NAVY TRAINING SYSTEM PLAN JOINT HELMET MOUNTED CUEING SYSTEM N78-NTSP-A-50-0103/D

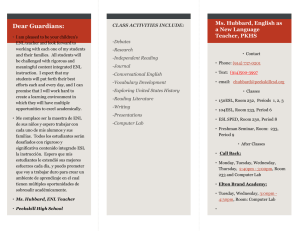

advertisement