

(a,

a)

...,

1(a), (2.1), (3.2),

by Proposition

3,

and

(3.13). |

and we have, by the central

for renewal processes,

^

Z ~

deHned

(2.2)-(2.4), then bk

F(i)' -bt

where

can be

case.

This follows directly from Proposition

Proof.

Let 6

Ifx^k solves

3.

earlier, a similar analysis

which

A^(0, T.),

covariance matrix S, where

Letting F*{i)

=

is

=»

is

as

<

-^ oo,

(3.1G)

normal random variable with mean zero and

a multivariate

S

Z

defined in (3.14)-(3.15).

mm\<,k<h' Fk(i) and denoting the kth component

of

Z by

Z;-,

we

have

Urn

Pr{F*{t)<x\/i + at)^

1

- Pr(

mm

Z^ >

x).

(3.17)

Thus, the asymptotic performance of the multi-type policy can be analyzed by studying

the

minimum

3.3.

A

of Slepian's

of A'

dependent normal random variables.

Comparison of

lemma

Proposition

Policies.

(see Slepian [6]) that

4.

Let

X

=

We

is

(Xk) and

begin this section by stating a generedization

due to Kahane

Z =

[3].

(Zk) be normal

K — dimensional

vectors

such that

E[X,Xk]<E[Z,Zk]i((j,k)eA,

E[XjX,] > E[ZjZk]

if (j,A-)

E[XjXk] = E[ZjZk]

if (j,

17

e B,

k)^AW B.

(3.18)

Let f{x

=

)

f{xi,...,Xk) be a function defined on

df

with second derivatives satisfying

>

if

{j,k) e A,

<0

if

(i,A-)

dxjdxk

df

R^

dxjdxk

6 B.

(3.19)

ThenE[f{X)]<E[f{Z)].

With the

aid of the Slepian inequahty,

we

will provide a multi-type

poHcy that out-

performs the single-type policy.

Proposition

Provf.

For

5.

j

/

k. Iljk

Ti:i> itsi;!: Jollovvs fioiu

>

and

is

independent of the design Xsk-

Proposition l(b} and (3.15).

B

Let us again consider the design

defined in (2.25).

Proposition

matrix

satisfies

^^k <

Proof. From

--kk

-

2

s^

For the design Xsk defined in (3.20), the corresponding covariance

6.

sj.

(3.3)

X{1

=

for k

and

-

—

1,...,A'.

(3.14)

q)[L{l

we have

- p)p + LHl - pf] f

1

^^

+ Ml-,)Lil-p)(Y^C-i^)

The

first

term on the righthandside

is

1

:\

(3.21)

).

non-positive since X^,=i(^j/a'j)

^

^k/ftk-

Under

design (3.20),

.2

„2

3

s=l \

^k

k

J

2/1

/U-"itE;=l("j//^j'

^

1

>

'

and hence the second term on the righthand

side of (3.21)

18

is

<

also non-positive

0.

(3.22)

Proposition

Under design

7.

,.

Hm

B

—^^ >

E[F*{t)]

-^

,.

lim

E[N*it)]

^

!-^.

3.23)

This follows from central limit theorems (3.5) and (3.16), and Propositions

Proof.

4-6,

(3.20),

where, in Proposition

4,

the set

A

corresponds to the diagonal elements and the set

=

corresponds to the ofF-diagonal elements, and f{x\^...^Xf^)

Although design (3.20) outperforms the single-type

able multi-type design.

design, one wants to

make

Prc-positions 4

(2.2)-(2.4),

it

follows

and

5, it is clear

it is

|

..., a-;^-).

not necessarily a desir-

that in order to find an effective

the diagonal terms Tjkk of the covariance matrix of F{i) as small

In particular, since n'^

as possible.

LP

By

policy,

min(xi,

X^s=i

-i^

sk^sk

is

from (3.14) that the terms

a constant for

nl"^ Yfs=\

designs that solve

all

^Ik^lk^^

=

1'

•••.

A'

need to

be made as small as possible.

We now

propose two mathematical programs (that

differ

tions) that should lead to effective, not optimal, designs.

straint set (2.4)

and

(2.23)-' 2.24),

only by their objective func-

Both programs have the con-

which has the same form as the constraints of a trans-

portation problem; this constraint set guarantees that a feasible solution will be an optimal

solution to

LP

(2.2)-(2.4).

The two

objectives are

--EE^^^

(3.24)

and

min max

V^^iJ^.

5=1

(3.25)

^

Although objectives (3.24) and (3.25) may both lead to an

(3.25) will lead to a

effective design, objective

problem with non-linear constraints, which

than the quadratic program generated by objective (3.24).

the popular assumption that Y^k are Bernoulli

19

random

It

will

be harder to solve

should be noted that under

variables for

all 6

=

1,...,S

and

k

=

1,...,A'

(and the yield

and

If

is

E^

the variables

were

x^jt

math programs

asymptotic

(i

—

>

t

)

normal random

an iterative approximation

(it is

normal random

these estimates by c^

and

f.

still

(3.7)

=

and

c.

Csfk),

depend on

x^jt,

and hence

and

(3.17).

it

follows that an

variables.

[2]

Using

his approximation,

minimum

has developed

moments

=>

mm(Ai,

of

we can estimate

Zj^)] and, for the sake of concreteness, let us

by

of sets

denote

(3.5) that

...,Xk) as

r

—

>

oc,

(3.2

1

)

c^y/i

+

at.

(3.28)

C:Vi

+

at.

(3.29)

be estimated by

and E[F'(i)]

will

—

(3-26)

2) technique to calculate the

Notice that the quantity at appearing in (3.28) and (3.29)

Cj-

Cg^ki^

we can estimate E[N*(t)] by

Similarly, E[F*{t)] can

of E[N'{t)]

=

variables, hi particular, Clark

c-, respectively. It follows

r=

for large

fisk)

can be performed by studying the

exact for A'

^h')] and E[vmn{Zi

£'[min(A']

—

and F*{f), which are the cumulative number

for the various policies,

of A' (possibly dependent)

and thus

but the second term would

oo) analysis of A'*(f

of A'

/is/t(l

are not trivial in this case.

produced up to time

minimum

=

term on the righthand side of (3.26) would

Asymptotic Performance Analysis. By

3.4.

the

1,

a^^^

^Ec.xL-4E^^-^.-

=

integer, the first

all

be a constant by Proposition

the

multiplicative), then

be negative

if

is

the deterministic estimate

there was no variability in the production system.

(recall that

A"

and Z have mean

zero),

it

follows that the

naive deterministic analysis overestimates the actual cumulative production of

20

Since

sets.

The

difference in expected cumulative production

type policy grows in proportion to

and

\/i,

between a multi-type policy and the

approximated by

is

{c^-c,)Vi.

(3.30)

Thus, although the average production rates of the two policies both converge to

difference in the cumulative production

4.

A

being addressed

we

the

between the two pohcies diverges.

present a numerical example that

data from an actual

=

o,

Numerical Example

We now

A'

single-

is

As mentioned

V)ased

is

on disguised, but representative,

in the Introduction, the

problem currently

to allocate rows of a wafer to various chip types.

Our example has

facility.

4 chip types and ten rows, but to keep consistent with past notation and terminology,

will refer to the

rows as

sites,

fraction of a particular row that

A

made up one type

set is

=

4 chips, and so n^

20" rule to hold here:

yield

assumption

(1,

25%

=

(.05

10.

Readers should interpret Xak as the

allocated to type k chips.

chip,

1.3,20) for k

one type 2 chip, three type 3 chips, and twenty type

=

1, ...,4.

It is

and the related data

.05

.07

uncommon

not

of the chip types account for

(2.5) holds

c,

1

is

=

and thus S

80%

for the universal "80-

of the set.

The

multiplicative

is

.09

.09

.11

(3G

72

48

.13

.13

.14

.14)

(4.1)

and

/;i

Recall that

The

figk

lot size

=

L =

Cgfj.^

=

can be greater than one since

20, the probability of

defective wafer in a non-defective lot

is

a defective

p

=

.12,

CO).

.s

(4.2)

indexes an entire row of the wafer.

lot is ^

and the

=

.05,

the probability of a

arrival rate A of wafers,

which

does not affect our analysis, equals one. Finally, the transpose of the matrix of variances

21

a;^

given by

is

_

~

2

'^''^

The

policy

is

2

40

45

4

4

24

3

38'

4

42

15

40

44

12

30

12

18

15

20

4

10

18

30

2

44

4

18

20

20

4

14

14

4

20

40

40

4

4

6

20/

calculation (2.1) of the fraction of starting lots fk of type k for the single- type

given by

=

(4/63

2/63

48/63).

9/63

(4.4)

The

Five different policies were tested in our simulation experiment.

'ynp policy Menotec' by SINGLE

m

Table

and k

=

One

The design

6.

*;

(2.25),

first

policy

lots arc released

The

in''':

where Xsk

=

fki for s

=

1,...,10

were derived by solving mathematical programs.

last three designs

that solves the quadratic

program

(3.24), (2.4), (2.23)-(2.24) will

be denoted

the design that solves the program (3.25), (2.4), (2.23)-(2.24) will be

MINMAX. The

last

design solves

A'

S

2

z.k

2

(4.5)

^

k=l s=l

subject to (2.4). (2.23)-(2.24). This design, which will be denoted by

it

the

policies are multi-type

maxVy^l^

ni

f-^ ^-^

because

is

Recall that this design was proven superior to the single-type design in

MINSUM, and

denoted by

(PROP)

the proportional design

1,...,4.

Proposition

by

is

where type

I),

The other four

the fab according to the product mix in (4.4).

policies.

(4.3)

I

A-

?ing!?

^

should lead to an ineffective design,

(2.24), thus enabling us to assess the

among

MAXSUM,

was tested

the designs that solve, (2.4), (2.23)-

range of performance

among

different

mult i- type

wafer designs.

For

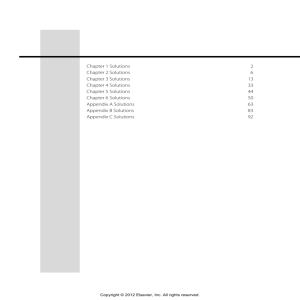

all five policies

tested, 100 independent runs

were made, each consisting of 2000

time units. For each policy, the cumulative production at times

and 2000 were

Table

I.

collected, along with

In Table

II,

95%

confidence intervals.

we present the percentage improvements

type policies over the single-type policy

at

time

99

t

=

2000.

t

The

in

=

250, 500, 1000, 1500,

results are displayed in

performance of the multi-

The cumulative production

at

time 2000

is

would occur

also expressed in this table as a percentage of the ideal production rate that

in a deterministic

environment.

CUMULATIVE PRODUCTION AT TIME

POLICY

t

=

250

f

=

500

t

=

1000

t

=

1500

t

=

2000

SINGLE

67S9(±356)

1565S(±467)

33146(±687)

49894f±969)

67792(±1150)

MAXSUM

S58G(±214)

17897(±290)

3652G(±396)

55116(±529)

735S0(±C18)

PROP

9229(±126)

18671{±179j

37240(±259)

55S34(±303)

74325(±335)

MINMAX

947G(±13S)

18815(±193)

37425(±253)

56275(±300)

75251(±350)

MINSUM

9526(±133)

18871(±171)

37633(±225)

56375(±296)

75342(±354)

TABLE

The

in

results

I.

Cumulative Production of Sets

show that the two proposed multi-type

cumulative production

at

time

MINMAX

and

MINSUM,

difference in cimiulative production

it

among

appears that any solution to the

effective in increasing the

an 11% improvement

=2000. Notice that percentage improvements are much

t

higher for lower time values, and are as high as

proposed pohcies,

policies offer

LP

production of

40%

at

time

f

both outperform

=

250.

Although our two

MAXSUM,

the multi-type poHcies

is

the percentage

relatively small. Thus,

(2.2)-(2.4) in the non-multiplicative case will

sets.

Therefore,

among

be

these policies, the designer

should probably allow other factors, such as ease of design, to dictate the wafer design

decision.

In particular, the

constraint set,

such as

and

MINMAX

and

MINSUM

solutions are interior points of the

so have mostly non-zero elements, whereas other less effective objectives,

MAXSUM (or MAXMIN) lead to more easily implemented extreme point solutions.

23

PERCENTAGE

POLICY

PRODUCTION AS

IMPROVEMENT OVER

A PERCENTAGE

SINGLE-TYPE POLICY

OF UPPER BOUND

SINGLE

88.7%

MAXSUM

8.5%

96.3%

PROP

9.6%

97.2%

MINMAX

11.0%

98.5%-

MINSUM

11.1%

98.6%

TABLE

II.

Comparison of Cumulative Production of Sets

at

Time

t=:2000.

However, the performance of the muUi-type policies seem even more impressive when

expressed as a function of the deterministic upper bound.

production at only

71%

of the deterministic rate at time

deterministic rate at time

t

the deterministic rate at

=

best multi-type

t

=

pohcy (96.3%.

2000, whereas the

The

t

MINSUM

=

single-type pohcy achieves

250 and only 88.7% of the

policy produces at 98.6% of

2000. In this light, the improvement from the worst to the

to 98.6%)

is

quite significant.

Although our analysis has been restricted to the case of one multi-type wafer design, an

important consideration

if

is

the marginal improvement in performance that can be attained

several distinct wafer designs were used to satisfy the

demand

release decisions of the various multi-type wafers does not

for sets.

If

the dynamic

depend on any state-dependent

information such as the resulting yields, then the upper bound on the performance of such

a policy

is still

that very

little

the deterministic production rate.

Therefore,

we conclude from Table

can be gained by using an additional wafer design, and thus

that the cost of a second

mask

set

it is

unlikely

would be covered by the marginal improvement

production. Moreover, recall that with electron

24

beam

technology, there are no

II

mask

in

sets,

and

a different multi-type design could be used for each lot of wafers entering the fab.

Table

is

II

suggests that very

little

used to satisfy demand with

production

will

be sacrificed

this technology, unless a

more

if

a single multi-type wafer

intelligent

(dynamic, state-

dependent) release policy were implemented with several (or many) distinctly designed

wafers.

TIME

t

=

2o0

t

=

500

t

=

1000

t

=

1500

t

=

2000

SIMULATED

TIME

References

[1]

Albin,

S. L.

tions in

[2]

J.

(1988).

IC Fabrication. To appear

Clark, C. E. (1961).

Research

[3]

and Friedman, D.

Kahane,

9,

in

The Greatest

The Impact

Management

of Non-Poisson Defect Distribu-

Science.

Random

of a Finite Set of

Variables. Operations

145-162.

J. -P.

(1986).

Une

Ineqalite

du Type de Slepian

et

Gordon sue

les

Processus

Gaussiens. Israel Journal of Mathematics 55, 109-110.

[4]

Kelly, F. P. (1979). Reversibility

and Stochastic Networks. Jolm Wiley and Sons, New

York.

[5]

Singh,

of

M.

R.,

Abraham, C.

T.,

Components When Yield

and Akella, R. (1988). Planning

is

Random.

Fifth

IEEE

for

Production of a Set

CHMT International

Electronic

Manufacturing Technology Symposium Proceedings.

[6]

Slepian, D. (1962).

The One-Sided

Barrier Problem for Gaussian Noiso. Bell System

Technical Journal 41, 463-501.

[7]

Stapper, C. H. (1985). The Effects of Wafer to Wafer Defect Density Variations on

Integrated Circuit Defect and Fault Distributions.

IBM Journal

of Research and De-

velopment 29, 87-97.

[8]

Stapper, C. H. (1986).

The

Defect-Sensitivity Effect of

of Solid-State Circuits SC-21, 193-198.

27

Memory

Chips.

IEEE

Journal

.52

Date Due

APR IS

mY3l

19S4

Lib-26-67

MIT IIE1RARIE5

3

TDfiO

OQSflBTSb

S