iiliii

advertisement

iiliii

M.f.T.

U'^*^'.^fi

-

D^^WEY

HD28

.M414

@

Dewey

ALFRED

P.

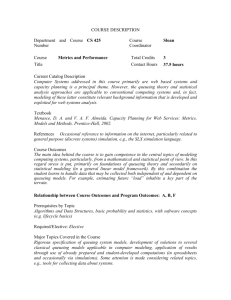

WORKING PAPER

SLOAN SCHOOL OF MANAGEMENT

Product-Form Make-to-Stock Queueing

Networks

Rodrigo Rubio

Lawrence M. Wein

#3672-94-MSA

April 1994

MASSACHUSETTS

INSTITUTE OF TECHNOLOGY

50 MEMORIAL DRIVE

CAMBRIDGE, MASSACHUSETTS 02139

Product-Form Make-to-Stock Queueing

Networks

Rodrigo Rubio

Lawrence M. Wein

#3672-94-MSA

April 1994

Product-Form Make-to-Stock Queueing Networks

Rodrigo Rubio

Operations Research Center, M.I.T.

and

Lawrence M. Wein

Sloan School of Management, M.I.T

Abstract

A

manufacturing

unsatisfied

amount

falls

demand

is

facility

produces multiple products in a make-to-stock manner, and

backordered.

A

simple production control policy

is

analyzed:

when

the

of work-in-process inventory plus finished goods inventory for a particular product

below a base stock

level,

then release another unit of product onto the shop

floor.

Under

a set of stationarity assumptions, we show that the cost minimizing base stock level for each

product

satisfies

a critical fractile expression for the steady state distribution of the products

total work-in-process inventory.

By

exploiting the relationship between the make-to-stock

system and an open queueing network, we identify

specific formulas for the base stock levels

under standard product-form assumptions. For the

lost sales case, a similar relation to a

closed queueing network can be used to characterize the optimal control parameters.

April 1994

1.

We

Introduction

consider a manufacturing system that produces a variety of products in a make-

to-stock mode; that

is,

completed units enter a finished goods inventory that services ex-

ogenous customer demand, and unsatisfied demand

this

backordered.

is

Production control

in

production- inventory environment has been moving away from the push philosophy em-

bodied

in materials

typified

ment

by kanban systems.

for

(MRP)

requirement planning

systems, and towards the pull philosophy

Unfortunately, kanban control policies are difficult to imple-

multi-product systems, particularly

if

a different buffer

level is set for

each prod-

uct at each production stage. Moreover, even single-product kanban-controlled production-

inventory systems axe difficult to analyze

(see, e.g.,

Mitra and Mitrani 1991), and to our

Mo-

knowledge, multi-product kanban systems have not been analyzed in the literature.

tivated by the difficulty of implementing

and analyzing kanban

policies in multi-product

production-inventory systems, we propose and analyze a very simple pull-type production

Our

control policy for a multi-product make-to-stock environment.

simpler or more natural: release a

total work-in-process

(WIP) plus

new

unit of a product onto the

finished

falls

1967, Solberg 1977

et al. 1990,

floor

whenever the

below a specified base stock

This policy can be viewed as a make-to-stock analog of the

Spearman

shop

goods (FG) inventory (where backordered demand

represents negative inventory) for this product

policy (see

policy could not be

CONWIP

(constant

.Xewell

and

Scarf's

for earlier studies),

and has

its

roots in Clark

(1960) echelon inventory policy for multistage uncapacitated inventory systems.

enjoys some of the same advantages as the traditional

al.

WIP)

and Koenigsberg 1958, Jackson 1963, Gordon and

and Whitt 1984

Whitt, Spearman et

level.

and Muckstadt and Tayur

robust (since controlling inventory

is

CONWIP

(1993):

it

is

1

policy

policy, as articulated

by

very easy to implement,

easier than controlling throughput),

tleneck starvation.

The

and prevents bot-

Readers are referred to Buzacott and Shanthikumax (1992)

survey of various production control strategies

our analysis

is

Buzacott et

performance measures

each station

is

(1992)

al.

for a

one

is

effect that,

when

In the initial

the base stock level of

this observation in a

more general

In Section 2, a multi-product production-inventory

proposed base stock

for

policy.

We

all

setting.

system

is

each product

level for

of the steady state distribution of the total

the optimal base stock levels are independent of the

WIP

WIP

considered under the

WIP

is

WIP

and FG

characterized as a

for that product;

moreover,

holding costs. Since the shop floor

viewed here as a black box, rather than as a network of queues,

as the total

their work,

stations except the

each product to minimize the long run expected average cost of holding

critical fractile

which

address the problem of choosing the optimal base stock level

and backordering FG. The optimal base stock

is

development of

in

system can be analyzed by means of a traditional open queueing

Our paper employs

network.

starting point for

and Lee and Zipkin (1992), who develop approximate

controlled by a base stock policy.

set to zero, the

The

multistage systems.

tgmdem single-product production-inventory system,

both make observations to the

last

for

an excellent literature

for

this result holds as long

process for each product possesses a steady state distribution with finite

mean, regardless of distributional assumptions, setup times, scheduling policy or routing

structure. In Section 3, the result

Jackson queueing network; that

demand

is

is

is,

specialized to the case where the shop

is

employed

at each station.

formula characterizing the optimal base stock

for the

optimal base stock

levels for

level

is

modeled

as a

each machine has exponential service times, exogenous

Poisson, job routing between workstations

served (FCFS) policy

is

level

is

Markovian, and the first-come

first-

Under these product-form assumptions, a

is

derived. Since a closed form expression

not available, we numerically

compute optimal base stock

some balanced production-inventory systems. Of particular

the optimal base stock level appears to grow almost linearly in the

interest

number

is

the fact that

of stations; this

linearity is partially explained

by an application of Chernoff 's exponential bound.

By modeling

Section 4 briefly discusses three generalizations.

work of quasireversible queues, we show how the powerful

queueing networks (see Baskett

results for

the shop floor as a net-

product-form multiclass

1975 and Kelly 1979) can be employed to determine

et al.

the optimal base stock level for each product in a multi-product system.

The remainder

of

the section deals with the single-product and multi-product cases for production-inventory

systems in which unserved demand

fact that the related

is

queueing network

lost.

is

Although additional

difficulties arise

closed, our analysis allows for a practical

from the

means

to

find the optimal base stock policy.

There axe several straightforward generalizations that we do not investigate

example

is

a mixed system (see Carr et

where some products are produced

mode. Another example

distributions to

is

in

al.

One

here.

1993 and Nguyen 1993 for the single queue case),

a make-to-stock fashion and others in a make-to-stock

to incorporate infinite server queues with general service time

model the transportation delays incurred

in material

handling systems on

the shop floor or in production-distribution systems.

2.

Base Stock Control of Make-to-Stock Systems

Consider a manufacturing

Completed units enter a

i

items demanded

starts with

a

new

Zi

units in

produces

finished goods inventory that

demand, and unsatisfied demand

of type

facility that

FG

in [0,i].

for

backordered.

is

Without

product

i

I

is

products indexed by

represents backordered

i,

let Zi{t)

demand, and

=

Let A^{t) denote the cumulative

loss of generahty,

let A^,(i)

FG

.

.

,

.

/.

number

we assume that the system

and no WIP. The proposed control policy

denote the

1,

depleted by exogenous customer

unit of a product onto the shop floor whenever a unit of that product

by a customer. For product

i

is

releases

demanded

inventory, where a negative quantity

be the amount of

WIP

inventory on the shop

floor at

FG

time

t.

demand

Since the

WIP

inventory and increases the

Ni{t)

+

Zi{t) for product

constant at

high

which

value of

its initial

the base stock level

i,

2,,

one unit of product

for

inventory by one unit, the total inventory position

the total physical inventory net backorders,

is

FG

Although product vs

z,.

simultaneously depletes the

i

backordered demand allows the

inventory

WIP

is

never larger than

is

inventory to attain arbitrarily

levels.

manufacturing

In Section 3, the

individual workcenters

demand

facility will

and corresponding

structure and queueing discipline.

be modeled as a queueing network with

service time distributions,

and a

specific routing

made

Here, no specific assumptions are

regarding the

distributions, the routing structure of the facihty, the scheduling policy, the service

time distributions, machine breaicdowns and repair, or setups. Instead, we treat the

as a black

Di{t)

held

is

the

box that

number

is

facility

characterized by a vector of stationary departure processes, where

of completed units of product

departure processes axe a function of the

demand

i

delivered to

FG

by time

t;

of course, the

processes, which act as the input processes

to the black box.

Under the proposed

Di{t)

—

{Nt{t),t

Ai{t) for

>

z

=

1,

.

.

.

policy,

,

/

and

it

t

>

follows that N^i^t)

0.

=

^4,(0

Our primary assumption

0} possesses a steady state distribution with finite

class of stochastic

models

a steady state distribution with

station, then this property

is

for the black

finite

mean.

possessed by

and ergodic inputs, services and routing

all

If

box that give

is

Z,(i)

=

is

that the

WIP

process

for

class of

rise to

the traffic intensity

is

a

=

i

1,

.

demand

WIP

less

.

.

.

/.

^,

+

We

processcn^

process having

than one

ai

each

Jackson-type networks with jointly slalintiarv

(Baccelli

multicla^s queueing networks (Kelly, Chapter 3).

multiclass queueing networks

and

A(0

mean

do not delve into the fundamental problem of characterizing the

and the

-

and Foss 1994) and

all

prodiici-lnrrn

However, the characterization of

an open problem, and

is

--lalili'

currently the subject of intiri>nf

Rybko and

research activity (see, for example,

Kumar and Meyn

Let

FG

time, hi be the corresponding

unit of product

holding cost rate, and

(zi,.

.

,zi) to

.

WIP

inventory for product

to find the base stock levels

is

then the problem

A^,,

is

If

Zi

we

to choose

/

^a(z.)=i]

1=1 \

t=l

"^(^' =

qE

n=0

'^)

+ ^'E ^^(^' = z,-k)-b,Y. kP{N, = z,*:=-oo

fc=0

=E

(^>

+

<

z,P{N,

^0

z,

-

+ Y.^P{N, =

I)

suffices to

The main

Proposition

study the steady state

result of this section

1

/

n)

b,z,

+ {c-K)E[NM.{\)

n=2.

t=i

it

k)]

oo

/

z*.

by

inventory per unit of

minimize

/

Thus,

z

WIP

and backordering inventory.

to minimize the long run expected average cost of holding

denote the steady state

in

i

be the cost of backordering one

6j

per unit time. The optimization problem

i

1993, Dai 1993 and

1993).

denote the cost of holding one unit of product

Ct

Bramson

Stolyar 1992,

is

WIP

Ni to determine the optimal base stock level

the following.

The optimal base stock

level z* is the smallest integer that satisfies

// this condition is satisfied with equality, then the expected cost obtained by using the optimal

base stock level

is

E

C^'iz*)

=

Proof. Equation

>

Ci{zi),

and so

(c

(1) implies

Ci{zi)

sumption, so that C,(0)

convex fimction of

f

+

k)E[N,] - {K

+

k)

2,

=

is

that | {Q{z^

-

1)

a convex function of

(1 4-

E nP(7V. = n))

n=0

1=1 \

i=l

Zi)

E

bi)E[Ni]

<

that must increase at

+

Q{z,

2,.

+

1))

= C,{z^)+^{k+K)P{N^ =

Furthermore, E[Ni\

oo and C,(oo)

some

.

/

=

oo.

<

oo by as-

Since the cost

is

a

point, the optimal value for the base

stock level

C,(z,

+

1)

A

level as

is

-

found by increasing

Cx{zi)

=

(/i,

+

bi)P{Ni

until C,(2,

2,

<

-

Zx)

6,,

+

a

critical fractile of the

level,

it

condition

is

^;

[(/i,

is

WIP

holding cost

is

<

but

z;)

will

-

b,]

>

which

0,

is

in genergd only a lower

is

1

obtained by substituting z' into equation

satisfied with equality,

1

(1) gives

result.

Also, because the optimal value for z'

.

+6,)P(iV,

Although Proposition

Equation

0.

characterizes the optimal base stock

1

not surprising that the

is

to be integer, the cost J2i=i C^'^iz') in Proposition

- Ct\z*) =

>

Ci{z,)

W'lP distribution. Since the W'lP process {Ni{t),t

not appear in the expression for z'

true optimal cost J2i=i Ci{z')

—

which proves the desired

few remarks are in order. First, Proposition

independent of the base stock

C,{z')

1)

zero

is

when

otherwise yield a value that

easy to derive, the result

is

(1).

is

>

0}

c,

does

is

restricted

bound; the

Notice that

the optimality

linear in z*.

deceptively powerful, because

very few conditions are imposed on the production-inventory system; for example, no as-

sumptions are made regarding the distributions of the service and demand processes, the

routing structure, or the queueing discipline.

Consequently, factories can gather historiced

data to generate an empirical distribution of the total

then employ Proposition

1

WIP

inventory for each product, and

to find the optimal base stock levels.

Monte Carlo simulation model could be used

to generate the

Alternatively, a detailed

WIP

distributions.

In

next section, we model the shop floor as a queueing network to obtain an analytical

the

WIP

distribution.

3.

Make-to-Stock Jackson Networks

Because each demand simultaneously depletes the

to the shop, the

shop

floor

inventory and triggers an arri\al

can be modeled as an open queueing network

corresponding to exogenous demands.

given by the steady state

FG

number

Therefore, the steady state

of type

i

customers

in

WIP

willi

arrivals

inventory

an open queueing network,

,V,

is

hi ihis

section,

we look

=

at the special case /

and model the shop

1,

floor as

an open Jackson

network; to simplify notation, the subscript denoting the product type will be omitted for

the remainder of this section.

K

Consider

where the server

single-server stations,

service time distribution with service rate

product-form solution, we

demand

Let the

Suppose the corresponding

A.

an exponential

although multiserver stations also give

restrict ourselves to single-server stations to

analysis relatively simple.

with rate

/i^;

at station j has

for the single

arrivals to the

product follow a Poisson process

shop

floor are

routed randomly to the

so that the arrivals are independent Poisson processes with rate \j,j

where SjLi

Aj

A.

After completing

station j with probability

— Y^f=\

with probability

1

P —

than

[pij]

is less

effective arrival rates

The

1

Ptj

and

,

.

.

.

,

service discipline

is

all

floor

(and hence enters the

items eventually exit the system.

j

is

we assume that

Pj

p^

=

<

u-,/ p,^

1,

j

v^

—

X^-^-

K

We

will consider

of

are distinct,

inventory)

Yl!k.=

Define the vector of

\

^kPkj,

=

1,...,/C.

Finally,

J

—

I,.

.

,

K.

assume that the FCFS

floor is

modeled

the two extreme cases where the

and where they are

all

and the

as a Jackson network,

WIP

distribution

independent geometric random variables with parameters

sum

FG

visits

where, to guarantee the existence of a steady

product-form solution implies that the steady state total

the

an item

used throughout the network.

Under these assumptions, the shop

classic

shop

v^) to be the solution to

traffic intensity at station

state distribution,

exits the

z,

= \...,K

where we assume that the spectral radius of the routing matrix

Pij,

so that

(i^i,

service requirement at station

its

a

keep the subsequent

K stations,

=

rise to

traffic intensities at

1

—

pi,

.

is

.

.

given by

,

1

—

pK-

the various stations

equal; our approach can easily be extended to any

intermediate case.

Without further

P\

<

P2

<

< pK <

loss of generality,

^-

If

we

assume that the stations are numbered so that

define the z-transform of the steady state total

WIP

A^ as

Pj;{z)

= E[z%

then

pT(. _ nf=.(i-P.)

n;=i(l - zp])

A

partial fractions expansion gives

a,

P(N =

=

=

n)

-^'-r:

ctjp^,

HJLi

;

-.

where

.

Ue^j{pj-Pe)

Hence, the cumulative distribution function of

N

is

P{N<n) = EY^c^jP]

:=U j=l

i-p;

^1

and substitution into the condition of Proposition

z'

is

this condition

is

Now

sum

I

-

=

l

Pj

^

+

b

Pj

satisfied with equality, then the

j

the

implies that the optimal base stock level

the smallest integer satisfying

P

If

1

'

j

=

\

h

optimal cost

vi

P])

consider the case of a balanced network, where

of iid shifted geometric

random

variables

given by

is

is

0<p\ —

=

pk~P<

1-

Since

a negative binomial random variable,

we obtain

P{N = n)=

An

^^l~^ ](1-P)V

I

application of Proposition

1

for

n

=

0,l,2...

shows that the optimal base stock

(3)

level z* is the smallest

integer such that

tr^"-'

n

n=0

and,

if

(4) is satisfied

\

with equality, then

C«V) =

(c

l(>-p)V>r^.

h + h'

/

th(>

optimal cost

+ fe)T^-(/. + fc)f:nf

1

-P

n=0

V

is

^^"-' ](l_p)V

"

(4)

Notice that z* in

(2)

and

increasing in the backorder-to-holding cost ratio |.

(4) is

Also, elementary queueing theory suggests that z* should be increasing in the pi's in (2)

and

in

p

in (4).

While the

we have only numerical

and

by a simple differentiation with respect to

latter result follows

results to support the former.

When

K—

both expressions

\,

p,

(2)

(4) yield

r

1

Inp

xi

/i

.

K^)

1

(5)

and

C«7(^*)

^

_^

P_

+

[(5

-

h)[{\

p)z*p^'

+ p''] -

/I

+

c]

,

P

where the integer

restriction

on

z*

is

ignored; these results are consistent with the single-

server results presented on page 105 of Buzacott

and Shanthikumax (1993).

Since (4) does not yield a closed form solution in general, we apply Chernoff 's bound

on the

tail

behavior of sums of random variables

149) to obtain an upper

bound on

variables satisfying E[Xi\

common

logarithmic

<

moment

z* for the

and P{Xi >

...

n

application of this

bound

any z > Kp/{1

—

p).

z*<

We

is

0,

and

Then

let

M{s)

Chernoff's

inf

.

=

.

,

X^ be

iid

random

\ogE{e^^') be their

bound

states thai

+ X„>0) <infM(5).

^

(6)

^~^

inf

ae(0,-lnp)

f

yi

-

1

pt°-

e-"^

(7)

)

This bound, used together with Proposition

1,

gives

(a-Mnf-i^^W

+ a-Mnf^H,

-

-ae{o,-inp)[

so that z*

>

0)

.

to (3) yields

PiN >z)<

for

example, see Billingsley 1986, pp. 147-

balanced case. Let Xi,

generating function.

-logF(Xi +

An

(for

upper-bounded by a

can tighten the bound

minimization of the right side of

\

h

by optimizing over a 6

(0,

\\

pe"

linear function of

in (8)

(8) is difficult

9

(8)

)]

K.

because

it is

-

Inp). Straight torw.ird

not convex in

a.

Howcwr.

ihc

value of a thai minimizes the

bound

in (7) is

Since a*

is

2

=

a

in

(9)

unknown base

a function of the

stock level

procedure to find the optimal value of a to employ

do

e (0,-lnp) and substitute

Then use

level zq.

Oo

= — lnp/2,

determine a

(9) to get

it

an updated value

a\,

and

so on.

after a\.

If

In all

120 cases, we used

we use

this

procedure to

then the large deviation approximation implies that this bound

Although a closed form solution

are easy to solve numerically,

investigation.

K

Start with an initial value

(8).

tight

is

— oo.

as /C

as

in

iterative

into the right side of (8) to obtain an initial base stock

and the value of a did not change

in (8),

we use the following

z,

,

the

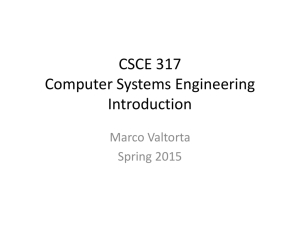

The primary

number

objective

is

of stations, increases.

and two backorder-to-holding

1

and plotted

in

Figures

not available in general, both (2) and (4)

is

and the remainder

to explore

To

balanced Jackson networks, using

for 120

Table

for z'

and

2.

how

this end,

=

3

the optimal base stock level z' varies

z*

=

10.

These

number

NumericaJ calculations of the upper bound

very tight, even for

K

as large as 40.

in (8)

for z' in (8)

with (10) replacing

(8).

The

show that

with the exact result

p

1

of a in (10),

that the optimal base

of stations, as suggested by (8).

l+a-Mn(-^

To compute the value

is

this

bound

Hence, we also consider the base stock

combines the slope of the Chernoff bound

In

results are reported in

grows considerably as the utilization

approaches unity. However, the most striking feature of the results

stock level grows almost Unearly with the

we employ the

level

values of p, 12 different network sizes

and ^

As expected,

devoted to a numericaJ

is

we compute the optimal base stock

five different

cost ratios, ^

1

of this section

-

for A"

^\{K-\).

=

1

is

not

level that

in (5):

(10)

pe"

iterative procedure described earlier, but

resulting base stock levels are displayed in Table 2 £Lnd, as can

10

z*

^

=

3

Base 250

Stock

'--*'200

.

150

.

100

-

50

.

.

!

=

3

I

350

-

300

-.

p =0.9

= 0.85

=0.8

-•—

=0.7

=0.5

5

10

Number

Figure

s.

-

-i

6:

15

of Stations

Optimal cost C{z*)

for

j-

=

10.

Extensions

4.

we

In this section,

briefly describe the generalizations of this

approach lo

product queueing networks, and to the single-product and mulu-producl

lost sales cases.

Multi-Product Systems

4.1.

The powerful theory

sider

for

product-form rnulticlass queueing networks allows us to con-

any network of quasireversible queues. For example, consider a multi-product system

where each product, or customer type

mand

process with rate

A,,

z

=

1, 2,

.

terminology, has an independent Poisson de-

in Kelly's

.

.

.

and

/

its

own

arbitrary deterministic route through

the network of workstations. Suppose each workstation, indexed hy j

of a single machine, service times of

random

variables with

2* for

z

=

As

1,

.

.

.

,

it

1,2, ....

the

FCFS

queueing discipline

is

iid

K

,

consists

exponential

employed. Theorem

be used to numerically find the optimal base stock

will

level

/.

in Kelly, let

be the stage

1

=

operations at the workstation are

all

mean ^j\ and

and Proposition

3.1 in Kelly

this

rnulli-

i_,(/)

be the type of the customer

has reached along

its

route.

customer, and the state of queue j

is

Then

in position

=

Cj{l)

/

in

(ij(/), «_,(/))

queue

number

of type

i

and

let Sj{l)

denotes the class of

given by the vector {cj{l),Cj{2),

chajacterize the steady state distribution of the

j,

.

.

.

customers

,c-,{N.,{t))).

in

To

the sysu^m.

define

.... —

dj{l, s)

A,

J

Vj

let pj

=

Xl'^i ZljJi Oj{i, s),

= ^,

where S{i)

then by Corollary 3.4

n customers

stage s of customer type

i

is

at station j,

otherwise,

I

and

if

<

in

is

the total

number

of stages

on type

z's

rouuv

If

we

Kdly, the steady state probability that queue j coniains

is

P(N,=n) =

(l-p,)p';,

n

=

0,l,...

Furthermore, in steady state queue lengths at each station are independent, and

is

in position

/

The z-transform

E[z'^'], is

queue j then

in

it is

a type

customer with probability

i

number

of the steady state total

partial fractions expansion gives P(A^i

a,

P^^-

=

1

-

Pj

+

=

+

p]

=

n)

and

q,j

^

au

=

"^ H^.d - a.)

=

for all j y^

I;

-

ail)

the approach

is

easily

extended

For this case, the cumulative distribution

is

j=i

and Proposition

1

- a"+i

1

"'J

^

implies that the optimal base stock level z*

'

fr",

finite

defined as Pjj {z)

,

where

n;#j(atj

'^

a

yv,

-zp]ii])

Y.f=\ ^jOi^j,

^^

where some of these values are equal.

function for N^

pjixj

Pjli]

This corresponds to the case where

A

customers

Yls=\ 8j{i,s)/i/i.

nf=i(i-P.)

nj=i(i -

to cases

i

=

a customer

thus given by

pT ,. _

A

of type

7,_,

if

i-a,,

- k +

is

the smallest integer satisfying

^

h,

'

similar analysis carries through for the case where each workstation consists of

number

of identical machines; since the derivation

insights are developed,

we omit the

details.

is

rather tedious and no

new

Readers are referred to Chapter 3 of Kelly and

to Serfozo (1993) for other types of queueing networks that yield product-form solutions.

Also, the heavy traffic approximations in

estimate the

4.2.

WIP

distribution

The Single-product

For certain systems,

arrives to find

Nguyen and Harrison (1993) can be employed

when the exponential assumptions need

to

to

be relaxed.

Lost-sales Case

it

may be more

no inventory available

realistic to

in finished

17

assume that when a customer demand

goods, the sale

is lost.

If

the

manager

of a

single-product system

still

follows a control policy of establishing a hase stock level z

then releeising a production order every time a customer

model the system

the shop has

station,

A.

K

as a closed queueing network.

is

K

Customers queued

+

K

network

will

+

K

+

1

correspond to units

depletes the

1

unit onto the shop floor. This observation

FG

was

in

FG

possible to

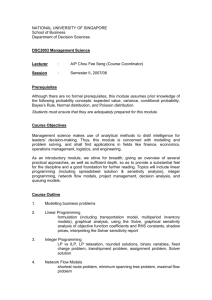

is

Figure

inventory,

demand

made by Nguyen

(1993),

rate

and a service

inventory and triggers a release of a

first

7. if

have an additional

with a single server whose service rate equals the

I,

at station

completion at station

it

In particular, as illustrated in

stations, then the resulting closed queueing

denoted by

served, then

and

who

new

considers a

queueing system that employs a combination of make-to-order and make-to-stock operations.

She also notes that the

by an excess

is

life

service time in a busy period at station A"

first

and consequently we need

distribution,

to

-I-

1

is

characterized

assume that the demand process

exponentiaJ to ensure that the two systems in Figure 7 are statistically indistinguishable.

Unlike the backorder case, the steady state distribution of the total

depends upon the base stock

level z; hence, there is

we model the shop

black box, and instead

entire production-inventory system can be

stations

and

no advantage

WIP now explicitly

in viewing the facility as

as a Jackson network, as in Section 3.

modeled

a

Thus, the

as a closed Jackson network with A"

-I-

1

z customers.

We now

backorder cost

turn to the problem of finding the optimal base stock

6,

a cost

/

is

Instead of a

incurred for every lost sale. Let T{z) denote the throughput rate

of the closed queueing network; that

any given node per unit time

in

rate at which sales are lost.

we

If

is,

the average

steady state.

let

It

number

of customers passing through

follows that A

- T{z)

is

the steady state

Nj{z) denote the steady state average queue length at

station j, then the steady state cost function

C{z)

level.

is

= hNK+i{z) + cf;

A^;(z)

+

/

(A

- r{z))

(12)

.'Mthough closed form expressions for thr throughput and expected queue lengths of closed

18

Lost-Sales Make-to-Stock System:

Production

Finished

orders

Job Shop

K

Manager

<^

Stations

yv

Jackson networks are unavailable, several

algorithms exist to compute them (see

efficient

VValrand 1988 and references therein).

The second-order

properties of the cost function (12) need to be investigated to nu-

merically determine the optimal base stock level

shown that T{z)

nondecreasing and concave for closed Jackson queueing networks when

is

the service rate at each station

If

the restriction h

convex

in z'.

Shanthikumar and Yao (1988) have

z'.

=

c

However,

\s

is

nondecreasing and concave in the station's queue length.

imposed, then the concavity of T{z) implies that equation (12)

it is

easy to find instances where h

>

c

>

Q

and

(12)

is

is

not convex.

.Although in these examples the cost function appears to be quasi-convex, and hence well

behaved, we have been unable to prove the quasi-convexity of (12) for closed Jackson networks. Nevertheless, for

all

we have

the cases that

considered,

the optimal base stock level z' by calculating C{z) for ^

We

0, 1, 2,

A"

all

-I-

station equals the rate of customer

j

=

1,2,

.

.

,

.

/C

-t-

1

and T{z)

_,

demand.

—

,

7^

Differentiating equation (13) twice proves

=

if

.9

.

until

C{z'

-I-

1)

>

C{z').

>

It is

in

same

traffic intensity.

which the capacity of each

known (Walrand,

pg.

190) that A^j(2)

=

-^^, and hence

hz

^W =

z*

.

single-server stations have the

1

This case represents a balanced production-inventory system

-j^,

.

conclude this subsection with a special case that admits a closed form expression

Let us assume that

for z*.

=

has been possible to find

it

cKz

\IK

+ TcTT + TTl?-

its

convexity,

and the

,,„,

<"'

first-order condition yields

and

'_

z

=

/•

-f

/ n - An'

+ VP-^^y

-U

,

\^g<0,

(14)

2

where f

= 2K +

\

and

"=(>-^)'^('^^'>From equation

roughly linear

(14)

in

the

it

follows that z'

number

= 0{K)

of stations.

20

and hence the optimal base stock

level

is

The Multi-Product Lost

4.3.

One

system producing / products.

a product

Ai,

i

is

sold.

is

=

z

1,

the

If

.

.

,

.

/,

Case

where a base stock policy

Finally, consider the case

each product type

Sales

possible policy

and

demand

for

product

i

is

used to manage a

i

z^

for

item into the shop every time such

an independent Poisson process with rate

then this policy leads to a multichain, multiclass closed queueing network, where chain

populated by

customers

z,

for

i

=

1,...,/.

If

the shop consists of

station

K+

i

has a single exponential server with rate

inventory for product

Let z

of type

=

{z\,

.

.

=

z

1,

.

.

,

.

/,

stations, then

stations,

where

and represents the

i.

,zi)

be the vector of base stock

this multiclass

throughput rate T{z)

=

and %{z) be the throughput

levels,

items corresponding to the base stock control.

i

form assumptions,

total

.

A, for

K

K+I

the queueing network for the production-inventory system will have

FG

lost sales

to establish a base stock level

is

to release a type

is

Under the

traditional product-

queueing network has the undesirable property that the

Y.[=\

%{z) need not increase

in Zi, as

noted

in Section 8.6 of

Buzacott and Shanthikumar (1993). This property highlights the need to exert a different

sort of control

An

upon the product type

of items that are released into the shop.

alternative policy consists of setting an aggregate base stock level z

releasing a production order into the shop every time an item

being for a type

relative

7

=

(71,

i

item with probability

throughput rates

.

.

.

,

7/). If the

process with rate

At,

for the various

demand

for

7t,

where

Z]t^=i 7i

is

=

sold, the

1.

production order

Under

products are determined by the

and then

this policy,

the

relesise probabilities

each product arrives according to an independent Poisson

then this policy leads to a single-chain, multiclass queueing network.

This network model has a product-form distribution under the usuaJ assumptions; see Section

3.4 of Kelly for details.

The

decision variables for the base stock policy are the aggregate^

base stock level z and the release probabilities

21

7.

The

single-chain

of each product

model has two advantages over the multichain model: the throughput

monotone nondecreasing

is

in

the aggregate base stock level

any arbitrary

release probabilities 7 cam achieve

set of relative

2,

throughput rates

emd the

for the

various products; the multichain model, in contrast, can only achieve a discrete set of relative

throughput rates via the integer choices of

To

random

customer types. Let

Upon completing

service at station j, a type

FG

K+

i

=

1,

.

.

,

.

/.

For the closed network,

at station j a type

and

all

type

I

K+

where station

I stations,

i

item

will

next

P]k

=

P)k>

p"k+x

=

P),K+i:

P'K+x,k

=

7.'Pofc,

let

i

p^jj.'

i=

i,i

aJ =

ll[=\ a}. J

=

Jackson network with

•

•

•

K+

,

^+

/,

will

next

first

/ different

operation

the

is

products, or

at station j.

k with probability

visit station

Under the aggregate hase

a closed queueing network

A, for

be the probability that upon completing service

J

/c

as a type

=

i'

item; then

l,---,K; k=l.,...,K,

=

l,...,K,

If

sold,

we

lei

then Q|c+,

tor

I

=

number

a^ be the expected

=

1

for

1,...,/; J

i

=

and T{z) be the throughput

I stations,

is

=\,...J] k=\,...,K,

'-

1,

item

l,.-..,I: J

it is

j

where Nj{t)

has a single exponential server with rate

i=l,---,I;

j before

visits station

i

visit station

a =

Let

populated by

may be modeled by

other transfer probabilities are zero.

product

is

and service rates

example, a multiserver queue.

for

with probability p]^k+i-

stock policy considered here, the system

with

can model,

be the probability thai product Vs

p^.

or will exit the shop and enter

pjfc,

rj(-)

and the shop

policy,

stations,

variables with rale fj,jrj{Nj{t)),

queue length at station j and the function

Each server uses the FCFS

K

suppose the shop consists of

illustrate the procedure,

at station j are iid exponential

z.

z customers, the

same

=

1

,

.

.

.

,

1,...,K.

/ ajid

of limes a

a^ satisfies

(lo)

of a corresponding closed

service rates as the single-

chain multiclass network, ajid relative

visit rates aj.

rate of the single-chain multiclass network,

Then T{z)

and since orders are released into the system

according to the probabilities 7, the throughput rate for type

for

z

=

1,

.

.

,

.

Let N^{z) denote the steady state

/.

also the total throughput

is

number

products

i

of type

i

is

%{z)

cost parameters for

z

=

1,

.

,

.

.

/.

Then

and the vector 7

positive integer z

and

/,

computed

be the product dependent

the optimal base stock policy

found by choosing a

is

to

^ KN'^^,{z) + ^ ^

min

let h^, c,

'^/iT{z)

customers at station

j in the single-chain multiclass network with z customers in total, which can be

with standard algorithms (see Walrand). Finally,

=

1=1

c.N;{z)

+ Y^ h iK -

l^T{z))

!=1

Z=l J=l

/

subject to

y^7t

=

1

!=1

7,

As

>0, z=l,...,/.

in the single-product lost sales case, the objective function of this

though generally well behaved (quasi-convex). In the case where

/ij

=

problem

Cj

=

/i

not convex,

is

for

i

=

1,

.

,

.

.

/,

the objective becomes

min hz-T{z)Yk'y, +

!=1

which

convex

is

this case

if

Tj{x)

is

Yk\,

1=1

increasing and concave in x for

all

stations j

=

1,

.

.

,

.

K; hence,

can easily be solved.

A ck now ledgment

This research

at

MIT

is

supported by a grant from the Leaders

and National Science Foundation Grant DDM-9057297.

23

for

Manufacturing Program

References

Baccelli, F.

and

Foss.

S.

Stability of

Jackson-Type Queueing Networks.

INRIA Centre

Sophia Antipolis, Valbonne, France, 1994.

Baskett, F. K.,

Chandy, R. R. Muntz and

.\1.

F.

Open, Closed and Mixed

G. Palacios.

Networks of Queues with Different Classes of Custonners.

J.

Assoc.

Computing Machinery

22, 248-260, 1975.

and Measure, 2nd

Billingsley, P. Probability

Brannson, M. Instability of

Wiley and Sons,

cd.

FIFO Queueing Networks. To appear

New

in

York, 1986.

Annals of Applied Prob-

ability, 1993.

Buzacott,

J.

A., S. Price,

and

J.

G. Shanthikumar. Service Levels in Multistage

Base Stock Controlled Production Systems. In

New

MRP

and

Directions for Operations Research

in

G. Fandel, T. Gulledge and A. Jones), Springer, Berlin, 445-163,

Manufacturing, (Eds.

1992.

Buzacott,

A. and

J.

Prentice-Hall,

Btizacott,

in

J.

New

A. and

J.

Stochastic Models of Manufacturing Sysians.

G. Shanthikumar.

Jersey, 1993.

J.

G. Shanthikumar.

A

General Approach

Multiple-Cell Manufacturing Systems. Production

for

Coordinating Produeiion

and Operations Management

1. :il-')J.

1992.

Carr,

S.

A., A.

R. Gullu, P. L. Jackson

and

.1.

A.

.Muckstadt.

An Exact

Analysis

<.t

i

Production- Inventory Strategy for Industrial Suppliers. School of Operations Research and

Industrial Engineering, Cornell

L'.,

Ithaca, N\', 1993.

24

Clark A.

and H.

J.

ment Science

Dai,

J.

6,

On

G.

Scarf.

475

-

Optimal

Policies for a Multi-echelon Inventory

490, 1960.

the Positive Harris Recurrence for Multiclass Queueing Networks:

Approach Via Fluid Limit Models.

W.

and G.

J.

A

Unified

School of Mathematics and Industrial/Systems Engi-

neering, Georgia Institute of Technology, Atlanta,

Gordon,

Problem. Manage-

F. Newell. Closed

GA,

1993.

Queueing Systems with Exponential Servers. Op-

erations Research 15, 254-265, 1967.

Harrison,

J.

M. and V. Nguyen. Brownian Models

rent Status

and Open Problems. Queueing Systems

Jackson,

R. Jobshop-Like Queueing Systems.

J.

Kelly, F, P. Reversibility

of Multiclass

13, 5-40, 1993.

Management Science

P.

R. and

S. P.

Meyn.

Stability of

J.

and

P. Zipkin.

Tandem Queues

1979.

9, 22-35, 1958.

Queueing Networks and Scheduling

partment of Electrical and Computer Engineering, University of

Lee, Y.

10, 131-142, 1963.

and Stochastic Networks. John Wiley and Sons, New York,

Koenigsberg, E. Cyclic Queues. Operational Research Quarterly

Kumar,

Queueing Networks: Cur-

Illinois,

Policies.

Urbana,

De-

IL, 1993.

with Planned Inventories. Operations Research

40, 936-947, 1992.

Kanban

Discipline for Cell Coordination in Produc-

Mitra, D. and

I.

tion Lines,

II:

Stochastic Demands. Operations Research 39, 807-823, 199L

Muckstadt

J.

A. and

nisms, Part

I:

Mitrani. Analysis of a

S.

R. Tayur.

A Comparison

of Alternative

Background and Structural Properties. To appear

25

Kanban Control Mecha-

in

IIE Transactions, 1993.

Nguyen, V. Fluid and Diffusion Approximations of a Two-Station Mixed Queueing Network.

To appear

Math, of Operations Research, 1993.

in

Rybko, A. N. and A.

lions of

L. Stolyax.

Ergodicity of Stochastic Processes Describing the Opera-

Open Queueing Networks. Problemy Peredachi

Serfozo,

Infarrnatsii 28, .3-26, 1992.

Queueing Networks with Dependent Nodes and Concurrent Movements.

R. F.

Queueing Systems 13, 143-182, 1993.

Shanthikumar,

J.

G. and D. D. Yao. Second-Order Properties of the Throughput of a Closed

Queueing Network. Math, of Operations Research 13, 524-534, 1988. Prentice-Hall, .New

Jersey, 1993.

A Mathematical Model

Computerized Manufacturing Systems.

Solberg,

J.

4th

Conf. on Production Research, Tokyo, 22-30, 1977.

Intl.

J.

Spearman, M.

L.,

D. L. Woodruff,

of

and

VV. J.

ban. Int.

J.

Prod. Res. 28, 879-894, 1990.

Walrand,

J.

An

Whitt,

Hopp.

CONWIP: A

Pull Alternative to

Introduction to Queueing Networks. Prentice-HaJl,

W. Open and Closed models

for

In Proa.

New

Kan-

Jersey, 1988.

Networks of Queues. AT&:T Bell Labs Technical

63, 1911-1979, 1984.

26

J.

MIT LIBRARIES

3

'loao

ooa43tbq

i

3248 02

Date Due

JUL.

etc:

29 W!4

2a

'^